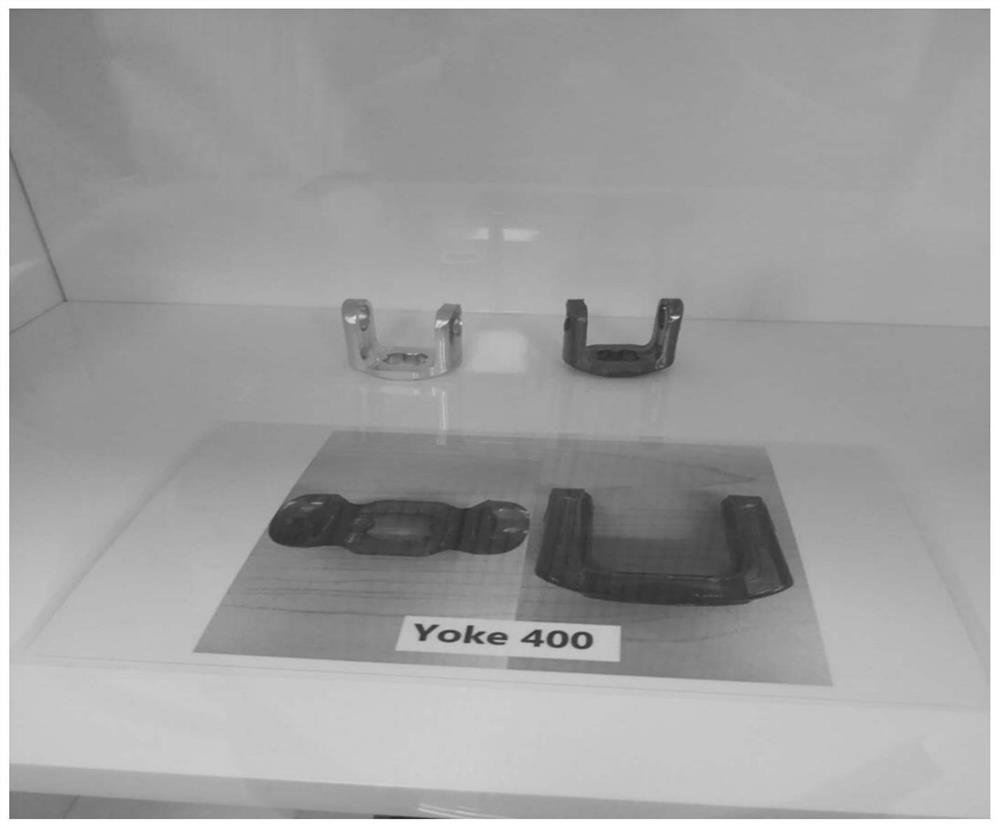

Steel for cold forging of universal joint fork of passenger car and manufacturing method of steel

The technology of a universal joint fork and a manufacturing method, which is applied to the field of iron-based alloys, can solve the problems of broken fibers, easy generation of blisters in castings, low dimensional accuracy of formed parts, etc., and achieves the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the examples. The examples are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0059] Production method of steel bars for cold forging of passenger car universal joints: production process route with manufacturing specifications of Φ20mm—Φ40mm: molten iron pretreatment—converter primary smelting—refining—continuous casting—continuous casting slab cooling—continuous casting slab heating— Rolling—cooling—spheroidizing annealing—wagon—finishing—inspection—finished product storage. details as follows:

[0060] The specifications of the steel products in Examples 1 and 2 are Φ20 mm, and the cumulative rolling ratio is 183.4.

[0061] Pretreatment of molten iron: Immerse the cross-shaped stirring head poured with refractory material (corundum) and baked to a certain depth below the liquid level of the molten iron pool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com