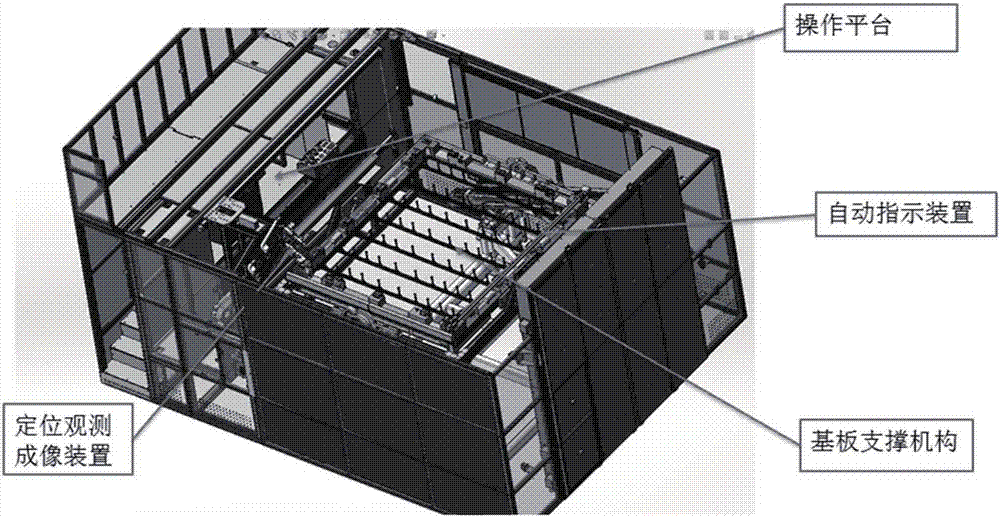

Check assembly part, macroscopic check system and related check method

A technology of macro inspection and inspection team, applied in the field of macro inspection system, which can solve the problems of low inspection efficiency and inability to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

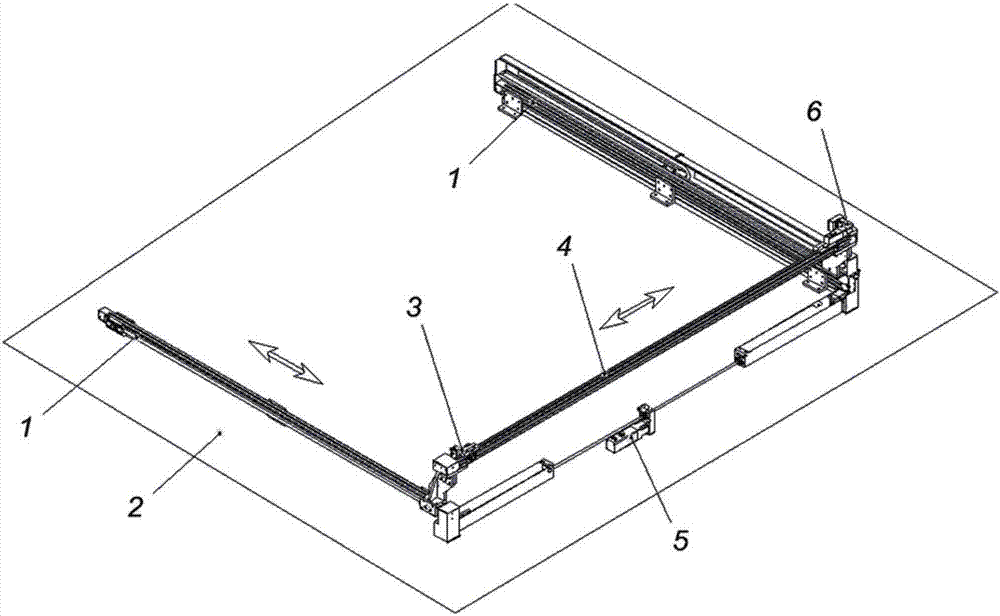

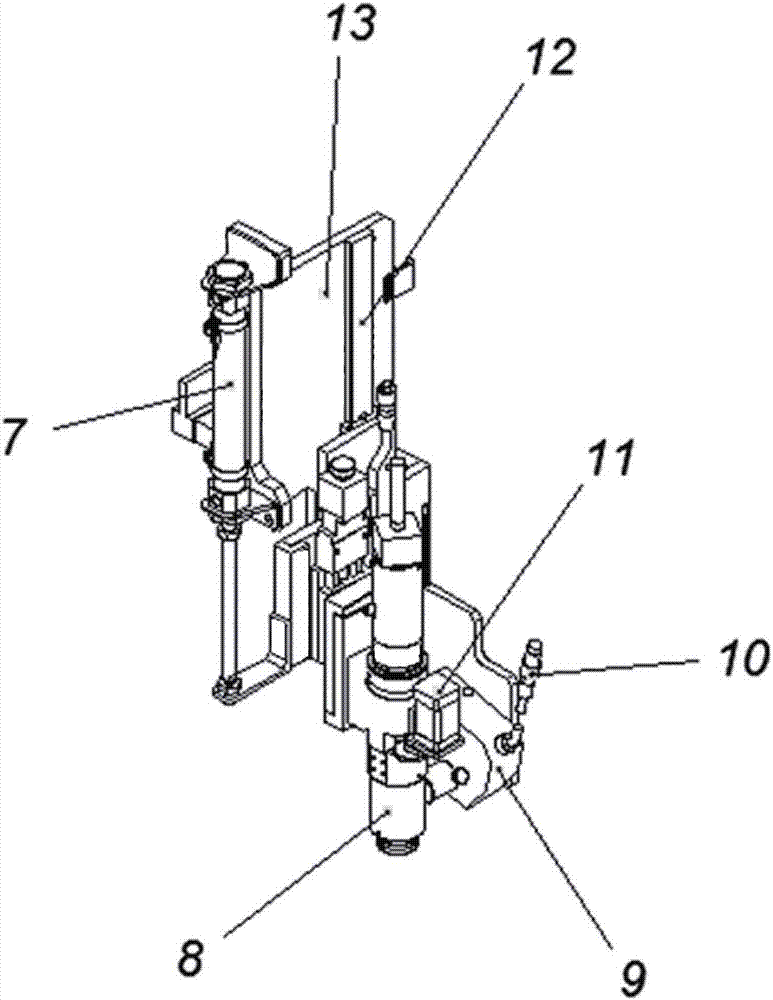

[0023] The inventor of the present invention integrated the automatic pointing mechanism and the positioning observation and imaging mechanism for the first time, that is, the two actually become a "point observation module". Thus, the automatic pointing mechanism and the positioning observation mechanism can be moved synchronously to the same position, for example, the coordinate position of the defect.

[0024] In this paper, the automatic indicating mechanism may include several components to realize the automatic indicating function, but they are called "automatic indicating mechanism" as an organic whole. Similarly, the positioning observation and imaging mechanism may include several components to achieve different functions such as positioning, observation, imaging, etc., but it is called a "positioning observation and imaging mechanism" as an organic whole. In a word, in the present invention, the automatic pointing mechanism and the positioning observation and imaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com