Method for manufacturing delivery steel pipe serving acid environment

A manufacturing method and technology for steel pipes, applied in the direction of manufacturing tools, tubular articles, applications, etc., can solve the problems of poor corrosion resistance of steel pipes and poor uniformity of steel pipe structure, and achieve high corrosion resistance, improved heat treatment process, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

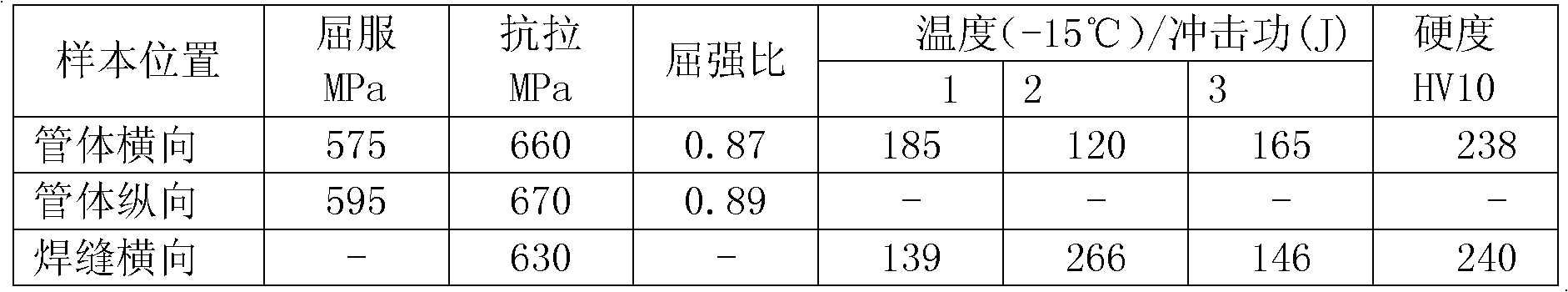

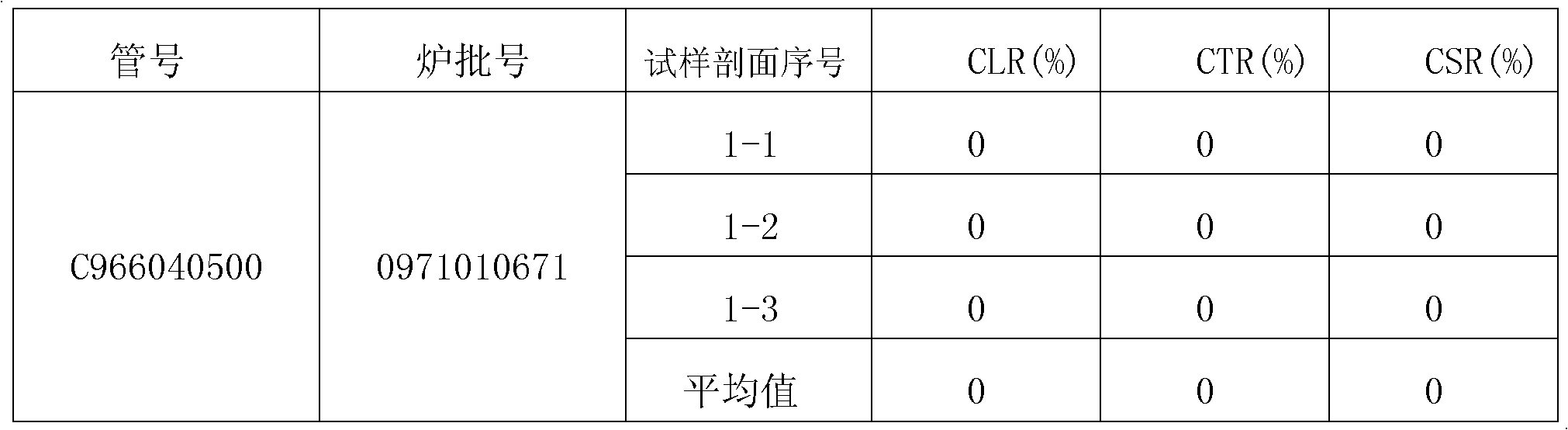

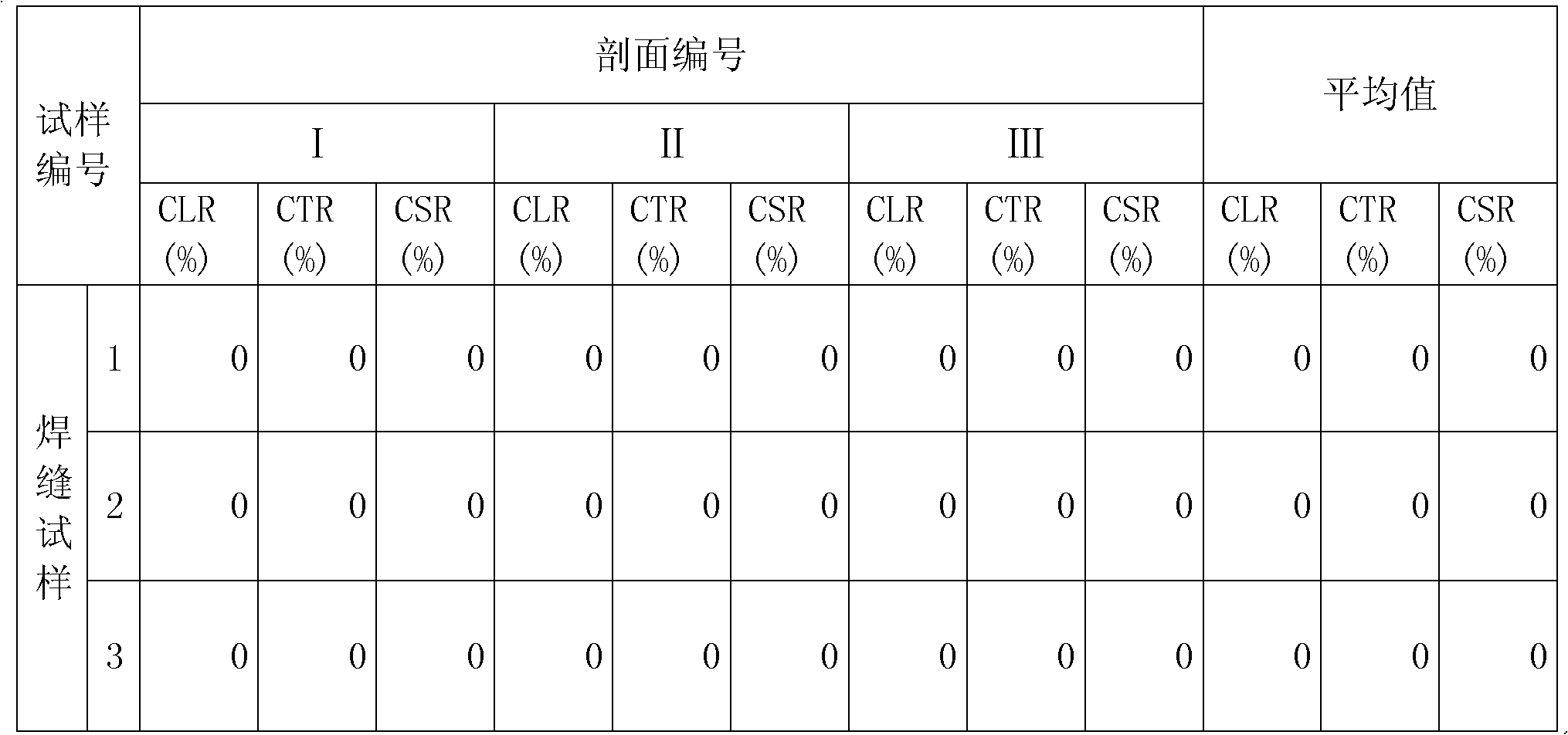

[0028] The invention discloses a method for manufacturing steel pipes for service in acidic environments. The process of the method includes raw material inspection, uncoiling butt welding, loop storage, steel plate edge milling, steel pipe forming, steel pipe welding, heat treatment of weld seams, air cooling and water cooling, Steel pipe sizing, steel pipe straightening and steel pipe cutting.

[0029] The present invention controls the H resistance of the pipeline steel pipe from the material factors and the pipe making process. 2 S performance, first of all, resistance to H 2 In addition to maintaining the fine grain and high toughness of ordinary pipeline steel, S pipeline steel has higher requirements on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com