Macroscopic inspection system for glass substrate

A technology for macro inspection and glass substrates, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the difficulties of finding glass substrates in more detail, observing glass substrates in multiple directions, and inspecting glass substrate defects and other issues, to achieve the effect of improving the yield rate, reducing production costs, and observing defects clearly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, and are not used to limit the present disclosure.

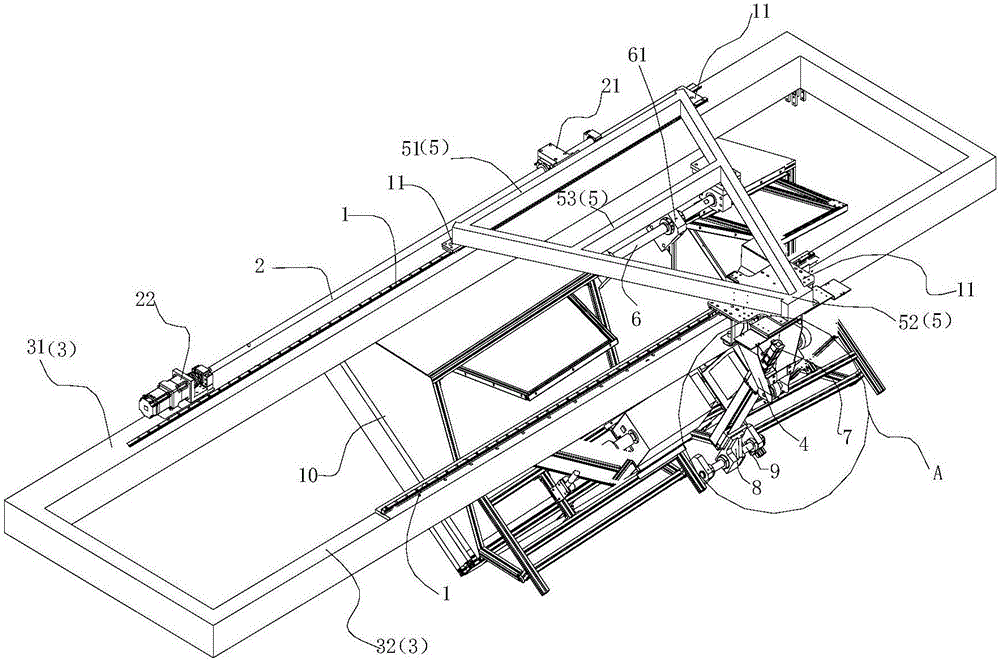

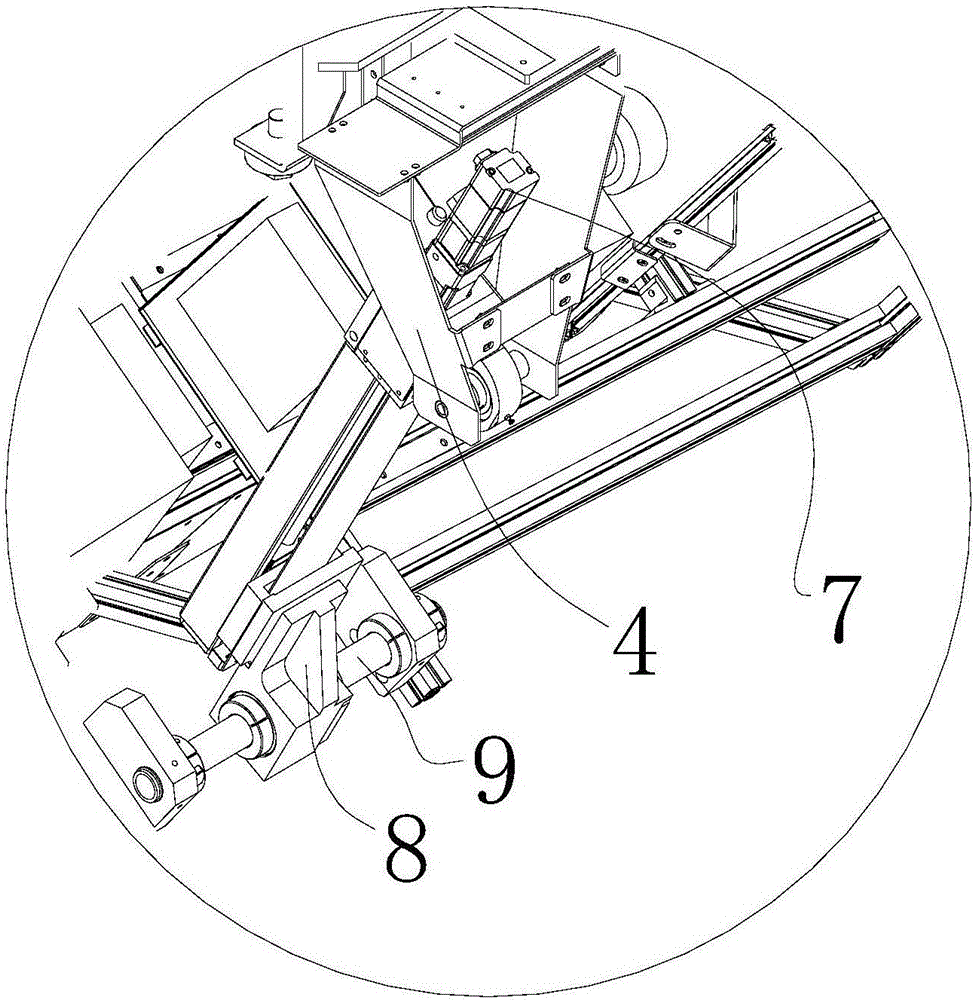

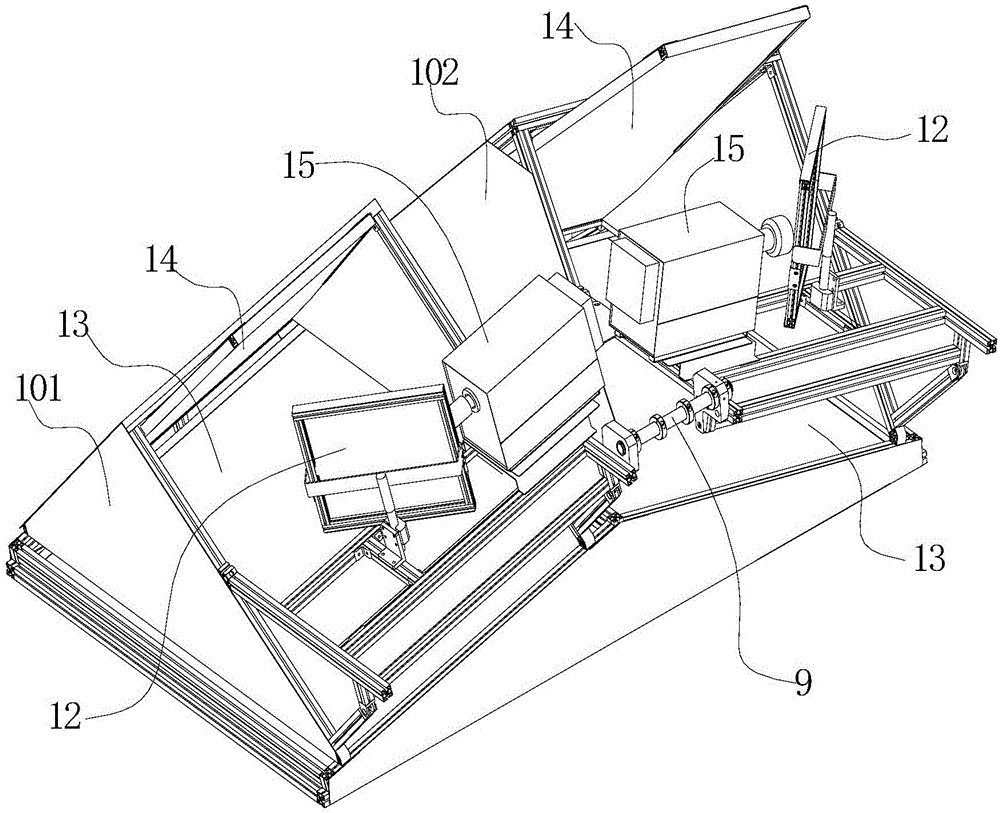

[0034] Such as Figure 1 to Figure 4 As shown, the present disclosure provides a macroscopic inspection system for glass substrates, including a lighting device and a mounting frame for fixing the lighting device. On the one hand, the lighting device can be rotated on the mounting frame to change different illumination angles; On the one hand, it is also possible to realize the translation of the lighting device on the installation rack to adapt to the size of different glass substrates. The following two aspects will be further explained.

[0035] Such as figure 1 As shown, in order to realize the rotation of the illuminating device, in this embodiment, one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com