Control method for improving internal defects of high-carbon chromium bearing steel bloom

A technology of high-carbon chromium bearing steel and control method, which is applied in the field of metallurgy, can solve problems such as compression cracks and center segregation, achieve the effects of reducing tensile stress, increasing force on the center, and achieving stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the control method for improving the internal defects of high-carbon chromium bearing steel blooms includes the following steps:

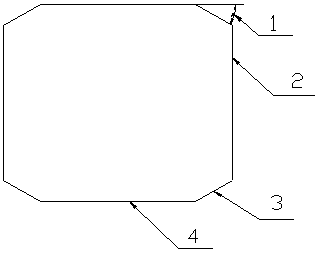

[0038] (1) Cast molten steel into a large chamfered bloom with a liquid core: the size of the continuous casting slab is 280×325mm, the angle between the corner of the continuous casting slab and the wide surface of the slab is controlled to be 30°, and the length of the hypotenuse of the continuous casting slab is 60mm ;

[0039] (2) Control continuous casting parameters: control the superheat of molten steel in the tundish to 15-25°C, the casting speed to 0.70m / min, the current intensity of electromagnetic stirring in the mold to 400A, and the frequency to 2.4Hz;

[0040] (3) Light reduction is carried out on the large chamfered bloom with liquid core, which is divided into two stages: dynamic reduction and static reduction:

[0041] a. In the stage of dynamic soft reduction, the reduction amount of a single reduction ...

Embodiment 2

[0050] In this embodiment, the control method for improving the internal defects of high-carbon chromium bearing steel blooms includes the following steps:

[0051] (1) Cast molten steel into a large chamfered bloom with a liquid core: the size of the continuous casting slab is 280×325mm, the angle between the corner of the continuous casting slab and the wide surface of the slab is controlled at 40°, and the length of the hypotenuse of the continuous casting slab is 45mm ;

[0052] (2) Control continuous casting parameters: control the superheat of molten steel in the tundish to 20-30°C, the casting speed to 0.85m / min, the current intensity of electromagnetic stirring in the mold to 500A, and the frequency to 1.2Hz;

[0053] (3) Light reduction is carried out on the large chamfered bloom with liquid core, which is divided into two stages: dynamic reduction and static reduction:

[0054] a. In the stage of dynamic soft reduction, the reduction amount of a single reduction rol...

Embodiment 3

[0063] In this embodiment, the control method for improving the internal defects of high-carbon chromium bearing steel blooms includes the following steps:

[0064] (1) Cast molten steel into a large chamfered bloom with a liquid core: the size of the continuous casting slab is 280×325mm, the angle between the corner of the continuous casting slab and the wide surface of the slab is controlled to be 32°, and the length of the hypotenuse of the continuous casting slab is 50mm ;

[0065] (2) Control continuous casting parameters: control the superheat of molten steel in the tundish to 18-23°C, the casting speed to 0.75m / min, the current intensity of electromagnetic stirring in the mold to 430A, and the frequency to 1.5Hz;

[0066] (3) Light reduction is carried out on the large chamfered bloom with liquid core, which is divided into two stages: dynamic reduction and static reduction:

[0067] a. In the stage of dynamic soft reduction, the reduction amount of a single reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com