Corroding agent for dendritic corrosion macroscopic examination and effluent treatment system

A waste liquid treatment system and low magnification inspection technology, applied in the field of chemical analysis and detection, can solve problems such as complex treatment steps, and achieve the effects of convenient treatment, improved detection range and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

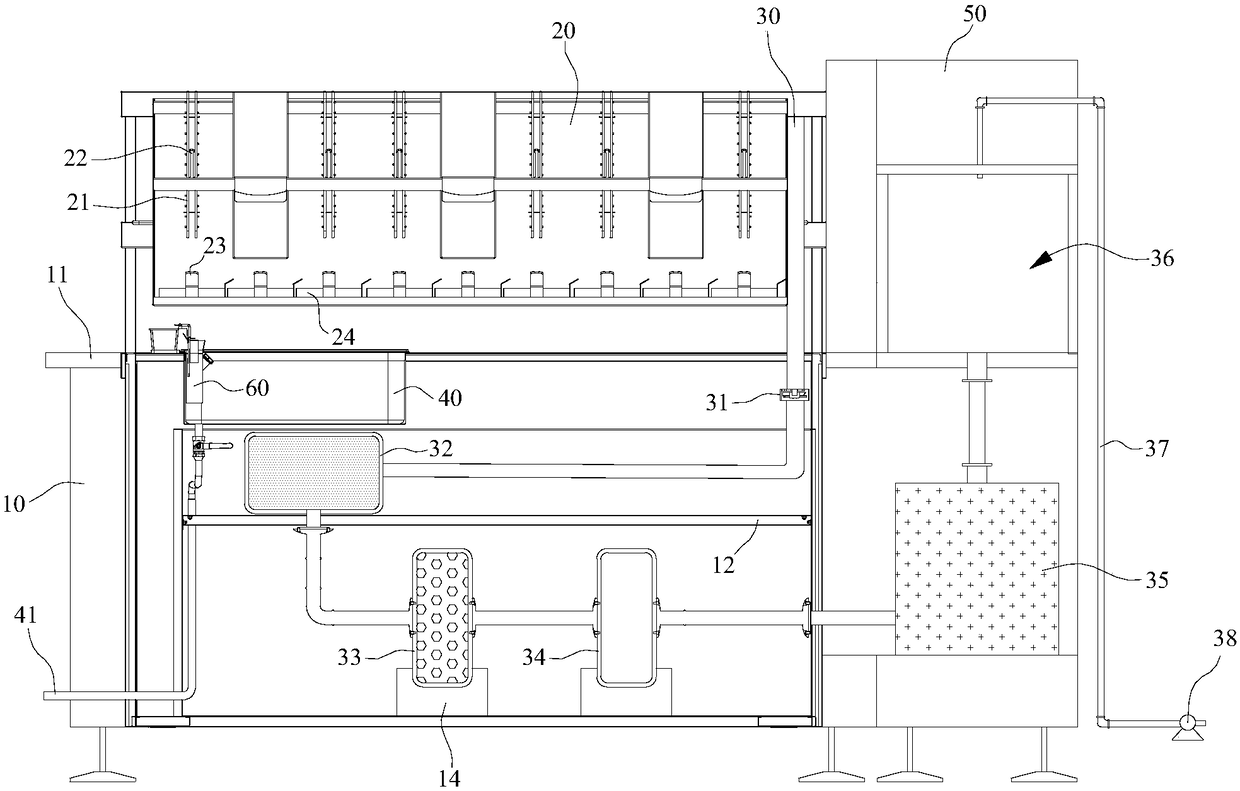

Embodiment Construction

[0022] Embodiments of the present invention firstly provide an etchant for low-magnification inspection of dendrite corrosion. The components in the etchant include: copper chloride (CuCl 2 )0.01%~1.0%, copper nitrate (Cu(NO 3 ) 2 )0.01%~1.5%, magnesium chloride (MgCl 2 )0.01%~1.5%, ferric chloride (FeCl 3 )0.01%~3.0%, ferrous chloride (FeCl 2 ) 0.01% to 2.0%, hydrochloric acid 1.0% to 4.0%, absolute ethanol 40% to 50%, and the balance is water. Wherein the mass concentration of hydrochloric acid is: 29%~34%.

[0023] The components and their contents in the etchant are preferably: 0.1% to 0.8% of copper chloride, 0.1% to 0.8% of copper nitrate, 0.1% to 0.8% of magnesium chloride, 0.1% to 2.0% of ferric chloride, and 0.1% of ferrous chloride ~1.5%, hydrochloric acid 2.0%~3.0%, absolute ethanol 42%~48%, and the balance is water.

[0024] The components in the corrosive agent are further preferably: 0.15% to 0.6% of copper chloride, 0.15% to 0.6% of copper nitrate, 0.1% to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com