Strengthening and toughening heat treatment method of hot work die steel 4Cr5MoSiV1

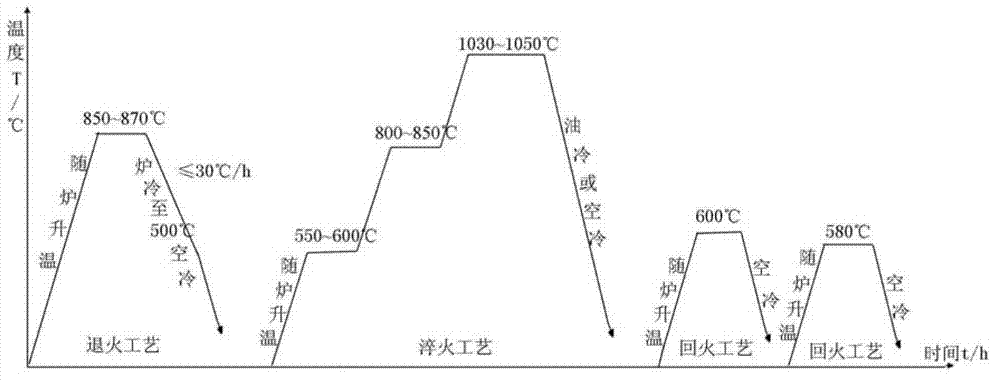

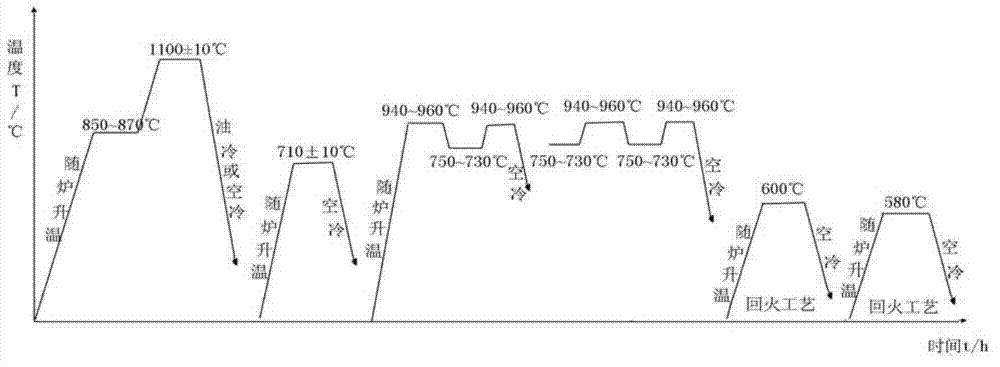

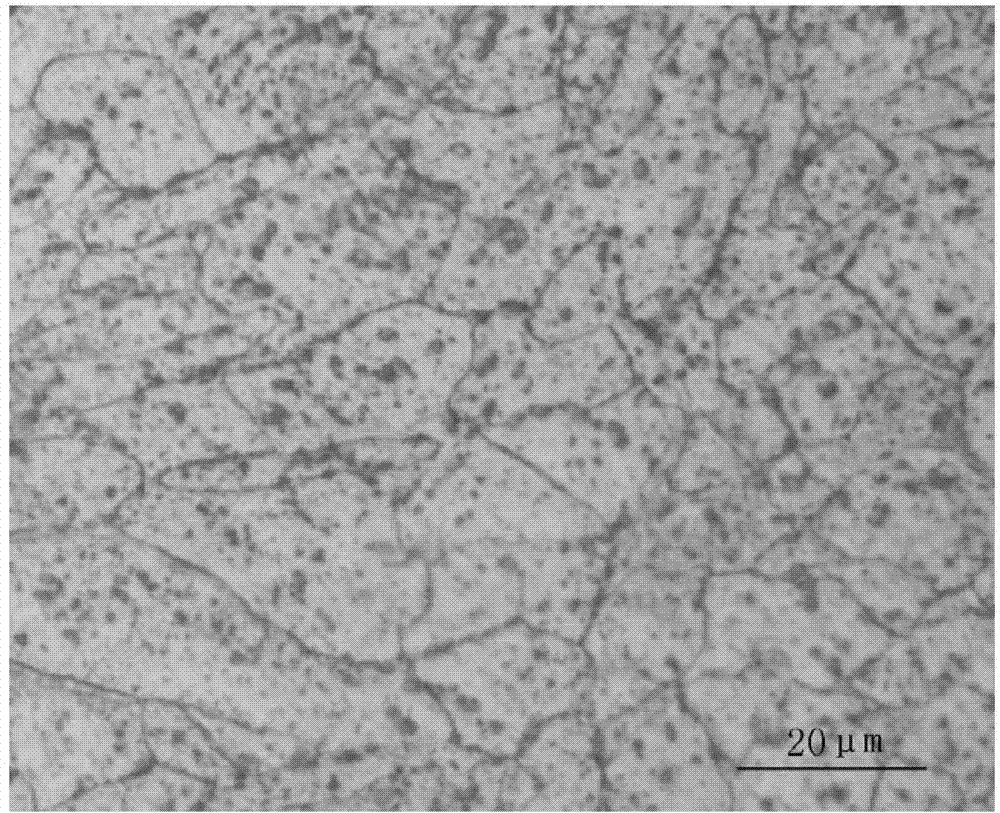

A technology of hot work die steel and heat treatment method, applied in the field of hot work die steel, which can solve the problems of reducing the strength and toughness, carbide and banded structure segregation of hot work die steel 4Cr5MoSiV1, achieve uniform microstructure and reduce large-scale carbonization The effect of reducing objects and bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put the 4Cr5MoSiV1 steel material into the resistance furnace, raise the temperature to 850°C, and control the holding time to 60s per mm of steel material thickness;

[0026] (2) Continue to heat up to 1090°C, control the holding time to 70s per mm of steel thickness, and air cool to room temperature;

[0027] (3) Put the 4Cr5MoSiV1 steel material into the resistance furnace again, raise the temperature to 700°C, keep it warm for 90min, and air cool to room temperature;

[0028] (4) Put the 4Cr5MoSiV1 steel material into the salt bath furnace, raise the temperature to 940°C, and control the holding time to 60s per mm of steel material thickness;

[0029] (5) Take it out and quickly put it into a salt bath furnace with a temperature of 730°C, and control the holding time to 60s per mm of steel thickness, then take it out and quickly put it into a salt bath furnace at a temperature of 940°C, and control the holding time to 60s per mm of steel thickness 60s;

[0030...

Embodiment 2

[0034] (1) Put the 4Cr5MoSiV1 steel material into the resistance furnace, raise the temperature to 860°C, and control the holding time to 75s per mm of steel material thickness;

[0035] (2) Continue to heat up to 1100°C, control the holding time to 80s per mm of steel thickness, and air cool to room temperature;

[0036] (3) Put the 4Cr5MoSiV1 steel material into the resistance furnace again, raise the temperature to 710°C, keep it warm for 90min, and air cool to room temperature;

[0037] (4) Put the 4Cr5MoSiV1 steel material into the salt bath furnace, raise the temperature to 950°C, and control the holding time to 75s per mm of steel material thickness;

[0038] (5) Take it out and quickly put it into a salt bath furnace with a temperature of 740°C, and control the holding time to 75s per mm of steel thickness, then take it out and quickly put it into a salt bath furnace at a temperature of 950°C, and control the holding time to 75s per mm of steel thickness 75s;

[0039...

Embodiment 3

[0043] (1) Put the 4Cr5MoSiV1 steel material into the resistance furnace, raise the temperature to 850-870°C, and control the holding time to 90s per mm of steel material thickness;

[0044] (2) Continue to heat up to 1110°C, control the holding time to 90s per mm of steel thickness, and cool to room temperature with oil;

[0045] (3) Put the 4Cr5MoSiV1 steel material into the resistance furnace again, raise the temperature to 720°C, keep it warm for 90min, and air cool to room temperature;

[0046] (4) Put the 4Cr5MoSiV1 steel material into the salt bath furnace, raise the temperature to 960°C, and control the holding time to 90s per mm of steel material thickness;

[0047] (5) Take it out and quickly put it into a salt bath furnace with a temperature of 750°C, and control the holding time to 90s per mm of steel thickness, then take it out and quickly put it into a salt bath furnace at a temperature of 960°C, and control the holding time to 90s per mm of steel thickness 90s;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com