Hot acid electrolytic corrosion method for macroscopic examination of metal samples

A technology of electrolytic corrosion and low-magnification inspection, applied in the preparation of test samples, etc., can solve the problems of difficult inspection of white spot defects of wheel products, limited ability of reaction product ions to evacuate outward, limited ability of passive film formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

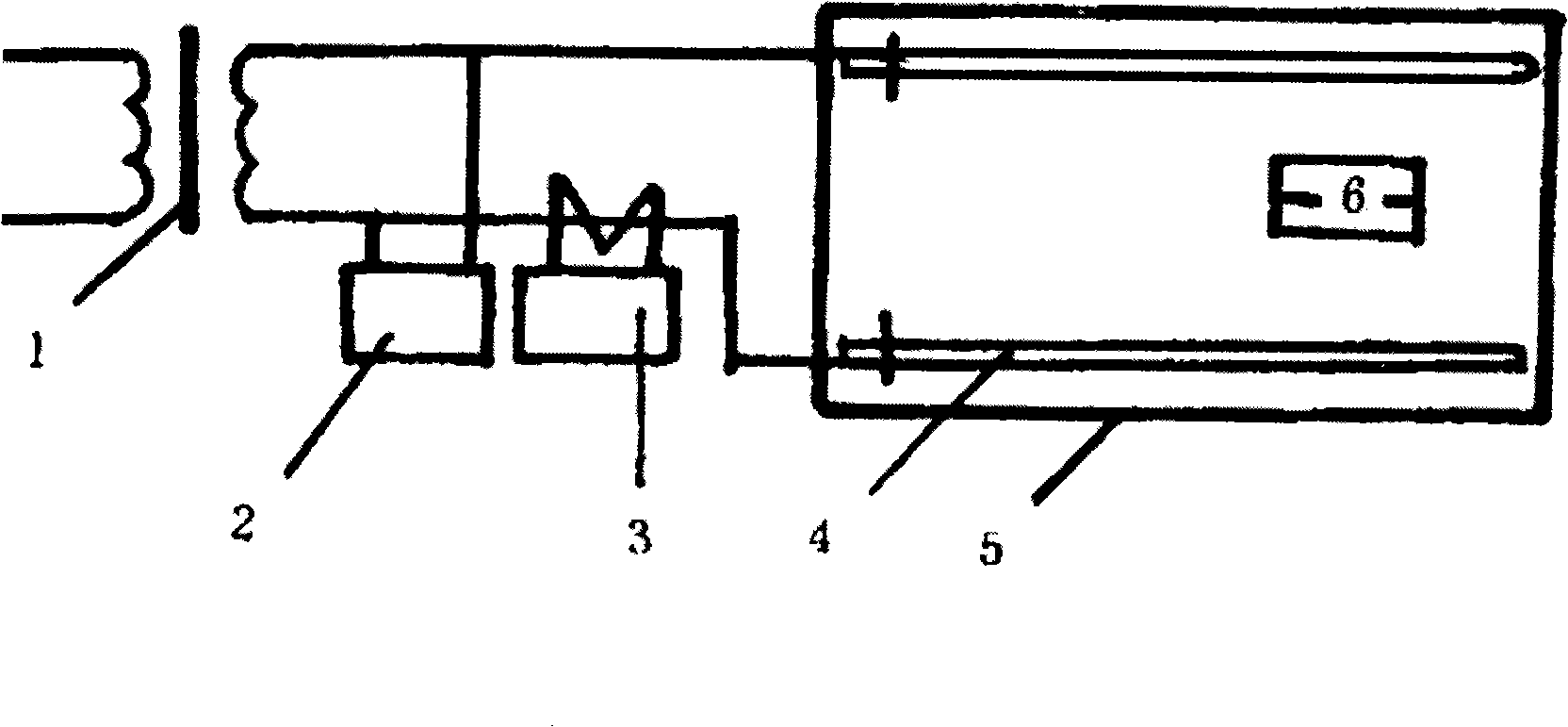

Method used

Image

Examples

Embodiment 1

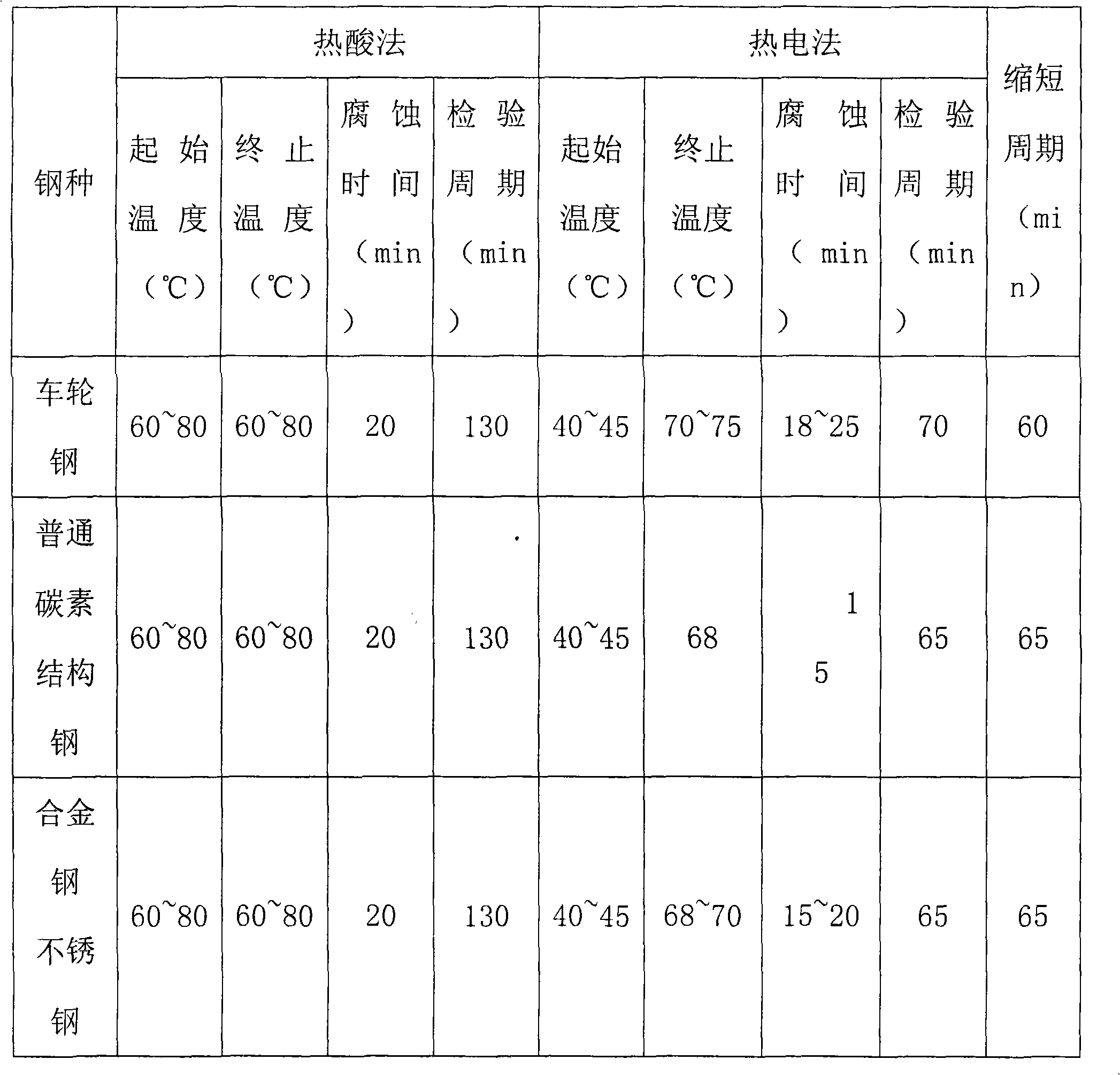

[0015] For relatively dense materials such as wheel steel, the hot acid electrolytic corrosion method is as follows:

[0016] Add 15%-30% (volume ratio) industrial hydrochloric acid aqueous solution into the low-power pickling tank, heat the acid solution from room temperature to 40°C-45°C, turn off the power, then place the sample, and turn on the power for 18-25 minutes After power off, take out the sample, wash it with 3%-5% sodium carbonate aqueous solution and hot water and dry it, and the sample can be rated. Compared with the hot acid method, the inspection cycle is shortened by 60 minutes, and the initial acid temperature is reduced by 15-40°C.

Embodiment 2

[0018] The hot acid electrolytic corrosion method for ordinary carbon structural steel and other materials is as follows:

[0019] Add 15%-30% (volume ratio) industrial hydrochloric acid aqueous solution into the low-power pickling tank, heat the acid solution from room temperature to 40°C-45°C, turn off the power, then place the sample, and turn off the power after 15 minutes Electricity, take out the sample, brush with 3%-5% sodium carbonate aqueous solution and hot water and dry it, the sample can be rated. Compared with the hot acid method, the inspection period is shortened by 65 minutes, and the initial acid temperature is reduced by 15-40°C.

Embodiment 3

[0021] The hot acid electrolytic corrosion method for alloy steel is as follows:

[0022] Add 15%-30% (volume ratio) industrial hydrochloric acid aqueous solution into the low-power pickling tank, heat the acid solution from room temperature to 40°C-45°C, turn off the power, then place the sample, and turn on the power for 15-20 minutes After power off, take out the sample, wash it with 3%-5% sodium carbonate aqueous solution and hot water and dry it, and the sample can be rated. Compared with the hot acid method, the inspection period is shortened by 65 minutes, and the initial acid temperature is reduced by 15-40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com