Method for determining morphology of metal molten pool for electroslag remelting

An electroslag remelting and metal molten pool technology, applied in the field of metallurgical technology, can solve the problems of difficult operation, danger, and inability to intuitively see the degree of dendrite segregation solidification structure information, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

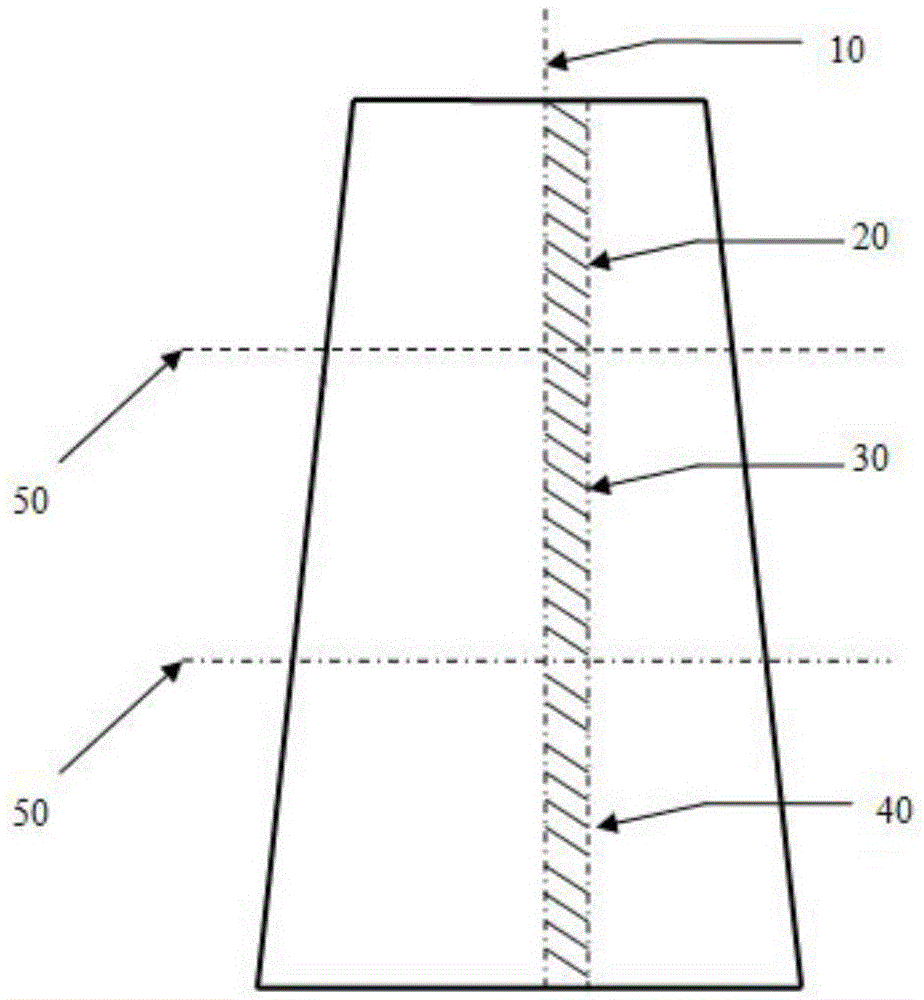

[0028] A method for measuring the morphology of an electroslag remelted metal bath, including the following steps:

[0029] (1) In the whole process of electroslag remelting, add iron sulphur particles into the slag pool evenly every 1.5 hours. The sulphur content of iron sulphur particles is 24%, the diameter of iron sulphur particles is 4mm, and the addition amount is 140g / time. ;

[0030] (2) Dissecting the electroslag ingots obtained by electroslag remelting longitudinally to prepare low-power acid leaching samples;

[0031] (3) Acid leaching low power inspection

[0032] (31) Place the low-power acid leaching sample horizontally in a trough-shaped container, with the inspection side facing up,

[0033] (32) Pour an aqueous solution of nitric acid with a concentration of 40wt% onto the test surface of the low-power acid immersion test piece, and repeatedly scrub the test surface with a brush, and constantly replenish the aqueous solution of nitric acid with a concentration of 40wt%...

specific Embodiment 2

[0040] A method for measuring the morphology of an electroslag remelted metal bath, including the following steps:

[0041] (1) During the whole process of electroslag remelting, add iron sulphur particles into the slag pool evenly every 2.5 hours. The sulphur content of iron sulphur particles is 34%, the diameter of iron sulphur particles is 6mm, and the dosage is 200g / time. ;

[0042] (2) Dissecting the electroslag ingots obtained by electroslag remelting longitudinally to prepare low-power acid leaching samples;

[0043] (3) Acid leaching low power inspection

[0044] (31) Place the low-power acid leaching sample horizontally in a trough-shaped container, with the inspection side facing up,

[0045] (32) Pour an aqueous solution of nitric acid with a concentration of 40wt% onto the test surface of the low-power acid immersion test piece, and repeatedly scrub the test surface with a brush, and constantly replenish the aqueous solution of nitric acid with a concentration of 40wt%.

[0...

specific Embodiment 3

[0052] A method for measuring the morphology of an electroslag remelted metal bath, including the following steps:

[0053] (1) In the whole process of electroslag remelting, add iron sulphur particles into the slag pool evenly every 2 hours. The sulphur content of the iron sulphur particles is 30%, the diameter of the iron sulphur particles is 5mm, and the addition amount is 170g / time. ;

[0054] (2) Dissecting the electroslag ingots obtained by electroslag remelting longitudinally to prepare low-power acid leaching samples;

[0055] (3) Acid leaching low power inspection

[0056] (31) Place the low-power acid leaching sample horizontally in a trough-shaped container, with the inspection side facing up,

[0057] (32) Pour an aqueous solution of nitric acid with a concentration of 40wt% onto the test surface of the low-power acid immersion test piece, and repeatedly scrub the test surface with a brush, and constantly replenish the aqueous solution of nitric acid with a concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com