Patents

Literature

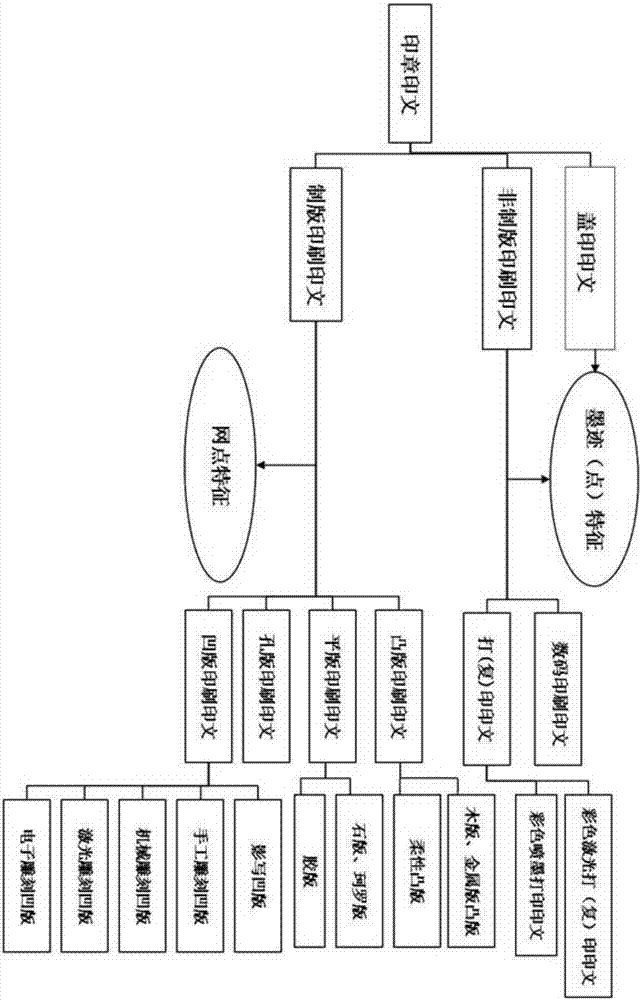

44 results about "Macroscopic examination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macroscopic Examination is used either independently or in addition to another test method to identify any discontinuities located on the subsurface of the test part. Macroscopic Examination is performed on a transverse section, longitudinal section, or on the through thickness to evaluate the subsurface.

Dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of continuous cast blank and preparation method thereof

ActiveCN102174699ASolve the problem that the dendritic solidification structure of the continuous casting slab cannot be clearly displayedDisplay without reductionPreparing sample for investigationOptically investigating flaws/contaminationAlcoholCopper chloride

The invention discloses a dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of a continuous cast blank and a preparation method thereof. The reagent comprises the following components by mass percent: 0.28-1.09% of copper chloride, 0.17-0.27% of magnesium chloride, 0.56-1.60% of ferric chloride, 1.28-1.30% of hydrochloric acid with the mass concentration of 36-38%, 54.70-55.80% of absolute ethyl alcohol and the balance of water. The preparation method comprises the following steps: adding the water into a container, and then adding the copper chloride, magnesium chloride, ferric chloride and hydrochloric acid; and adding the absolute ethyl alcohol after all the added raw materials are fully dissolved, and evenly stirring. Compared with the prior art, the invention solves the problem that other corrosive reagents can not clearly display the dendritic crystal solidification structures of a continuous cast blank; and the reagent has the characteristic of original-size display without expansion or reduction for interior defects of a continuous cast blank when used for dendritic crystal corrosion macroscopic examination on the solidification structures and defects of the continuous cast blank.

Owner:苏州东大汉森冶金实业有限公司

Continuous casting alloy steel bloom convex combined roller and heavy pressing process

The invention discloses a continuous casting alloy steel bloom convex combined roller and a heavy pressing process. The core quality problem of a continuous cast bloom is solved. The technical schemecomprises the convex combined roller and the heavy pressing process; the convex combined roller is characterized in that a pulling-straightening roller is designed to be a constant-curvature boss-freeconvex roller body capable of improving the segregation in the flowing direction of enriched molten steel before the continuous cast bloom is solidified and a gradually-changed-curvature boss convexroller body capable of compensating severe looseness and cavity shrinkage defects formed by volume shrinkage; the constant-curvature boss-free convex roller body is located at the position where the central solid phase ratio is 0.2; the gradually-changed-curvature boss convex roller body is located at the position of the solidification ending point; the accurate pressing parameters of the convex roller bodies are determined; and pressing under large deflection is conducted in sequence at the two positions. The continuous casting alloy steel bloom convex combined roller and the heavy pressing process have the beneficial effects that by adoption of the convex combined roller equipment and the heavy pressing process, the quality defects of the segregation of chemical components, solidification center cavity shrinkage and severe looseness of the continuous cast bloom are overcome, and the macroscopic examination shows that the core quality of the continuous cast bloom is remarkably improved and quality is stable.

Owner:DONGBEI SPECIAL STEEL GRP DALIAN SPECIAL STEEL CO LTD

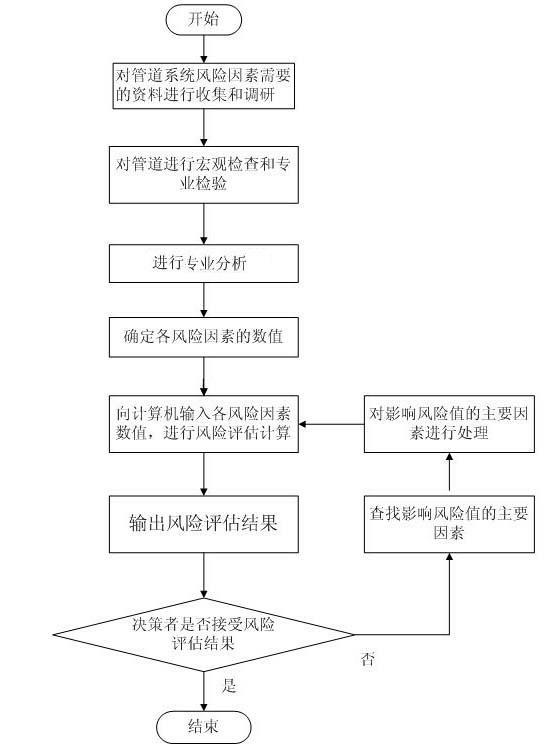

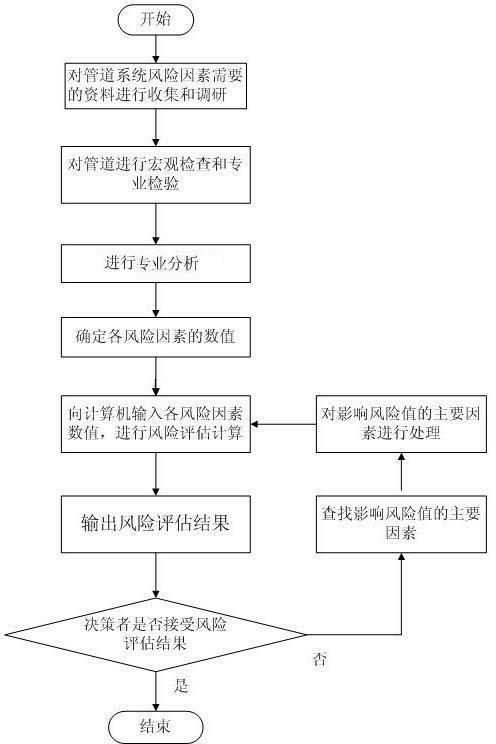

Risk assessment method for thermal pipeline system

InactiveCN102663653AExtended service lifeFrom lossData processing applicationsMacroscopic scaleDecision maker

The invention relates to a risk assessment method for a thermal pipeline system. The method comprises the following steps of: 1, collecting and surveying materials required by pipeline system risk factors; 2, performing macroscopic test and professional inspection on pipelines; 3, performing professional analysis; 4, determining numerical values of the risk factors according to the technical standard, operating parameters and expert assessment; 5, inputting the numerical values of the risk factors to a computer, and performing risk calculation by using a risk assessment model; 6, outputting a risk assessment result, so that a decision maker decides whether to accept according to the risk assessment result; 7, if the risk assessment result cannot be accepted by the decision maker, finding and processing the major factor influencing the value at risk and performing risk calculation again; and 8, if the risk assessment result is accepted by the decision maker, finishing the assessment procedure. According to the risk assessment method, risk assessment is performed by using the risk model, so that a decision-making basis is supplied to the decision-maker, accidents such as breakage, collapsing or burst are reduced or avoided, the service life of the pipelines is prolonged, and human life and property are prevented from being lost.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

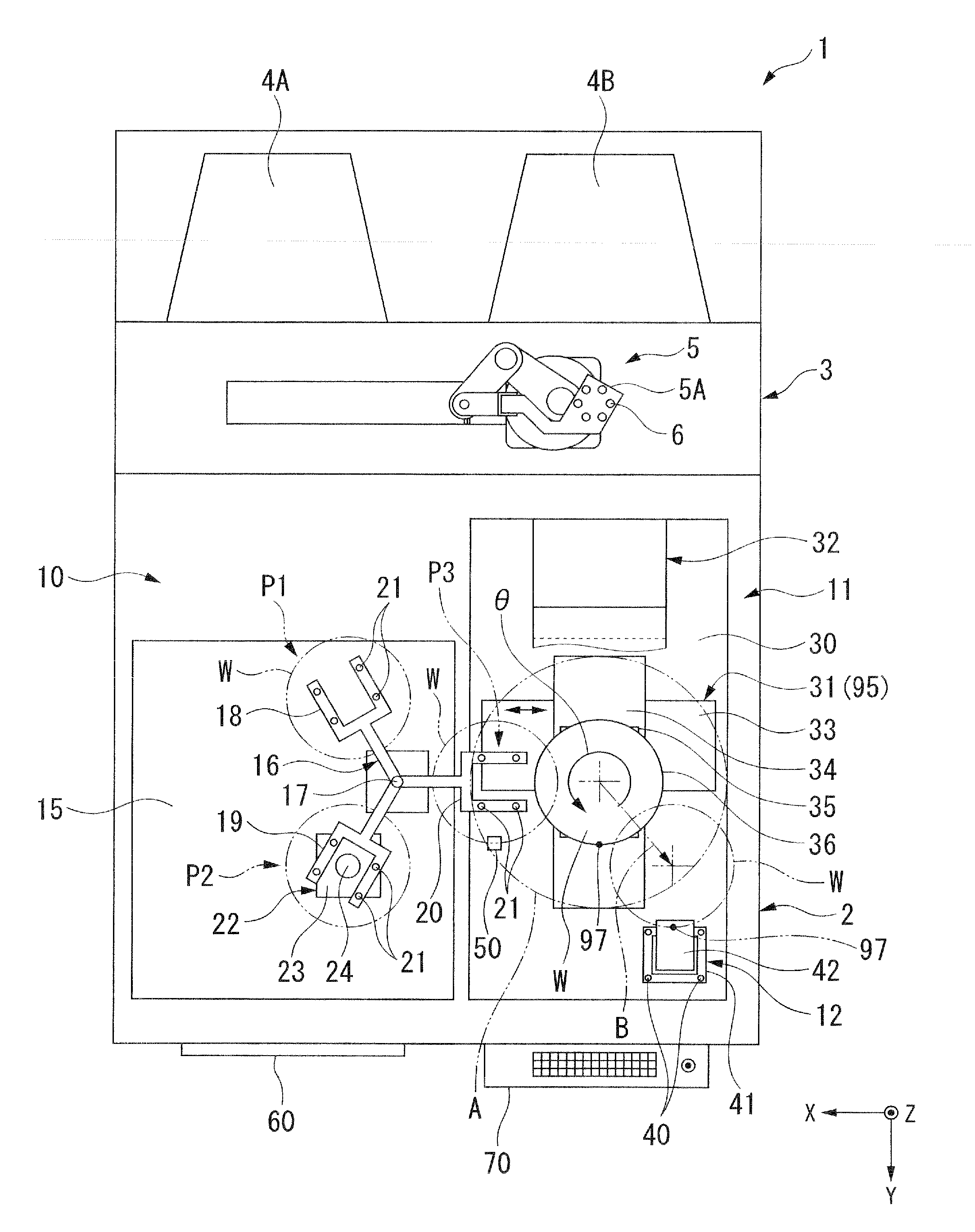

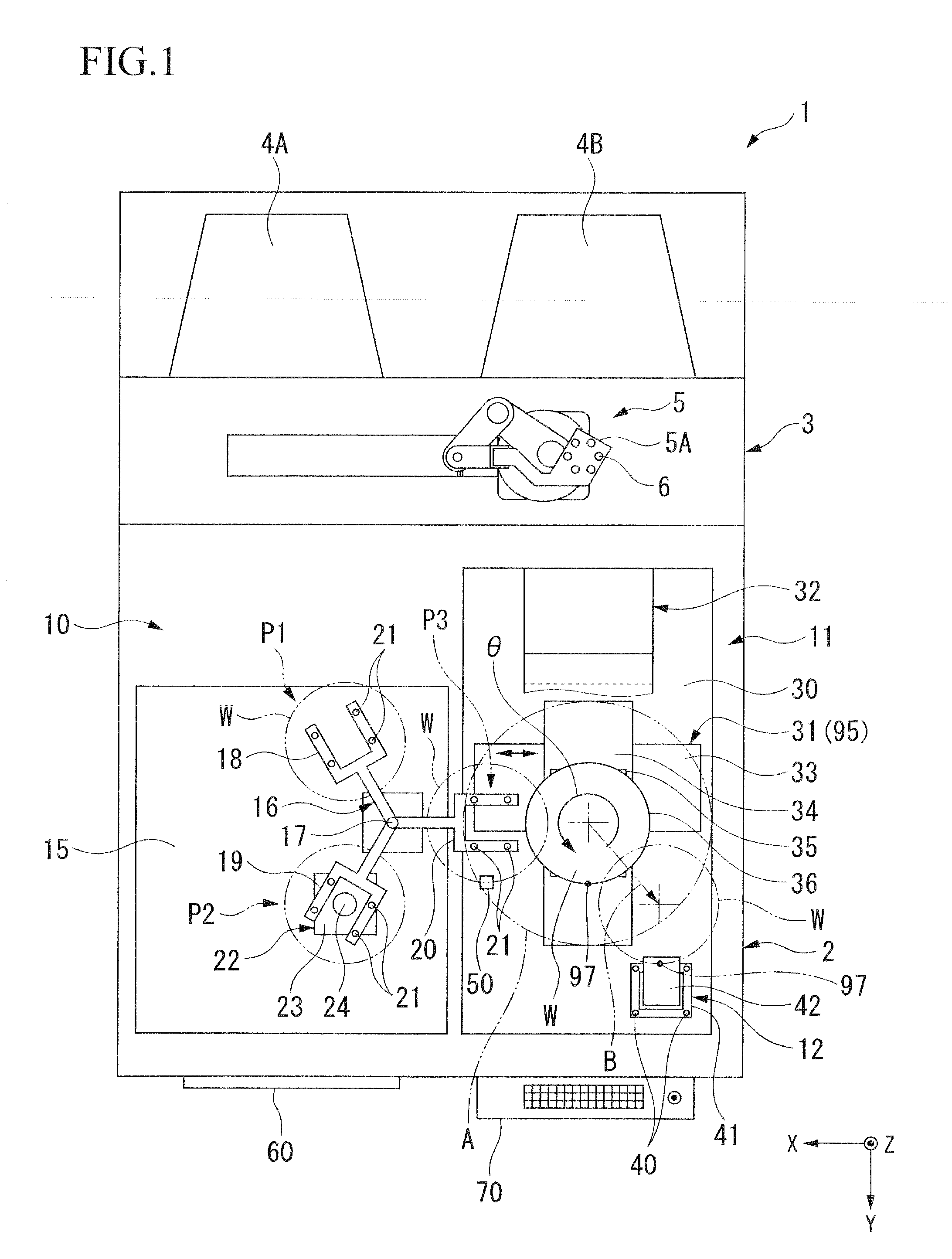

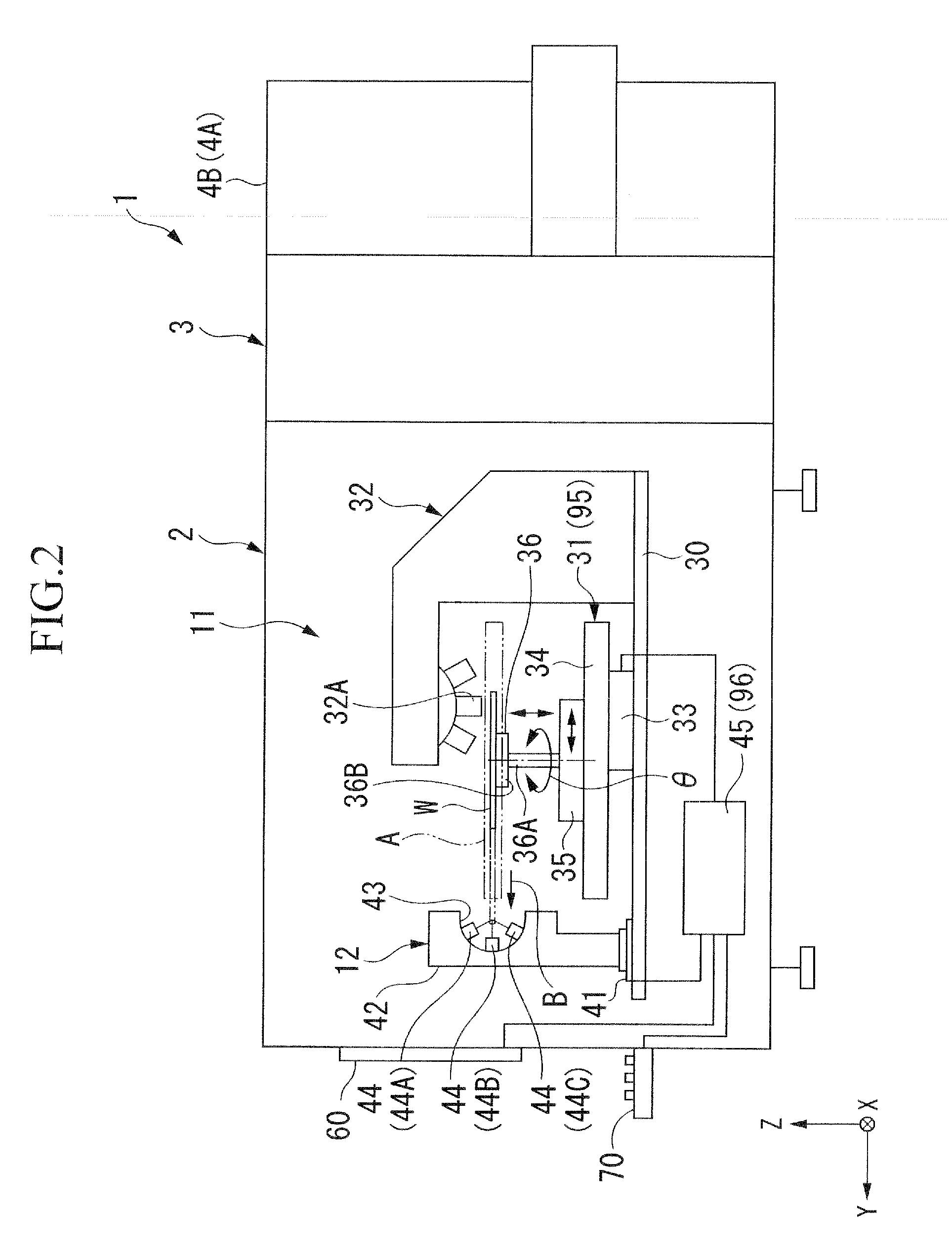

Visual inspection apparatus, visual inspection method, and peripheral edge inspection unit that can be mounted on visual inspection apparatus.

InactiveUS20090316143A1Simple configurationShorten takt timeMaterial analysis by optical meansWaferingVisual inspection

This visual inspection apparatus has a macro-inspection section and a micro-inspection section. In the micro-inspection section, a inspection stage and a microscope are loaded into a loading plate. The inspection stage can be moved in any directions of the X, Y, and Z directions, and can also be rotated in the θ direction. Moreover, a peripheral edge inspection section that acquires an enlarged image of a peripheral edge of wafer W is fixed to the loading plate. The peripheral edge inspection section is arranged so as to image the peripheral edge of wafer W held by the inspection stage.

Owner:OLYMPUS CORP

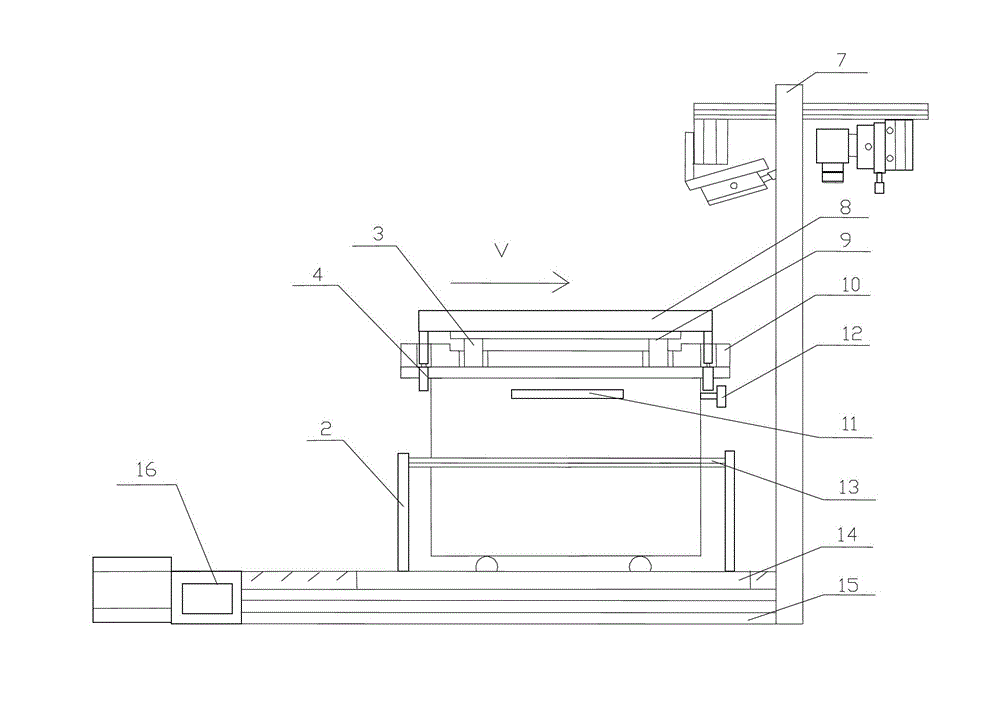

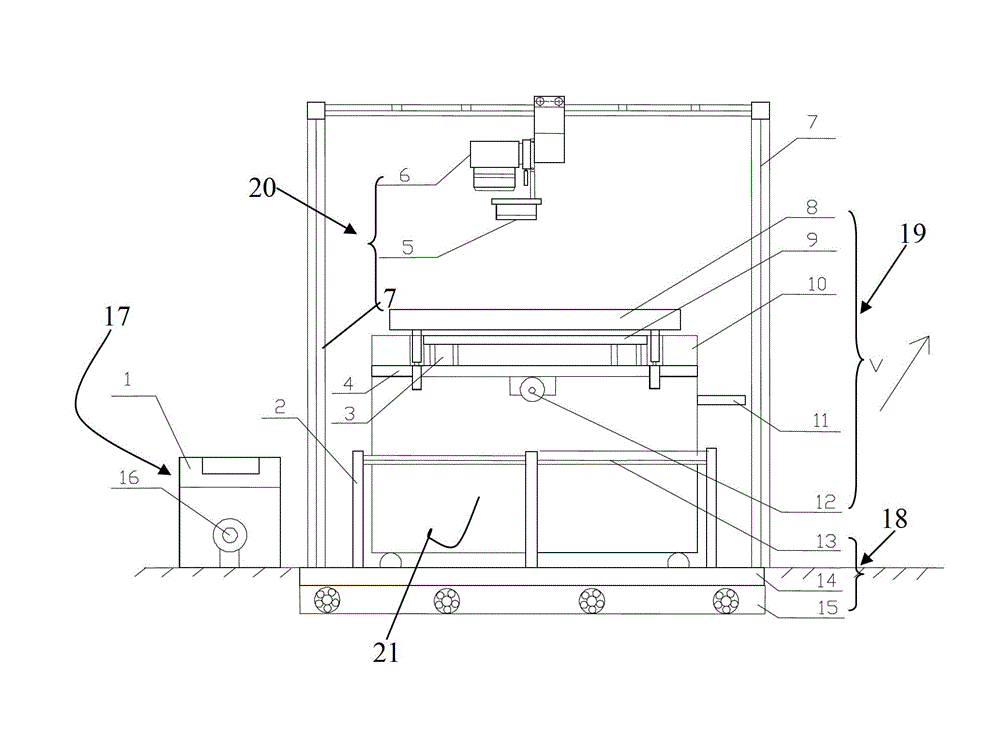

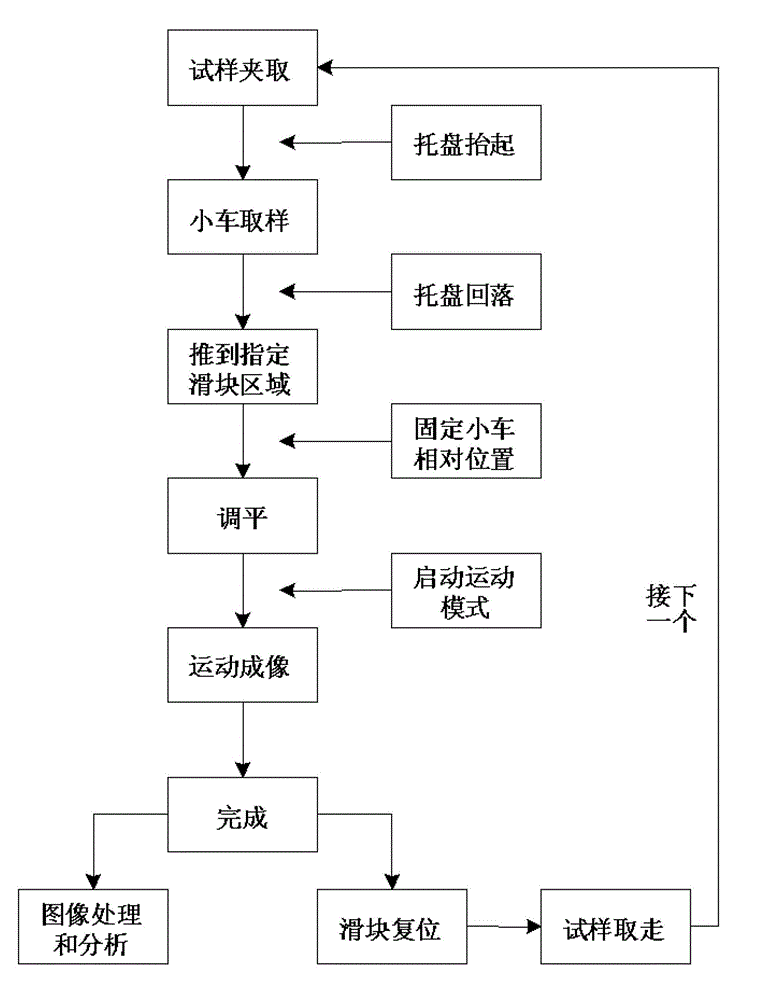

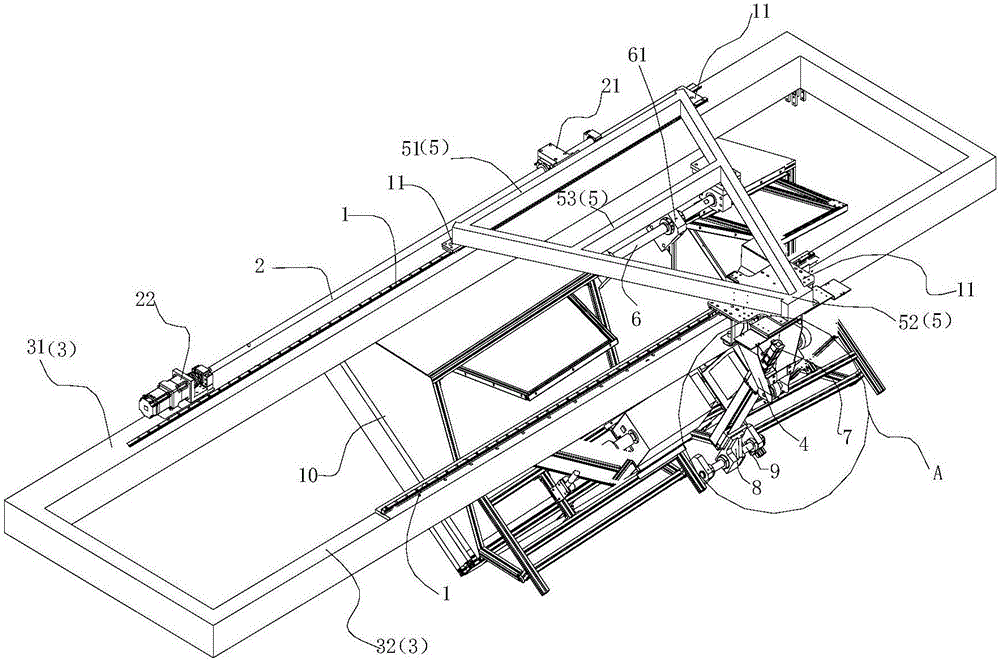

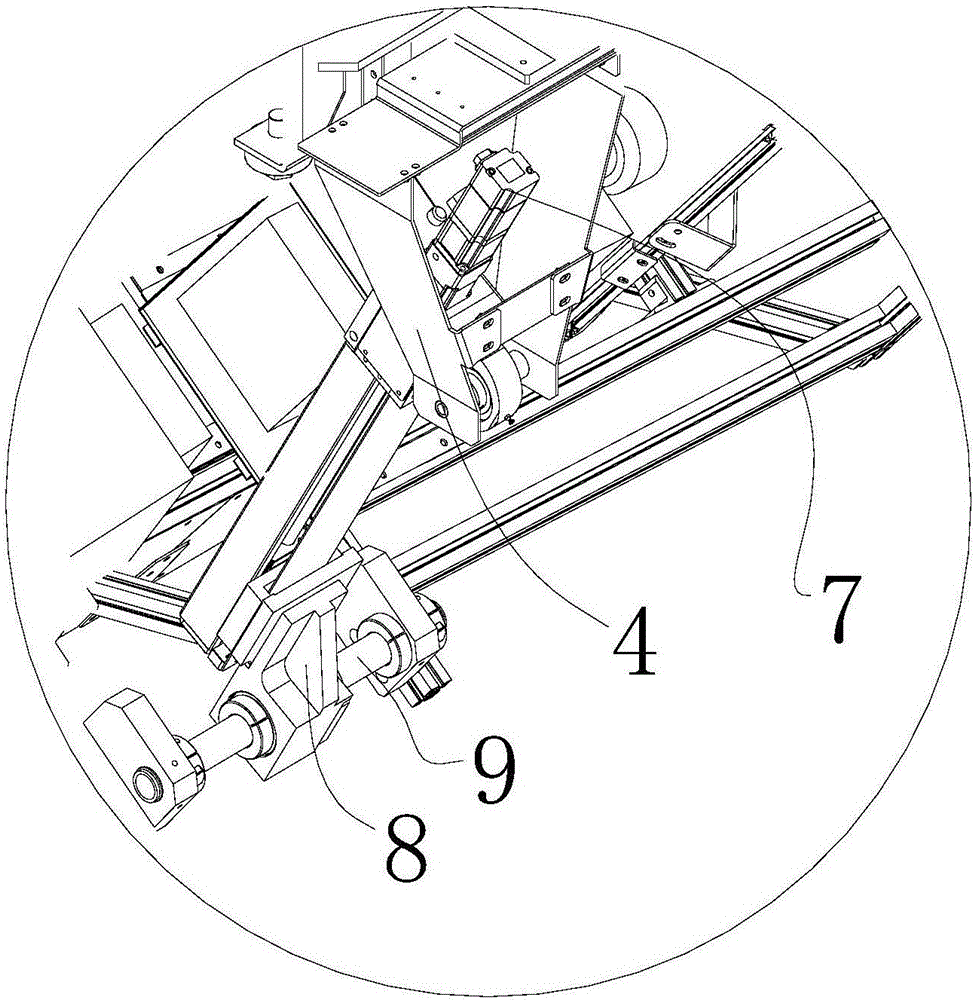

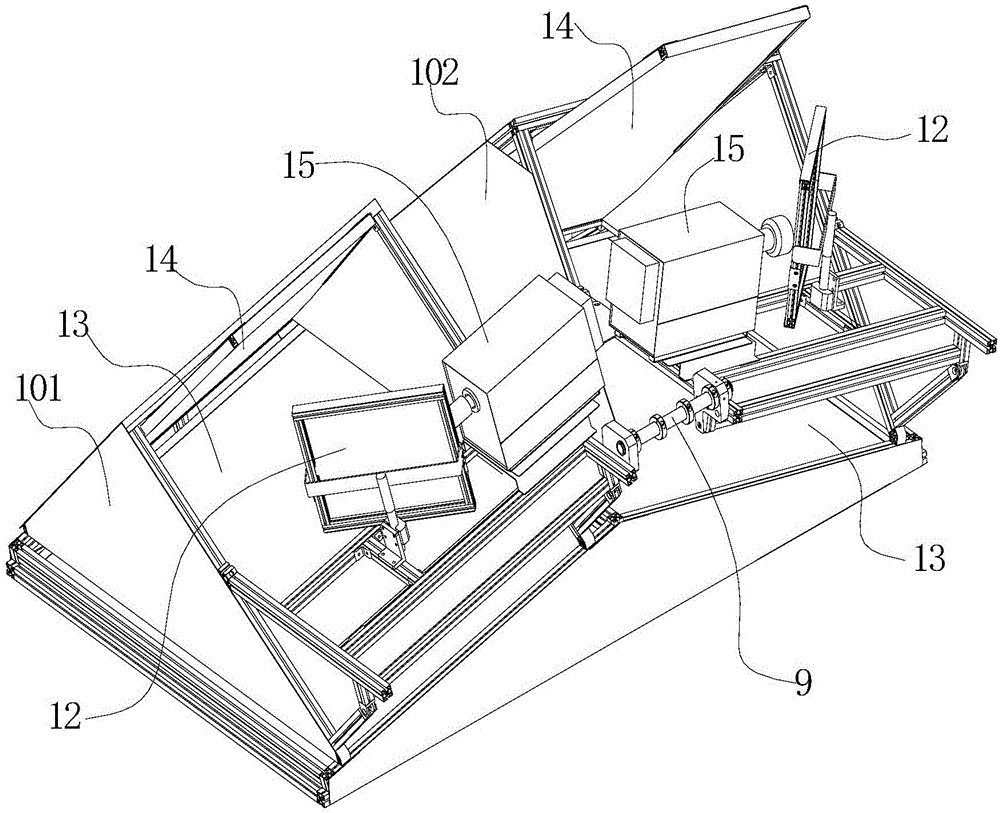

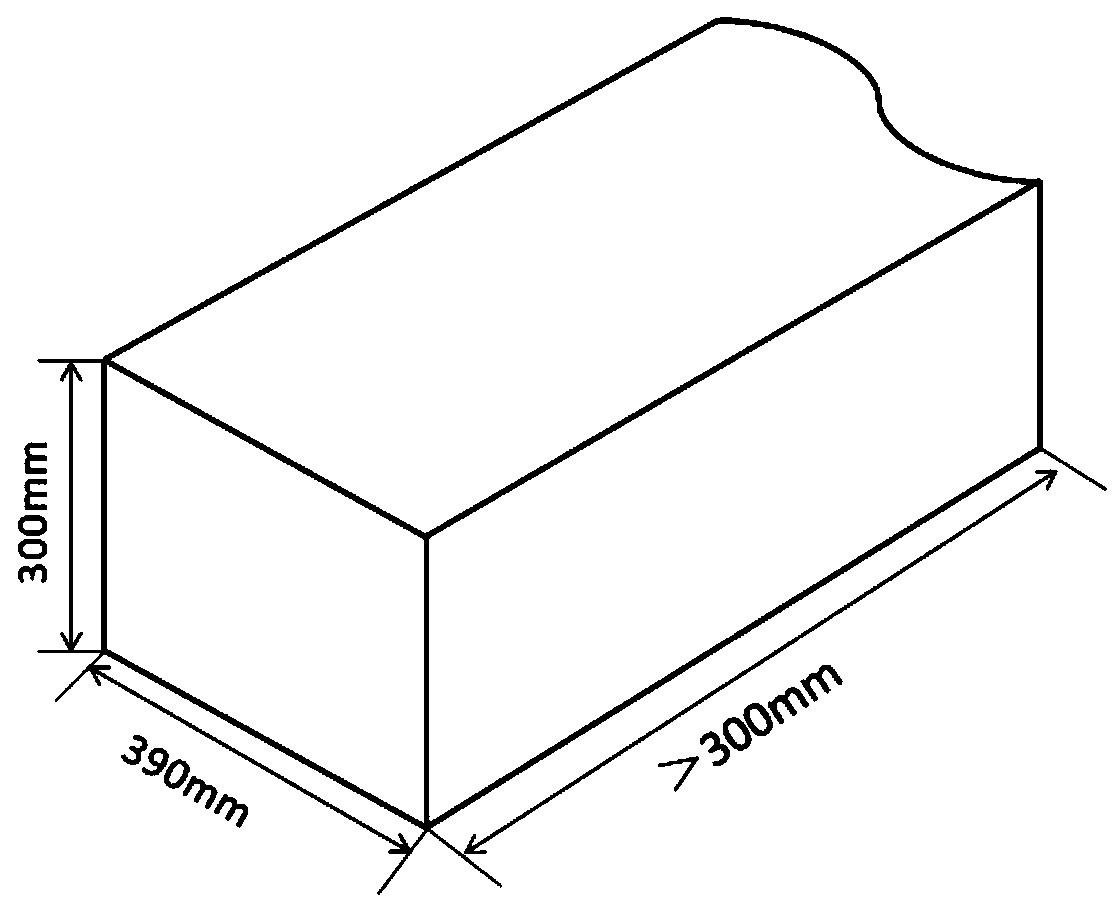

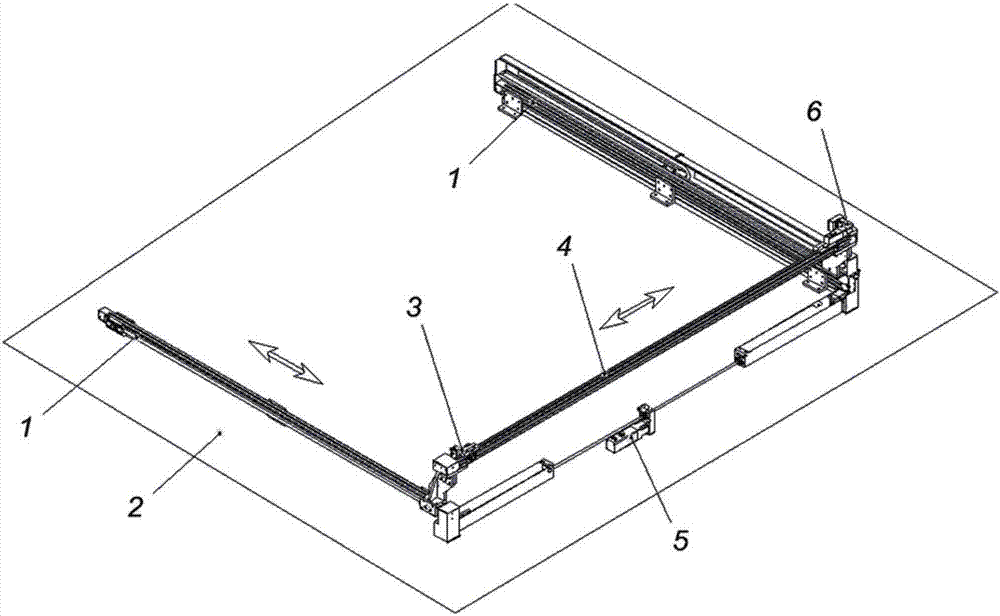

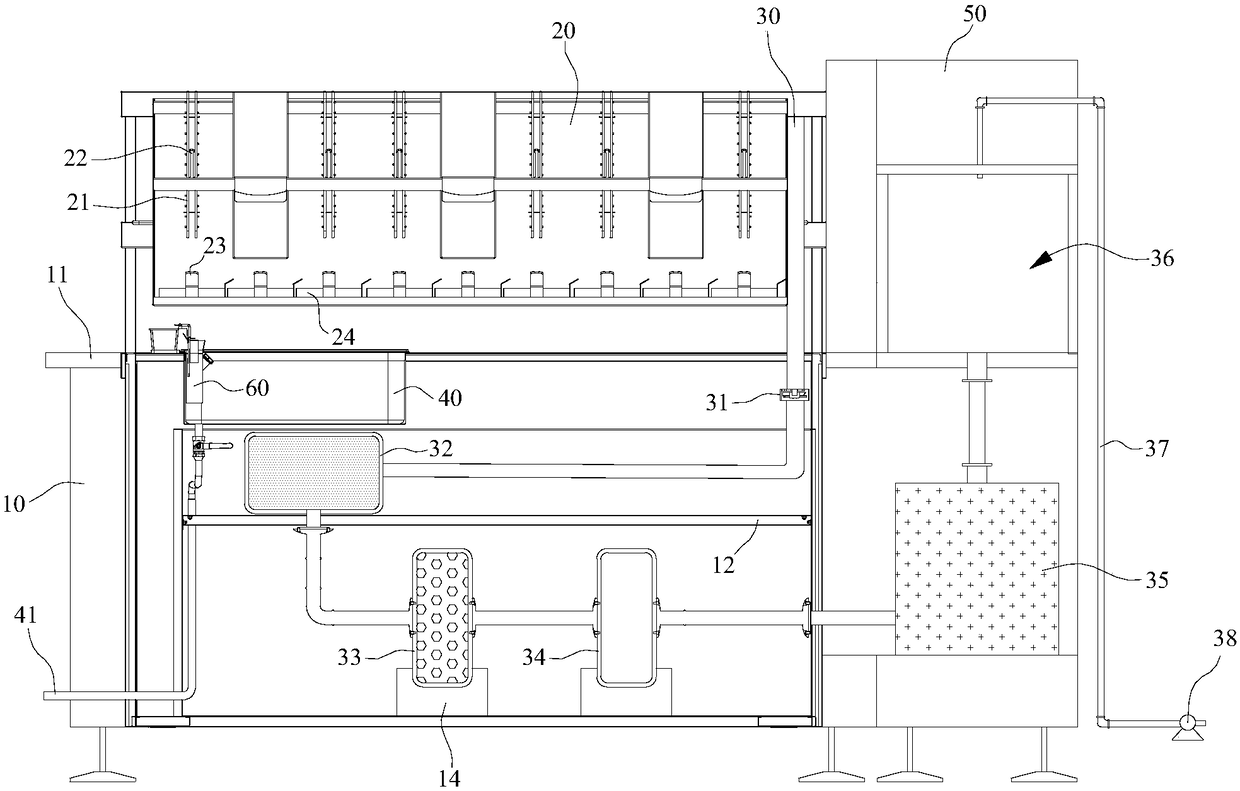

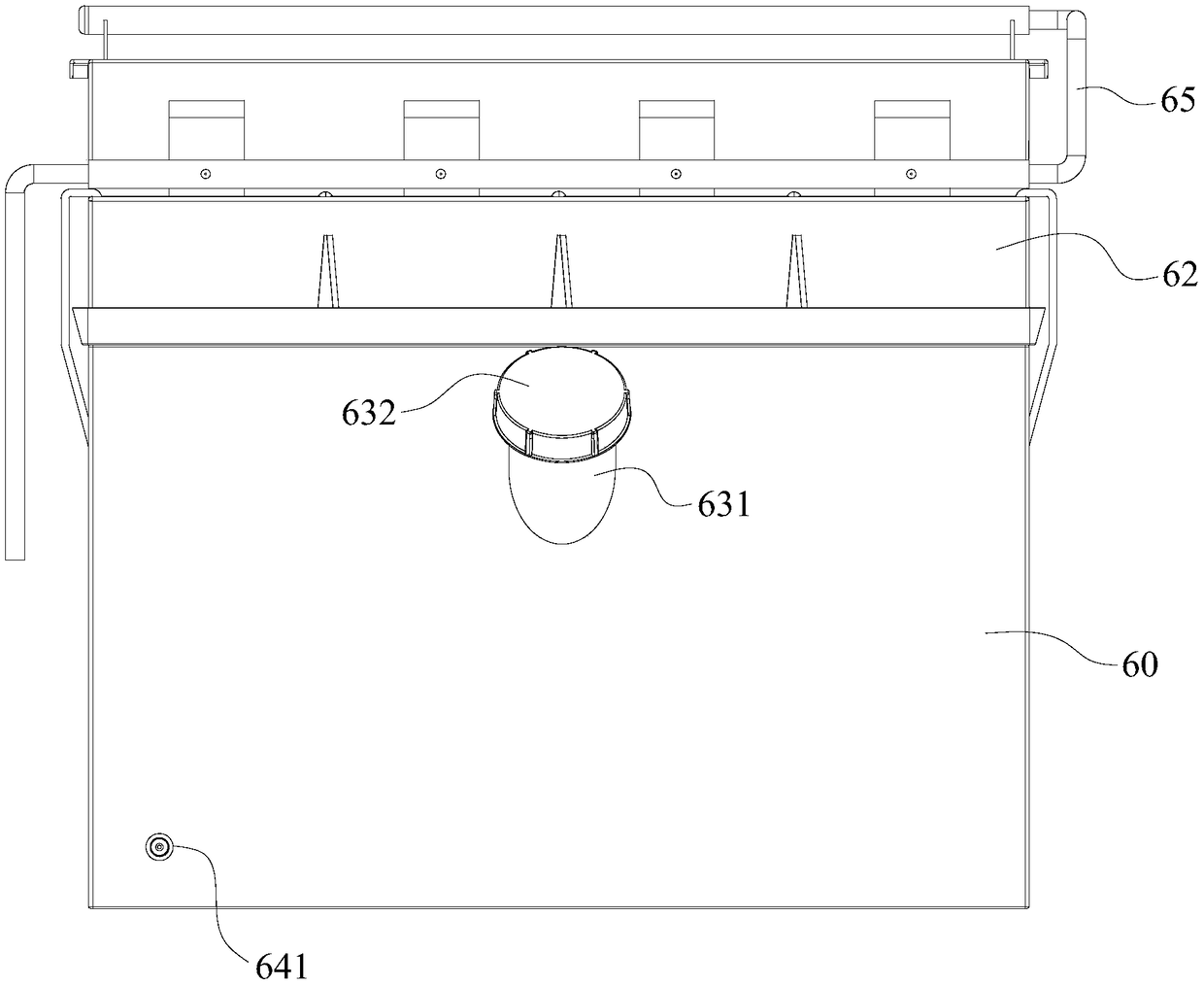

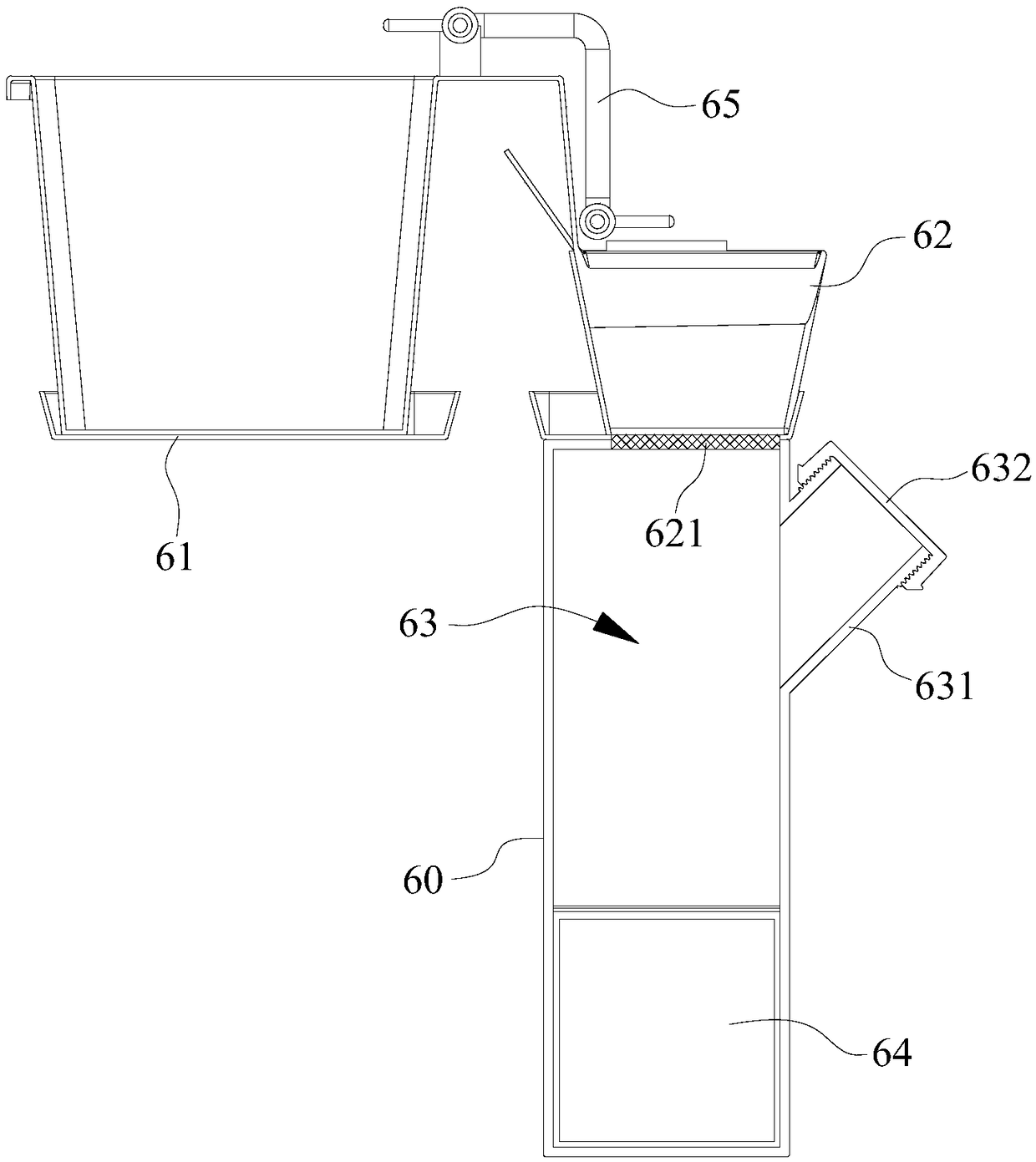

Test bench for off-line detection on surface of continuous casting slab

ActiveCN104101604AGuaranteed uptimeEasy to useOptically investigating flaws/contaminationUsing optical meansThick plateEngineering

A test bench for off-line detection on the surface of a continuous casting slab comprises a dolly movement control platform, a test-bench movement platform, a mobile dolly platform and an imaging system; the dolly movement control platform drives the test bench to move; the test-bench movement platform is used to fixing a mobile dolly and enables the mobile dolly to be slidably installed on a rail; the mobile dolly platform is movably installed on the test-bench movement platform, and is used for placing of a continuous casting sample plate and leveling of the continuous casting sample plate; and the imaging system is across installed above the test-bench movement platform and makes synchronous motion along with the test-bench movement platform. The test bench is capable of enabling the dolly to be pushed out of a movement rail. By performing horizontal adjusting on the bottom of the continuous casting slab, the imaging position of the continuous casting slab is guaranteed to satisfy the field-depth requirement of a camera; the imaging system is capable of performing moving adjustment along the movement rail direction of the test bench, and the camera is capable of imaging in the full-length full-width scope of a to-be detected sample plate. The test bench is reliable to operate and convenient to use, and is capable of realizing off-line on-line macroscopic examination on a thick plate.

Owner:BAOSHAN IRON & STEEL CO LTD

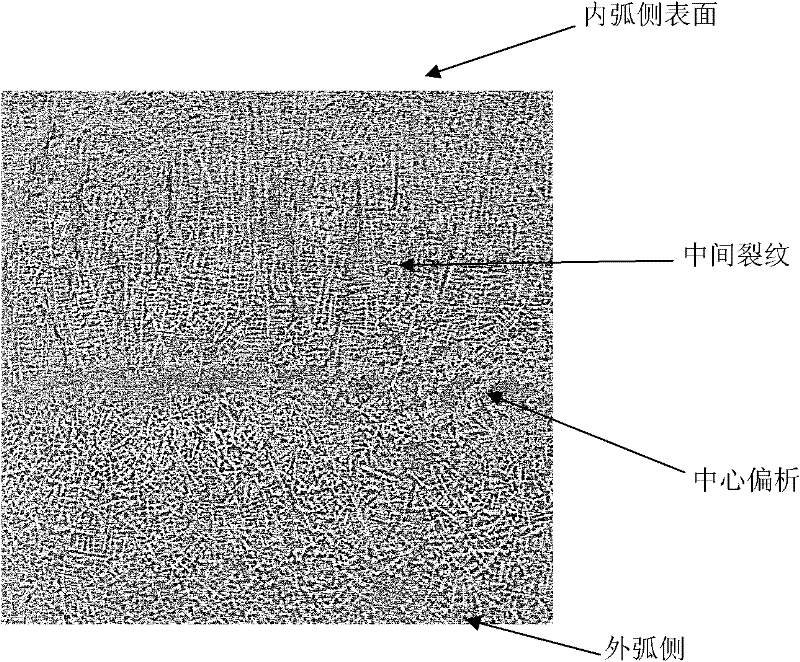

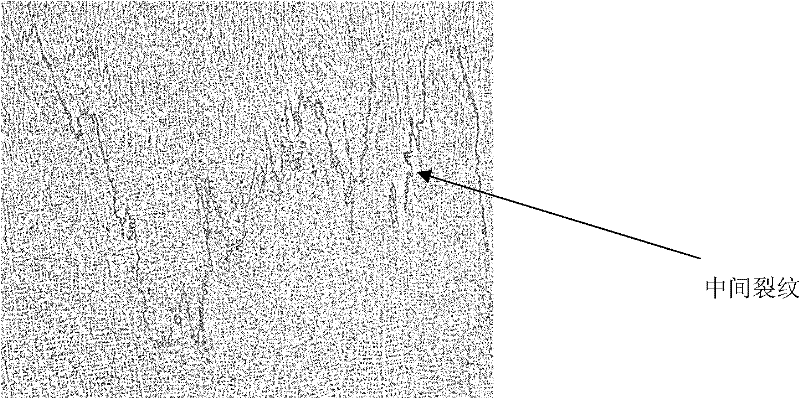

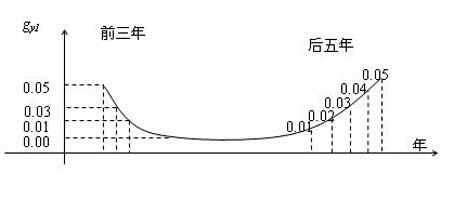

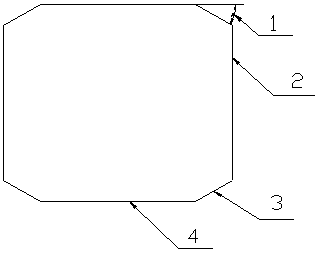

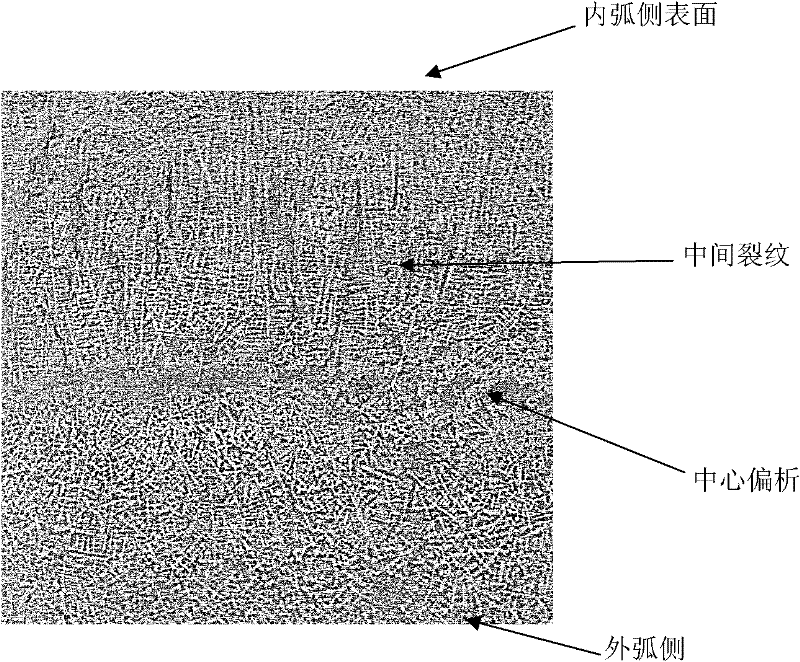

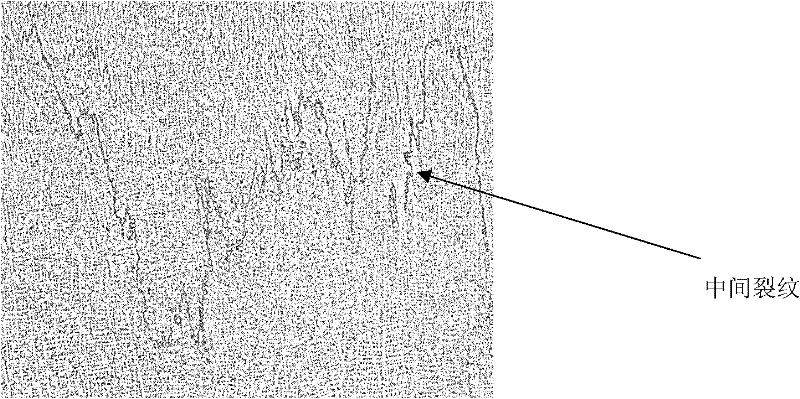

Control method for improving internal defects of high-carbon chromium bearing steel bloom

ActiveCN110523942ASolve depression cracksSolve internal defects such as center segregationLiquid corePorosity

The invention discloses a control method for improving internal defects of a high-carbon chromium bearing steel bloom. The control method comprises the steps that molten steel is cast into a large-chamfer bloom with a liquid core, continuous casting parameters are controlled, and a soft reduction process is carried out on the large-chamfer bloom with the liquid core. According to the method, the included angle between the corner of the continuous casting billet and the wide surface of the casting billet is controlled to be 30-40 degrees, and the length of the bevel edge is controlled to be 45-60 mm; the superheat degree of molten steel in the tundish is controlled to be 15-30 DEG C, and the casting speed is controlled to be 0.70-0.85 m / min; and dynamic soft reduction and static soft reduction are respectively carried out on the large-chamfer continuous casting billet with the liquid core. The internal defects of reduction cracks, center segregation and the like of the high-carbon chromium bearing steel bloom are overcome; the high-carbon chromium bearing steel bloom is subjected to macroscopic examination, the macroscopic examination comprises 0-0.5 grade of center porosity, 0.5-1.0 grade of center segregation, 0-0.5 grade of shrinkage cavity, 0-0.5 grade of middle cracks, 0-0.5 grade of center cracks and 55-68% of isometric crystal ratio; and the carbon segregation index of the center of the continuous casting billet is 0.95-1.06.

Owner:XINGTAI IRON & STEEL

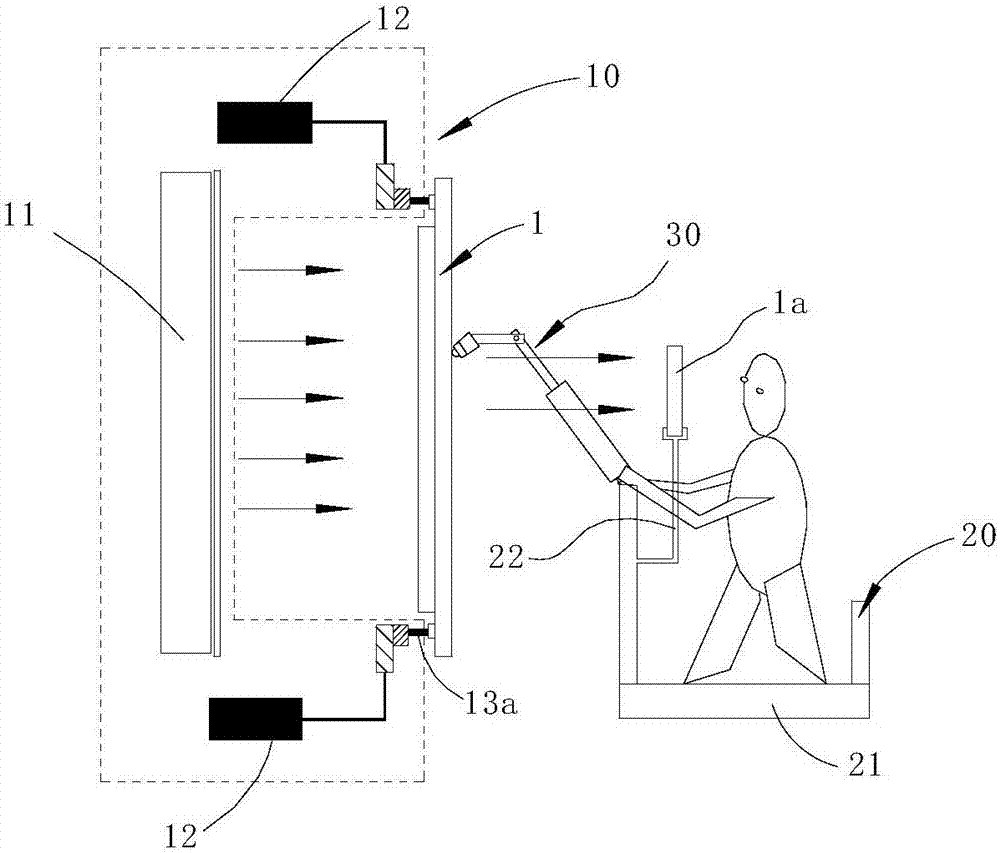

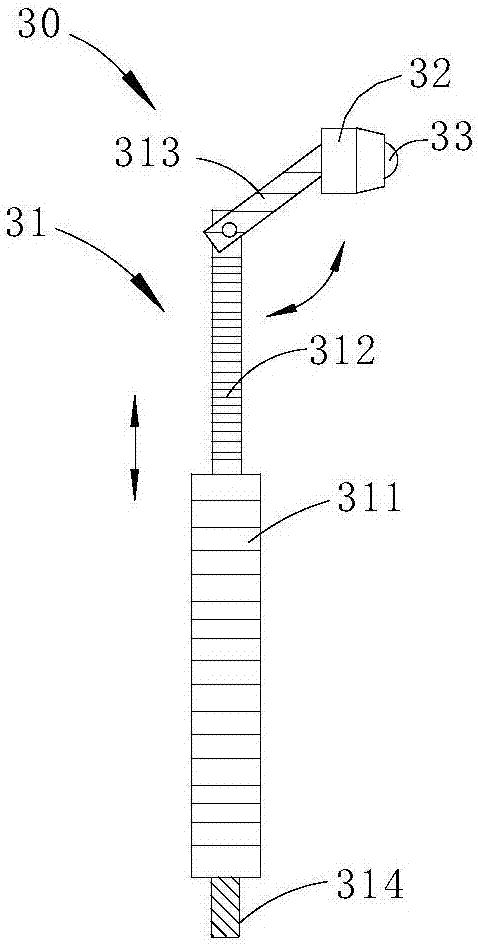

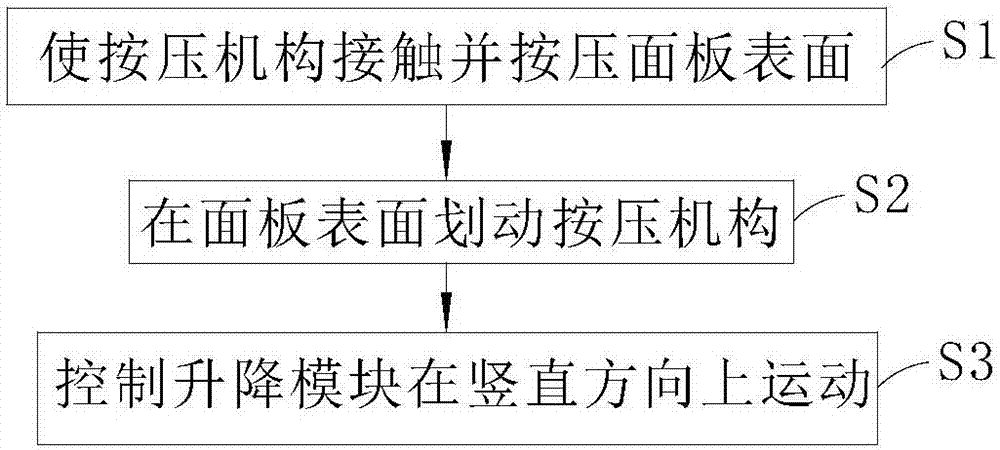

Macroscopic inspection device and macroscopic inspection method

InactiveCN106990567AAvoid scrappingImprove stabilityOptically investigating flaws/contaminationNon-linear opticsProduction lineEngineering

The invention discloses a macroscopic inspection device and a macroscopic inspection method. The macroscopic inspection device comprises a lighting module, a lifting module and a pressing module, wherein the lighting module is used for simulating lighting of a panel without a TFT lateral polaroid, the lifting module is arranged at one side of the lighting module in a spaced mode, can move in the vertical direction and is internally provided with an operation panel used for controlling the height of the lifting module, and the pressing module is used for making contact with and pressing a substrate on the surface of the pressing panel so as to observe the surface of the substrate obtained after pressing. By putting the panel without the TFT lateral polaroid beside the lighting module and arranging the lifting module opposite to the panel, the TFT lateral polaroid and the pressing mechanism can move up and down along with the lifting module, after the lighting module is started, the substrate can be subjected to macroscopic inspection by penetrating the TFT lateral polaroid, by pressing different parts of the substrate through the pressing mechanism, detection can be effectively conducted on an alignment anomaly caused by HVA optical alignment, the phenomenon that the HVA alignment anomaly leaks to secondary lighting to cause a lot of scraps is avoided, and therefore the product yield is increased, and the production line stability is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Macroscopic inspection system for glass substrate

PendingCN106680289AImprove yield rateEasy for statistical analysisOptically investigating flaws/contaminationEngineeringMacroscopic examination

The invention relates to a macroscopic inspection system for a glass substrate. The macroscopic inspection system comprises an illuminating device and a mounting rack for fixing the illuminating device, wherein one side of the illuminating device is connected to the mounting rack through a rotating shaft (6), and the other side of the illuminating device is connected to the mounting rack through a first driving mechanism; the first driving mechanism can drive the illuminating device to rotate around the rotating shaft (6). In this way, defects of the glass substrate at different angles can be observed under the condition that an operator performs observation without motion, the observation is clearer, defect forming reasons are calculated and analyzed conveniently, upstream process parameters are improved, the yield of the glass substrate is increased, and the production cost is reduced.

Owner:JIANGSU HONGXIN YITAI INTELLIGENT EQUIP CO LTD

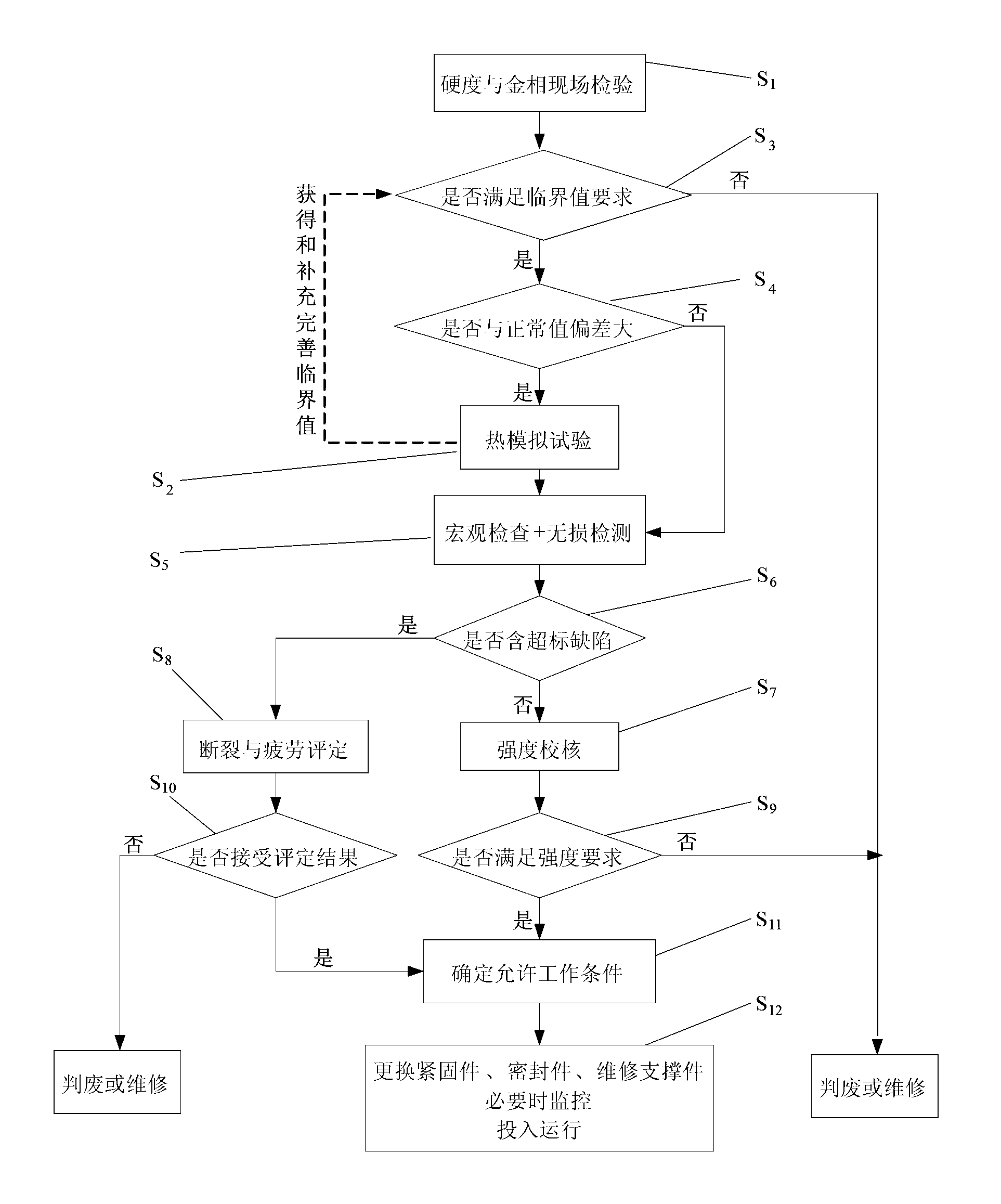

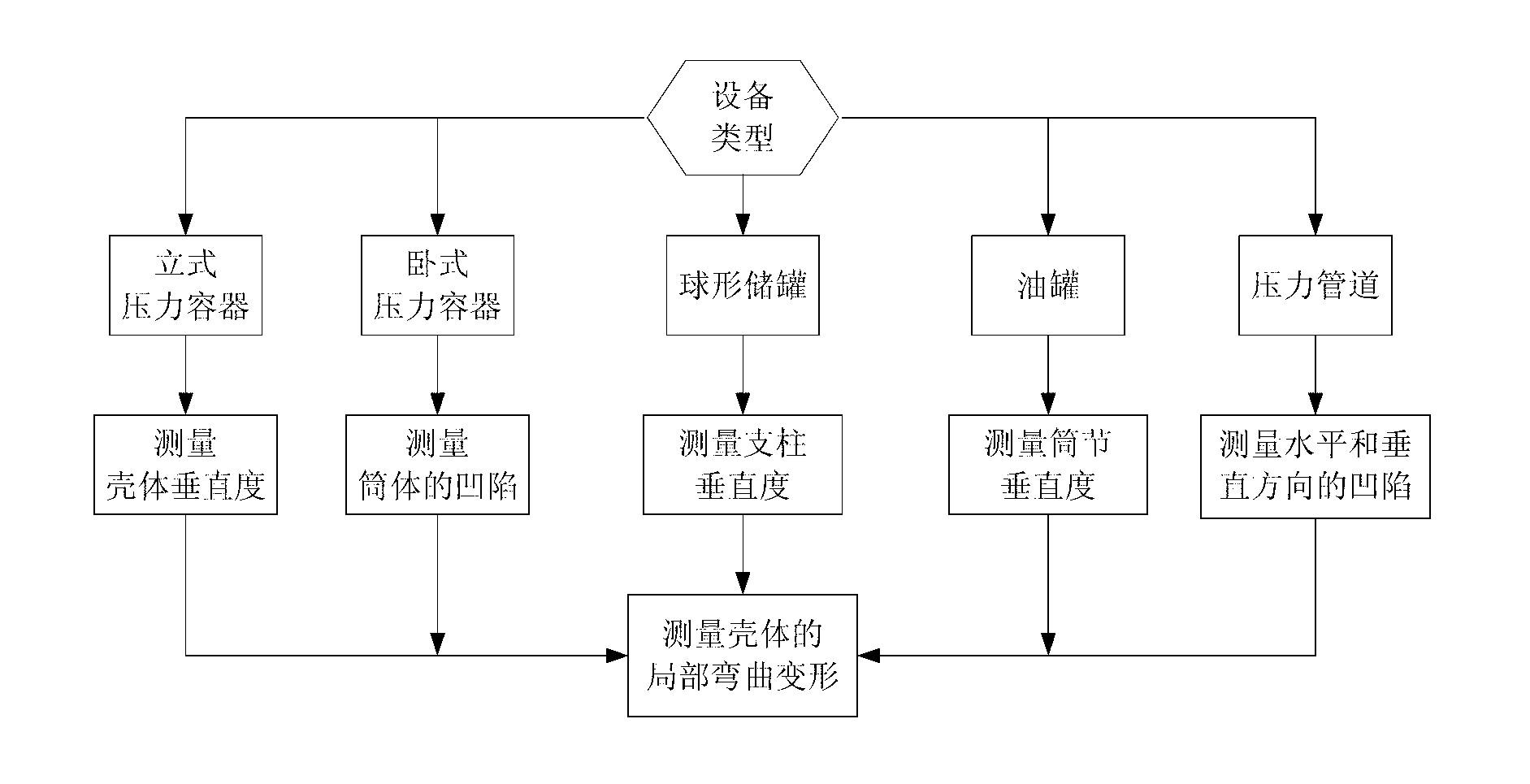

Method for assessing safety of pressure bearing apparatus after fire hazard

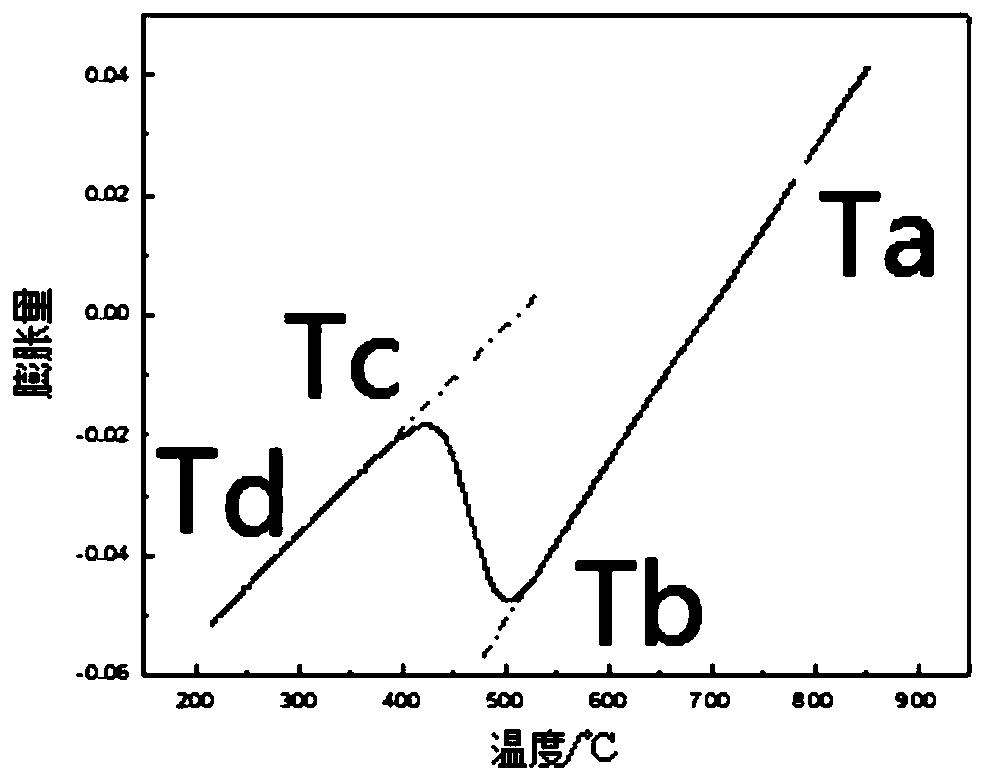

ActiveCN103278525AAchieve safety assessmentImprove evaluation efficiencyMaterial flaws investigationInvestigating phase/state changeThermal stimulationHardness

The invention belongs to the field of the safety assessment of pressure bearing apparatuses, and concretely relates to a method for assessing the safety of a pressure bearing apparatus based on damage thermal stimulation. The method concretely comprises the following steps: carrying out onsite examination of the hardness and the metallographic phase; carrying out a thermal simulation experiment to obtain the hardness and the metallographic structure critical value; comparing the onsite examination measure values of the hardness and the metallographic phase with the metallographic structure critical value and a normal value, carrying out a next step if conditions are satisfied, and directly discarding if the conditions are not satisfied; carrying out macroscopic inspection and nondestructive detection: determining a standard exceeding defect, directly carrying out strength check if there is no standard exceeding defect, and carrying out fracture and fatigue evaluation if there is a standard exceeding defect; and determining an allowed work condition after the strength check and fracture and fatigue evaluation are qualified, afresh allowing the apparatus to run, and directly discarding or maintaining if the strength check and fracture and fatigue evaluation are unqualified. The method has a high evaluation efficiency, and can rapidly and effectively evaluate whether the pressure bearing apparatus subjected to the fire hazard can be used or not.

Owner:HEFEI GENERAL MACHINERY RES INST +1

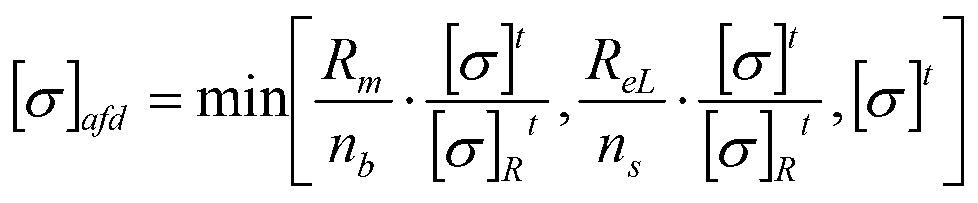

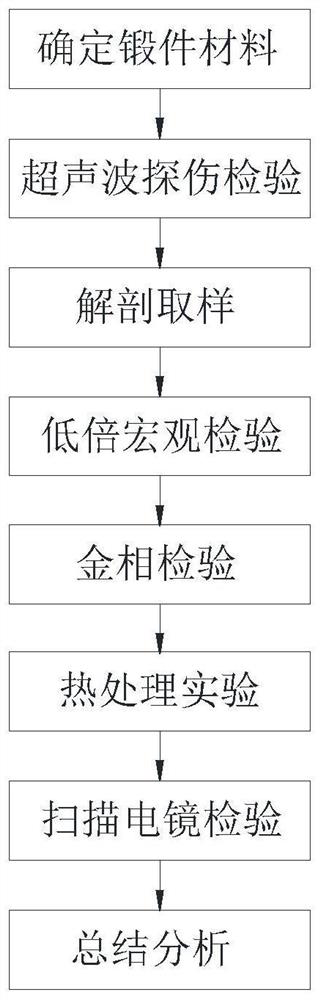

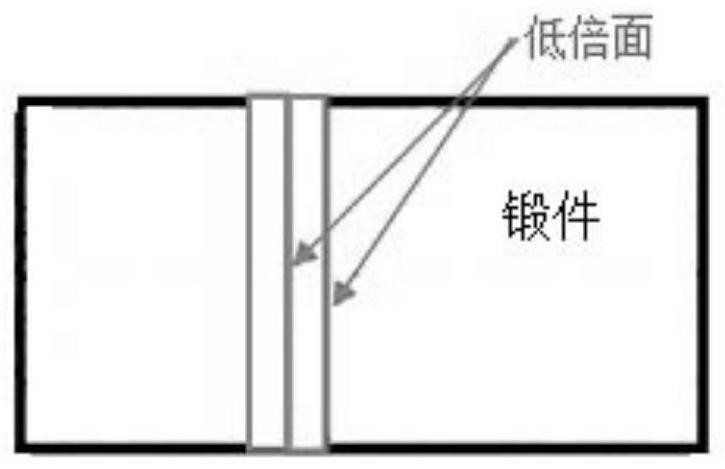

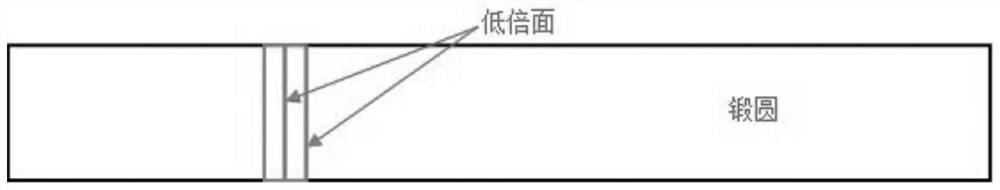

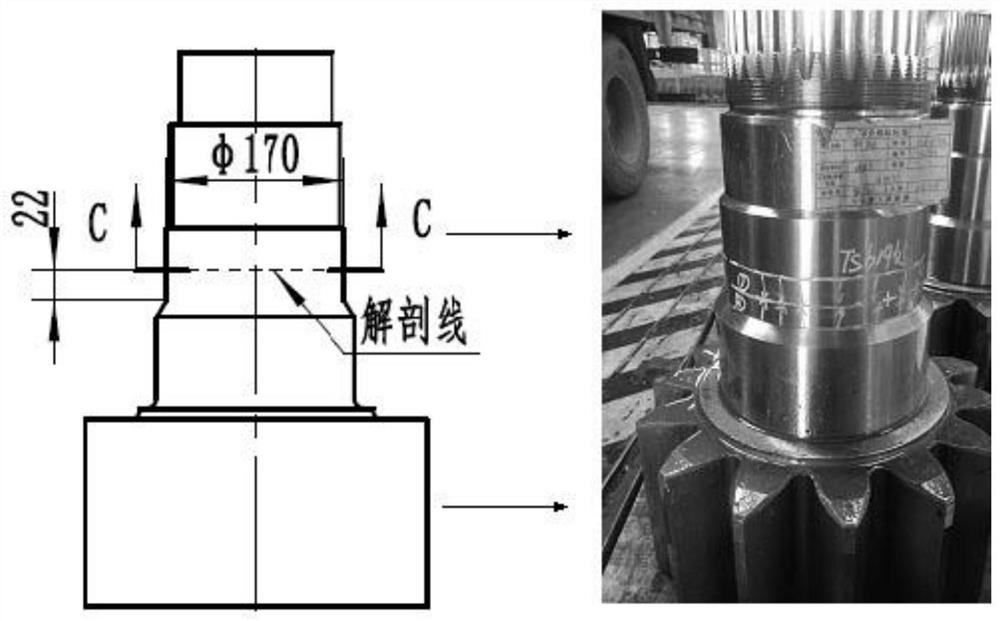

Defect analysis method for 410 material forging

PendingCN112666336AReduce waste of resourcesAvoid wasting manpower and material resourcesAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationMacroscopic scaleScanning electron microscope

The invention relates to a defect analysis method for a 410 material forging. The defect analysis method comprises the following steps: 1, determining of a forging material; 2, ultrasonic flaw detection; 3, dissecting and sampling; 4, low-power macroscopic inspection, 5, metallographic inspection, 6, scanning electron microscope inspection and 7, conclusion analysis. According to the method, ultrasonic flaw detection, dissection and sampling, low-power macroscopic examination, metallographic examination, heat treatment examination and scanning electron microscope examination are carried out on the forged round blank and the round bar forge piece, specific defect types on the forged round blank and the round bar forge piece are gradually examined, formation reasons of defects are compared and analyzed, instructive suggestions are provided for eliminating the defects, resource waste caused by quality defects in the production process of forged round blanks is reduced, scrapped parts of round bar forgings in the forging process are reduced, essential reasons for defect generation are found, and waste of manpower and material resources caused by repeated defect detection is avoided.

Owner:NANJING DEV ADVANCED MFG

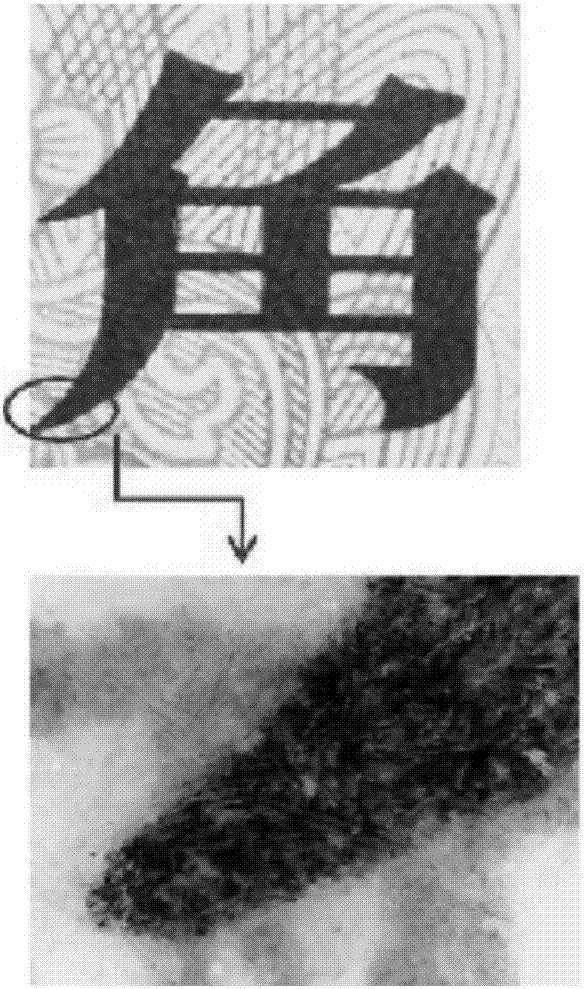

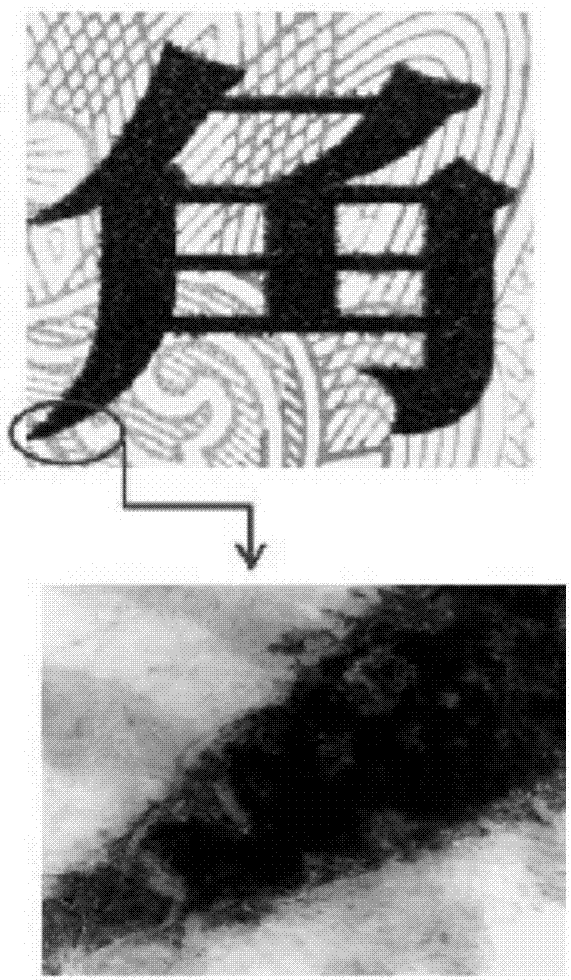

Method for identifying seal and print formation mode based on microcosmic trace point characteristics

InactiveCN107345922AImprove accuracyEasy to operateMaterial analysis by optical meansLetterpress printingComputer science

The invention relates to a method for identifying a seal and print formation mode based on microscopic trace point characteristics and belongs to the technical field of document examination. The method mainly comprises the following steps: (1) carrying out macroscopic examination on seal and print based on objective facts and living knowledge; and (2) deeply analyzing the seal and print by utilizing the microscopic trace point characteristics, wherein the microscopic trace point characteristics includes ink mark characteristics, ink point characteristics and dot characteristics; the seal and non-plate-making printing print are identified by adopting the ink mark characteristics and the ink point characteristics, and the plate-making printing print is identified by adopting the dot characteristics; and when no dot characteristic exists, whether the seal and print are sealed or printed in a non-plate-making way or formed by a woodblock and a metal plate in letterpress printing is judged, and when the dot characteristic exists, whether the seal and print are formed by the plate-making printing print is judged. The method provided by the invention has the beneficial effects that print production method identification utilizing the trace point characteristics is high in examination accuracy and convenient in operation and thus is a nondestructive and fast identification method.

Owner:韩伟

Smelting method for stably controlling temperature of heavy rail steel U75V tundish

The invention discloses a smelting method for stably controlling the temperature of a heavy rail steel U75V tundish. The smelting method comprises the processes of pre-desulfuration for molten iron, smelting in a rotating furnace, LF refining, RH refining and continuous casting. According to the smelting method, under the condition of not increasing the production cost, the viscosity of refining slag of a steel ladle is controlled to achieve a good heat preservation effect, the temperature change of the tundish is lower than 10 DEG C in the casting process, so that the superheat degree of themolten iron of the tundish is controlled within a change section of 20-30 DEG C, the loose center and shrinkage cavity defects of a casting blank are obviously overcome, the macroscopic defects such as center cracks, middle cracks and corner cracks of the casting blank are effectively prevented, and the demand for a heavy rail steel at present is met; the qualification rate of the temperature of the molten iron of the tundish produced for the heavy rail steel is greater than or equal to 95%, so that the degradation judgement change rate of temperature ultralimit is lowered by 90% or above, macroscopic examination for the steel rail is qualified, the flaw detection qualification rate is 98-99.5%, low-superheat-degree casting is achieved, the quality stability and qualification rate of products are improved, and the smelting method has a wide application prospect.

Owner:HANDAN IRON & STEEL GROUP +1

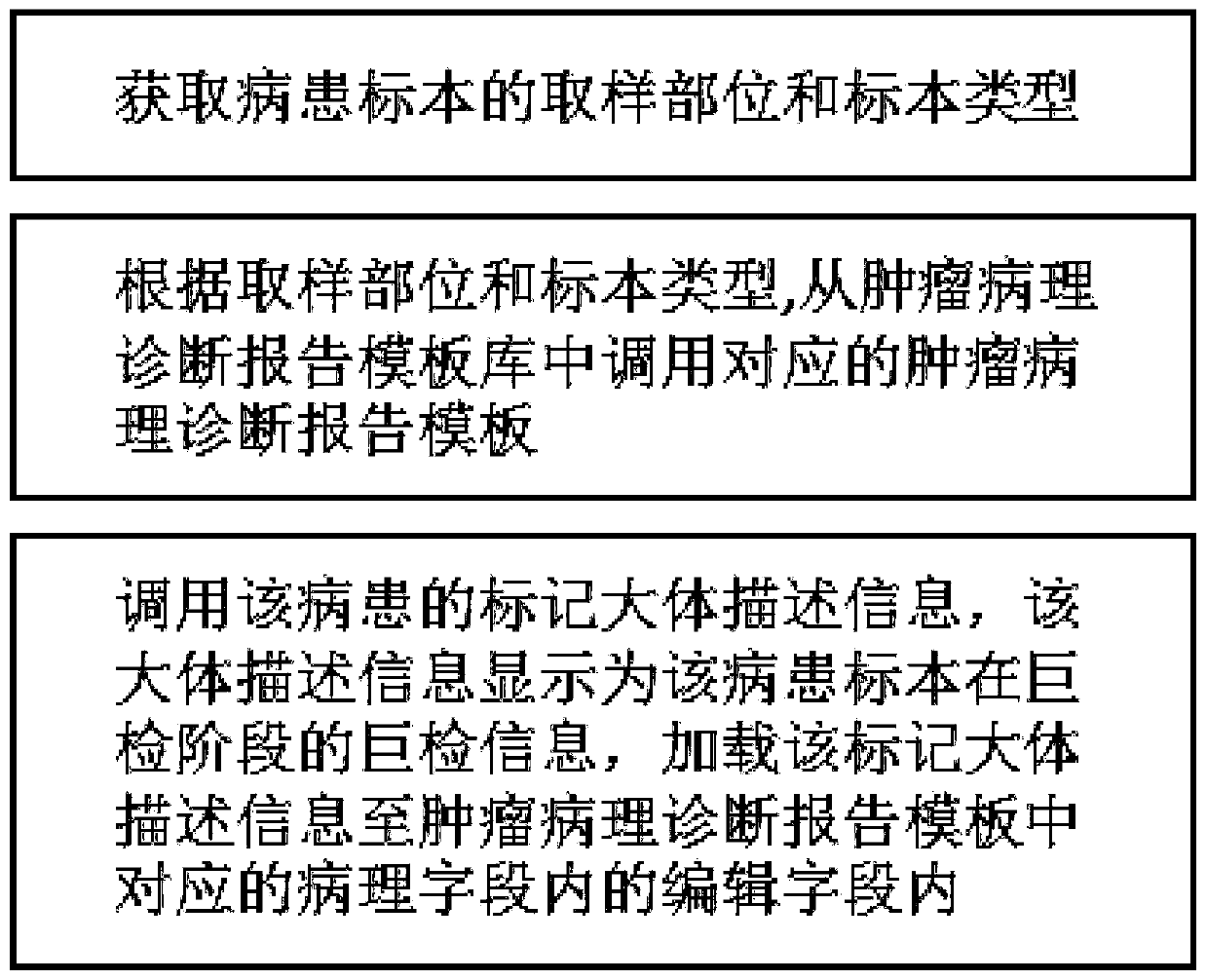

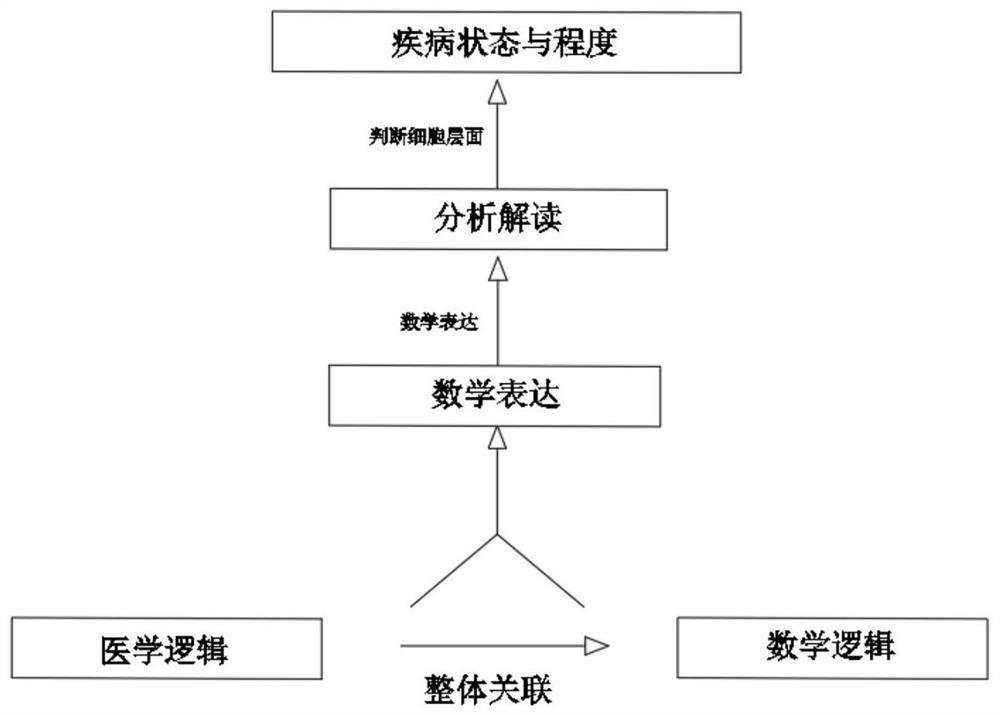

Standard edited tumor pathological diagnosis report template generation system and method

InactiveCN110335657AImprove accuracyImprove filling efficiencyNatural language data processingSpecial data processing applicationsPhases of clinical researchWilms' tumor

The invention provides a standard edited tumor pathological diagnosis report template generation system and method. The method comprises the following steps: acquiring a sampling part and a specimen type of a patient specimen; according to a sampling part and a specimen type, calling a corresponding tumor pathological diagnosis report template from a tumor pathological diagnosis report template library and calling the general description information of a marker of the patient, wherein the general description information is displayed as the macroscopic examination information of the patient specimen in the macroscopic examination stage; loading the general description information of the marker into an editing field in a corresponding pathological field in the tumor pathological diagnosis report template, and executing the industry specification in a standard editing mode.

Owner:杭州大伽信息科技有限公司

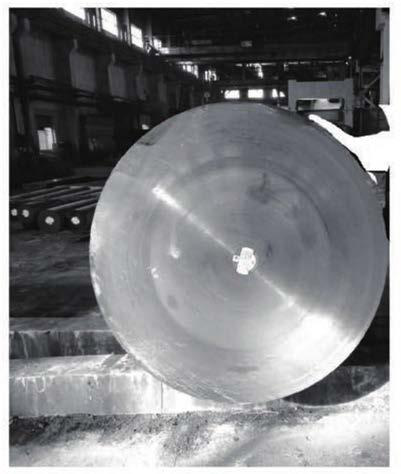

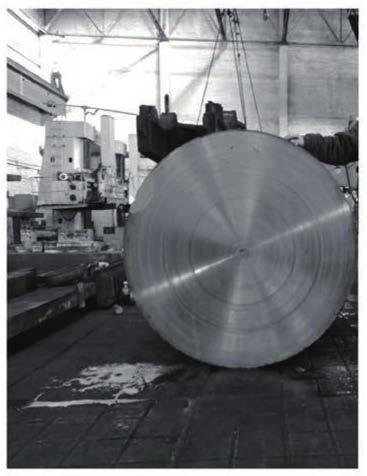

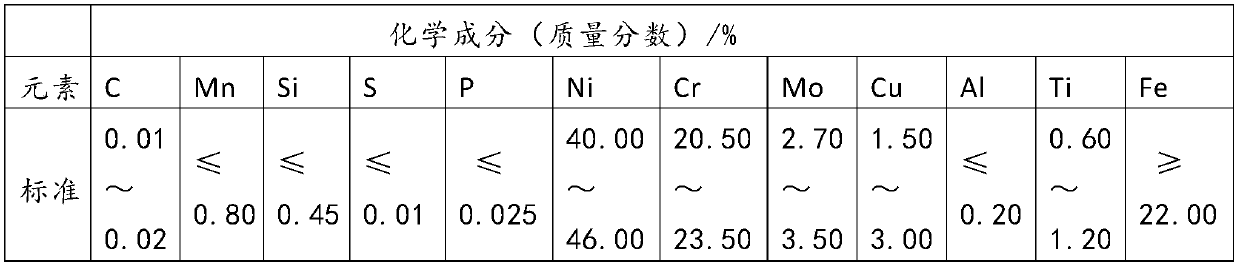

Manufacturing method of 825 anti-corrosion alloy bar material with super-large diameter

The invention discloses a manufacturing method of 825 anti-corrosion alloy bar material with a diameter phi of 1300 mm. The purpose is to solve the technical problem that the risks that chemical compositions and homogeneity do not meet a standard stipulation can be caused, and segregation and porosity existing in a macroscopic examination structure can be caused when the diameter of a steel ingotis increased. According to an electric furnace and electroslag smelting novel technology and forging technology, 1, the technical route comprises the steps of smelting through a non-vacuum induction furnace, processing through an LF furnace, processing through a VOD furnace, conducting electroslag remelting, processing through an 8000 t high-speed forging machine, smoothing on a lathe and conducting packaging; 2, according to the specific solving measures and beneficial effects, (1) a superior raw material is selected to avoid drag-in of a harmful element; (2) the slag whitening time of the LFfurnace is prolonged to effectively reduce the content of D-type inclusion; (3) the vacuum degree of VOD is reduced, the degassing time is shortened, and the content of gas elements is reduced; (4) in the pouring process, ultra-low carbon protecting slag is used for optimizing the surfaces of electrodes, and the deficiency of double skin of the surfaces of the electrodes is overcome; and (5) increasing of the ingot case of steel ingot electroslag meets the requirement for the size of the finished products of phi 1300 mm, and meanwhile, the annealing requirements are increased to avoid the risk of cracking of the steel ingot.

Owner:FUSHUN SPECIAL STEEL SHARES

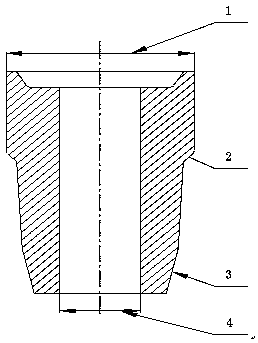

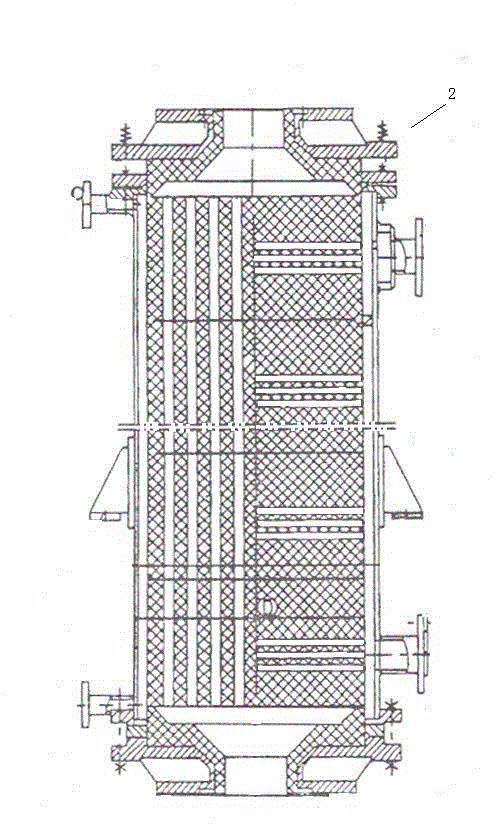

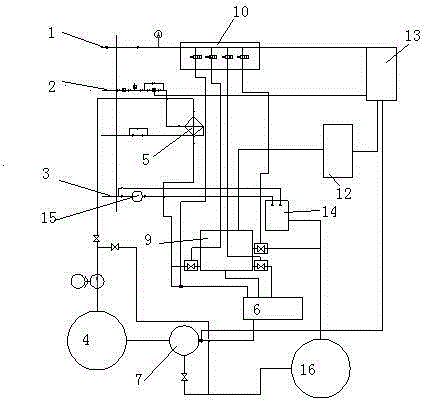

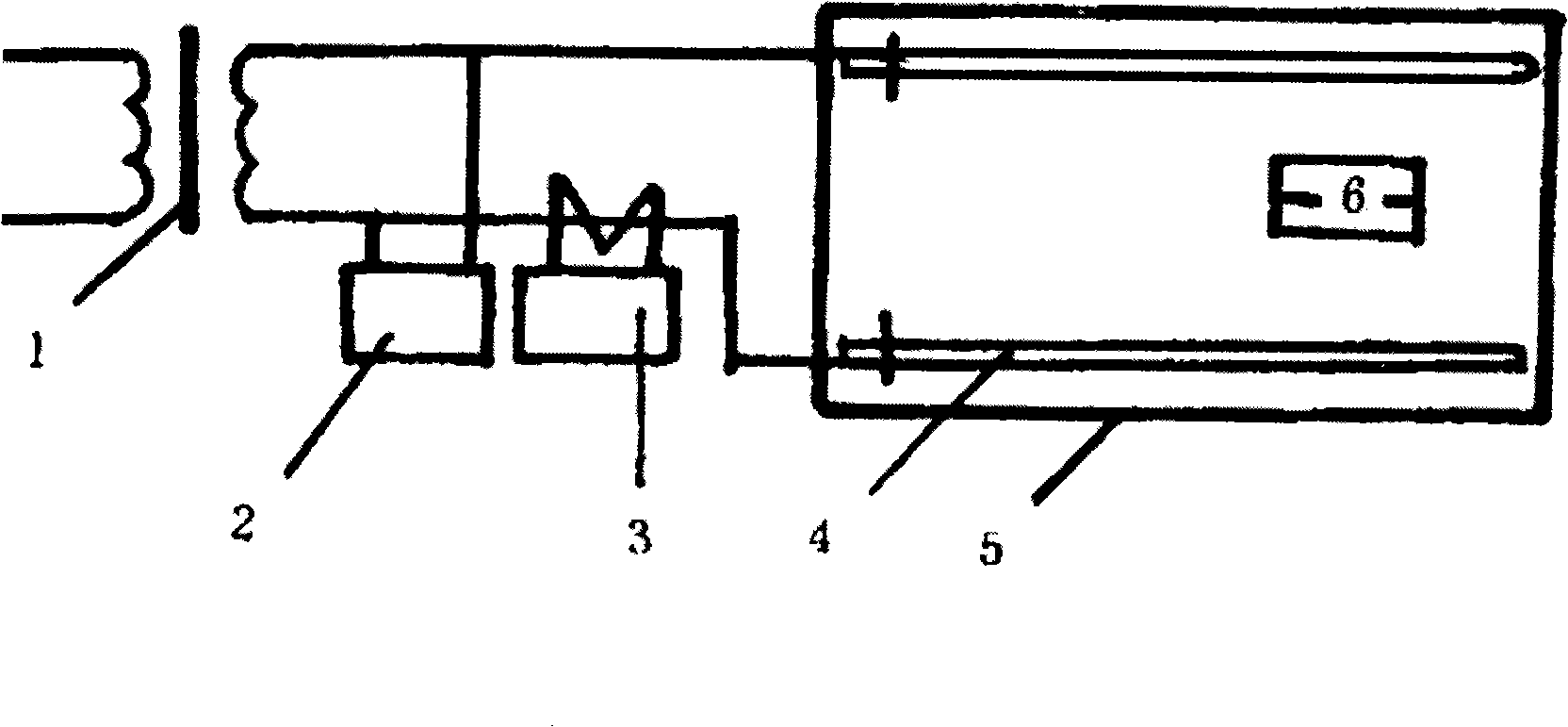

Steel product acid dipping test erosion integration device

InactiveCN103063501AEvenly heatedGuaranteed temperaturePreparing sample for investigationLiquid storage tankElectric control

The invention discloses a steel product macroscopic examination device. A steel product acid dipping test erosion integration device comprises a compressed air source, a vapor source, a tap water source, an acid liquor preheating circulating system, an acid dipping test circulating system, an acid fog neutralizing tower, a rinse tank and a waste liquid tank , wherein the acid liquor preheating circulating system comprises an acid liquor preheating tank and a graphite heat exchanger which are successively connected, and the graphite heat exchanger returns to the acid liquor preheating tank through an acid buffer pool and an acid returning middle tank; the acid dipping test circulating system shares each device of an acid liquor preheating system and a pickling tank is arranged between the graphite heat exchanger and the acid liquor buffer pool, and the compressed air source can control pneumatic valves at the acid liquor inlet and acid liquor outlet of the pickling tank through a pneumatic control box; the acid fog neutralizing tower is controlled by an electric control cabinet and is connected with the pickling tank, the tap water source is connected with the cold water inlet of the rinse tank and is simultaneously connected in parallel with a water heater and is connected with the hot water inlet of the rinse tank; and the outlets of the rinse tank and the pickling tank are respectively connected with a waste liquid storage tank. The steel product macroscopic examination device provided by the invention has the advantages that the heating speed is rapid and uniform, and the acid concentration is unaffected.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

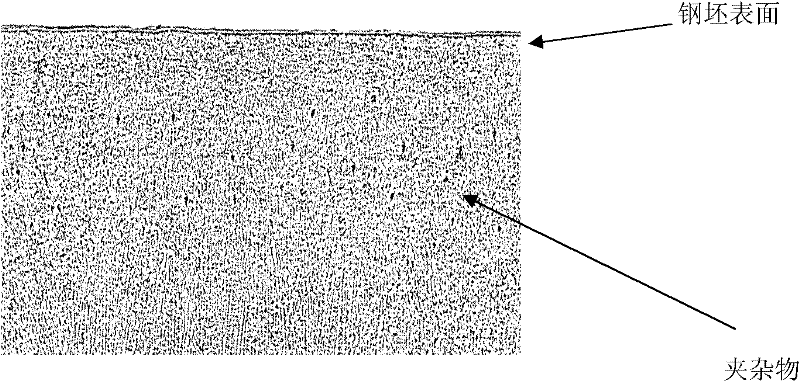

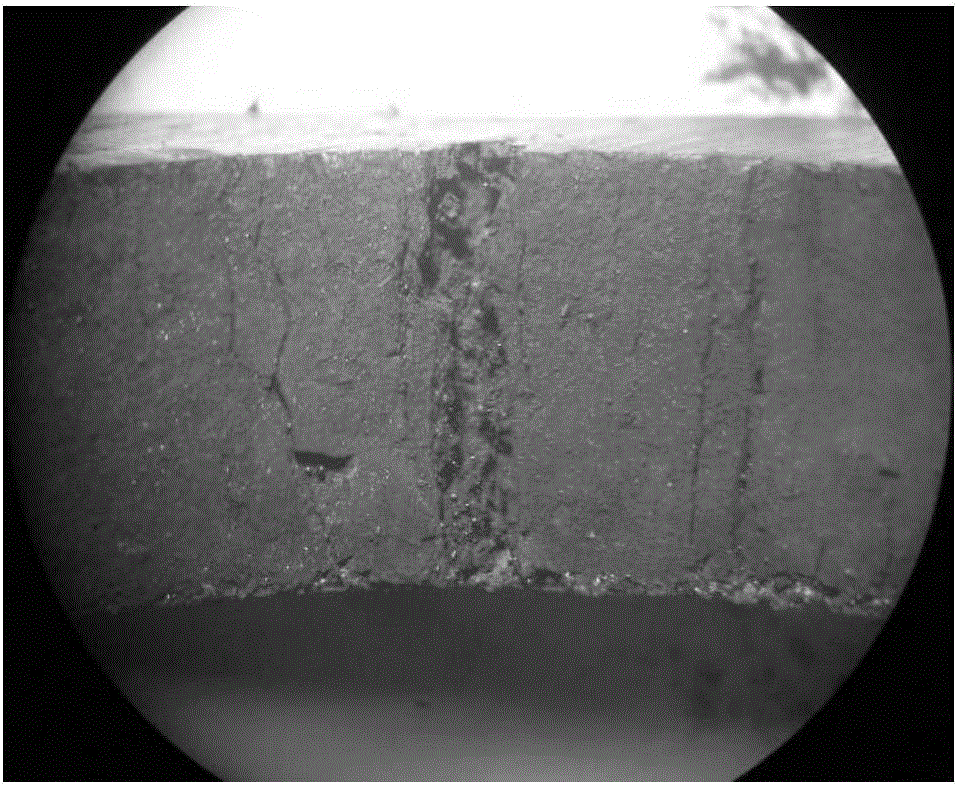

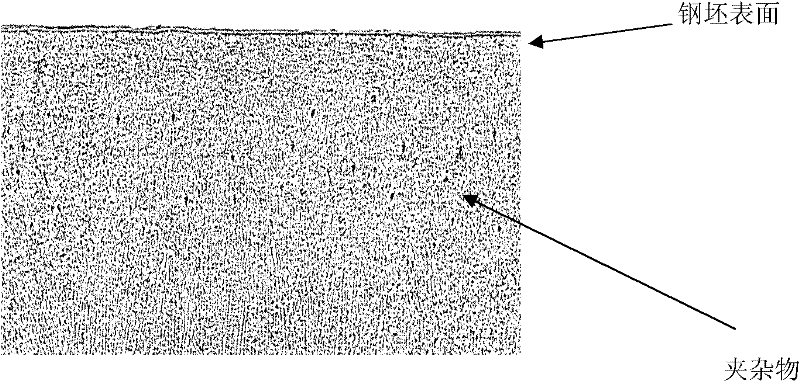

Examination method for determining position of subsurface inclusion defect of continuous casting billet

ActiveCN106546596APrecise positioningThe contrast effect is obviousPreparing sample for investigationOptically investigating flaws/contaminationAcid etchingMagnification

The invention provides a macroscopic examination method for determining a position of a subsurface inclusion defect of a continuous casting billet. The method comprises the steps: firstly, taking a transverse low-magnification sample from the continuous casting billet having the subsurface inclusion defect, and preparing the sample; then corroding the upper surface of the sample with a cold acid etching reagent; next, dipping and etching the sample with a hot acid solution, scrubbing with cold water, and blowing to dry with hot air; and finally, carrying out statistics on the number of aggregative distributed subsurface inclusions, carrying out multi-point measurement, then averaging, and positioning the position of the subsurface inclusion defect in the casting billet. The method can display the position, the form, the distance from the surface of the casting billet and other information of the subsurface inclusion defect of a cross section of the continuous casting billet in a solidification organization structure in an original appearance manner; the problems that the subsurface inclusion defect position cannot be accurately positioned and the relationship between the defect and the solidification structure cannot be determined by a conventional examination method are solved.

Owner:ANGANG STEEL CO LTD

Method for determining morphology of metal molten pool for electroslag remelting

InactiveCN105675513AEasy to joinEasy to operatePreparing sample for investigationColor/spectral properties measurementsSlagElectro-slag remelting

The invention relates to a method for determining morphology of a metal molten pool for electroslag remelting, and belongs to the field of metallurgical technology. The method for determining morphology of the metal molten pool for electroslag remelting comprises the following steps: (1) in a whole process of electroslag remelting, ferrous sulfide particles are uniformly added into a slag bath every 1.5-2.5 hours, sulfur content of the ferrous sulfide particles is 24-34%, diameter of the ferrous sulfide particle is 4-6mm, and addition is 140-200g / every time. (2) vertical dissection of an electroslag ingot is carried out by electroslag remelting, and a macroscopic acid dipping sample is prepared; (3) acid dipping macroscopic examination is carried out; (4) morphology of the surface to be detected of the macroscopic acid dipping sample is observed directly, morphology of the metal molten pool for electroslag remelting and morphology of a solidification structure are obtained, and depth of the metal molten pool is obtained by direct measurement according to morphology of the surface to be detected of the macroscopic acid dipping sample.

Owner:XINING SPECIAL STEEL

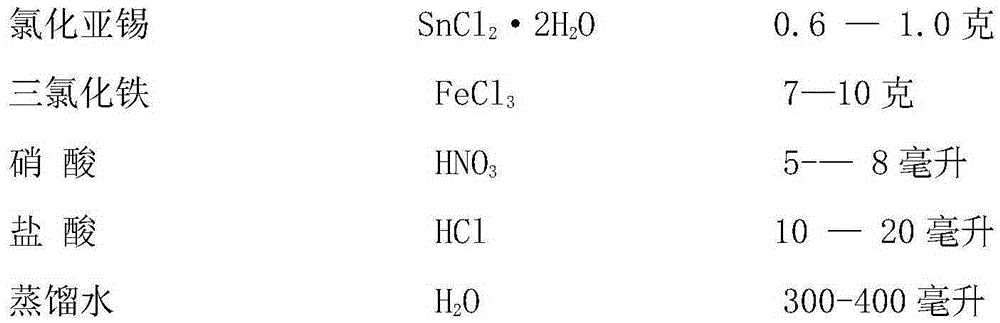

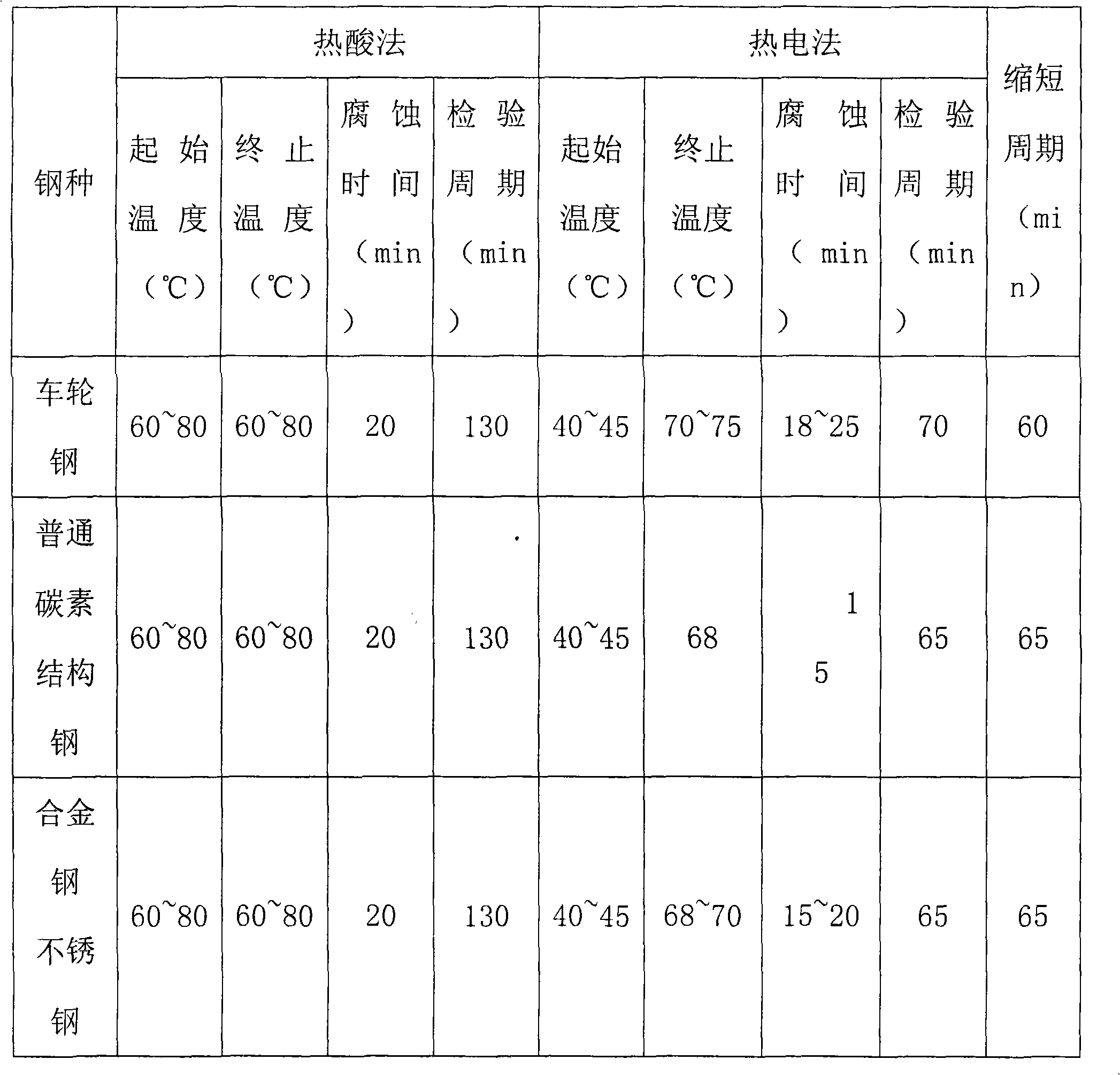

Hot acid electrolytic corrosion method for macroscopic examination of metal samples

ActiveCN101539497AAccelerated corrosionGood for occupational healthPreparing sample for investigationElectrolysisAlternating current

The invention discloses a hot acid electrolytic corrosion method for macroscopic examination of metal samples, which is characterized in that 15-30 percent of industrial hydrochloric acid solution is added to a macroscopic examination pickling tank; the hydrochloric acid solution is energized and heated and deenergized until the temperature is increased to 40-45 DEG C; the samples stand, is energized for electrolytic corrosion for 15-25min by alternate current and is deenergized; the samples are taken out, washed by 3-5 percent of sodium carbonate solution and hot water and dried by blowing.

Owner:MAANSHAN IRON & STEEL CO LTD

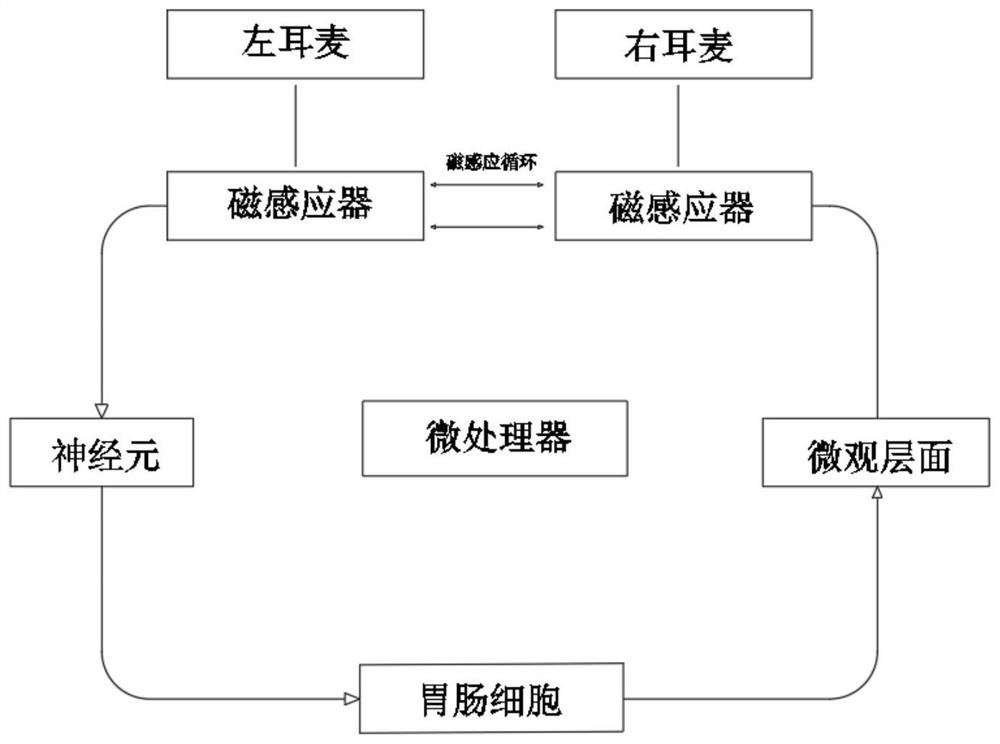

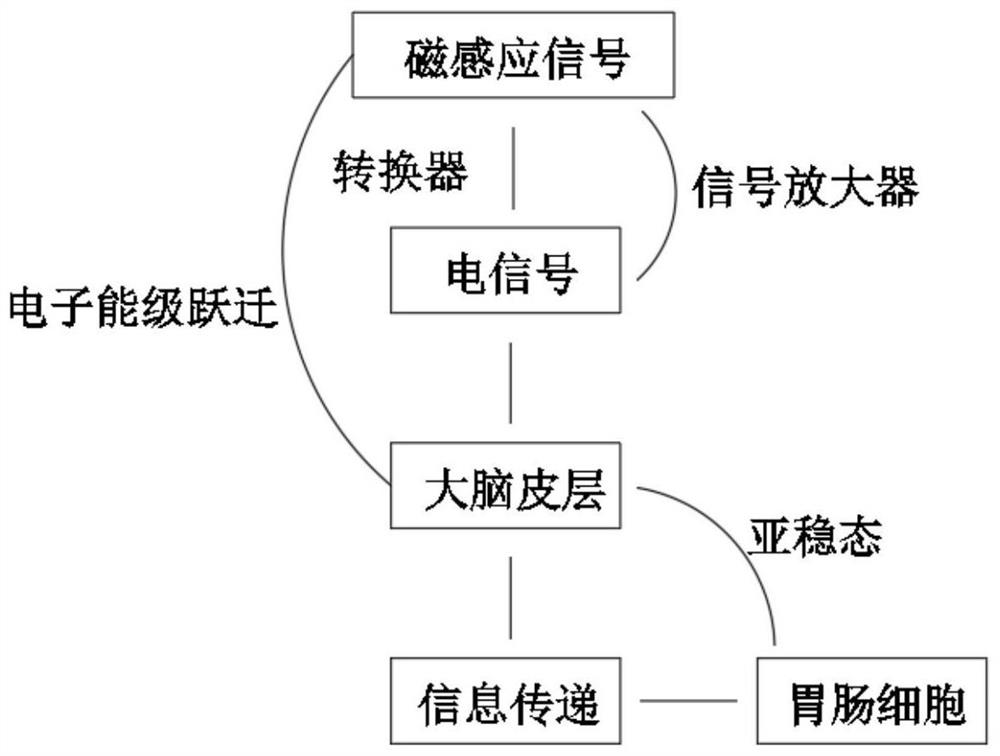

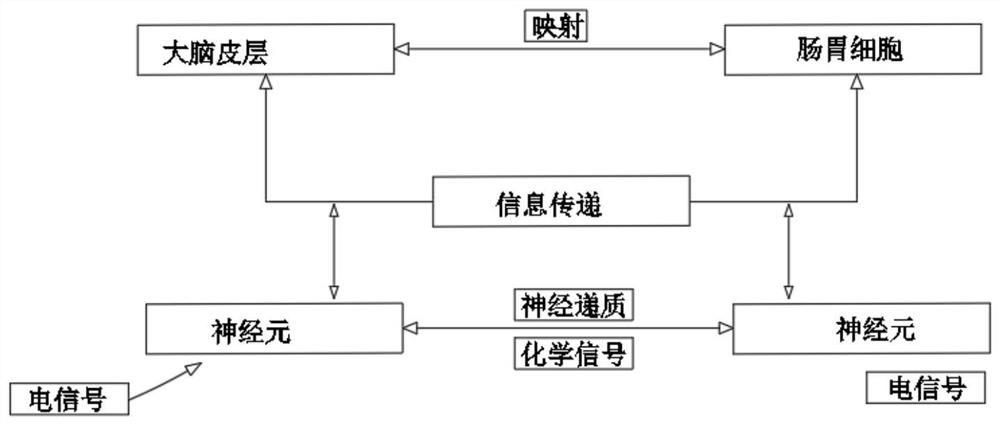

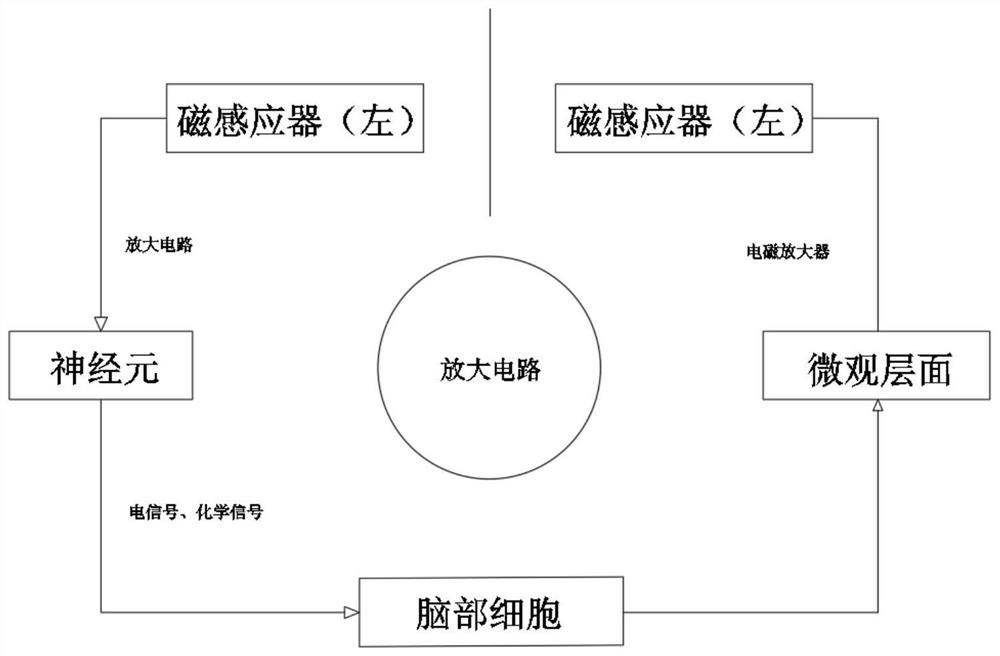

Gastrointestinal cancer postoperative cancer cell monitor based on big data and use method thereof

InactiveCN112932450AHigh precisionEasy to monitorDiagnostic recording/measuringSensorsInformation processingGastrointestinal cancer

The invention discloses a gastrointestinal cancer postoperative cancer cell monitor based on big data, the gastrointestinal cancer postoperative cancer cell monitor comprises a left headset, a right headset, a microprocessor and an amplification circuit, magnetic sensors are arranged in the left headset and the right headset, and a magnetic induction cycle is formed between the two magnetic sensors; the invention further provides a use method of the gastrointestinal cancer postoperative cancer cell monitor based on the big data. The use method comprises the following steps: S1, a monitoring process; S2, postoperative monitoring; S3, information processing; and S4, comparing and judging. The system is reasonable in structure, the monitoring headset is arranged, electromagnetic waves are spread in a human body, the health state and the cell map of human cells are received, the cell state is analyzed and compared through an existing cell map, and information received by postoperative cells of a patient with gastrointestinal cancer is analyzed and compared from the microcellular level. The spectrum of postoperative cells of gastrointestinal cancer patients on the cellular level is analyzed and examined, and the defects existing in macroscopic examination are overcome.

Owner:芭雅医院投资管理(上海)有限公司

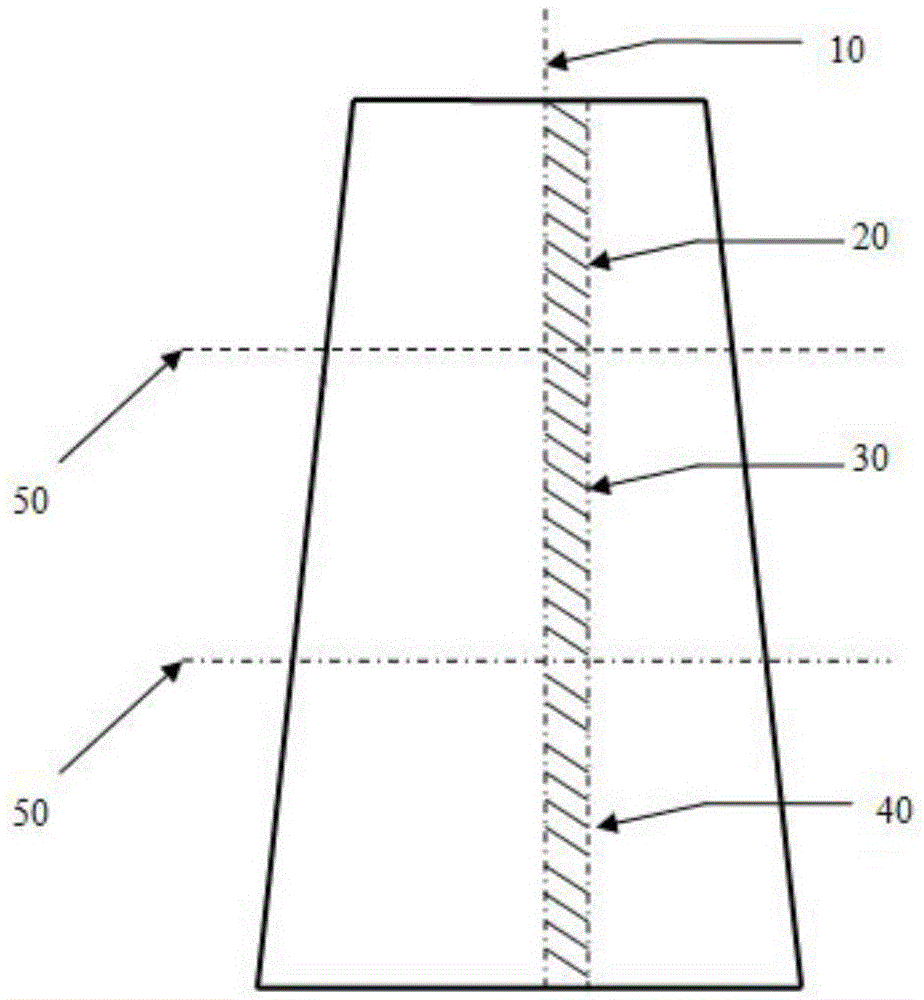

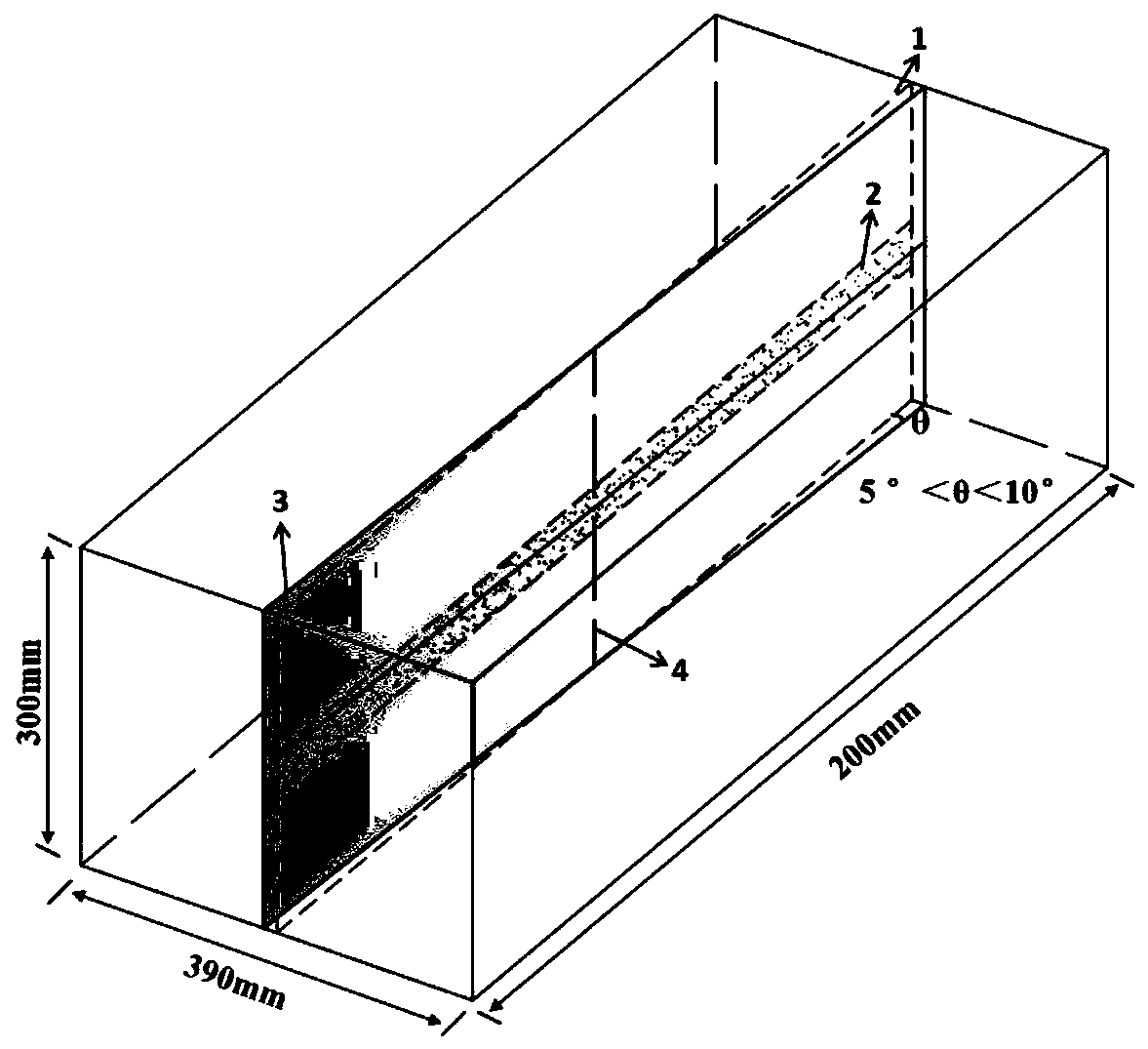

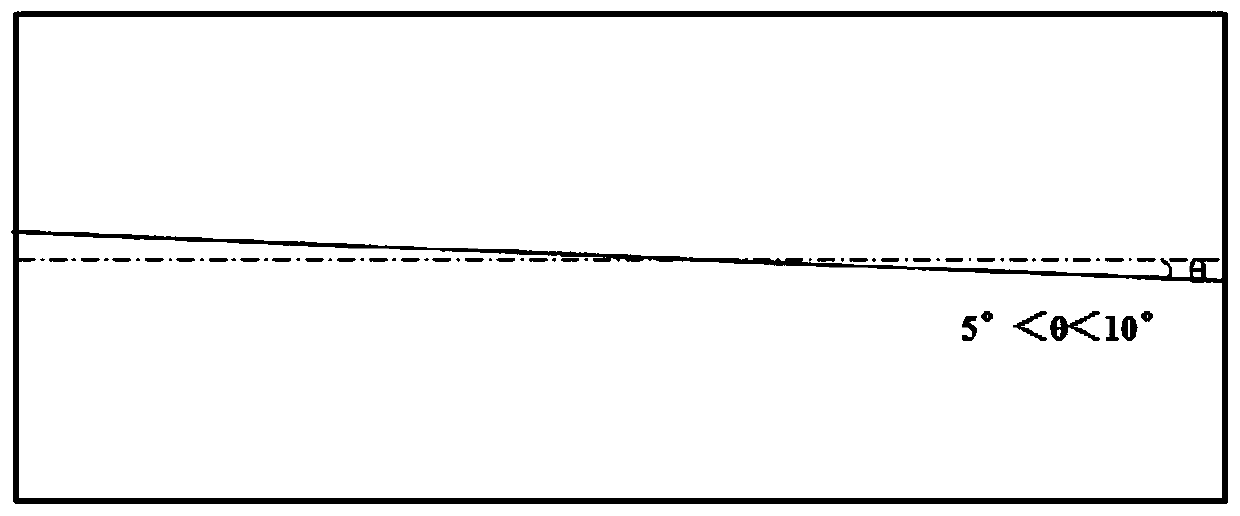

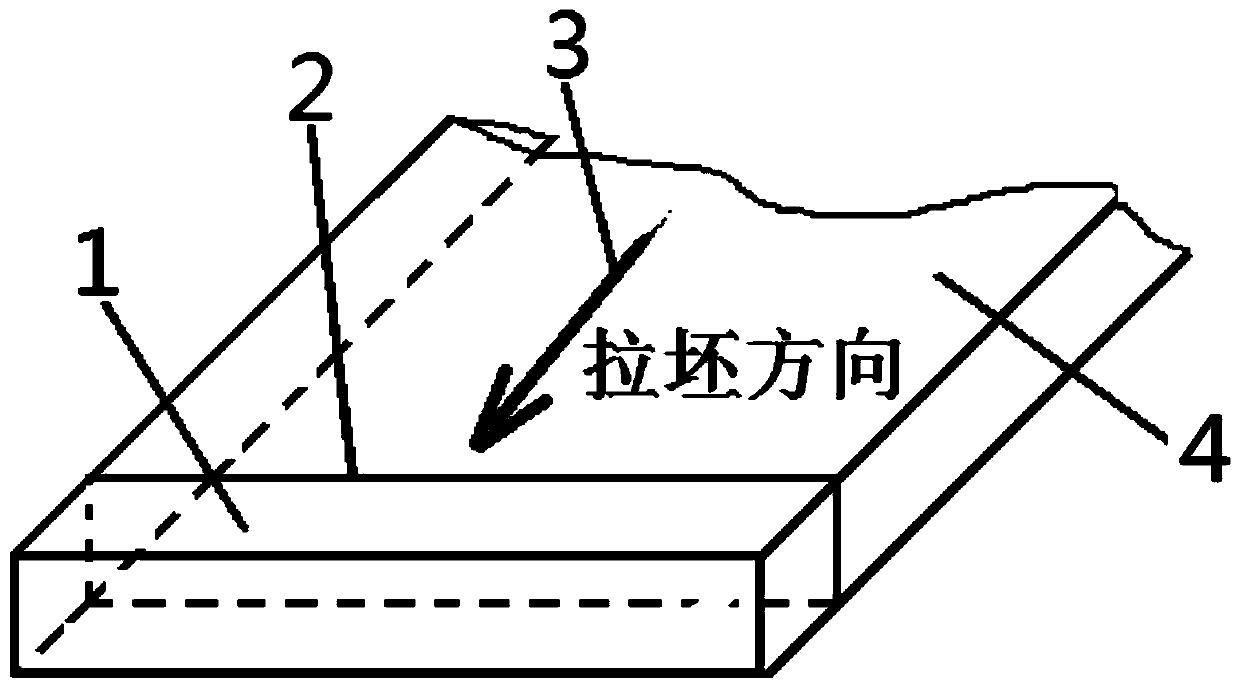

Square billet center macrosegregation analysis method

ActiveCN111537691AImprove representationReduce biasWithdrawing sample devicesPreparing sample for investigationMetallurgical assayVertical plane

The invention discloses a square billet center macrosegregation analysis method, and belongs to the technical field of metallurgical analysis. The method comprises the following steps: carrying out sampling, sample processing, macroscopic examination and drilling chemical analysis on a square billet continuous casting billet by using a vertical plane forming an included angle with the central longitudinal section. According to the invention, the vertical sample cutting method forming a certain included angle with the central longitudinal section is creatively applied to the sample preparationmethod in the center macrosegregation analysis process of the square billet continuous casting billet; the deviation of a casting blank center segregation analysis result caused by a sample cutting position factor can be reduced, the accuracy of casting blank center segregation condition analysis is improved, and accurate reference information is provided for casting blank quality monitoring or process improvement.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Macroscopic examination method of high-manganese high-titanium microalloying steel casting slab

InactiveCN110749467ASimple stepsEasy for research and analysisWithdrawing sample devicesPreparing sample for investigationAlkaline waterManganese

The invention provides a macroscopic examination method of a high-manganese high-titanium microalloying steel casting slab applied to the technical field of steelmaking and continuous casting slabs. The macroscopic examination method of the high-manganese high-titanium microalloying steel casting slab comprises the examination steps that after the slab is out of a fan section, the slab is stackedoffline and cooled to normal temperature; a slab macroscopic sample is cut, the milling machine machining thickness of the examination surface of the slab macroscopic sample is controlled, and the roughness of the examination surface of the slab macroscopic sample is controlled; industrial hydrochloric acid with water are matched to form an acid solution, the acid solution is added to a pickling tank and heated; the slab macroscopic sample is put into the pickling tank for erosion, the examination surface of the slab macroscopic sample is cleaned with alkaline water, and the examination surface of the slab macroscopic sample is blown dry; and the slab macroscopic sample is rated, and the rating result is obtained. According to the macroscopic examination method of the high-manganese high-titanium microalloying steel casting slab, the rating result of the slab macroscopic sample can truly reflect the original slab quality of a continuous casting slab, and basic data are provided for theoptimization of a continuous casting technology and the research on the relationship with the quality of a rolled material.

Owner:MAANSHAN IRON & STEEL CO LTD

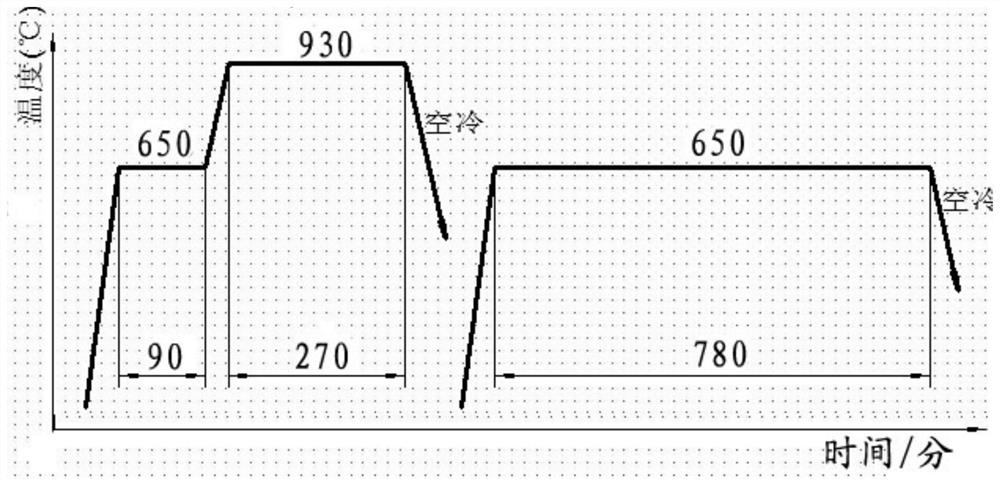

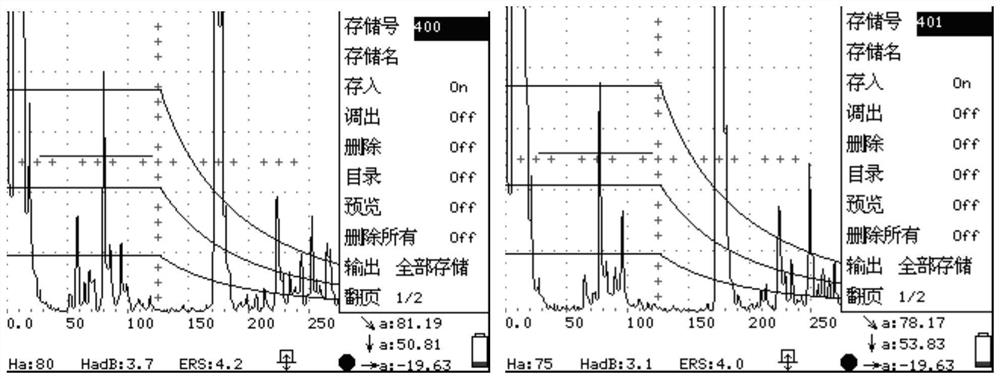

20CrMnMo open gear, detection method thereof and heat treatment method for reducing cracks of blank forging of 20CrMnMo open gear

PendingCN112662846AReduce crack defectsImprove pass rateAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesCrazingScanning electron microscope

The invention relates to a 20CrMnMo open gear, a detection method thereof and a heat treatment method for reducing cracks of a blank forging of the 20CrMnMo open gear, and belongs to the technical field of hot forging treatment processes. The heat treatment method comprises the steps that a square billet enters a furnace to be heated, the initial forging temperature is 1200 DEG C, the final forging temperature is 800 DEG C, the forging ratio is 7.5, carburization and heat preservation are conducted for 60 hours at the temperature of 930 DEG C, and the square billet is discharged out of the furnace; the square billet is quenched, wherein austenitizing is conducted, heat preservation is conducted for 4.5 hours at the temperature of 850 DEG C, and the square billet is discharged out of the furnace (oil cooling); and the square billet is tempered, wherein the square billet is heated to 210 DEG C, heat preservation is conducted for 12 hours, and the square billet is discharged out of the furnace (air cooling). The open gear is manufactured through the heat treatment method. The detection method comprises the following steps: ultrasonic flaw detection, dissection sampling, macroscopic examination, metallographic examination, hardness test, impact and tensile test, and impact fracture scanning electron microscope analysis. By means of the detection method, the crack state can be observed, the crack occurrence time can be judged, and the detection method has extremely important production guidance significance.

Owner:NANJING DEV ADVANCED MFG

Analysis method for thermal power generation unit boiler water cooling wall scaling types and reasons

InactiveCN106093040AAccurate diagnosisOptically investigating flaws/contaminationMaterial analysis using radiation diffractionX-rayPhase analysis

The invention discloses an analysis method for thermal power generation unit boiler water cooling wall scaling types and reasons. The thermal power generation unit boiler water cooling wall scaling types and reasons are comprehensively diagnosed by combining three means including macroscopic examination, metal metallographic examination and X-ray diffraction phase analysis. The analysis method mainly comprises the steps of macroscopic morphology observing, cutting, peeling, bisecting, cleaning, morphology observing after cleaning, metallographic analyzing on water cooling wall tube sample scales, X-ray diffraction phase analyzing on scale components and the like. According to the method, the thermal power generation unit boiler water cooling wall scaling types and reasons can be accurately and systematically diagnosed, and a basis is provided for prevention measure formulating and thermal equipment running mode optimizing; a diagnosis result obtained through the method is accurate and can be applied to chemical technology supervision work of a power plant.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

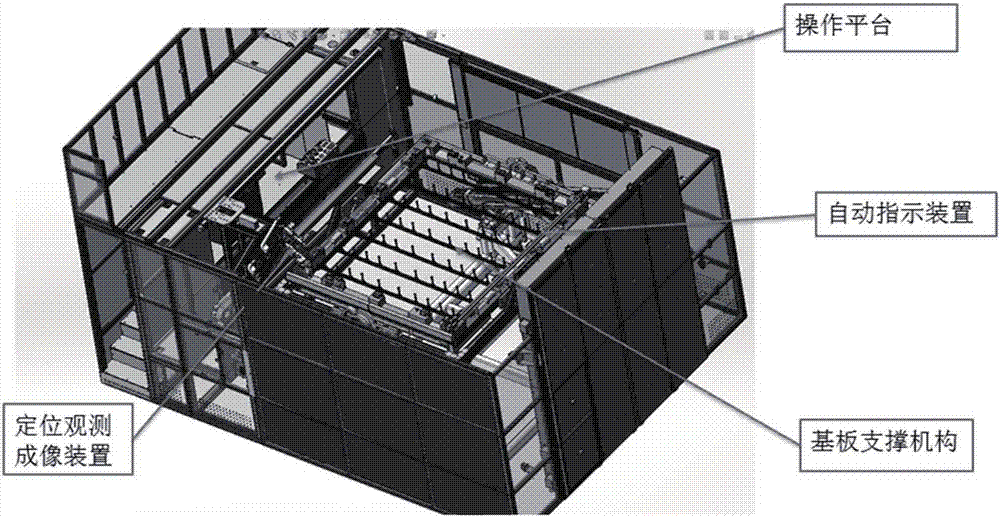

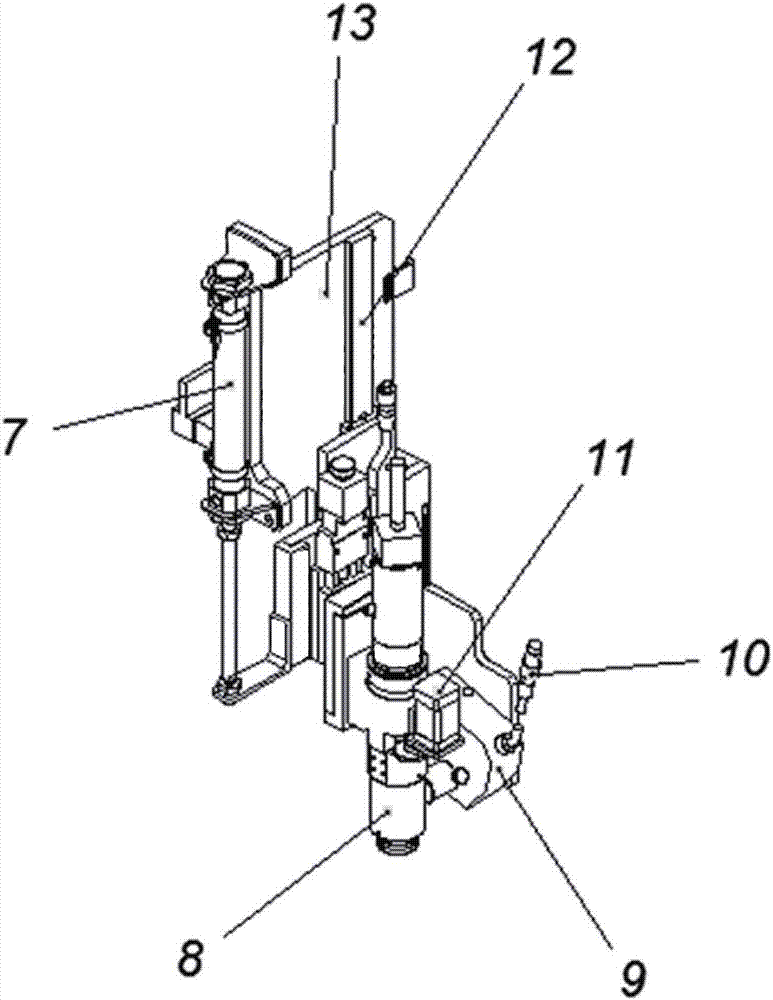

Check assembly part, macroscopic check system and related check method

The invention provides a check assembly part which comprises an automatic indicating mechanism and a locating, observing and imaging mechanism. The check assembly part is characterized in that the automatic indicating mechanism and the locating, observing and imaging mechanism are integrated, and the automatic indicating mechanism and the locating, observing and imaging mechanism can integrally connected through an installation bottom plate or directly integrally connected. The invention further provides a macroscopic check system which comprises an operation platform, a substrate supporting mechanism and the check assembly part, wherein the check assembly part is arranged on the operation platform or the substrate supporting mechanism. The invention further provides a method for using the check assembly part or the macroscopic check system to check glass substrate, especially panel display glass substrates.

Owner:JIANGSU HONGXIN YITAI INTELLIGENT EQUIP CO LTD

Dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of continuous cast blank and preparation method thereof

ActiveCN102174699BDisplay without reductionPreparing sample for investigationOptically investigating flaws/contaminationAlcoholCopper chloride

The invention discloses a dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of a continuous cast blank and a preparation method thereof. The reagent comprises the following components by mass percent: 0.28-1.09% of copper chloride, 0.17-0.27% of magnesium chloride, 0.56-1.60% of ferric chloride, 1.28-1.30% of hydrochloric acid with the mass concentration of 36-38%, 54.70-55.80% of absolute ethyl alcohol and the balance of water. The preparation method comprises the following steps: adding the water into a container, and then adding the copper chloride, magnesium chloride, ferric chloride and hydrochloric acid; and adding the absolute ethyl alcohol after all the added raw materials are fully dissolved, and evenly stirring. Compared with the prior art, the invention solves the problem that other corrosive reagents can not clearly display the dendritic crystal solidification structures of a continuous cast blank; and the reagent has thecharacteristic of original-size display without expansion or reduction for interior defects of a continuous cast blank when used for dendritic crystal corrosion macroscopic examination on the solidification structures and defects of the continuous cast blank.

Owner:苏州东大汉森冶金实业有限公司

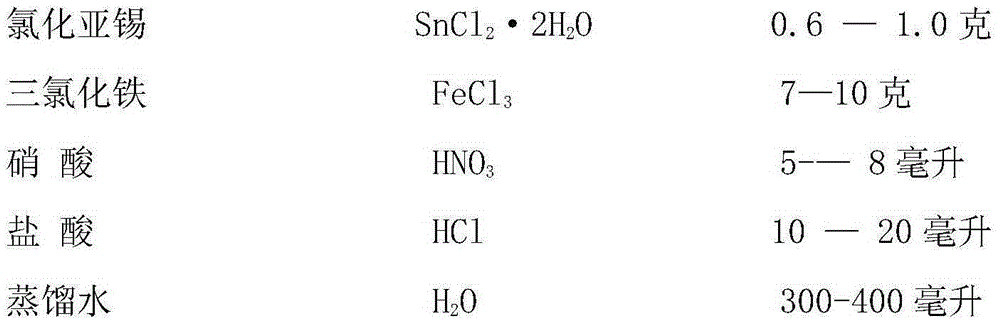

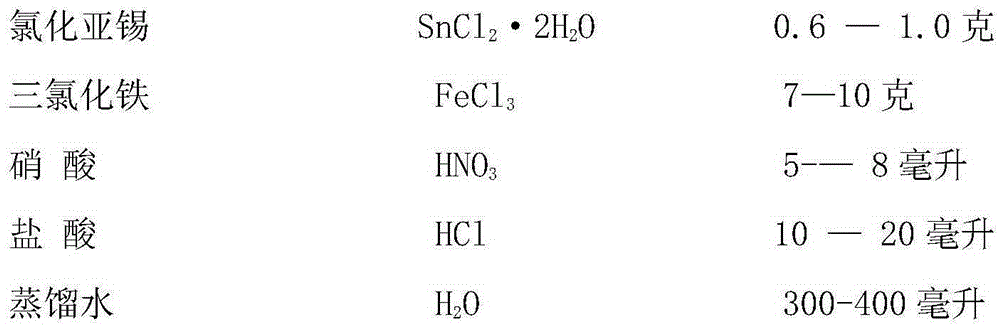

Macroscopic examination method for surface defects of iron-based high-temperature alloy disc

ActiveCN107991160AMild in naturePromote formationPreparing sample for investigationAlloyMaterials science

The invention aims at providing a macroscopic examination method for surface defects of an iron-based high-temperature alloy disc. The macroscopic examination method specifically comprises the following steps of (1) preparing of a macroscopic corrosion tank liquid; (2) cleaning of a part; (3) macroscopic corrosion; (4) cleaning; (5) treatment after macroscopic corrosion; (6) cleaning; (7) drying.The macroscopic examination method has the advantages that the process operation is simple, and the equipment requirement is simple; when a workpiece is processed by the macroscopic corrosion procedure, the clear and effective macroscopic corrosion layer can be obtained, and the processing purpose of examining the defects is realized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

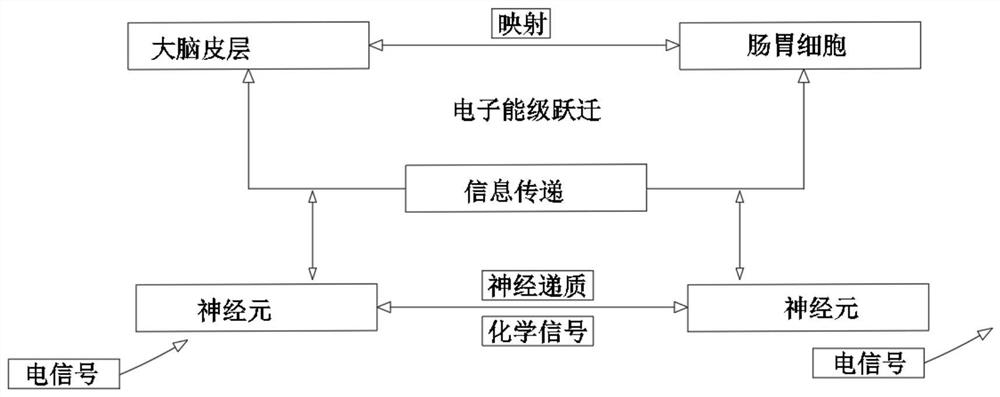

Children cerebral palsy assessment instrument based on overall association medical logic and use method thereof

InactiveCN112890797AImprove efficiencyImprove accuracyDiagnostic recording/measuringSensorsHuman bodyInformation processing

The invention discloses a children cerebral palsy assessment instrument based on overall association medical logic. The children cerebral palsy assessment instrument comprises a left magnetic inductor, a right magnetic inductor, an amplifying circuit, a signal transmitter, a resonator and a microprocessor, wherein a connecting headset is arranged between the left magnetic inductor and the right magnetic inductor; and the left magnetic inductor is in signal connection with the signal transmitter. The invention further discloses a use method of the children cerebral palsy assessment instrument based on overall association medical logic. The use method comprises the following specific steps of: S1, detecting process; S2, information processing; S3, analysis and assessment; and S4, logic basis. According to the children cerebral palsy assessment instrument disclosed by the invention, by setting the detection headset, the health state of human cells and a cell map are received by utilizing propagation of electromagnetic waves in a human body, and the cell state is analyzed and compared by utilizing the existing cell map, so that the information received by the brain of a cerebral palsy child patient is analyzed and checked from the microscopic cell level, and the defects in macroscopic examination are overcome.

Owner:芭雅医院投资管理(上海)有限公司

Corroding agent for dendritic corrosion macroscopic examination and effluent treatment system

ActiveCN109211646AExpand the scope of detectionEasy to handlePreparing sample for investigationCopper nitrateMaterials science

The invention relates to a corroding agent for dendritic corrosion macroscopic examination, and belongs to the technical field of chemical analysis. Various components in the corroding agent orderly comprise the followings according to mass percent: 0.01%-1.0% of copper chloride, 0.01%-1.5% of copper nitrate, 0.01%-1.5% of magnesium chloride, 0.01%-3.0% of ferric chloride, 0.01-2.0% of ferrous chloride, 1.0%-4.0% of hydrochloric acid, 40%-50% of absolute ethyl alcohol, and the rest of water. Through the above technical scheme, the components of the corroding agent are optimally selected, and the detection range on the black metal variety is improved. The invention further relates to an effluent treatment system for the corroding agent, a fume cupboard is designed in mating for a problem that the hydrochloric can escape to the air in the corrosion since the hydrochloric concentration in the corroding agent is high, the hydrochloric acid in the air in the corrosion process is extracted,thereby preventing the hydrochloric acid from injuring respiratory tract of an operator; and meanwhile, the waste acid produced in the corrosion process is centrally collected through an integrated treatment box, thereby facilitating the waste acid treatment.

Owner:沈阳市启光科技有限公司

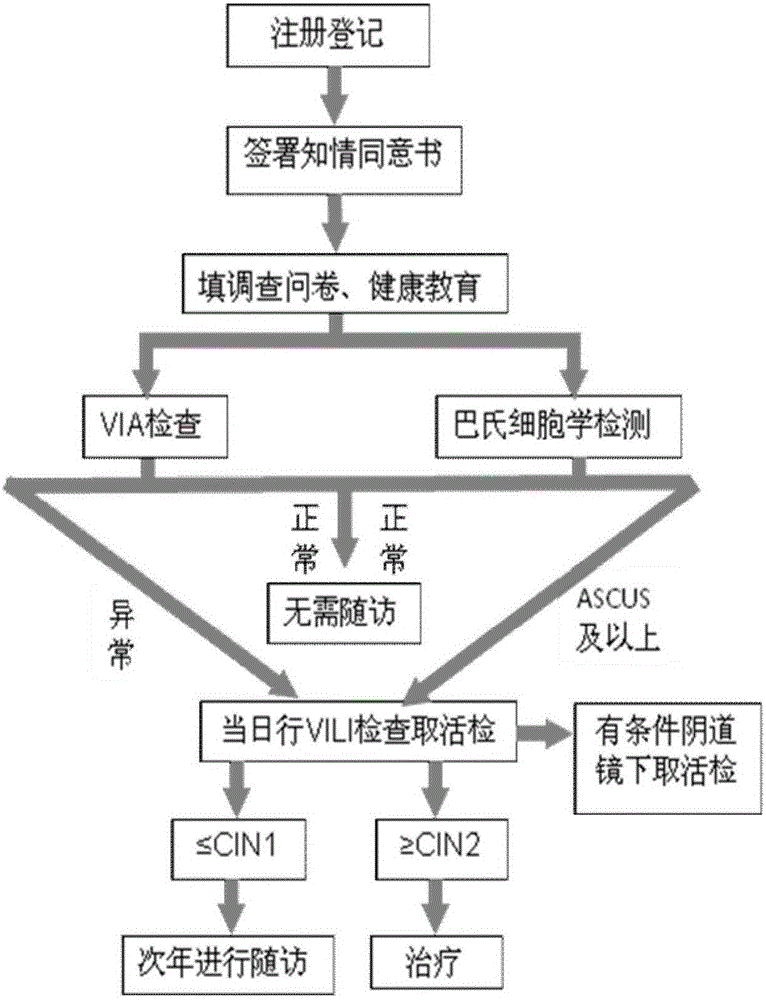

A kind of preparation method of improved Pap smear

ActiveCN103558150BNo bloodReduce overlapSurgical needlesMaterial analysis by optical meansEarly carcinomaStaining

The invention provides a screening method for cervical cancer, which uses the improved Pap smear method for screening; the steps are: extracting cervical secretions, then carrying out routine staining, film reading, and diagnosis; and improving the Pap smear method for cytological diagnosis For ASCUS or above lesions, pathological biopsy should be performed immediately under iodine staining. The present invention also provides a screening method for cervical cancer. After the cervical secretions are obtained by the improved Pap smear method, the acetic acid macroscopic examination is immediately used for screening. If the acetic acid visual examination is positive, pathological biopsy is taken If the diagnosis is negative, wait for the diagnosis result of the modified Pap smear method at the scene, and if the modified Pap smear method is diagnosed as ASCUS or above lesions, a pathological biopsy is taken immediately. The present invention screens women with two methods at the same time, not one. Before this invention, this was not possible. The method of the invention can improve the detection rate of cervical precancerous lesion and early cancer.

Owner:SHIHEZI UNIVERSITY

Grinding paste for processing dendrite macroscopic examination samples and preparation method of grinding paste

ActiveCN106189871AImprove accuracySimple production processPreparing sample for investigationPolishing compositions with abrasivesCarbide siliconToothpaste

The invention relates to grinding paste for processing dendrite macroscopic examination samples and a preparation method of the grinding paste, and solves the technical problems that conventional grinding paste cannot meet requirement that the surface roughness Ra of dendrite macroscopic examination billet samples of different steel kinds is smaller than or equal to 0.1[mu]m, and the production cost is high. The grinding paste for processing the dendrite macroscopic examination samples is prepared from 35-60 parts of green silicon carbide grinding powder, 25-35 parts of a lubricant and 15-35 parts of a grinding aid, wherein the lubricant is lithium lubricating grease, and the grinding aid is toothpaste. The grinding paste disclosed by the invention is used for performing polishing processing on the steel strand dendrite macroscopic examination samples.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com