Method for identifying seal and print formation mode based on microcosmic trace point characteristics

A technology of printing and stamping, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problem of cognition and utilization, identification methods and ideas began in the 1950s and 1960s and continues to this day, etc. problem, to achieve the effect of high accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

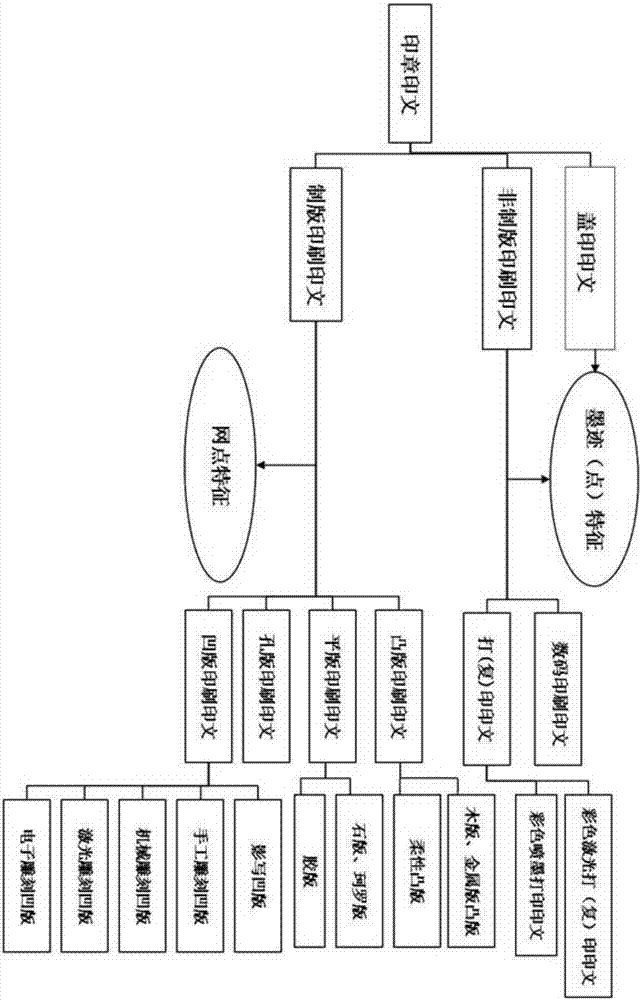

[0044] 1. Inspection and identification of whether the printed text is formed by printing

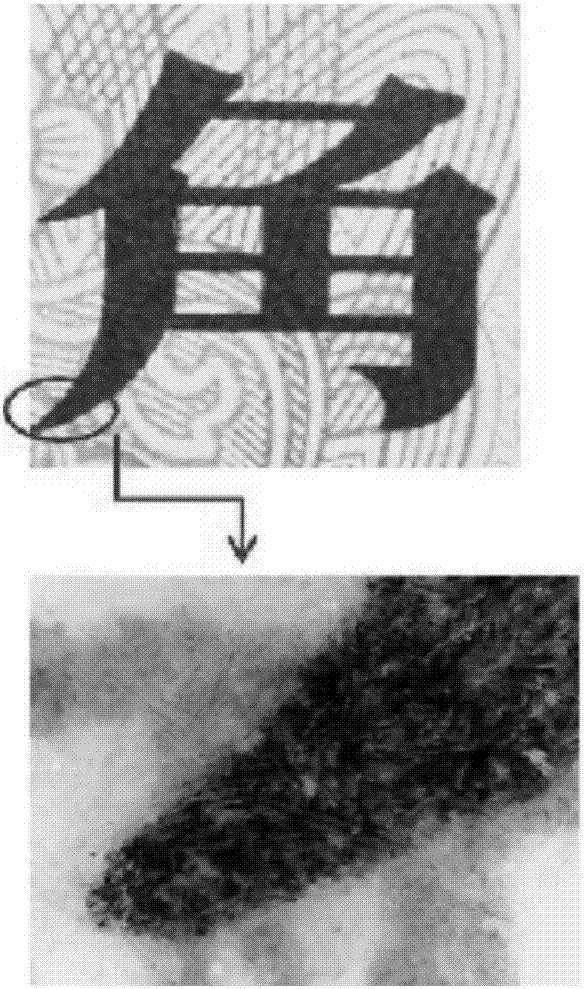

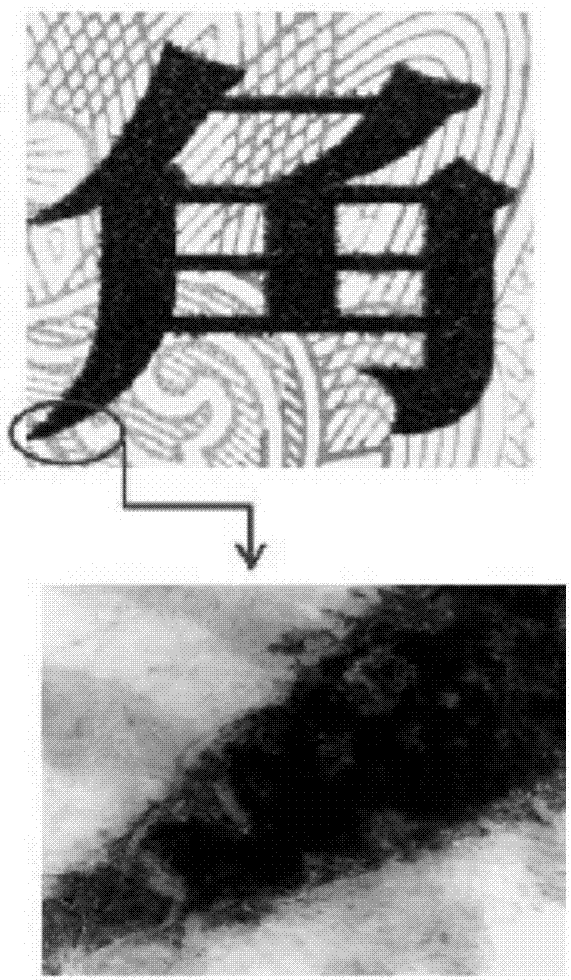

[0045] Whether there are dots or screen lines in the microscopic image of the seal is the first step to judge whether the seal is formed by printing. The dot (line) feature is a prominent feature of the printed matter. If there is a dot (line) feature in the microscopic image of the printed text, it can be judged that the printed text is formed by printing. Stamping and printing and copying have no feature of dots. The former reflects the characteristics of the adhesion, scattering and suppression pressure of the printed color material, and the latter highlights the trace characteristics of color ink dots.

[0046] In the printed matter, it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com