Defect analysis method for 410 material forging

A defect analysis and forging technology, which is applied to the use of wave/particle radiation for material analysis, material analysis, optical testing of flaws/defects, etc., can solve problems such as increasing economic losses, time-consuming and labor-consuming, and finding solutions, so as to reduce The effect of wasting resources, reducing scrapped parts, and avoiding waste of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

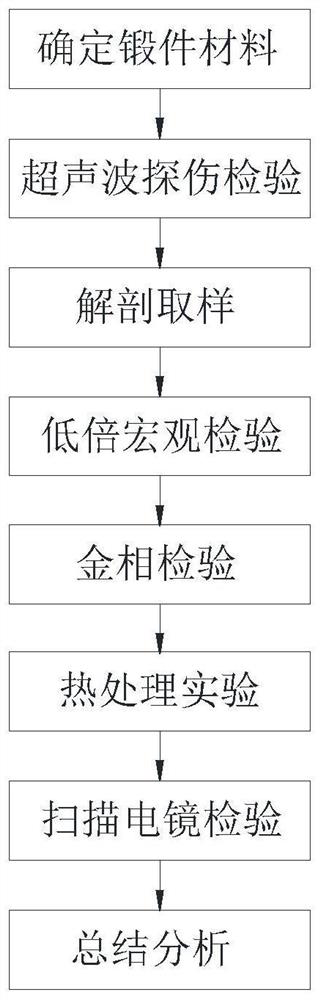

[0064] A forging circle with a diameter of 400 mm and a raw material of 410 was selected to forge a cross-section round bar with a diameter of 310 mm and a length of 618 mm. Strip and intermittent, the longitudinal length of the defect from the end of the nozzle is between 510-2100mm. In order to find out the specific reasons for the defects and summarize the solutions, two pieces of round bars and one piece of forged circle were inspected and analyzed.

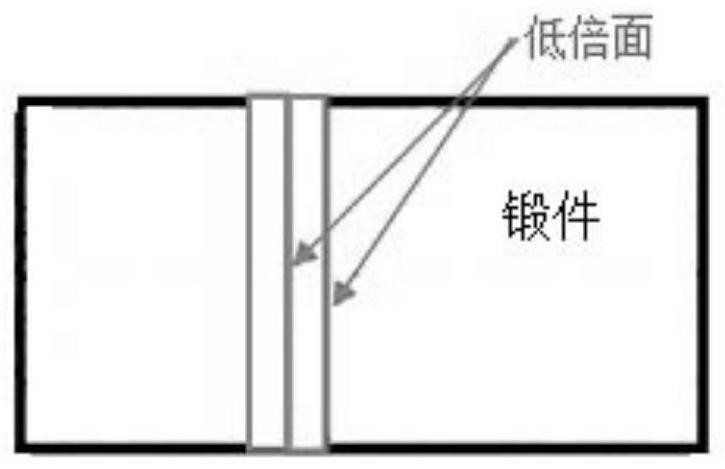

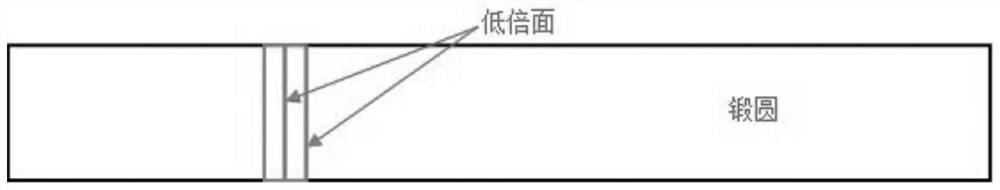

[0065] Anatomical sampling: Sampling and anatomical analysis of round bar forgings and forging round defects, the low-magnification anatomical sampling positions on the round bar forgings are shown as follows figure 2 As shown, the low-magnification anatomical sampling site on the forging round blank is shown as image 3 shown. Sampling of metallographic samples at defects: the metallographic sampling of low-magnification defects on round bar forgings is as follows Figure 4 As shown, the metallographic sampling diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com