Patents

Literature

33 results about "Metallurgical assay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metallurgical assay is a compositional analysis of an ore, metal, or alloy. Some assay methods are suitable for raw materials; others are more appropriate for finished goods. Raw precious metals (bullion) are assayed by an assay office. Silver is assayed by titration, gold by cupellation and platinum by inductively coupled plasma optical emission spectrometry (ICP OES). Precious metal items of art or jewelry are frequently hallmarked (depending upon the requirements of the laws of either the place of manufacture or the place of import). Where required to be hallmarked, semi-finished precious metal items of art or jewelry pass through the official testing channels where they are analyzed or assayed for precious metal content. While different nations permit a variety of legally acceptable finenesses, the assayer is actually testing to determine that the fineness of the product conforms with the statement or claim of fineness that the maker has claimed (usually by stamping a number such as 750 for 18k gold) on the item. In the past the assay was conducted by using the touchstone method but currently (most often) it is done using X-ray fluorescence (XRF). XRF is used because this method is more exacting than the touchstone test. The most exact method of assay is known as fire assay or cupellation. This method is better suited for the assay of bullion and gold stocks rather than works of art or jewelry because it is a completely destructive method.

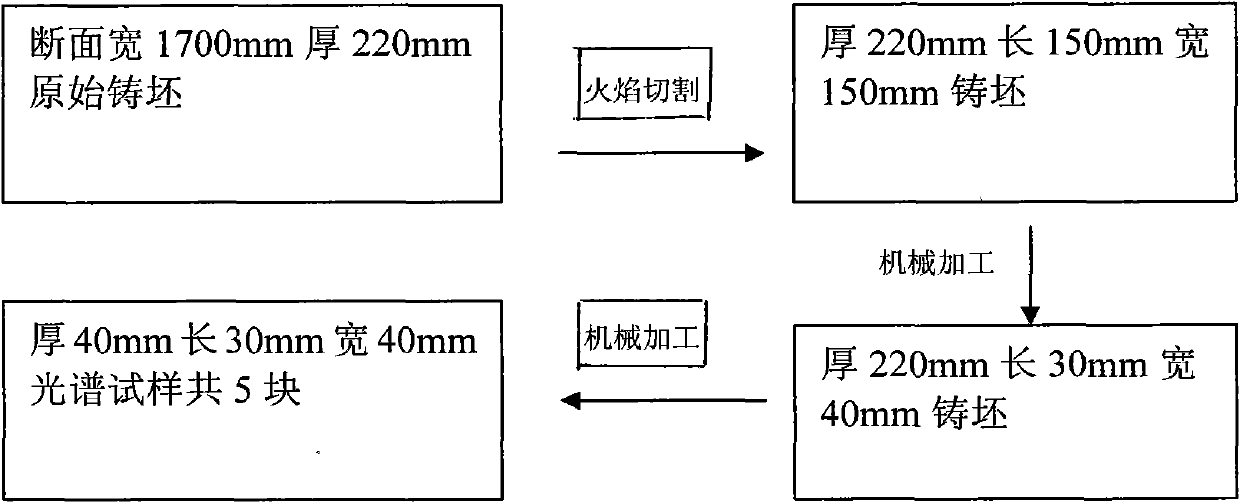

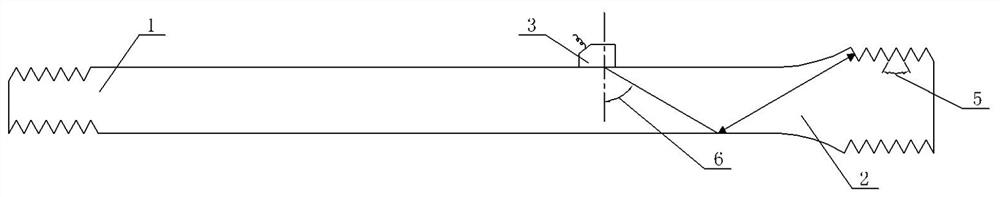

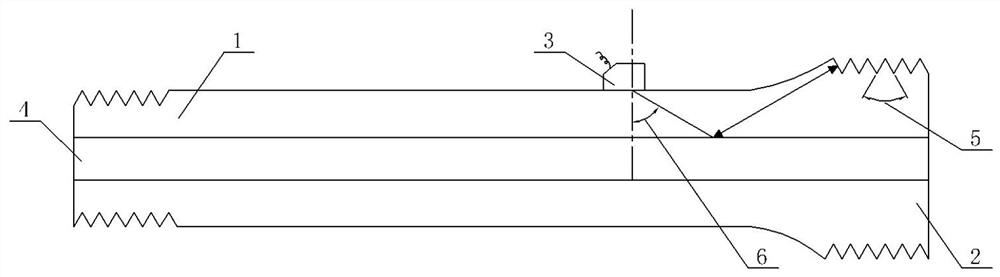

Method for rapidly testing casting blank segregation by utilizing direct-reading spectrometer

InactiveCN101949851AMeet the general quantitative detectionOvercoming complexityPreparing sample for investigationAnalysis by electrical excitationMetallurgical assayTest sample

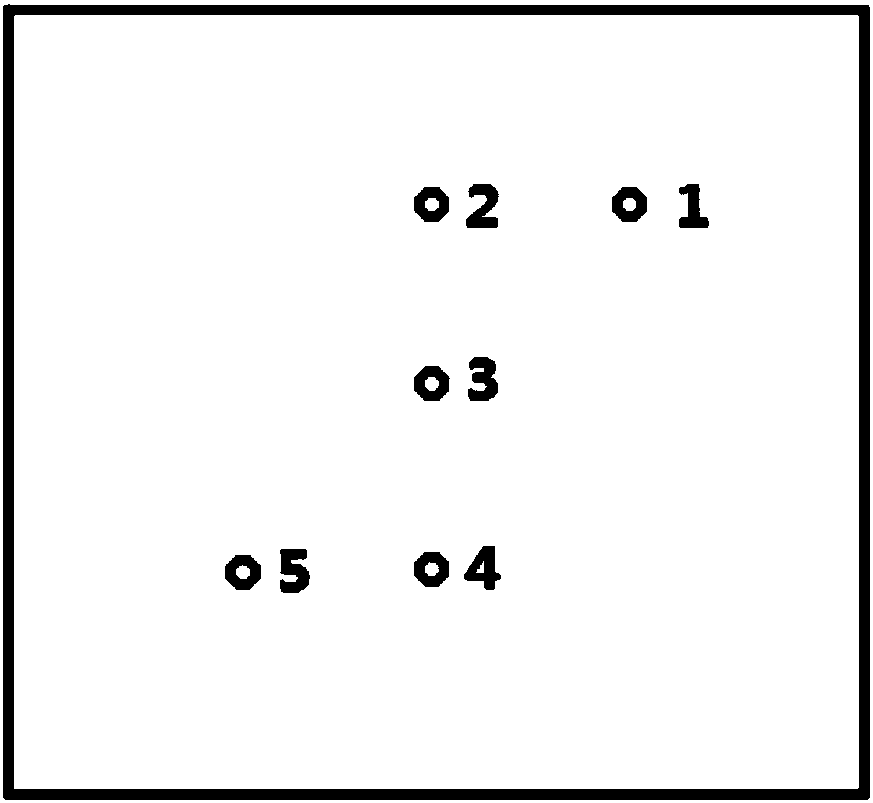

The invention discloses a method for rapidly testing casting blank segregation by utilizing a direct-reading spectrometer, which is suitable for the quantitative and trending detection in the casting blank segregation, belonging to the technical field of metallurgy analyzing and detecting. In the method, the direct-reading spectrometer is adopted to simulate an in-situ analyzer to detect the casting blank segregation; and the direct-reading spectrometer segments and dots a test sample, and simulates the in-situ analyzer to analyze the test sample, so as to quantitatively detect the continuously cast blank macrosegregation. The method can overcome the defects that the in-situ analysis sample preparation is complex, the testing period is long, the detection cost is high and the like, satisfies the generalized quantitative detection to the casting blank in the continuous casting production, and provides a good popularization and reference method for the iron and steel enterprises owning rapid spectrum analyzers in the trending and quantitative detection of the continuously cast blank segregation. Compared with the traditional pickling method for detecting the casting blank segregation, the method has the same trend on the description of the casting blank segregation as that of the pickling method; the casting blank segregation result detected by the direct-reading spectrometer not only can describe the casting blank segregation condition, simultaneously can clearly describe the component segregation curve of each element, and has the visual digitized function.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

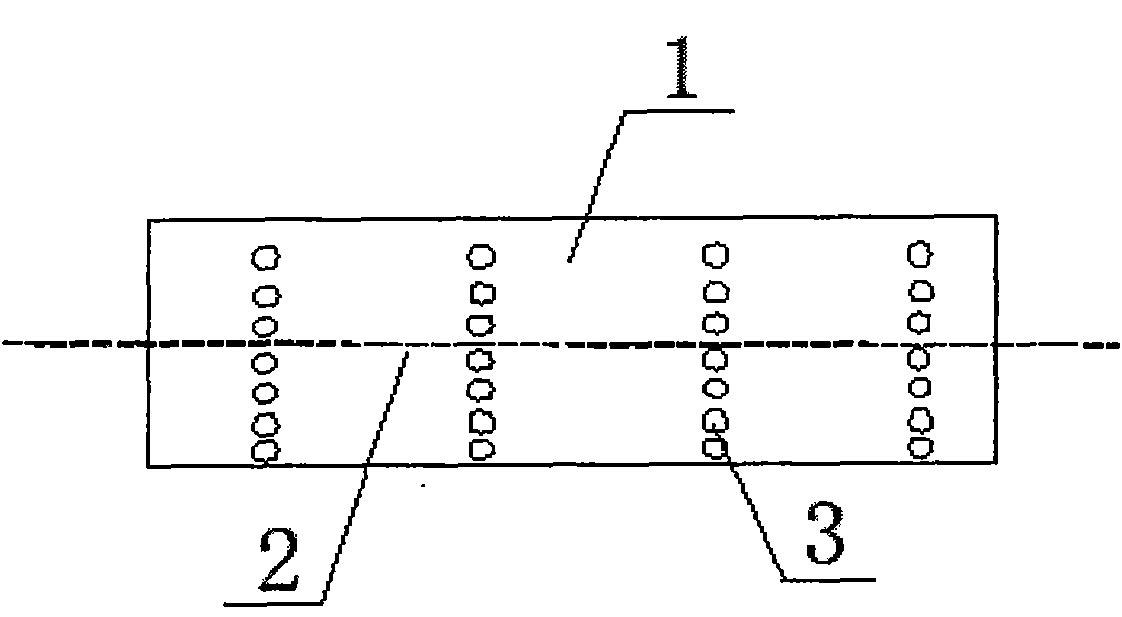

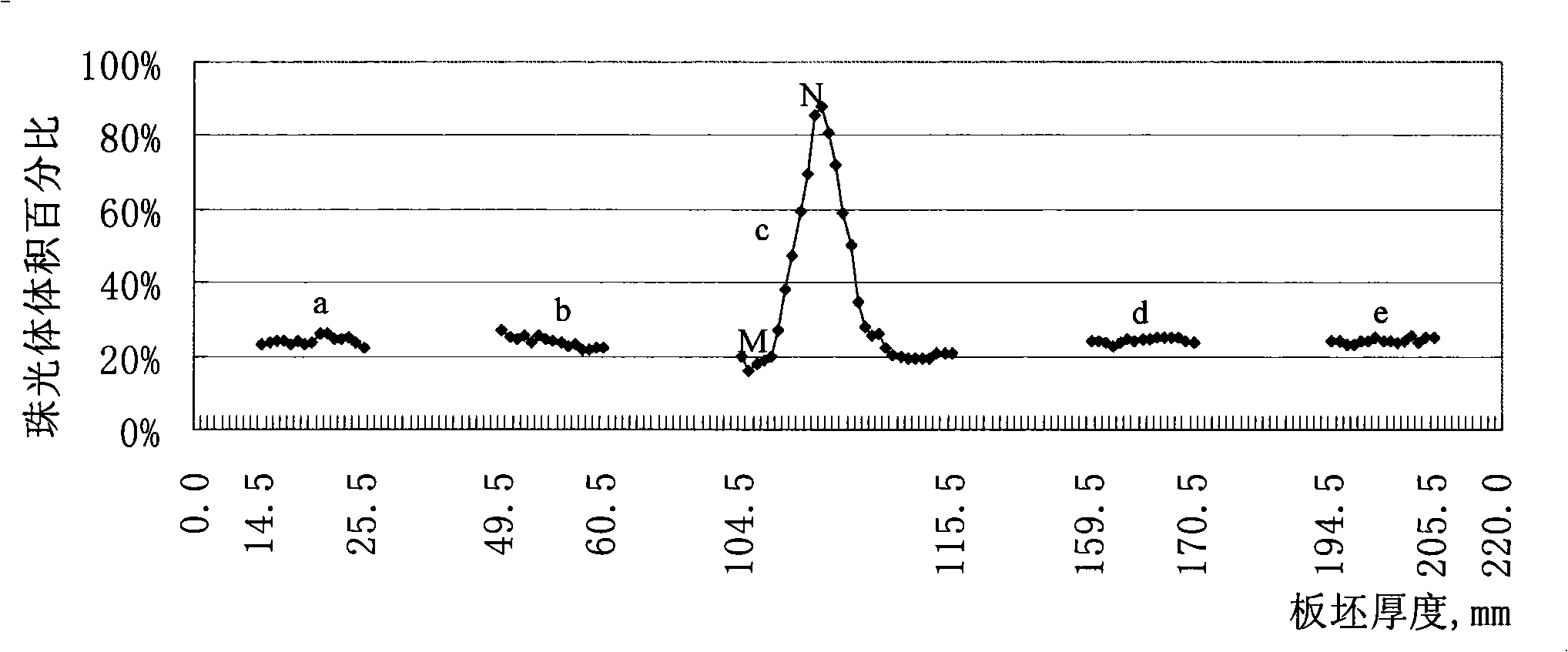

Method for quantitative analysis of continuous casting sheet billet gross segregation by image analysis method

ActiveCN101344490AObservation and analysis of carbon content distributionAccurate observationOptically investigating flaws/contaminationContent distributionMetallurgical assay

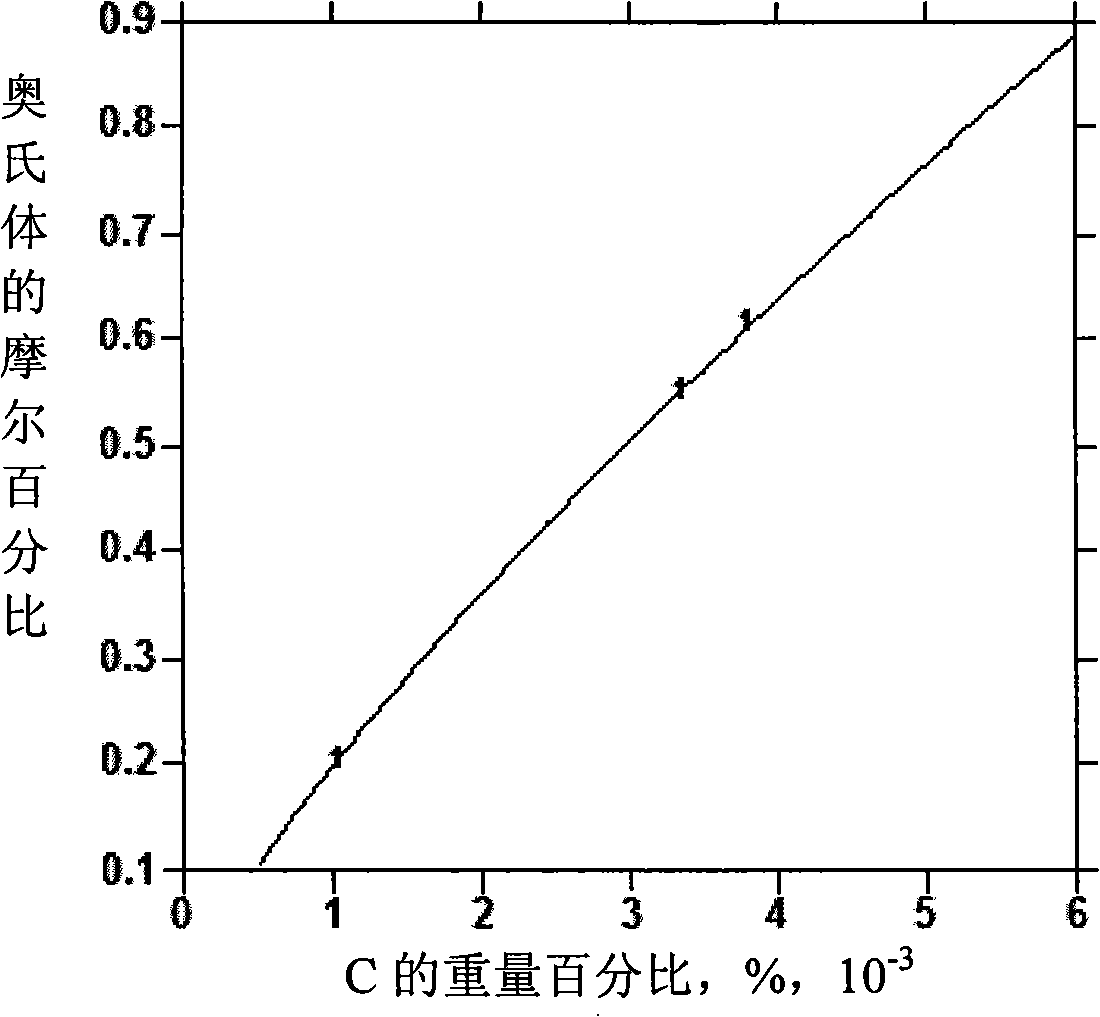

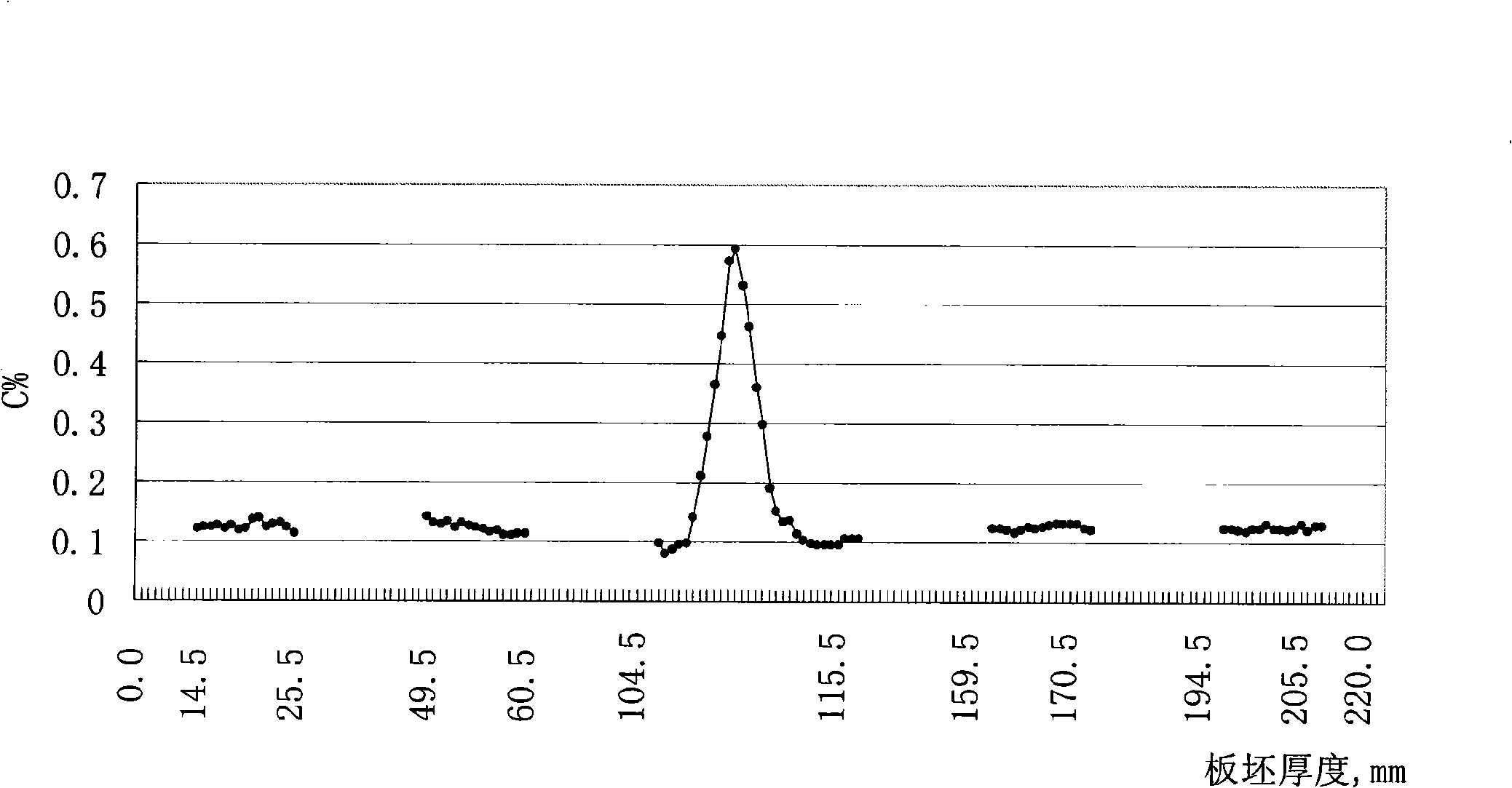

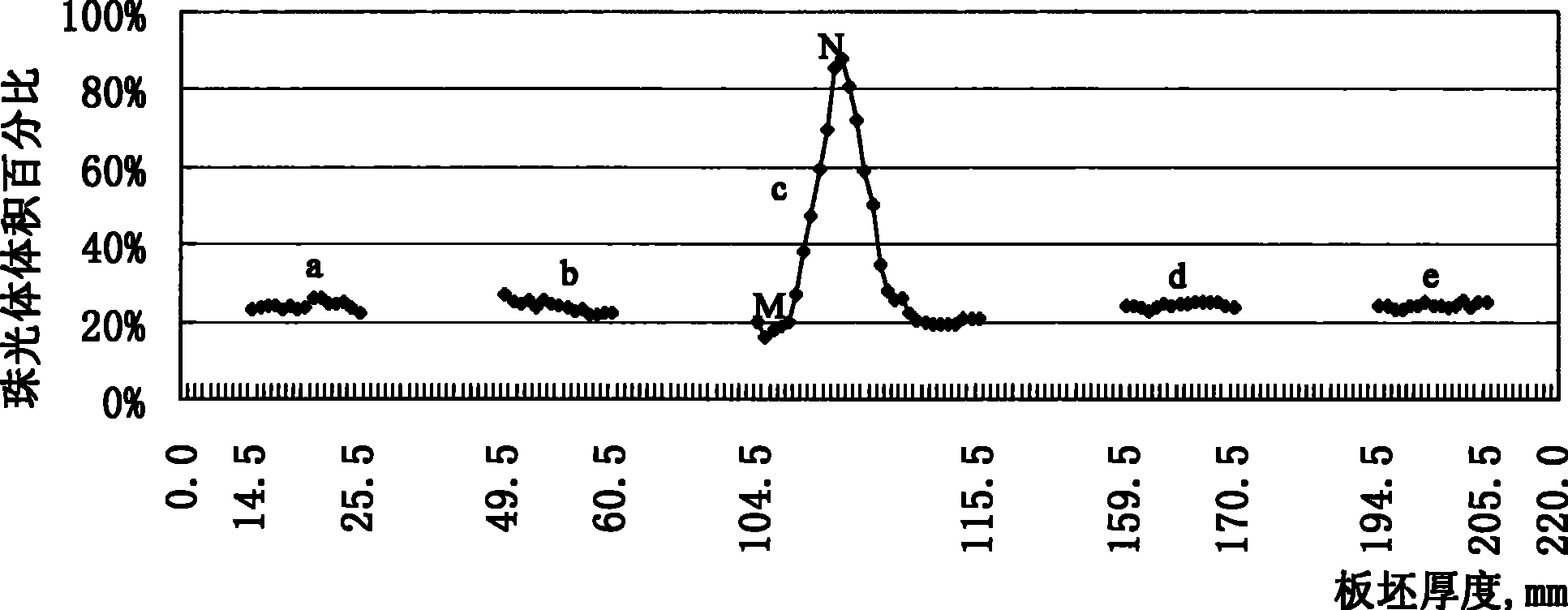

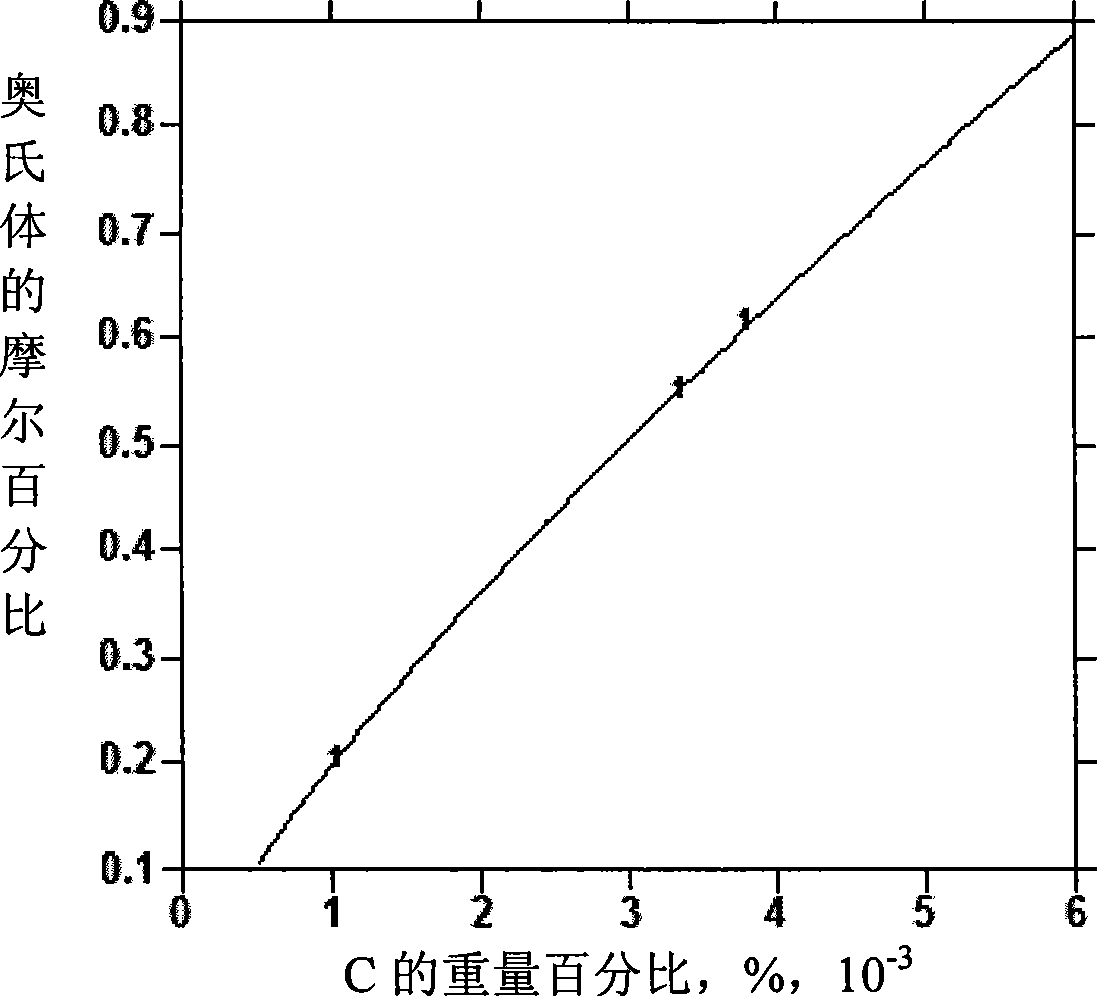

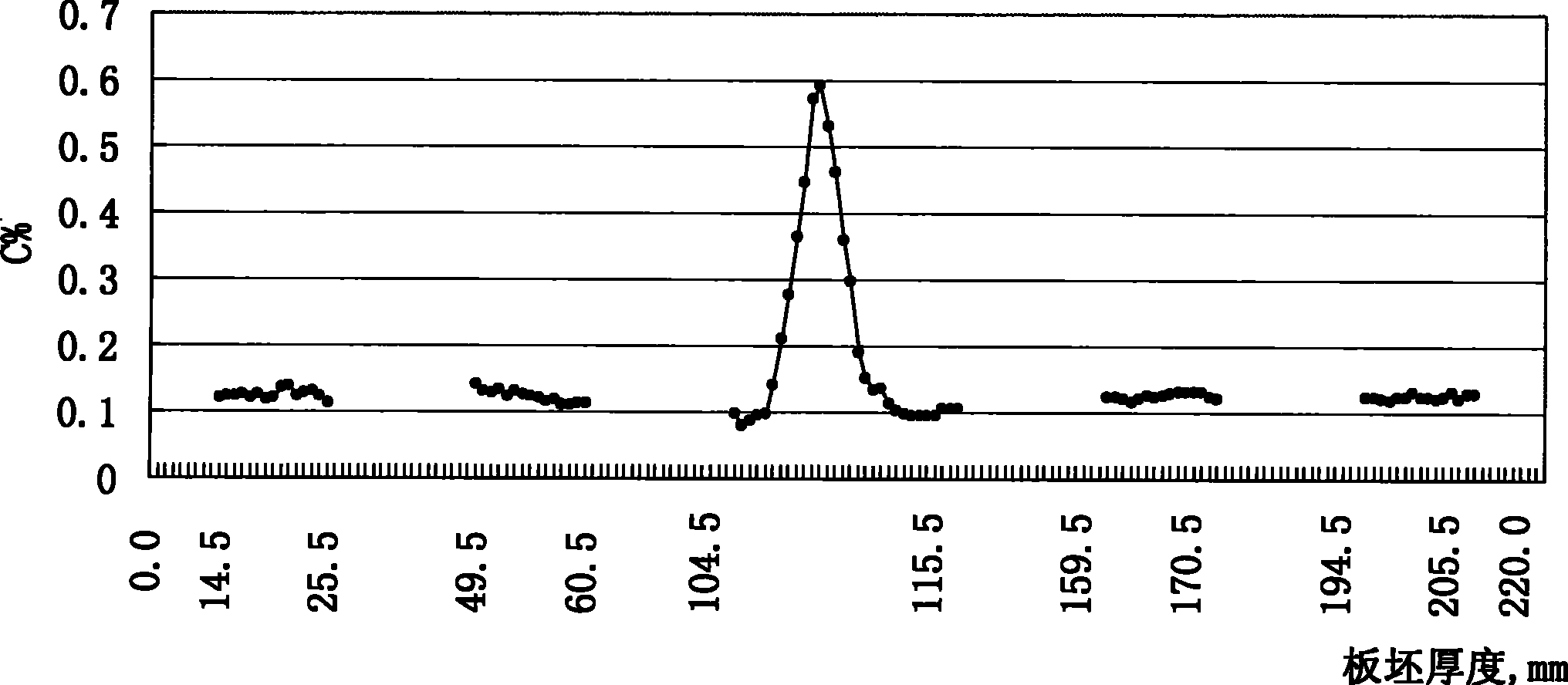

The invention discloses a gross segregation quantitative analyzing method of a continuous casting sheet billet that adopts an image analyzing method, belongs to the technical field of metallurgical analysis, and comprises the following steps: the structural content change of the sheet billet in the thickness direction is obtained through metalloid image analysis, the structural volume percent is converted into the mole percent through crystal lattice volume computation, a binary phase diagram of the carbon weight percent and the austenite structure mole percent is obtained through thermodynamic computation, and the structural mole percent in each analyzed region is converted into the carbon weight percent. The gross segregation quantitative analyzing method has the advantages that the analyzing method that combines the metalloid structure image analysis method with the thermodynamic computation is adopted for analyzing the gross segregation of the sheet billet, thus quantitatively analyzing the carbon gross segregation in the sheet billet, more precisely observing and analyzing the carbon content distribution in the sheet billet, and consequently providing a novel tool for examining and analyzing the gross segregation of the sheet billet.

Owner:SHOUGANG CORPORATION

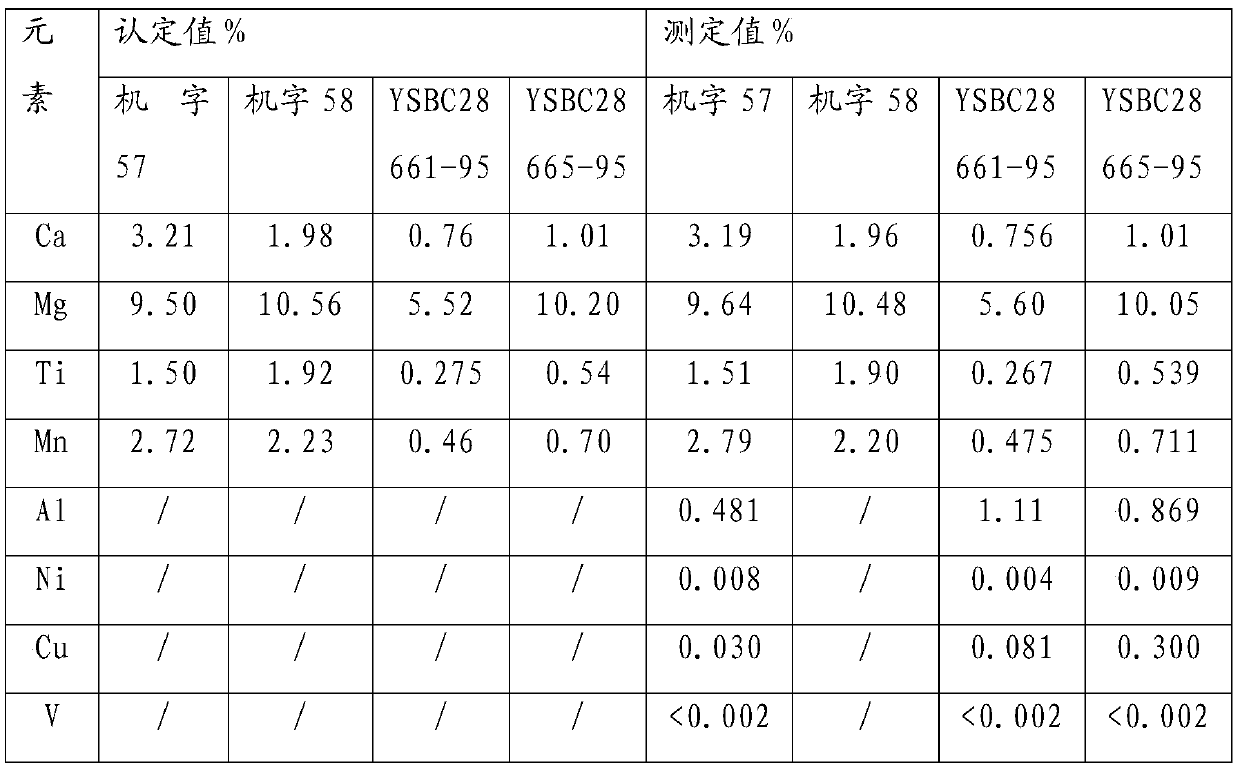

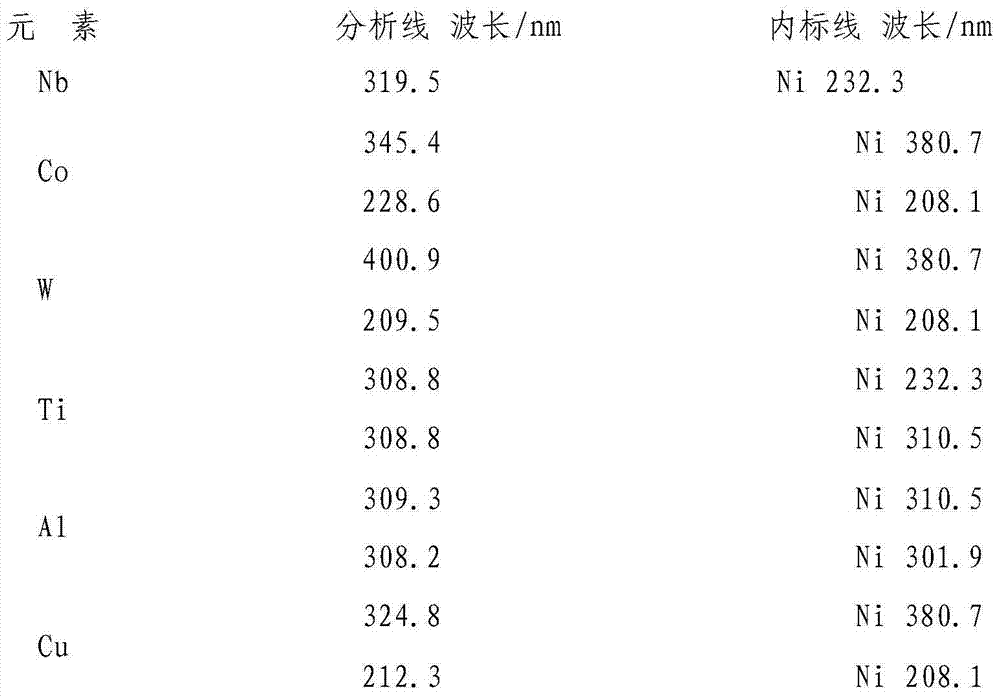

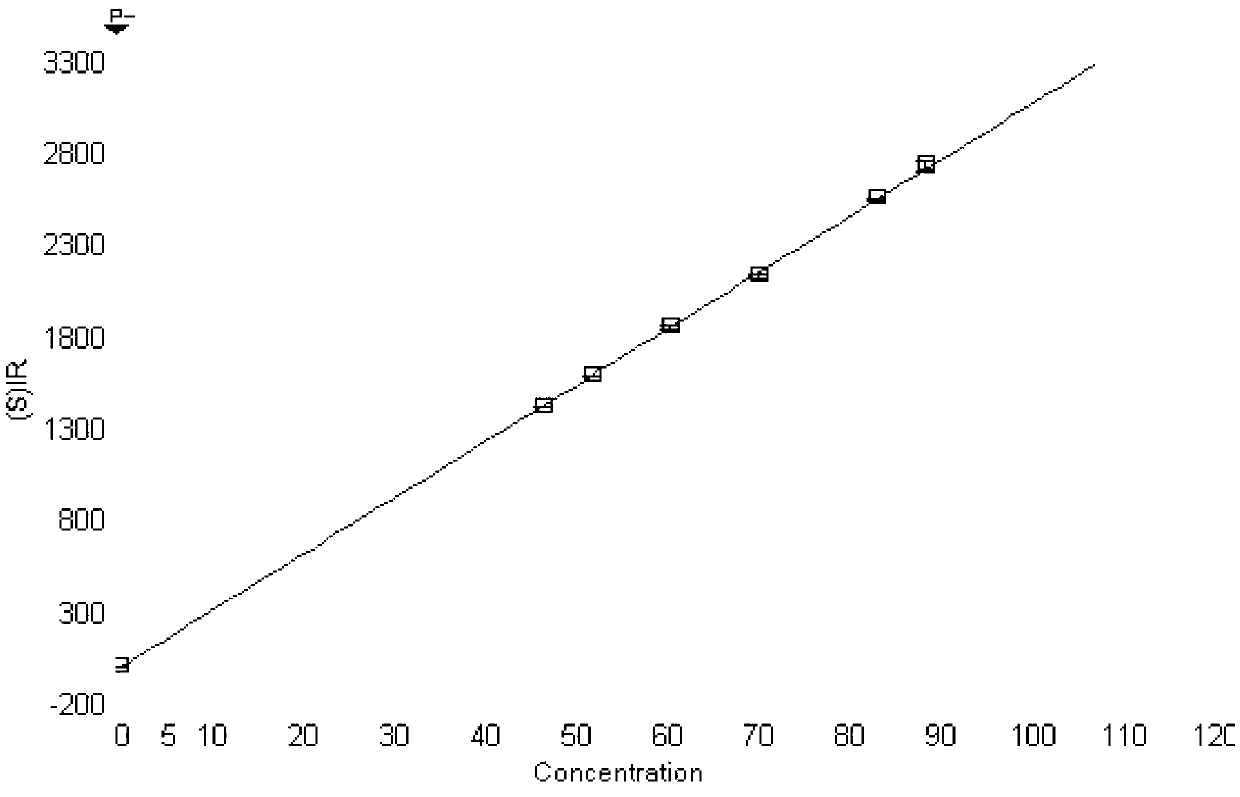

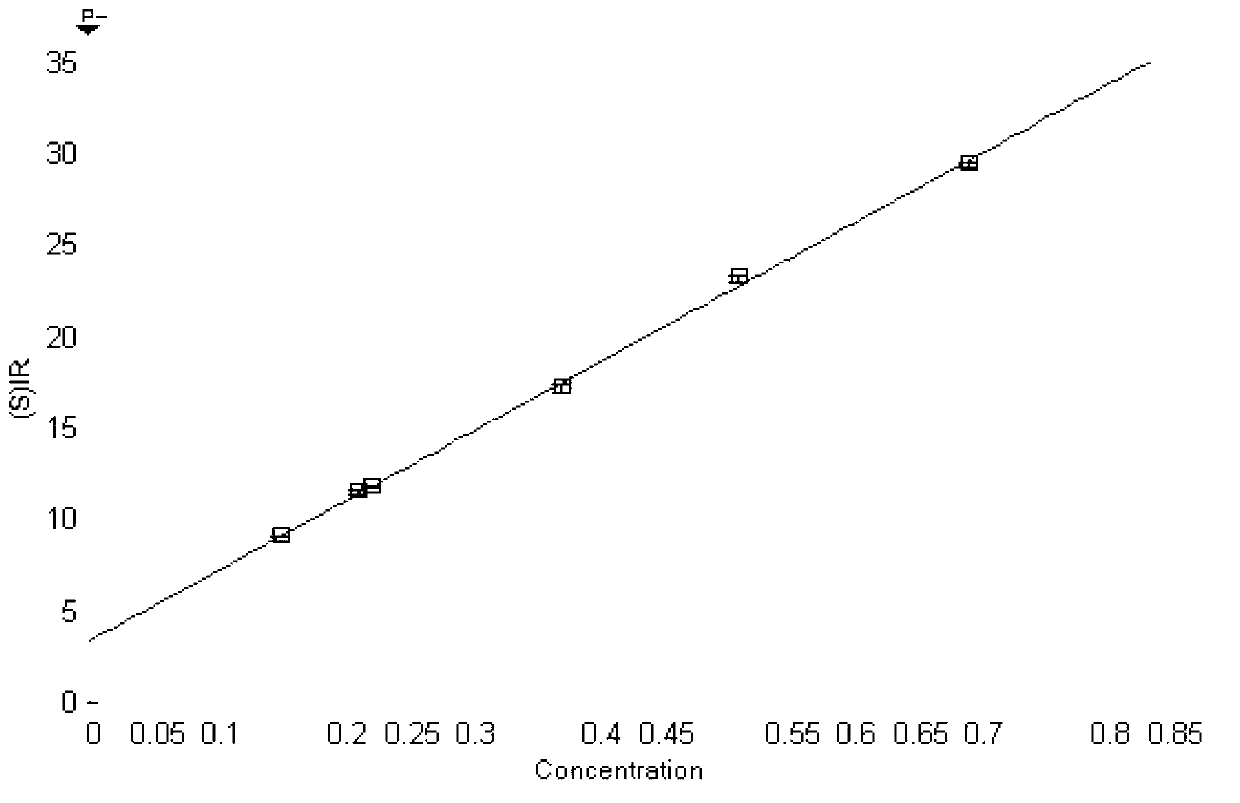

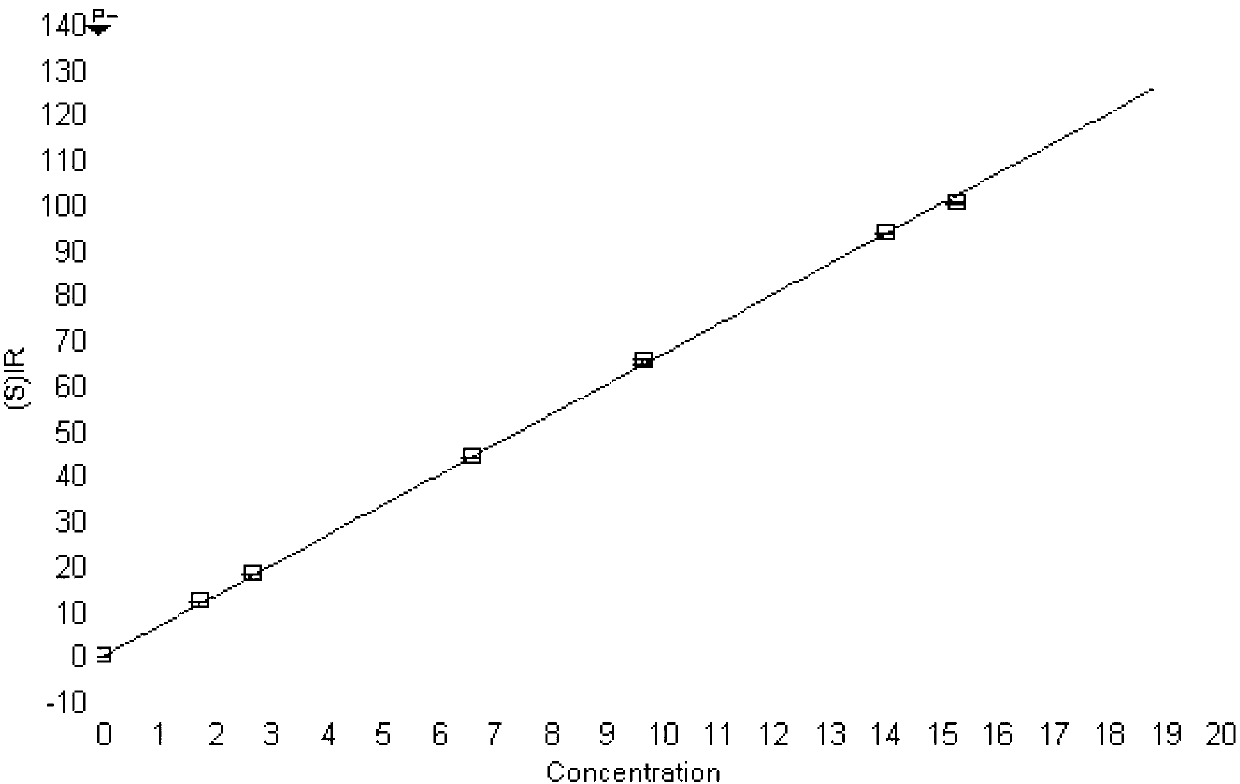

Method for measuring aluminum, magnesium, calcium, vanadium, titanium, nickel, copper and manganese in rare earth silicon-magnesium alloy

InactiveCN105510301AExpanding the Upper Limit of AnalysisEliminate distractionsAnalysis by electrical excitationAdditive ingredientManganese

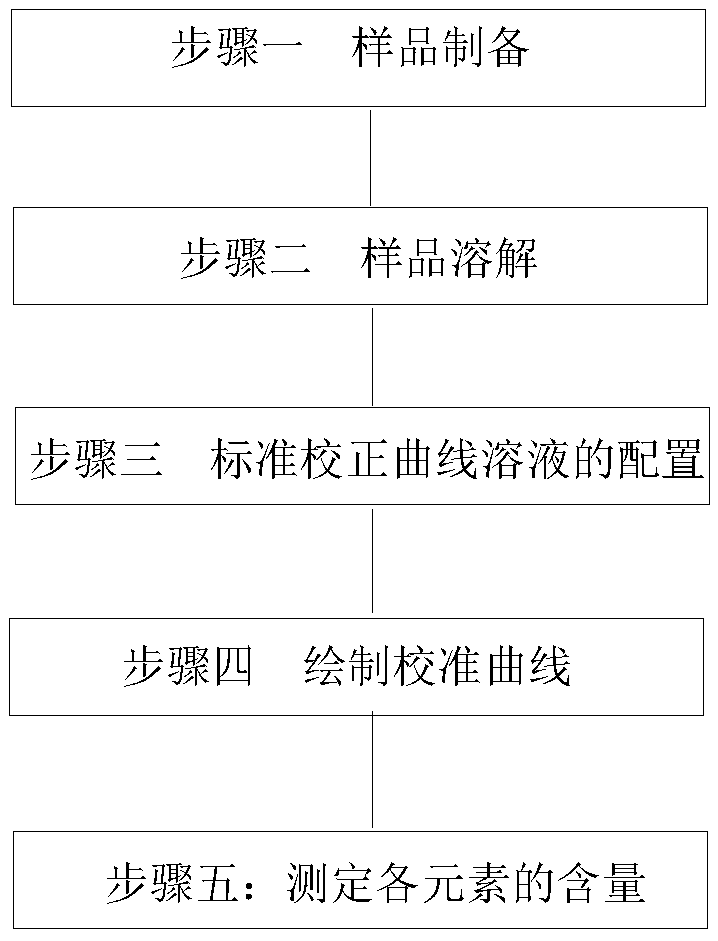

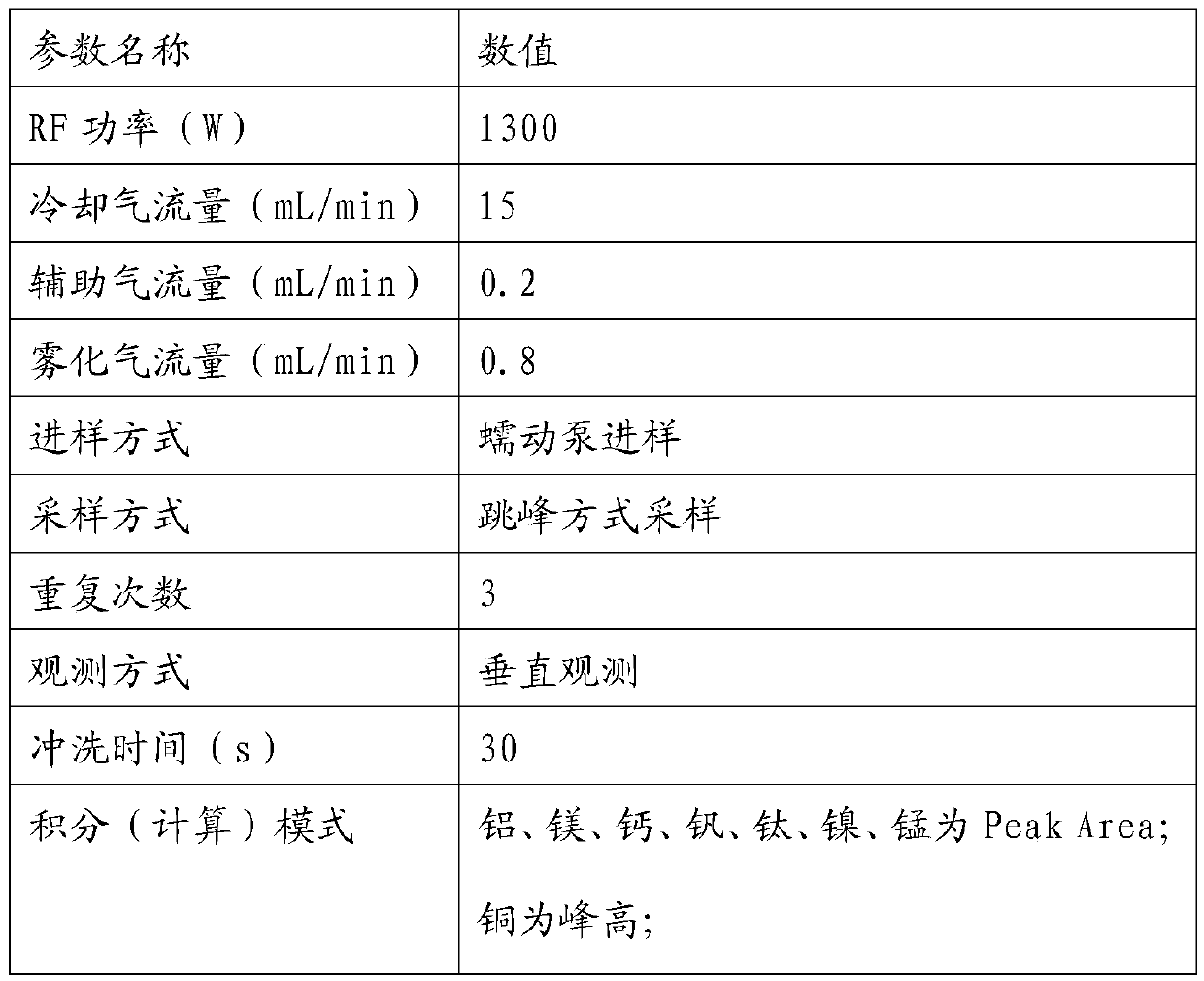

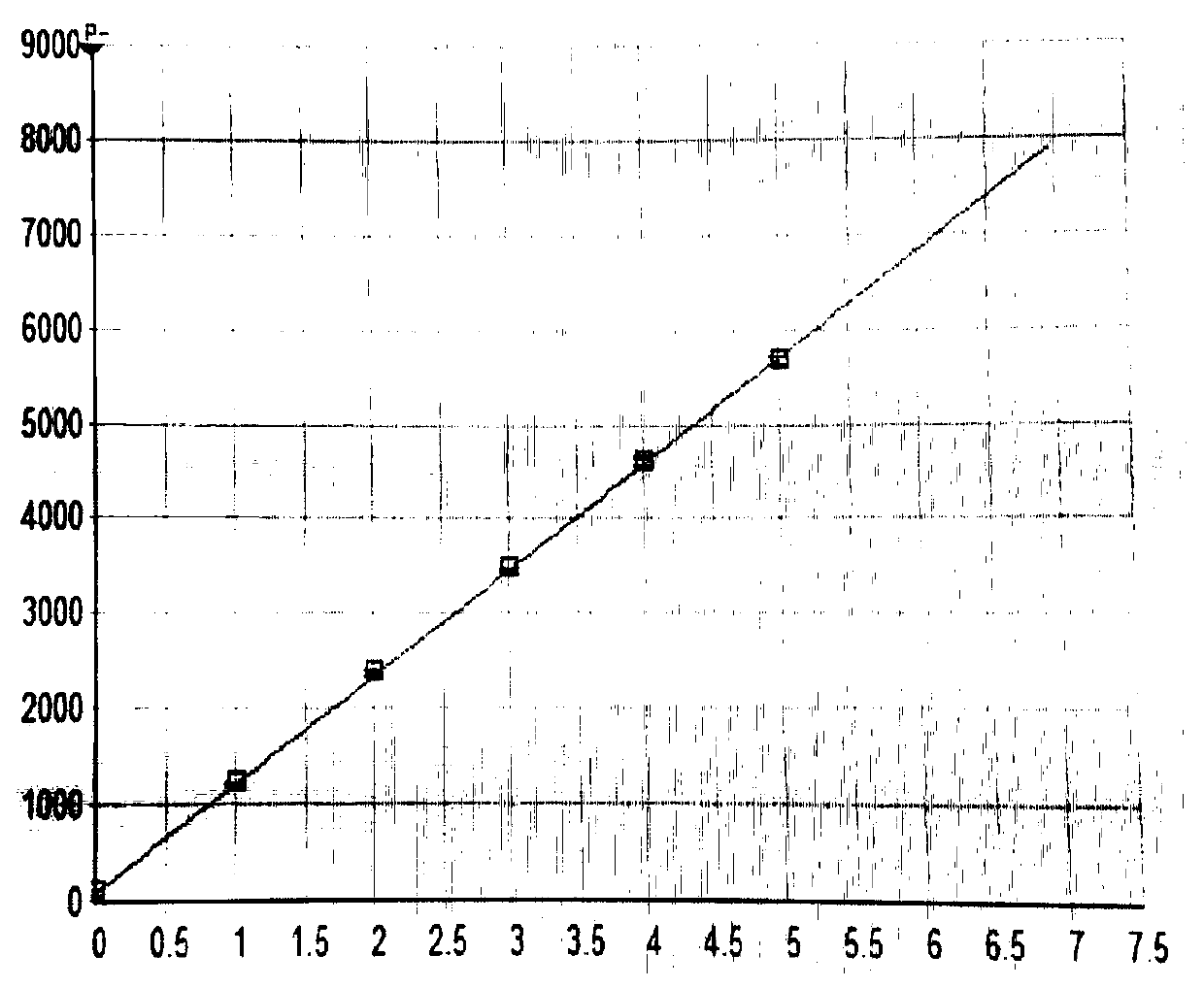

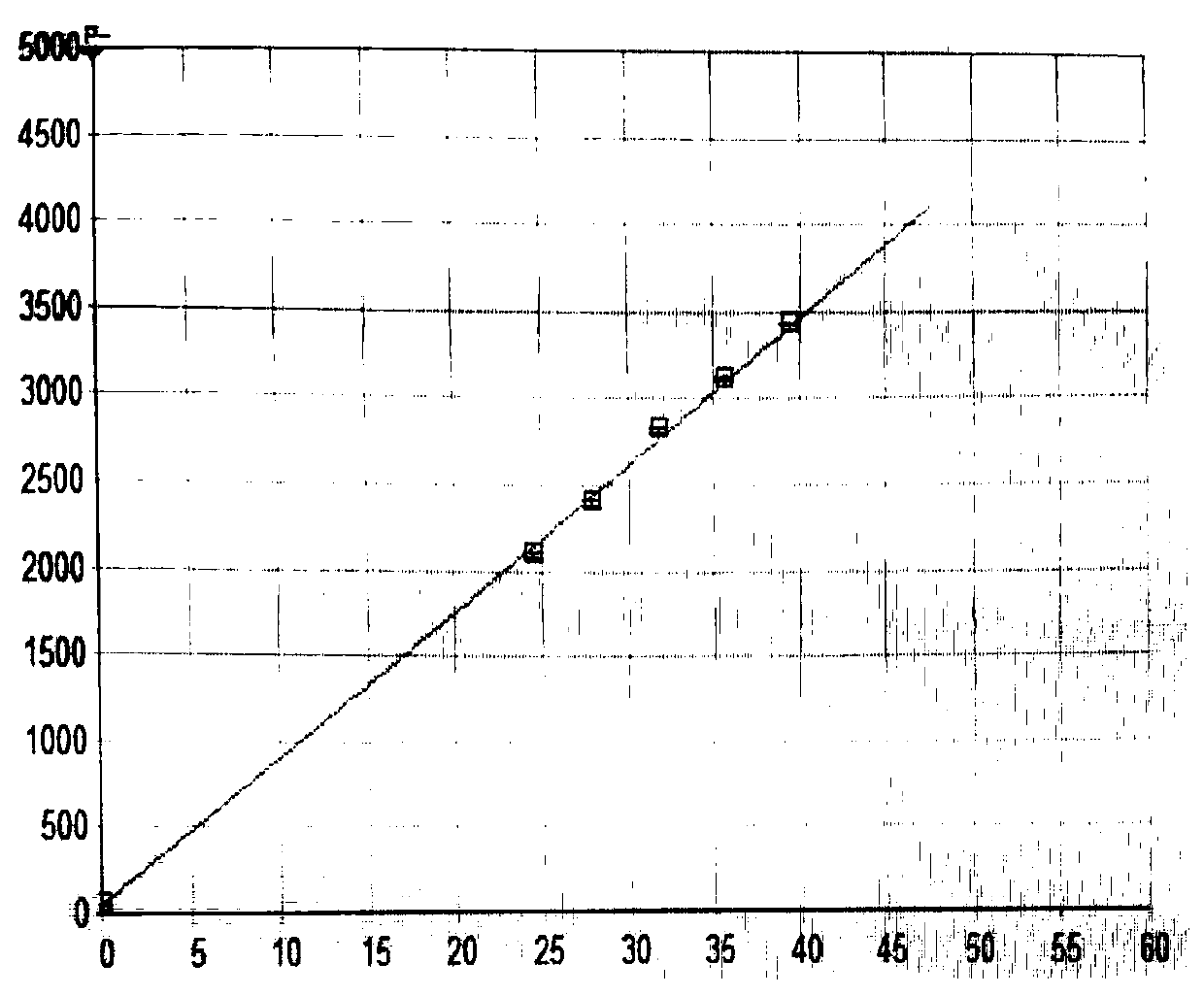

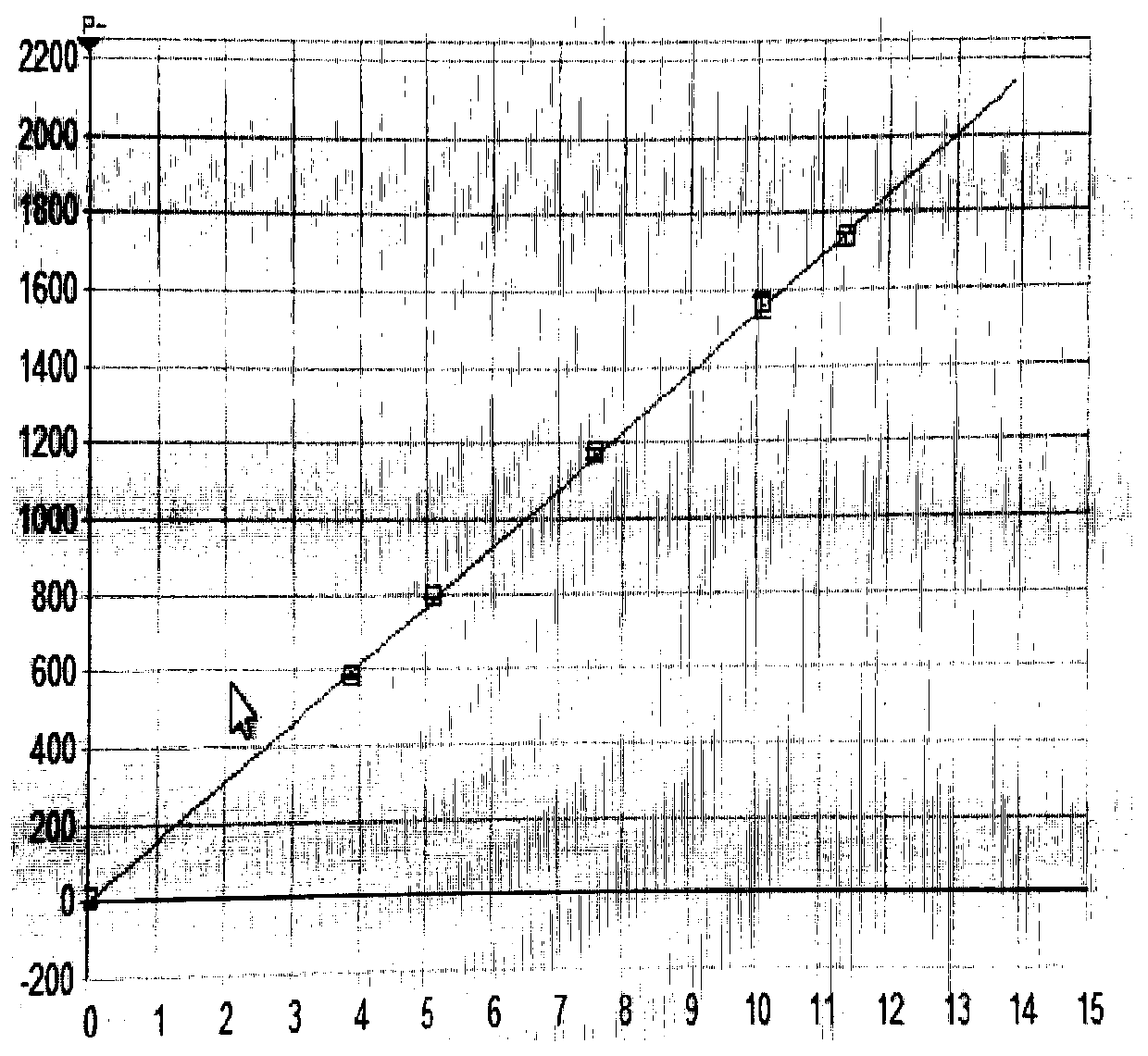

The invention discloses a method for measuring aluminum, magnesium, calcium, vanadium, titanium, nickel, copper and manganese in rare earth silicon-magnesium alloy, and belongs to the field of metallurgy analyzing methods. The aim that the provided method for measuring aluminum, magnesium, calcium, vanadium, titanium, nickel, copper and manganese in the rare earth silicon-magnesium alloy is high in sensitivity, high in measuring speed, easy and convenient to operate and small in interference relative to other methods, has good selectivity, and can provide accurate data for the smelting ingredient control process is achieved. The method comprises the following steps that 1, a sample is prepared; 2, the sample is dissolved; 3, a standard calibration curve solution is prepared; 4, a standard curve is drawn; 5, the content of all elements is measured. The method is high in precision, high in accuracy, fast, simple and convenient to use, and can be used for measuring the content of aluminum, magnesium, calcium, vanadium, titanium, nickel, copper and manganese in the rare earth silicon-magnesium alloy in production.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

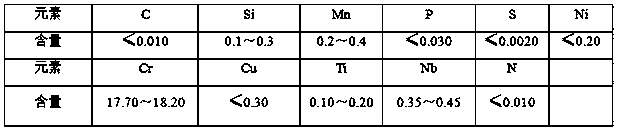

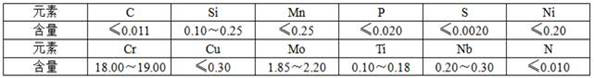

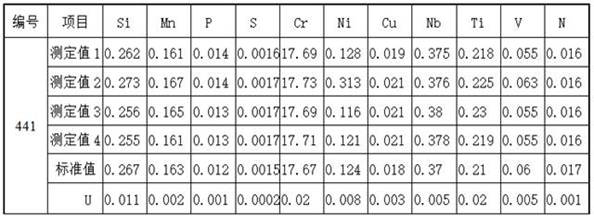

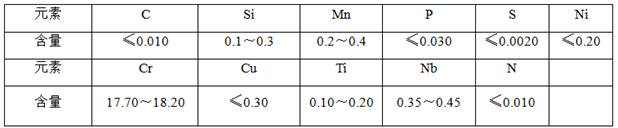

Preparation method of ultrapure ferritic stainless steel spectral standard sample

ActiveCN109596531AImprove uniformityImprove stabilityFoundry mouldsColor/spectral properties measurementsCooking & bakingProcess quality

The invention discloses a preparation method of an ultrapure ferritic stainless steel spectral standard sample, and belongs to the technical field of detection of metallurgical samples. The method comprises the following steps: design of a billet mold, baking and preheating of the billet mold, component design, selection of furnace material, smelting of a vacuum induction furnace, de-molding, testof physical properties, preliminary test of chemical composition and segregation, casting billet sampling, acceptance test of chemical compositions of the sample, preliminary test of uniformity, andprocessing of spectral blocks. The preparation method prepares the ultrapure ferritic stainless steel spectral standard sample with good uniformity and stability by strictly following the requirementsof GB / T15000 "International Standard Sample Working Guidelines" and YB / T082-1996 "Technical Specifications for International Standard Samples for Metallurgical Analysis", which can replace the standard sample of non-similar stainless steel for comparison and calibration of the direct reading spectrometer and the X-ray fluorescence spectrometer, and solves the problem of detection deviation causedby the matrix effect in the inspection of the ultrapure ferritic stainless steel sample, thereby achieving precise control of process quality.

Owner:JIUQUAN IRON & STEEL GRP

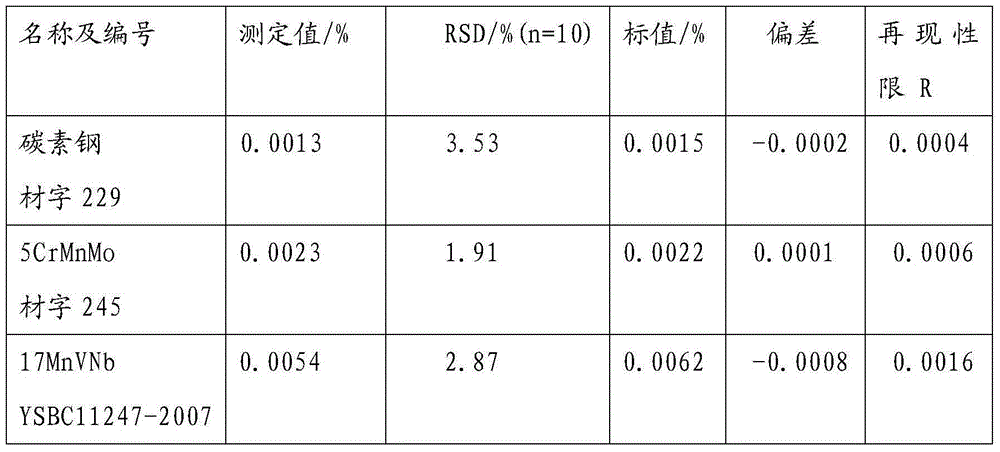

Multi-element standard solution for analyzing harmful elementary compositions in steel and preparation method of multi-element standard solution

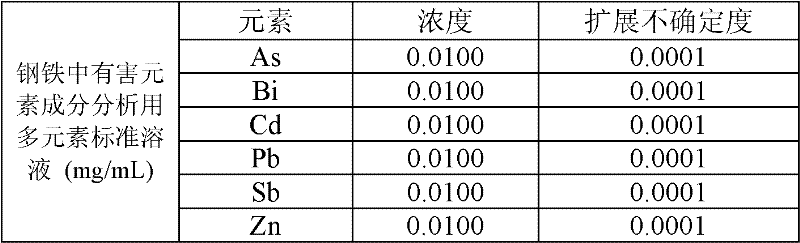

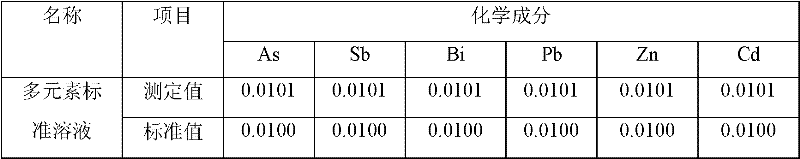

InactiveCN102200512ASolving Standard Problems for AnalysisSolve standard problemsAnalysis by thermal excitationStandard problemInductively coupled plasma

The invention discloses a multi-element standard solution for analyzing harmful elementary compositions in steel and a preparation method of the multi-element standard solution, and belongs to the technical field of metallurgical analysis. The solution contains the following elements of: arsenic (As), stibium (Sb), bismuth (Bi), plumbum (Pb), zinc (Zn) and cadmium (Cd); the content of each element is 0.01mg / mL; and a solution medium is HNO3 at the mass concentration of 5 percent. By tightly combining the characteristic of the alloy composition of a steel material, the standard problem of inductively coupled plasma (ICP) instruments for material alloy analysis can be solved, interferences of an iron base body and a background can be eliminated, traceability is realized, the analysis time is shortened greatly, and the multi-element standard solution is convenient for users.

Owner:山东省冶金科学研究院有限公司

Method for measuring components of nickel-based high-temperature alloy steel by using photoelectric direct reading spectrometer

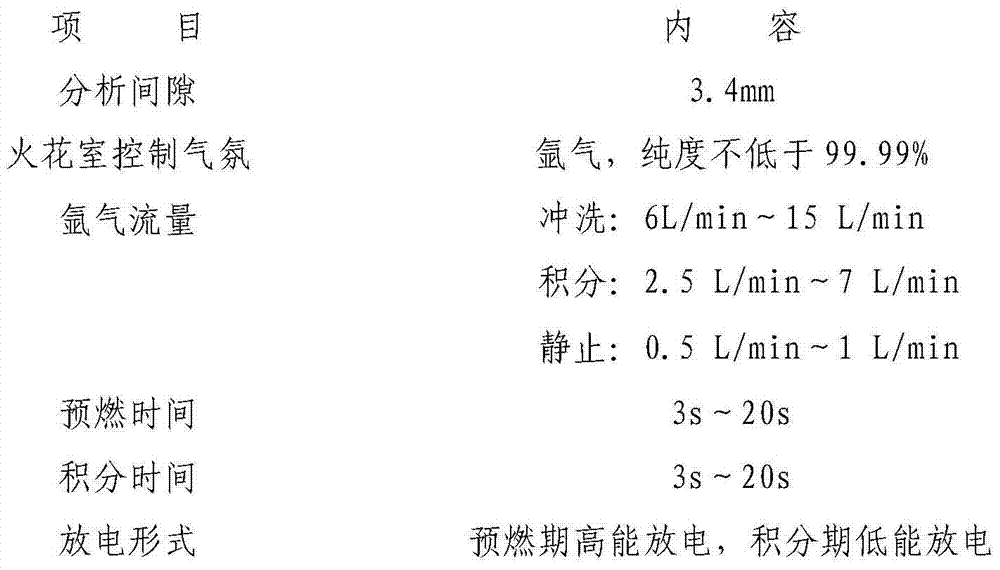

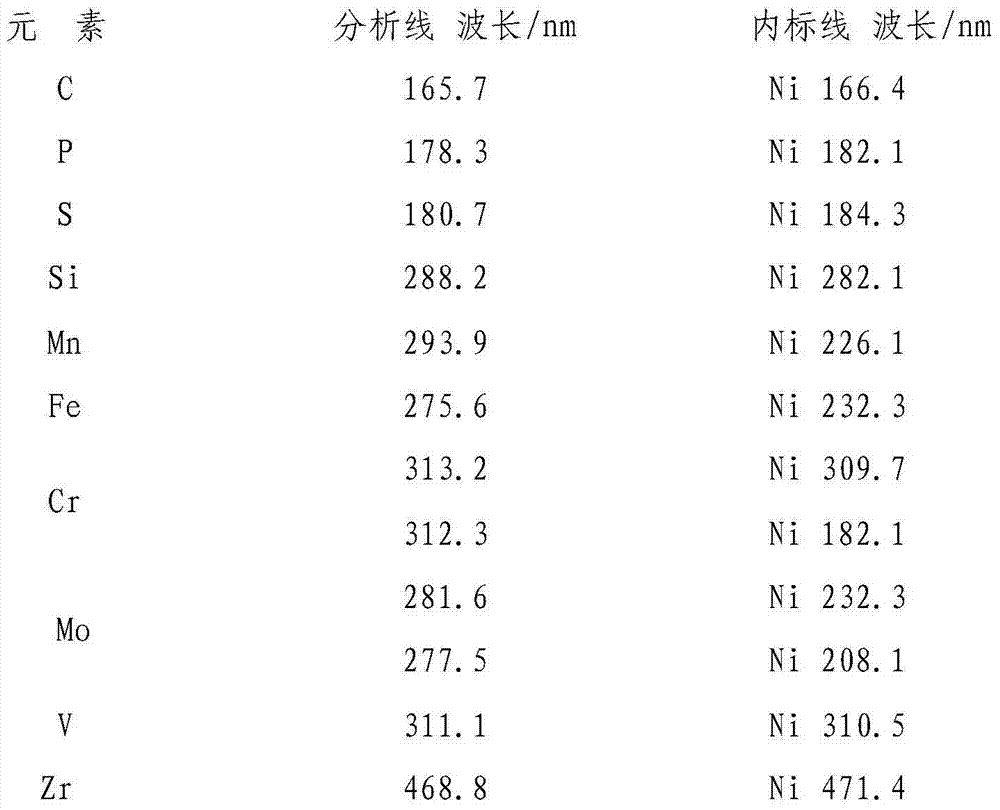

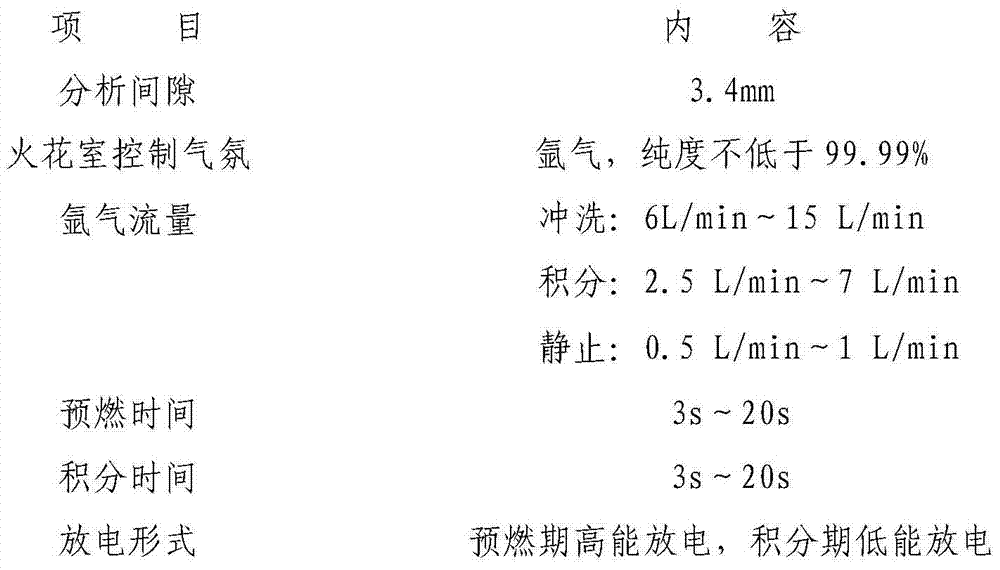

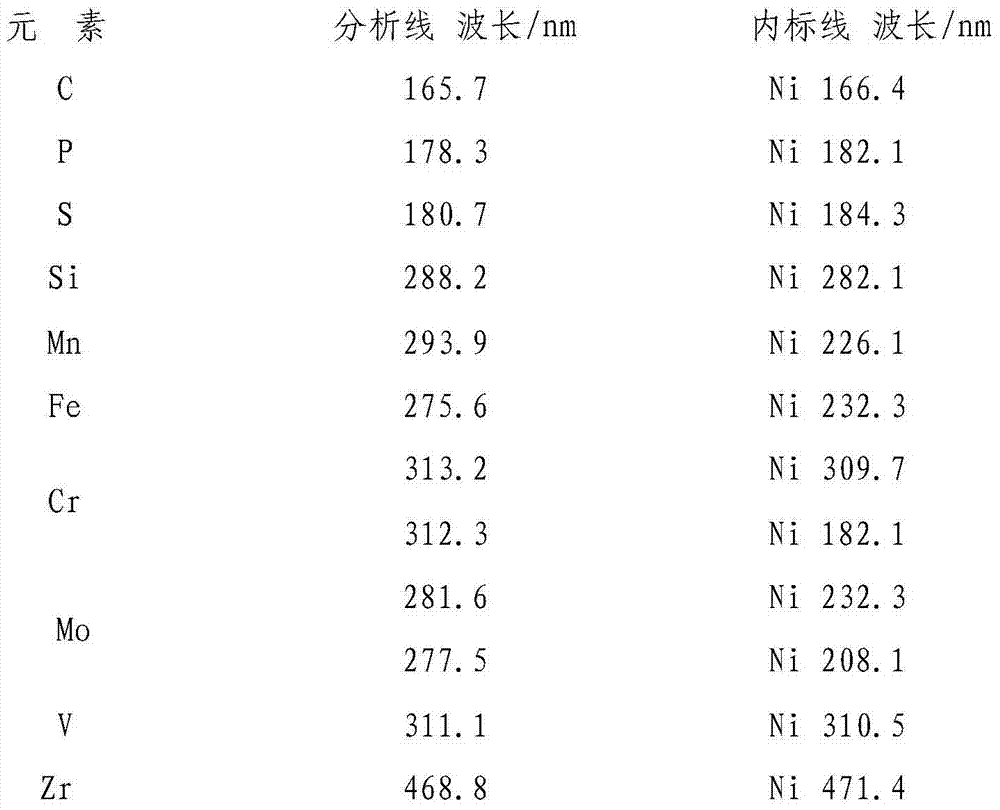

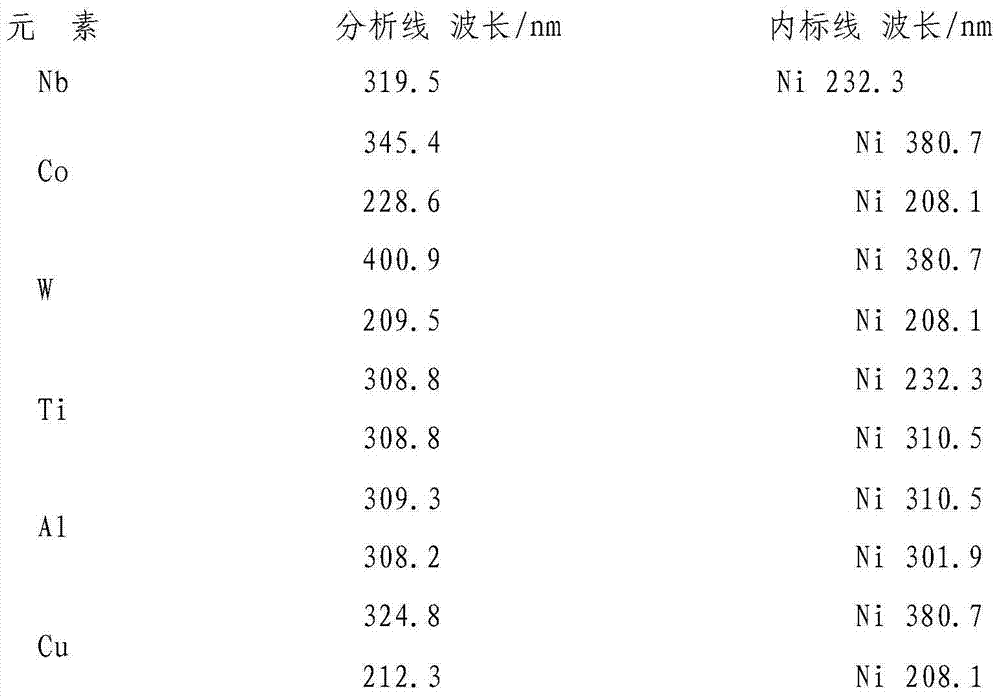

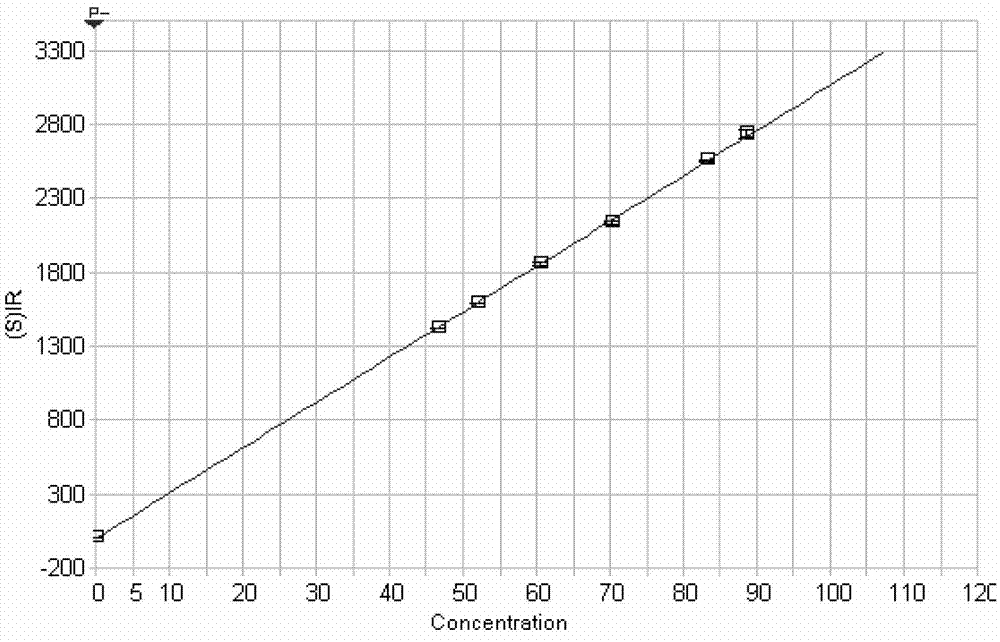

ActiveCN103575707ASimplify the analysis procedureShorten the analysis cycleAnalysis by material excitationMetallurgical assayOpto electronic

The invention belongs to the technical field of metallurgical analysis and relates to an improvement on a method for analyzing components of nickel-based high-temperature alloy steel. A method for measuring the components of the nickel-based high-temperature alloy steel comprises the following steps: determining an analysis condition; preparing an analysis sample; making a calibration curve; analyzing the sample; calculating the analysis result. The invention provides a method for measuring components of nickel-based high-temperature alloy steel by using a photoelectric direct reading spectrometer, so that analysis equipment is reduced, analysis procedures are simplified, analysis period is shortened, and analysis cost is reduced.

Owner:AECC AVIATION POWER CO LTD

Set of alum clay standard samples and preparation method thereof

ActiveCN103278362AImprove uniformityAccurate valuePreparing sample for investigationMeasurement testMeasuring instrument

The invention discloses a set of alum clay standard samples, belonging to the technical fields of new materials and metallurgical analysis. The set comprises five samples of which the Al2O3 contents are respectively 45-50wt%, 60-65wt%, 70-75wt%, 80-85wt% and 85-90wt%; and the five samples are simultaneously used for determining the contents of 12 components such as Al2O3, CaO, MgO, P2O5, Fe2O3, TiO2, SiO2, K2O, Na2O and the like. The set of alum clay standard samples covers the typical composition points of the currently used alum clay such as laterite, alumina, bauxite and the like. The standard samples are used for testing the quality of alum clay products, performing evaluation and unified measurement test on a calibration and measuring method of a measuring instrument, performing production control analysis on the products, and evaluating the technical levels of laboratories and analysis staff; and meanwhile, the standard samples are also applicable to the evaluation and arbitration of such products in external technical exchange and trading.

Owner:山东省冶金科学研究院有限公司

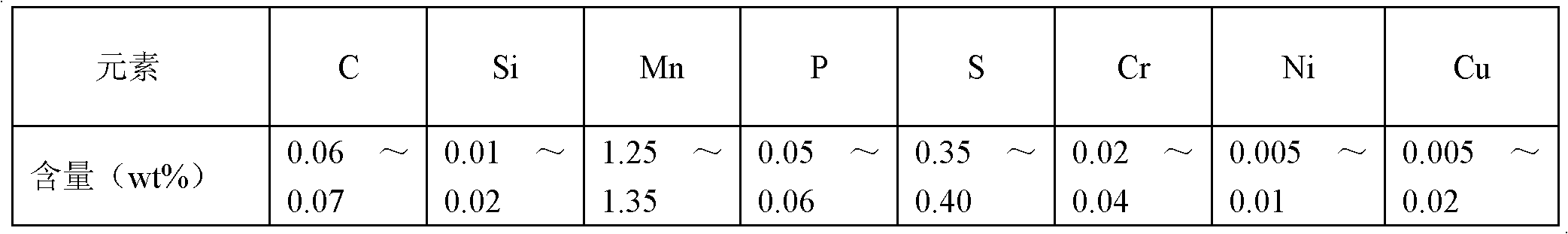

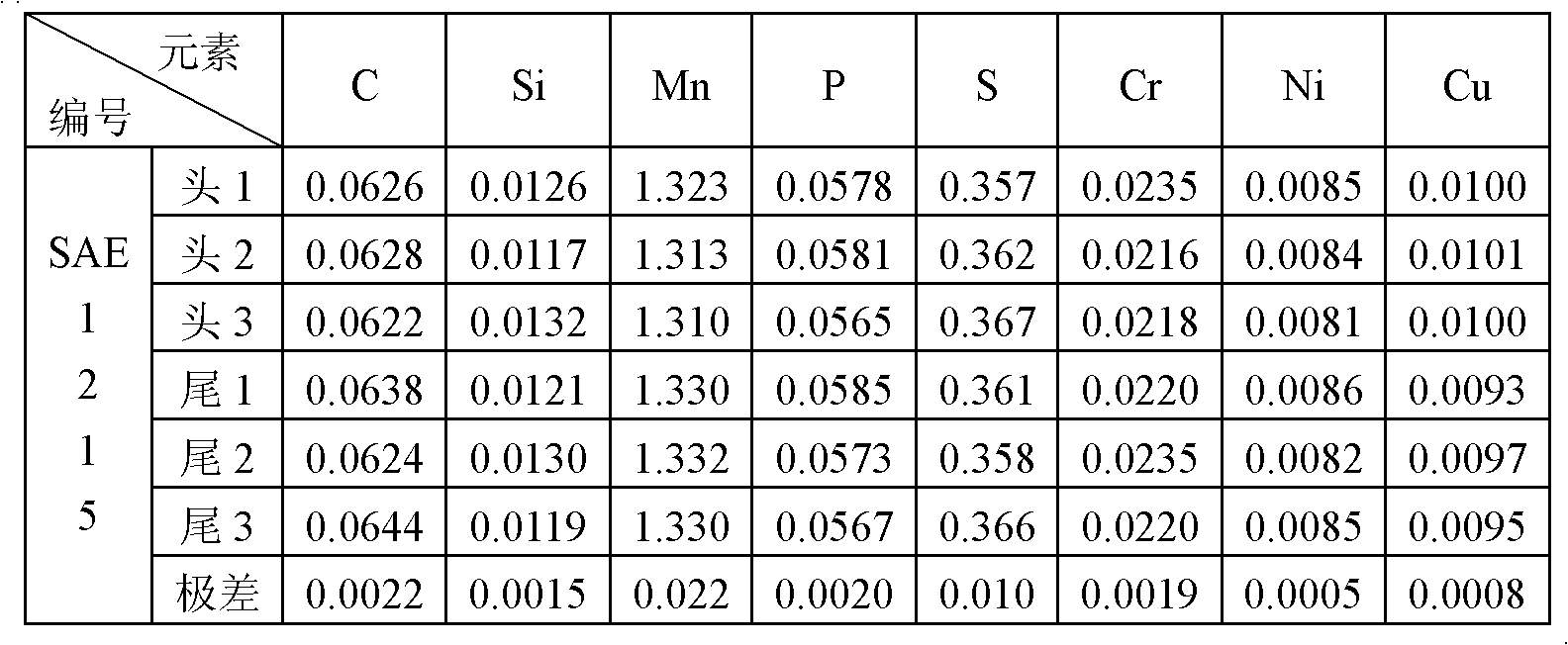

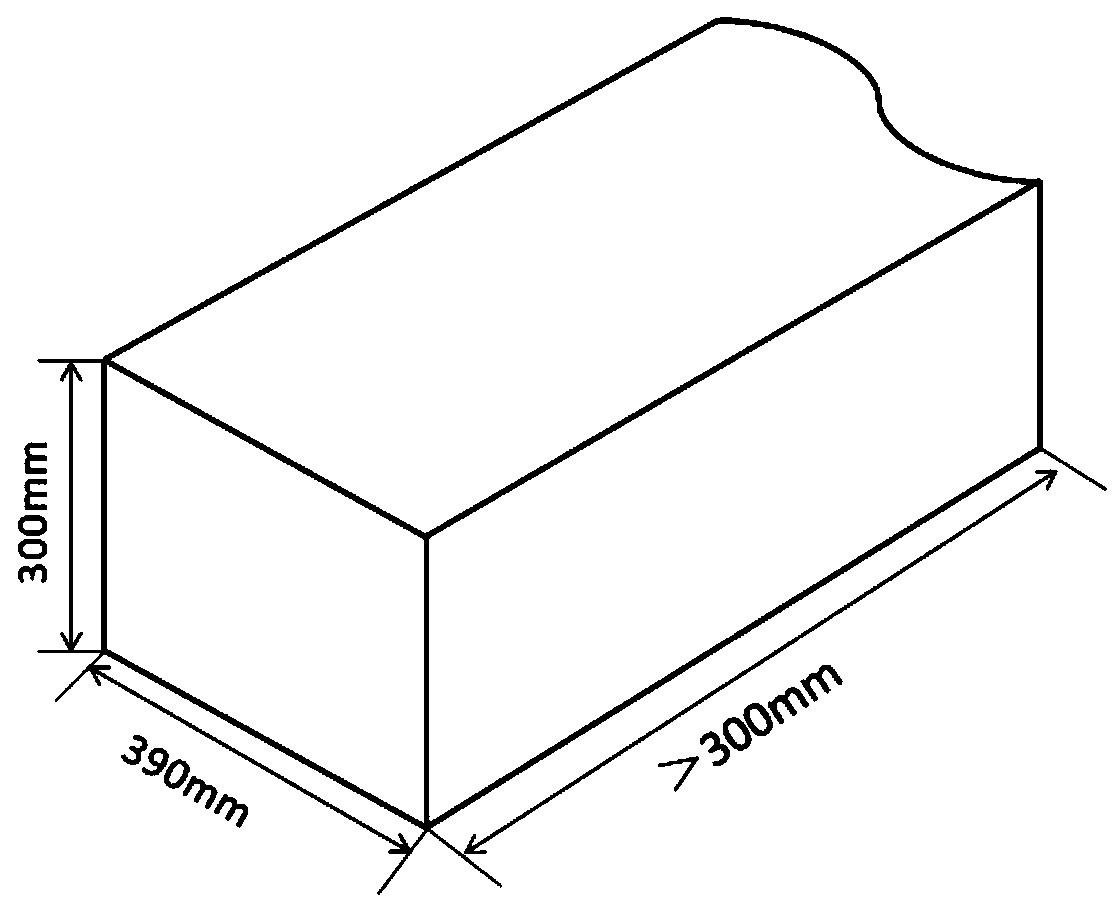

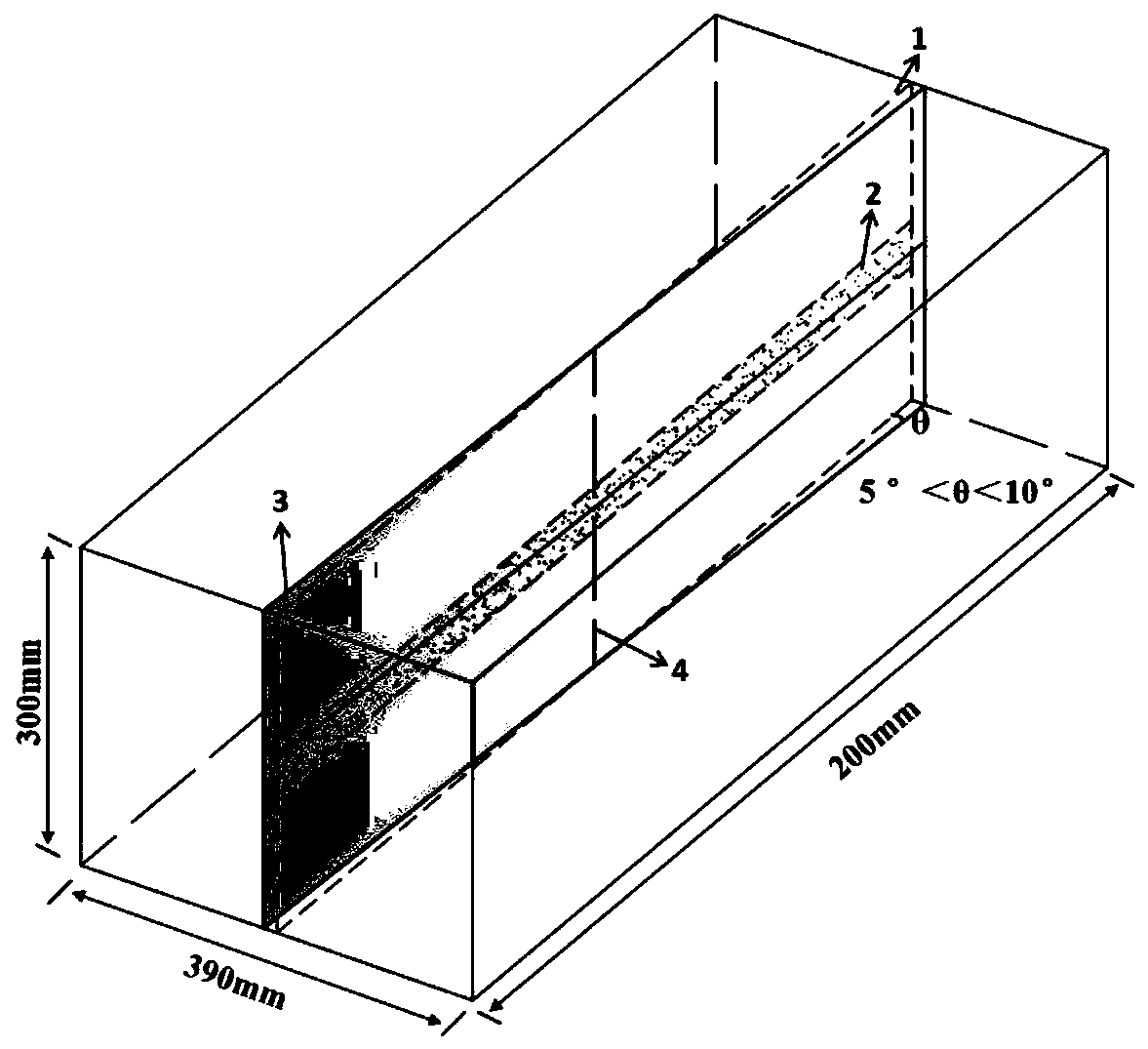

Standard sample for spectral analysis of free cutting steel SAE1215

InactiveCN102607906AImprove uniformityAccurate valuePreparing sample for investigationMetallurgical assaySpectral analysis

The invention discloses a standard sample for spectral analysis of free cutting steel SAE1215, belonging to the technical field of new materials and metallurgical analysis. Specification of the standard sample is a cylinder of phi 40 mm * 40 mm, the standard sample comprises iron which is matrix ingredient, alloy elements consisting of 0.06-0.07% of C by weight, 0.01-0.02% of Si by weight, 1.25-1.35% of Mn by weight, 0.05-0.06% of P by weight, 0.35-0.40% of S by weight, 0.02-0.04% of Cr by weight, 0.005-0.01% of Ni by weight and 0.005-0.02% of Cu by weight, and less than 0.05 of the other impurity elements by weight. The standard sample is featured with good uniformity, accurate measurement value, good stability and convenience, and is capable of meeting demands on calibration and test for spectrometer, so that the standard sample is a better material standard for measuring free cutting steel SAE1215.

Owner:山东省冶金科学研究院有限公司

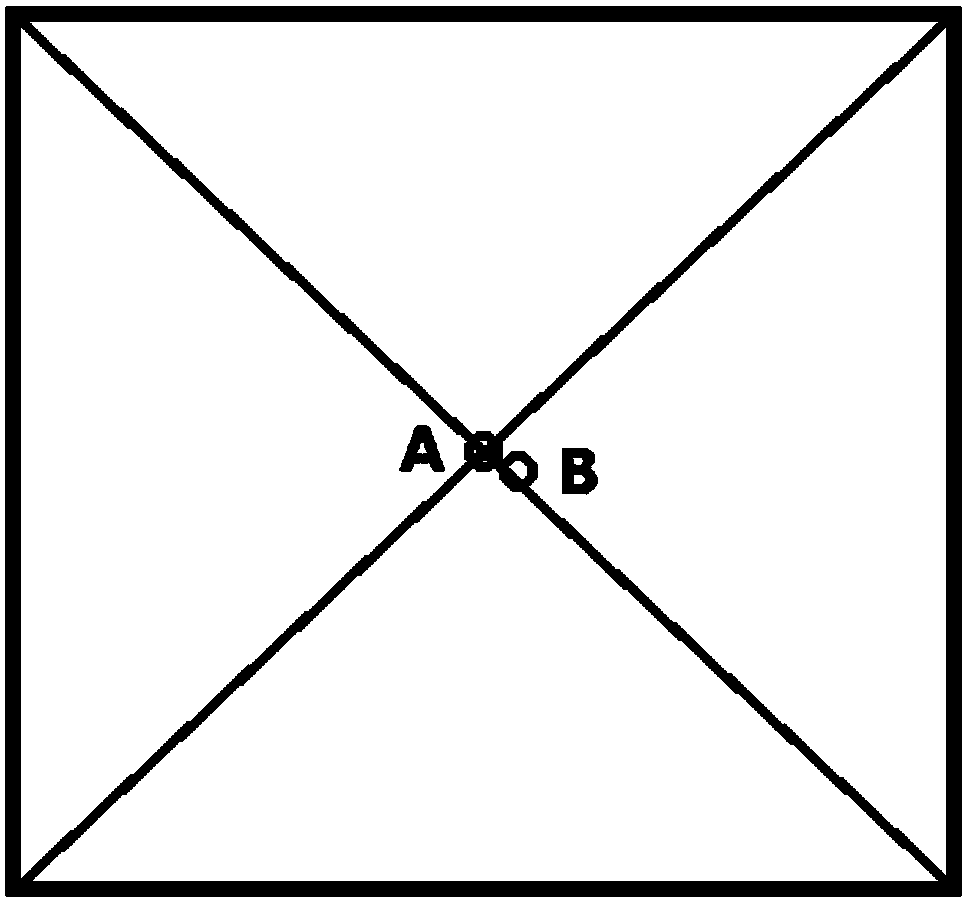

Square billet center macrosegregation analysis method

ActiveCN111537691AImprove representationReduce biasWithdrawing sample devicesPreparing sample for investigationMetallurgical assayVertical plane

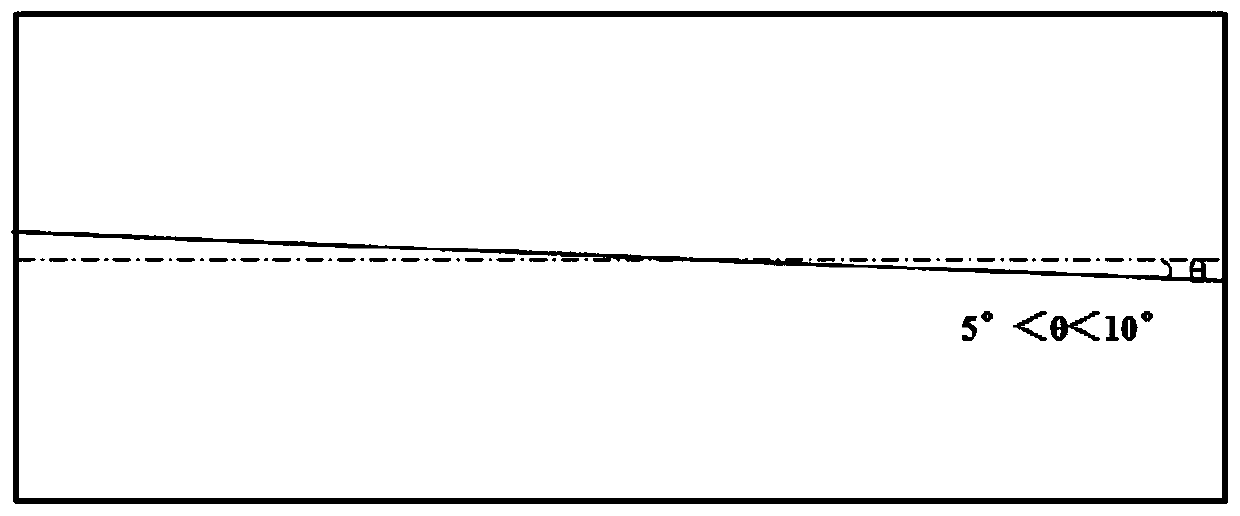

The invention discloses a square billet center macrosegregation analysis method, and belongs to the technical field of metallurgical analysis. The method comprises the following steps: carrying out sampling, sample processing, macroscopic examination and drilling chemical analysis on a square billet continuous casting billet by using a vertical plane forming an included angle with the central longitudinal section. According to the invention, the vertical sample cutting method forming a certain included angle with the central longitudinal section is creatively applied to the sample preparationmethod in the center macrosegregation analysis process of the square billet continuous casting billet; the deviation of a casting blank center segregation analysis result caused by a sample cutting position factor can be reduced, the accuracy of casting blank center segregation condition analysis is improved, and accurate reference information is provided for casting blank quality monitoring or process improvement.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Method for determining contents of silicon dioxide, aluminum sesquioxide and magnesium oxide in carbide slag

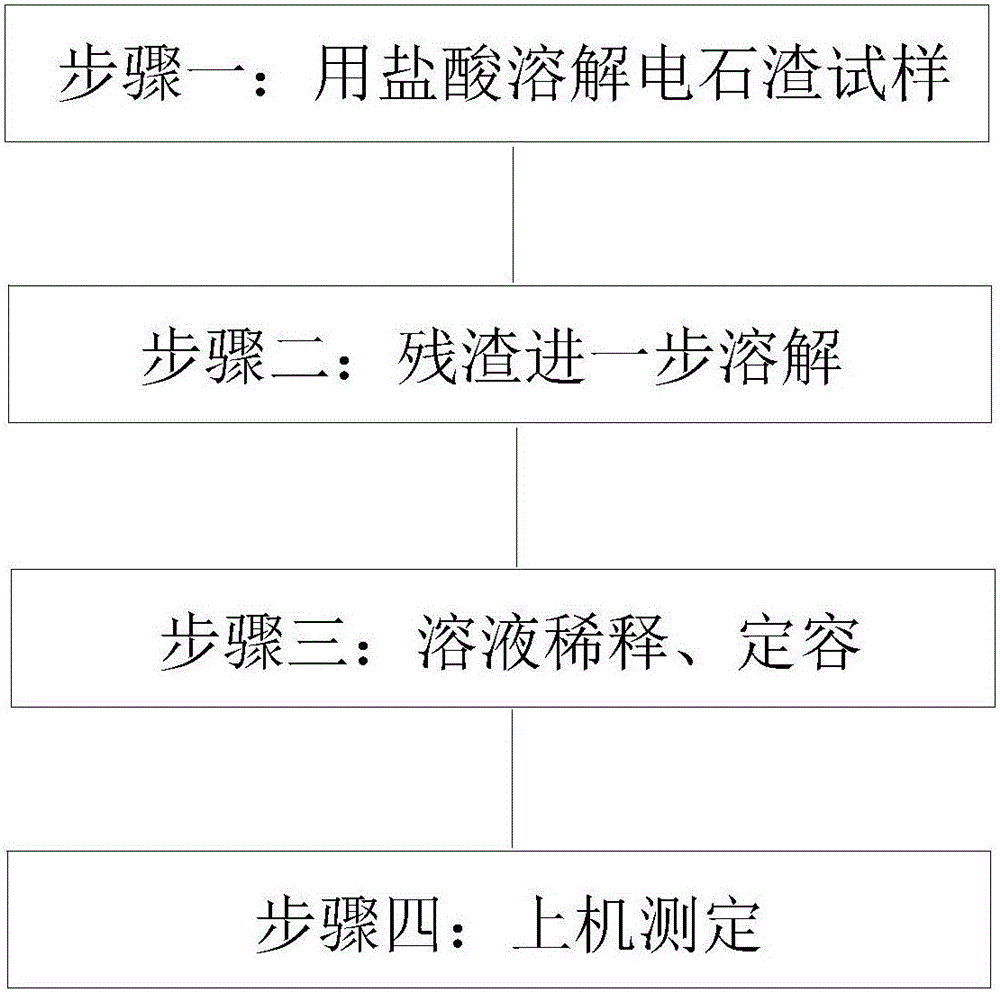

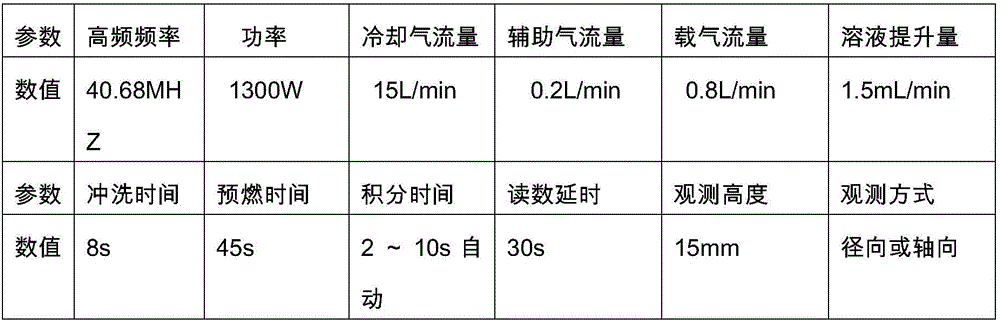

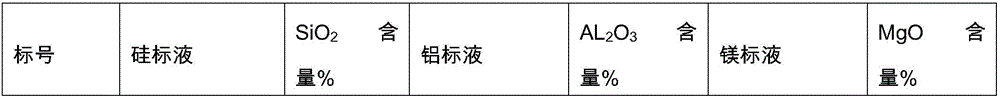

The invention discloses a method for measuring the content of silicon dioxide, aluminum oxide and magnesium oxide in carbide slag, belonging to the technical field of metallurgical analysis methods. The purpose is to provide a detection method with low pollution, fast speed, low detection limit and saving manpower and material cost for measuring the content of silicon dioxide, aluminum oxide and magnesium oxide in carbide slag. The main method flow is: use hydrochloric acid ( 1+1) Dissolve most of the samples, filter the solution, wash the residue and transfer the solution to a 250mL volumetric flask, dilute to the mark with water, and shake well. The plasma spectrometer is used for measurement, and the content of the analytical elements in the sample is obtained according to the calibration curve prepared by the standard solution. The determination method of the invention can be used for rapid determination of the content of silicon dioxide, aluminum oxide and magnesium oxide in carbide slag.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

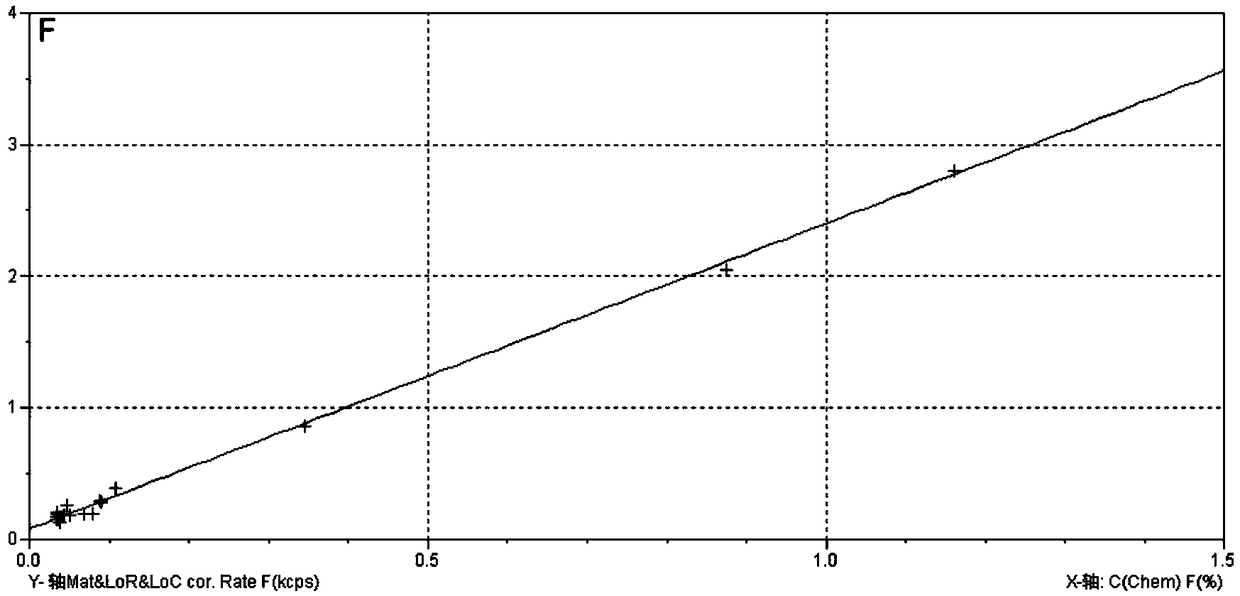

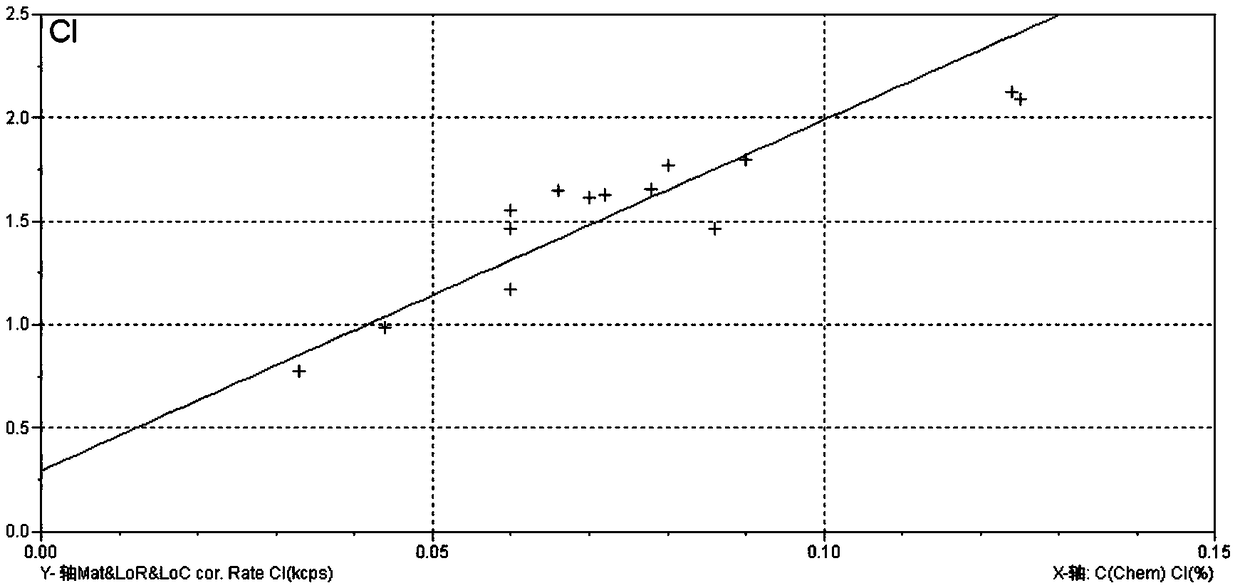

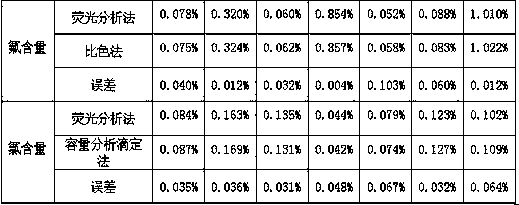

Method for analyzing fluorine and chlorine in smelting dust through X-ray fluorescence spectroscopy

InactiveCN109030528AReduce consumptionAvoid it happening againMaterial analysis using wave/particle radiationAnalysis dataX-ray

The invention relates to a method for analyzing fluorine and chlorine in smelting dust through X-ray fluorescence spectroscopy, and belongs to the technical field of metallurgical analysis. The methodcomprises the following steps of 1 analysis specimen preparation; 2 standard sample and monitoring sample preparation; 3 measurement condition selection; 4 standard curve drawing; 5 drift correction;and 6 sample analysis. According to the method, an X-ray fluorescence spectrometer is creatively applied in detection on fluorine and chlorine in smelting gas, and the test rate of fluorine and chlorine in the smelting gas is greatly increased; only a small amount of boric acid and binder is needed, consumption of chemicals is reduced, and compared with an existing analysis method, generation ofwaste acid, waste water and the like in the analysis process is avoided, and not only is manpower saved, but also pollution is reduced; and in addition, data of the adopted method is accurate and reliable, analysis data is quickly and accurately provided for the metal smelting process, and therefore the method is more beneficial to production control.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

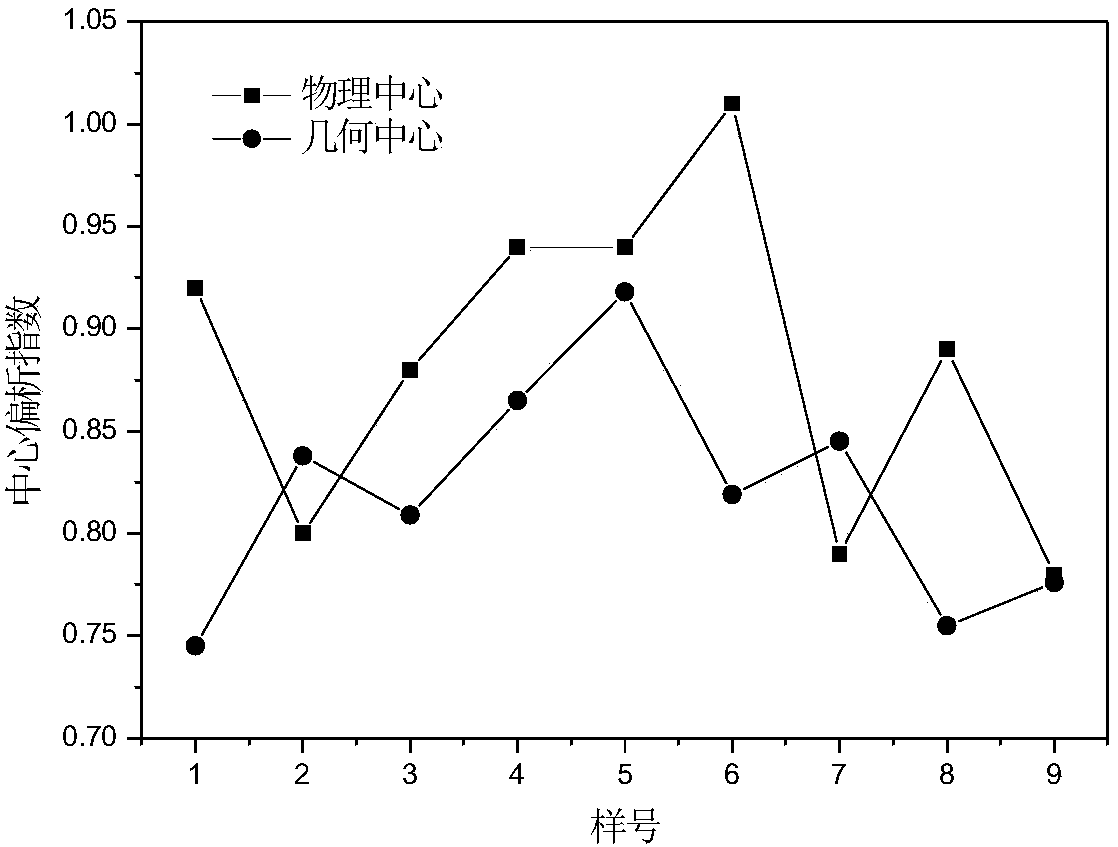

A Quantitative Evaluation Method for Center Macro Segregation of Billets

ActiveCN106018728BAvoid bias in segregation analysis resultsTesting metalsAcid etchingMetallurgical assay

A quantitative evaluating method for square billet center macrosegregation belongs to the technical field of metallurgical analysis. The quantitative evaluating method comprises the steps of finding out a solidifying physical center of a casting blank through a hot acid etching method; taking samples of 5 points through drilling, taking 3-5g per point and measuring the soluble element concentration of different positions to serve as evaluating basis of macrosegregation; using a data analyzing method to evaluate a center segregation average value and standard deviation according to segregation data of different samples and reflecting the quality controlling level and the controlling stability in a billet. The quantitative evaluating method has the advantages of accurately finding out the actual solidifying physical center of the casting blank, avoiding casting blank center segregation analysis result deviation caused by sampling position factors and providing accurate reference for quality monitoring or technique improvement.

Owner:SHOUGANG CORPORATION

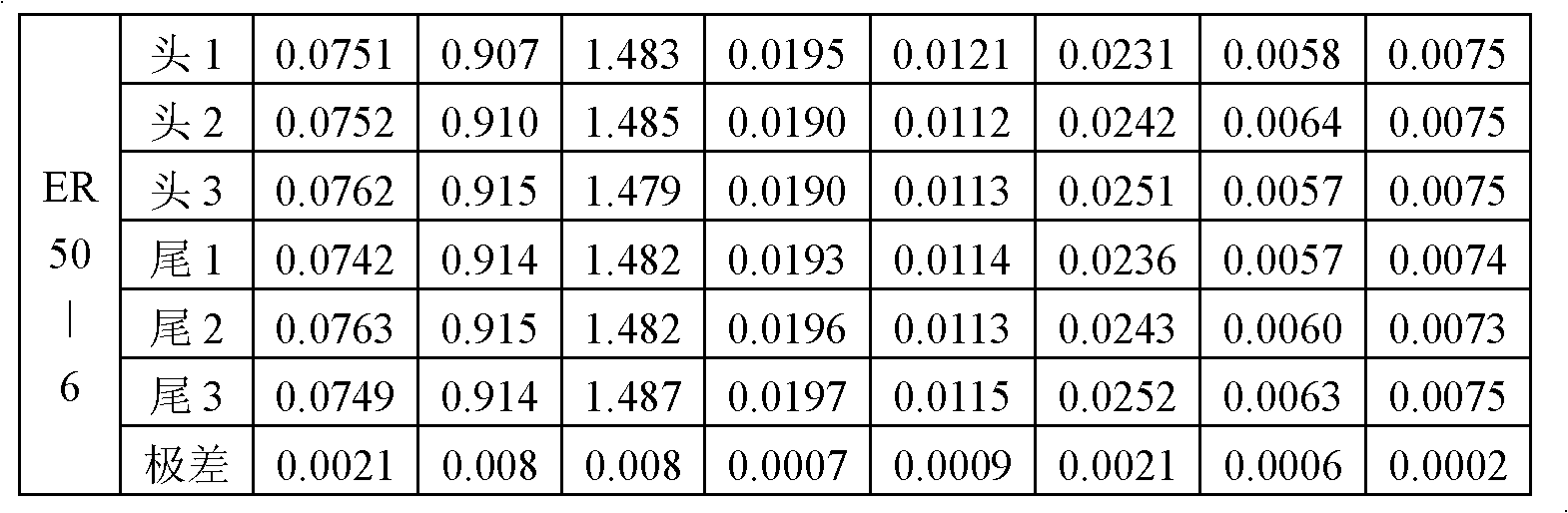

Standard sample for spectroscopic analysis of welding wire steel ER50-6

InactiveCN102590102AImprove uniformityAccurate valuePreparing sample for investigationAnalysis by material excitationSpectrographNew materials

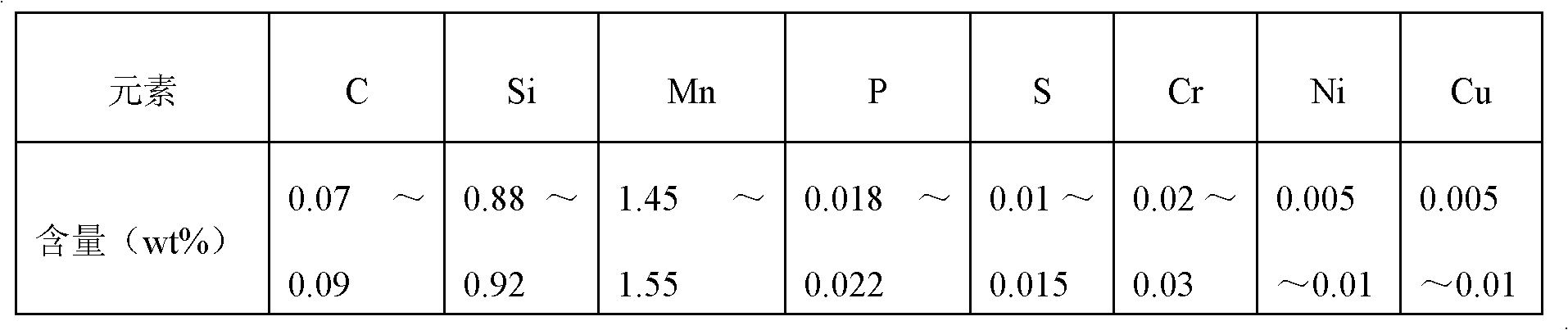

The invention discloses a standard sample for spectroscopic analysis of a welding wire steel ER50-6, and belongs to the technical fields of new materials and metallurgical analysis. The standard sample is a cylinder the standard of which is phi 40 mm* phi 40mm, and comprises the following constituents: iron serving as a matrix constituent; and alloying element constituents: 0.07-0.09% of C, 0.88-0.92% of Si, 1.45-1.55% of Mn, 0.018-0.022% of P, 0.01-0.015% of S, 0.02-0.03% of Cr, 0.005-0.01% of Ni,0.005-0.01% of Cu, and the contents of other impurity elements are all less than 0.005%. The standard sample has the advantages of good uniformity, exact magnitude and good stability, and is convenient to use; can meet job requirements of a spectrograph such as calibration and test, and provides a good material standard for measuring free cutting steel SAE1215.

Owner:山东省冶金科学研究院有限公司

Vanadium-nitrogen alloy standard sample for chemical analysis and preparation method thereof

ActiveCN103344472AEasy to useImprove uniformityPreparing sample for investigationMetallurgical assayGranularity

The invention discloses a vanadium-nitrogen alloy standard sample for chemical analysis and a preparation method of the vanadium-nitrogen alloy standard sample, belonging to the technical field of metallurgical analysis. The standard sample is a powdery solid substance with the granularity of less than or equal to 125 microns and comprises the following chemical elements in percentage by weight: 70-80wt% of V, 16-18wt% of N, 0.01-0.10wt% of Al, 0.01-0.10wt% of Cr, 0.001-0.005wt% of Mn, 0.001-0.005wt% of Ni, 0.01-0.1wt% of Si, less than or equal to 0.01 of Cu, 0.002-0.05wt% of Ca, 3-8wt% of C, 0.001-0.005wt% of S and 0.001-0.01wt% of P. The standard sample disclosed by the invention has good uniformity, is accurate in quantity value and convenient to use and can be used for solving the problem that no vanadium-nitrogen alloy determination standards are provided for enterprises.

Owner:山东省冶金科学研究院有限公司

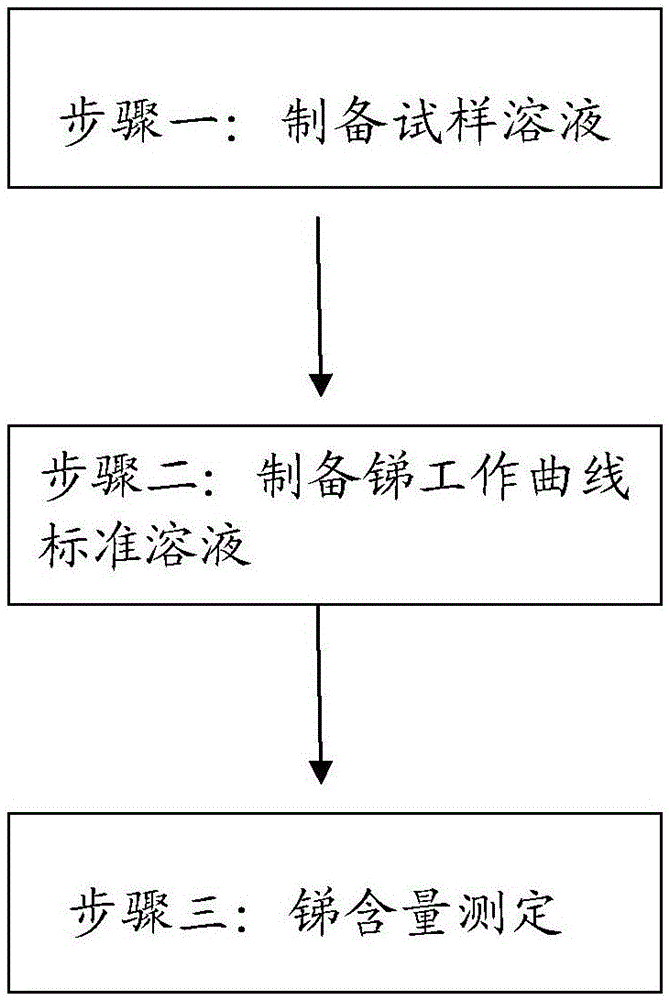

Method for measuring content of stibium in steel

InactiveCN105044197ALess distracting factorsLow limit of determinationMaterial analysis by electric/magnetic meansMetallurgical assayInterference factor

The invention discloses a method for measuring the content of stibium in steel and belongs to the field of metallurgical analysis methods. The method for measuring the content of stibium in steel aims at overcoming the defects that in the prior art, chemical reagents used for measuring the content of stibium in steel are more, harm is caused to the environment and the human body, interference factors are more, and the analysis speed is low. The method includes the following steps that firstly, a sample solution is prepared; secondly, a stibium working curve standard solution is prepared; thirdly, the content of stibium is measured. Chemical reagents used in the method are less, no harm is caused to the environment and testers, interference factors are less, a sample can be directly loaded on a machine to be measured after dissolving and being kept at constant volume, operation is easy, convenient and quick, the measuring range is 0.00001%-0.010%, the lower measuring limit is low, accuracy is high, and the method is suitable for measuring the content of stibium in steel in scientific research and production.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

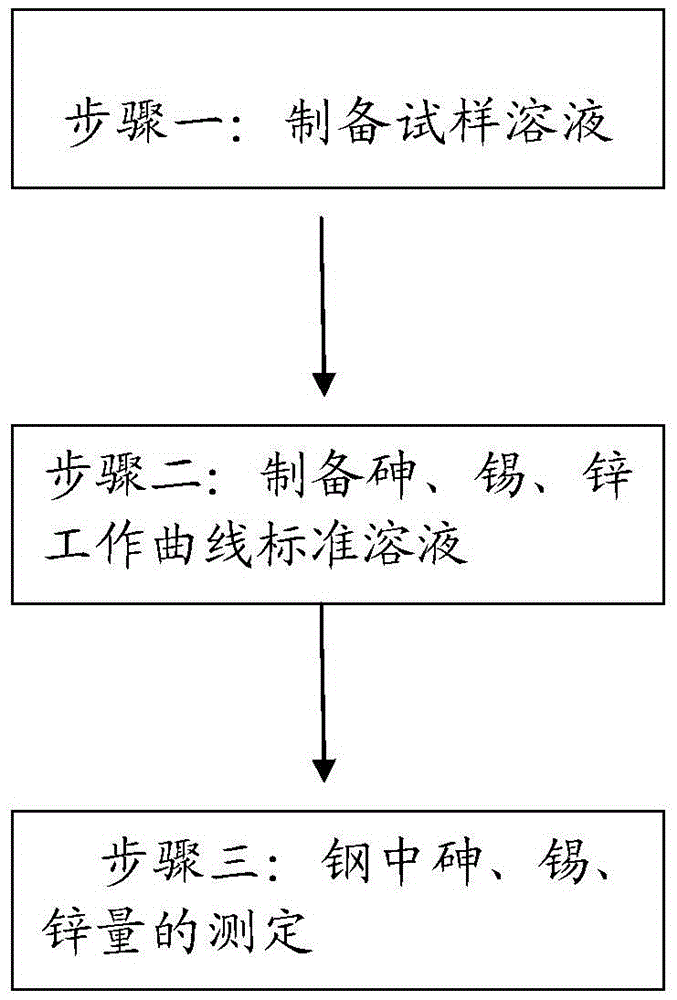

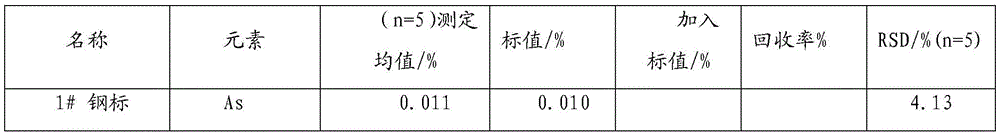

Determination method for content of arsenic, tin and zinc in steel

InactiveCN105548330ALow detection limitAnalysis method is simple and fastPreparing sample for investigationMaterial analysis by electric/magnetic meansMetallurgical assayInterference factor

Belonging to the field of metallurgical analysis methods, the invention discloses a determination method for the content of arsenic, tin and zinc in steel, and aims to solve the disadvantages of unable simultaneous determination of the content of arsenic, tin and zinc three elements in steel, a lot of use of chemical reagents, harm to the environment and human body, many interference factors, slow analysis speed, and low accuracy in the prior art. The determination method comprises the steps of: 1. preparation of a sample solution, 2. preparation of an arsenic, tin, zinc working curve standard solution, and 3. determination of the content of arsenic, tin and zinc in steel. The method provided by the invention has the characteristics of low detection limit of 0.10ng / ml, simple and fast analysis method, few reagent, little interference, fast analysis speed, good precision, and high accuracy, and is suitable for simultaneous determination of the content of arsenic, tin and zinc three elements in steel.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

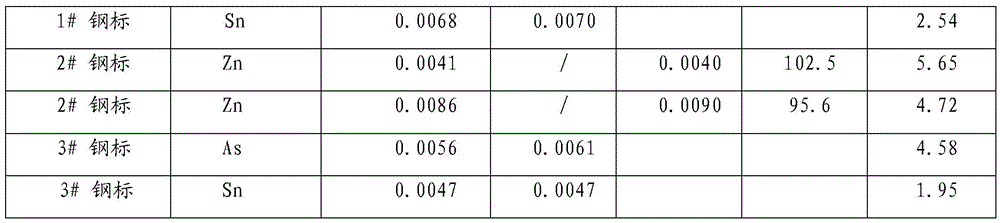

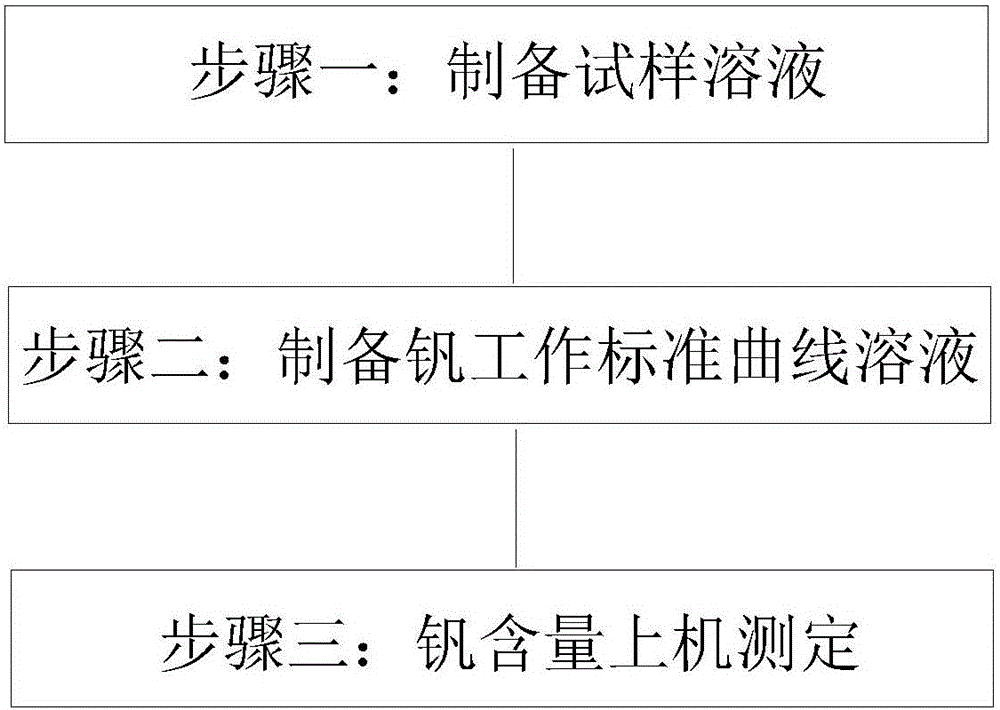

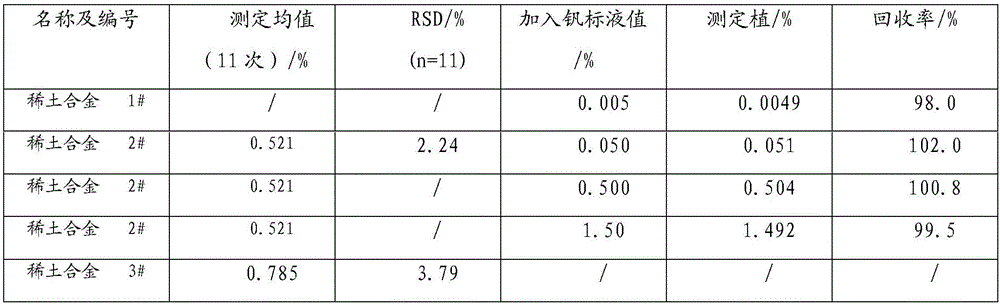

Method for measuring content of vanadium in rare earth alloy

InactiveCN105738349AAnalysis method is simple and fastFast analysisPreparing sample for investigationAnalysis by thermal excitationMetallurgical assayRare earth

The invention discloses a method for measuring the content of vanadium in rare earth alloy, and belongs to the technical field of metallurgical analysis methods. The method aims at solving the problem that a suitable method for measuring the content of the vanadium in the rare earth alloy does not exist. The method includes the following steps of 1, preparing sample solutions; 2, preparing working standard curve solutions of the vanadium; 3, online measuring the content of the vanadium. The method is rapid is analysis speed, good in precision degree and high in accuracy degree, and the requirement of scientific research and the requirement of production can be completely met; the method is suitable for rapidly measuring the content of the vanadium in the rare earth alloy.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for Determination of Composition of Nickel-base Superalloy Steel Using Photoelectric Direct Reading Spectrometer

ActiveCN103575707BSimplify the analysis procedureShorten the analysis cycleAnalysis by material excitationMetallurgical assayOpto electronic

The invention belongs to the technical field of metallurgical analysis and relates to an improvement on a method for analyzing components of nickel-based high-temperature alloy steel. A method for measuring the components of the nickel-based high-temperature alloy steel comprises the following steps: determining an analysis condition; preparing an analysis sample; making a calibration curve; analyzing the sample; calculating the analysis result. The invention provides a method for measuring components of nickel-based high-temperature alloy steel by using a photoelectric direct reading spectrometer, so that analysis equipment is reduced, analysis procedures are simplified, analysis period is shortened, and analysis cost is reduced.

Owner:AECC AVIATION POWER CO LTD

Set of alum clay standard samples and preparation method thereof

ActiveCN103278362BWide coverageReasonable layoutPreparing sample for investigationMeasurement testMetallurgical assay

The invention discloses a set of alum clay standard samples, belonging to the technical fields of new materials and metallurgical analysis. The set comprises five samples of which the Al2O3 contents are respectively 45-50wt%, 60-65wt%, 70-75wt%, 80-85wt% and 85-90wt%; and the five samples are simultaneously used for determining the contents of 12 components such as Al2O3, CaO, MgO, P2O5, Fe2O3, TiO2, SiO2, K2O, Na2O and the like. The set of alum clay standard samples covers the typical composition points of the currently used alum clay such as laterite, alumina, bauxite and the like. The standard samples are used for testing the quality of alum clay products, performing evaluation and unified measurement test on a calibration and measuring method of a measuring instrument, performing production control analysis on the products, and evaluating the technical levels of laboratories and analysis staff; and meanwhile, the standard samples are also applicable to the evaluation and arbitration of such products in external technical exchange and trading.

Owner:山东省冶金科学研究院有限公司

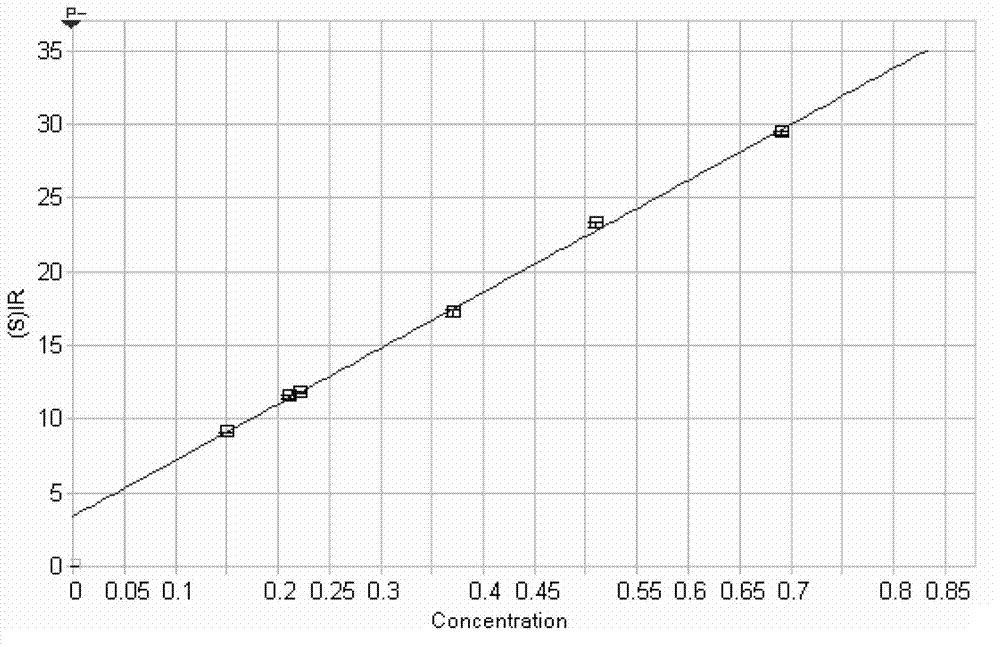

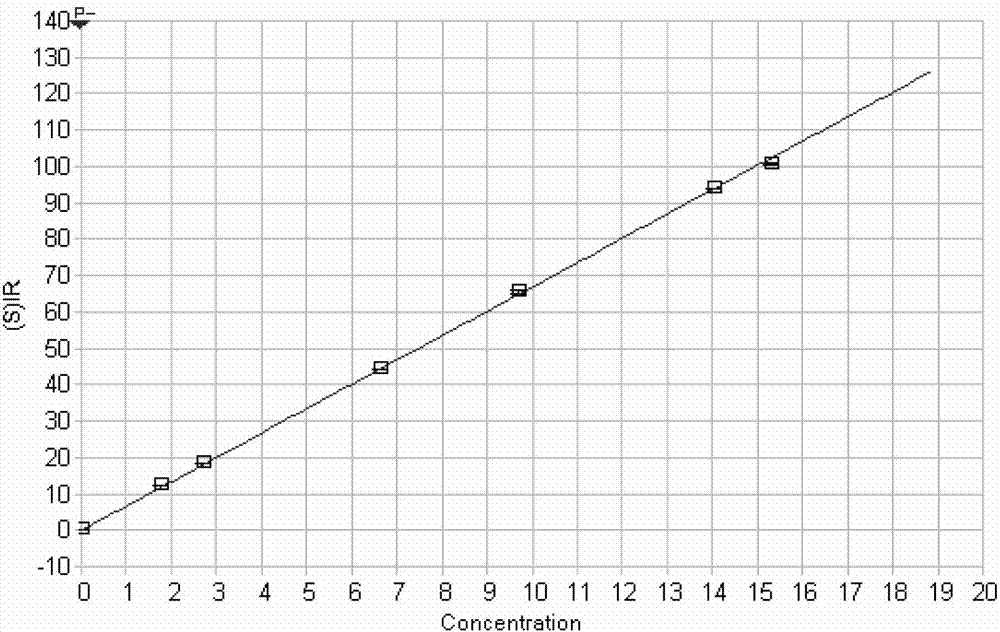

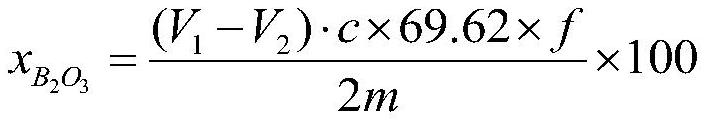

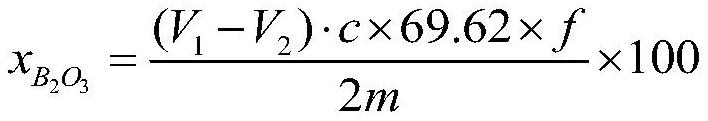

Comparison detection method for measuring content of diboron trioxide in metallurgical slag system

PendingCN114252440ARealize accurate detectionEliminate distractionsChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorMetallurgical slagMetallurgical assay

The invention belongs to the technical field of metallurgical analysis, and provides a contrast detection method for determining the content of diboron trioxide in a metallurgical slag system. Aiming at the special component characteristics of the metallurgical slag system, the invention provides a contrast detection analysis method to eliminate the interference of amphoteric elements and other factors on the titration result in the titration process so as to realize the accurate detection of the content of diboron trioxide in the metallurgical slag system. The method does not need to introduce other reagents, is relatively low in cost, simple, convenient and rapid to operate and accurate and reliable in determination result, and provides a way for determining the content of the diboron trioxide in the metallurgical slag system.

Owner:NORTHEASTERN UNIV

Analysis method for determining primary and secondary components in composite vanadium-nitrogen alloy

InactiveCN110823868AReduce varietyReduce dosagePreparing sample for investigationAnalysis by thermal excitationMetallurgical assayCrucible

The invention discloses an analysis method for determining primary and secondary components in composite vanadium-nitrogen alloy. According to the analysis method, a powdery composite vanadium-nitrogen sample and a sodium peroxide flux are added into a corundum crucible, a high-temperature muffle furnace is used for melting, hydrochloric acid is used for removal, a stable solution is formed and used for an ICP-AES method. The method has the advantages of being rapid, accurate and reliable, can help improving the automatic degree of metallurgical analysis instruments, and can be popularized tocomposite vanadium-nitrogen alloy acceptance check of all steel plants and process control of composite vanadium-nitrogen alloy production enterprises in the metallurgical industry.

Owner:NANJING IRON & STEEL CO LTD

Method for quantitative analysis of continuous casting sheet billet gross segregation by image analysis method

ActiveCN101344490BObservation and analysis of carbon content distributionAccurate observationOptically investigating flaws/contaminationContent distributionMetallurgical assay

The invention discloses a gross segregation quantitative analyzing method of a continuous casting sheet billet that adopts an image analyzing method, which belongs to the technical field of metallurgical analysis, and comprises the following steps: the structural content change of the sheet billet in the thickness direction is obtained through metalloid image analysis, the structural volume percent is converted into the mole percent through crystal lattice volume computation, a binary phase diagram of the carbon weight percent and the austenite structure mole percent is obtained through thermodynamic computation, and the structural mole percent in each analyzed region is converted into the carbon weight percent. The gross segregation quantitative analyzing method has the advantages that the analyzing method that combines the metalloid structure image analysis method with the thermodynamic computation is adopted for analyzing the gross segregation of the sheet billet, thus quantitatively analyzing the carbon gross segregation in the sheet billet, more precisely observing and analyzing the carbon content distribution in the sheet billet, and consequently providing a novel tool for examining and analyzing the gross segregation of the sheet billet.

Owner:SHOUGANG CORPORATION

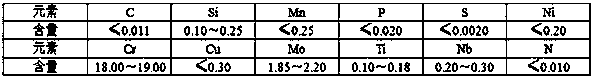

A preparation method of ultrapure ferritic stainless steel spectral standard sample

ActiveCN109596531BImprove uniformityImprove stabilityFoundry mouldsColor/spectral properties measurementsMetallurgical assayChemical composition

The invention discloses a method for preparing an ultra-pure ferritic stainless steel spectral standard sample, belonging to the technical field of metallurgical sample detection. The method includes the following steps: billet mold design → billet mold baking preheating → composition design → furnace material selection → vacuum induction furnace smelting → demoulding → physical performance inspection → chemical composition and segregation preliminary inspection → casting blank sample sampling → Qualified inspection of chemical composition of samples → initial inspection of uniformity → segregation inspection → spectral block processing. In strict accordance with the requirements of GB / T15000 "Guidelines for International Standard Sample Work" and YB / T082‑1996 "Technical Specifications for International Standard Samples for Metallurgical Analysis", the invention prepares ultra-pure ferritic stainless steel with good uniformity and stability The spectral standard sample can replace the standard sample of non-similar stainless steel for comparison and calibration of direct reading spectrometer and X-ray fluorescence spectrometer, which solves the problem of detection deviation caused by matrix effect in the inspection of ultra-pure ferritic stainless steel samples, thus To achieve precise control of process quality.

Owner:JIUQUAN IRON & STEEL GRP

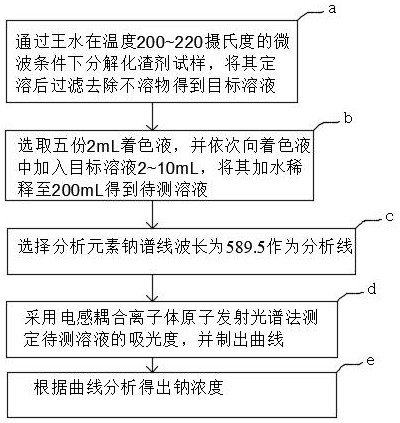

Method for measuring sodium content in slagging agent

PendingCN113406060AFast analysisWide dynamic linear rangePreparing sample for investigationAnalysis by thermal excitationMetallurgical assayPotassium ions

The invention provides a method for measuring the content of sodium in a slagging agent. The method comprises the following steps: a, decomposing a slag melting agent sample by using aqua regia under a microwave condition at the temperature of 200-220 DEG C, carrying out constant volume, filtering to remove insoluble substances to obtain a target solution, and adding a potassium ion solution with the content of 0.01 mg / mL into the target solution; b, selecting five parts of 2mL coloring liquid, sequentially adding 2-10mL of target solution into the coloring liquid, and adding water to dilute the coloring liquid to 200mL to obtain a to-be-detected solution; c, selecting an analysis element sodium with the spectral line wavelength of 589.5 as an analysis line; d, measuring the absorbance of the solution to be measured by adopting inductively coupled plasma atomic emission spectrometry, and making a curve graph; e, analyzing according to the curve graph to obtain the sodium concentration. The method is high in analysis speed, wide in dynamic linear range and higher in precision, and can be widely applied to modern metallurgical analysis.

Owner:SHANDONG IRON & STEEL GRP YONGFENG LINGANG CO LTD

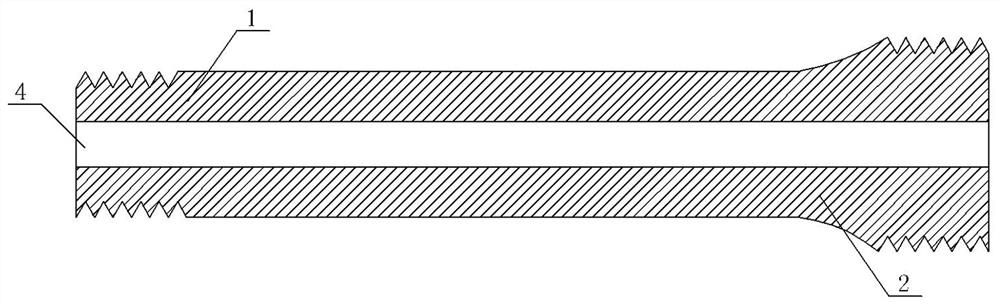

A device and method for ultrasonically inspecting the grain size of high-temperature fasteners in thermal power plants

InactiveCN108287195BReduce in quantityQuick checkAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgical assayPower station

The invention discloses a device and method for using ultrasonic waves to test the thermal power plant high temperature fastening part grain size, and relates to the technical field of metallurgical analysis. The device comprises an ultrasonic wave flaw detector and a bolt test block, the bolt test block comprises a comparison bolt test block of each grain size, the comparison bolt test block comprises a rigid end bolt and a flexible end bolt, and the rigid end bolt and the flexible end blot are integrally connected; the ultrasonic wave flaw detector comprises a probe. Through the ultrasonic wave flaw detector and the bolt test block, the grain size of a bolt to be tested is quickly detected, and the device is easy to operate, high in sampling efficiency and high in operability.

Owner:郭京洋

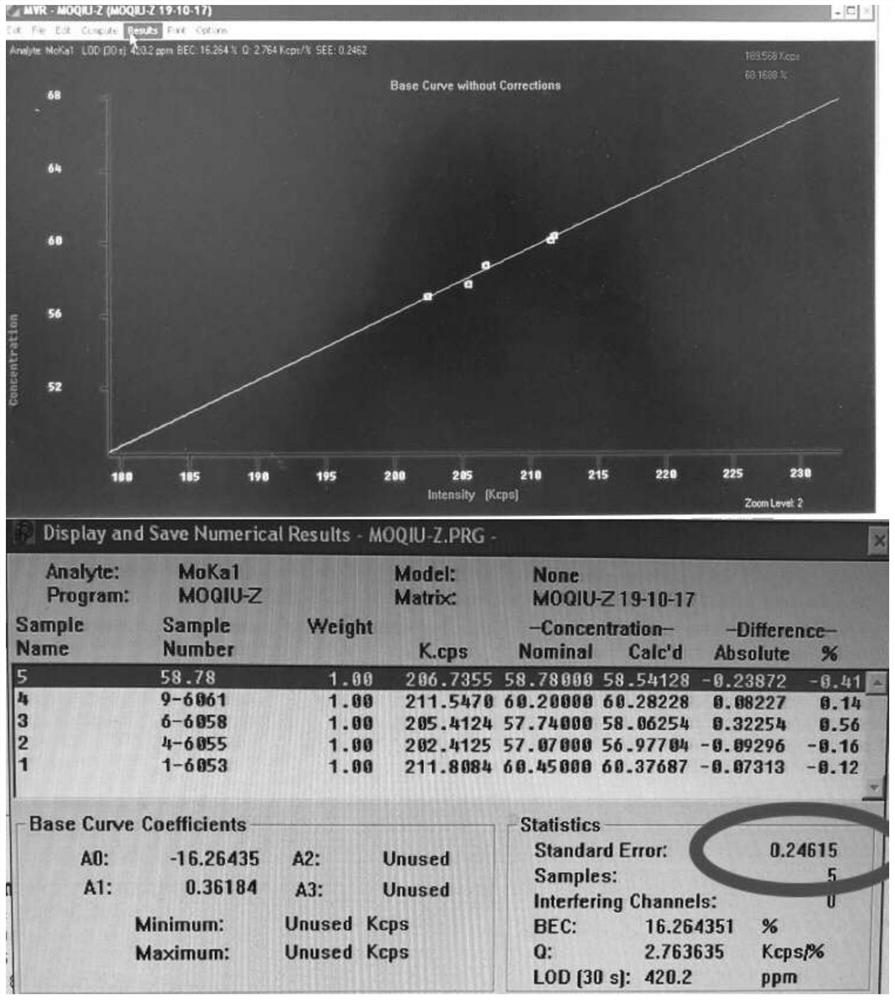

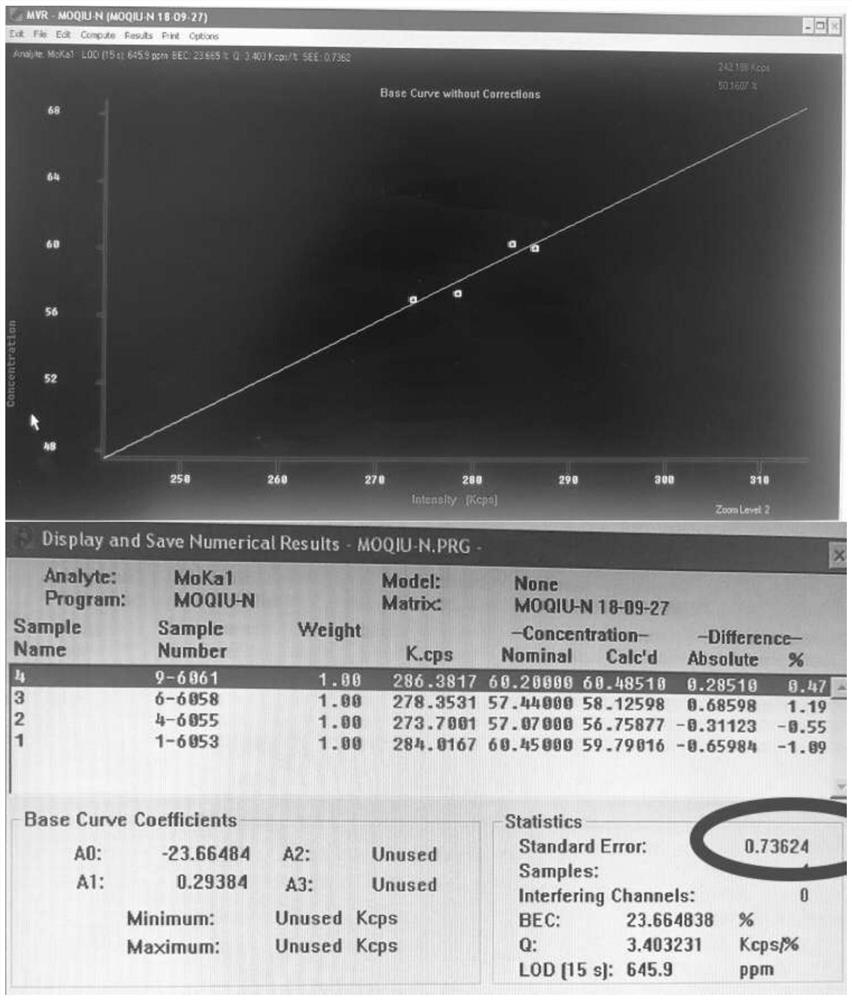

Preparation and analysis method of X-ray fluorescent fuse piece for determining molybdenum content in molybdenum oxide

PendingCN111879802AReduce usageReduce harmMaterial analysis using wave/particle radiationMetallurgical assayGlass chip

The invention discloses a preparation and analysis method of an X-ray fluorescence fuse piece for determining molybdenum content in molybdenum oxide, and relates to the technical field of metallurgical component determination and analysis, an inhibitor is added, low-temperature pre-melting is carried out under the action of the inhibitor, and then a flux and a pre-melted product are melted into astable, uniform and transparent glass sheet under a high-temperature state. Instrument analysis is adopted to replace chemical analysis, the problems that chemical analysis is serious in pollution, long in period, too high in personnel quality requirement and the like are solved, the whole analysis period is short, operation steps are few, and rapid, accurate and environment-friendly measurement is achieved. The method can be popularized and applied to production process control, acceptance check before use and the like of metallurgical production enterprises and iron and steel enterprises, and greatly promotes improvement of instrument analysis automation in the field of metallurgical analysis.

Owner:NANJING IRON & STEEL CO LTD

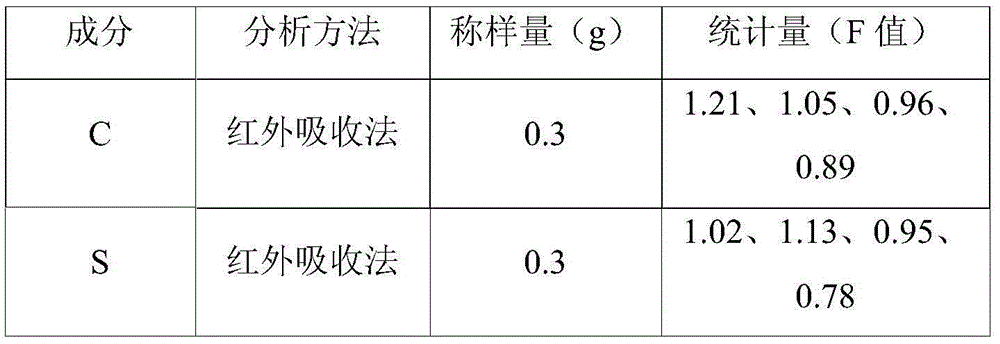

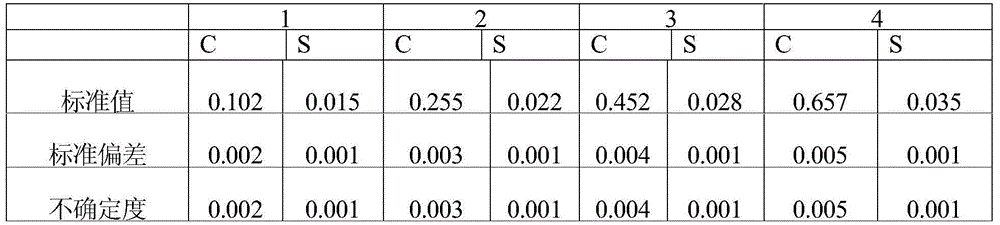

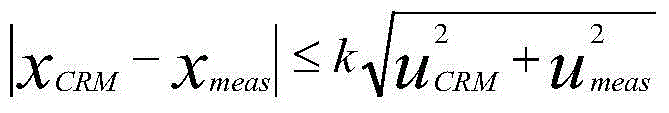

Special annular standard sample for quantitative carbon and sulfur analysis and manufacturing process of special annular standard sample

InactiveCN104458385AQuality assuranceFast processingPreparing sample for investigationChemical compositionMetallurgical assay

The invention discloses a special annular standard sample for quantitative carbon and sulfur analysis and a manufacturing process of the special annular standard sample and belongs to the technical field of metallurgical analysis. The special annular standard sample for quantitative carbon and sulfur analysis is a steel material or cast iron or pig iron comprising the following chemical components of, by weight, 0.10% to 0.75% of C and 0.010% to 0.035% of S. The special annular standard sample for quantitative carbon and sulfur analysis is annular. A traditional special chip-shaped standard sample for carbon and sulfur analysis is changed into the special annular standard sample for carbon and sulfur analysis, and the special annular standard sample for quantitative carbon and sulfur analysis is short in machining process, not prone to pollution and capable of guaranteeing evenness, so that the quality of the standard sample is guaranteed, and the detection speed is increased.

Owner:山东省冶金科学研究院有限公司

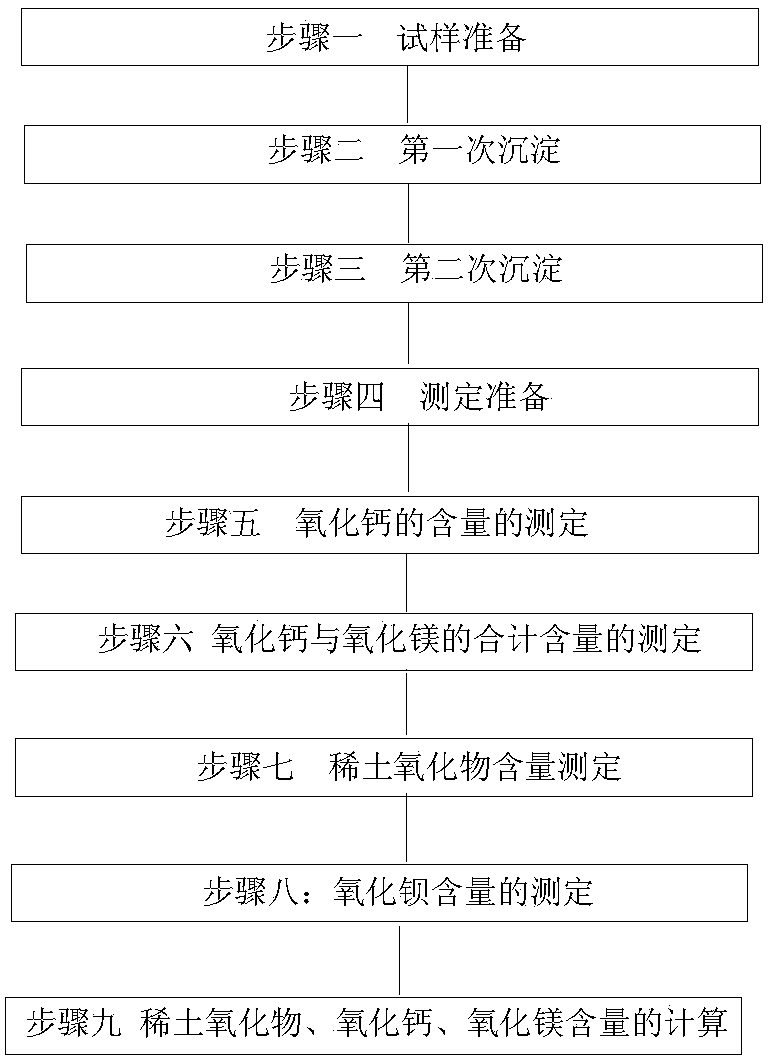

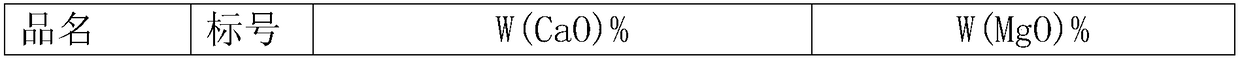

A method for continuous determination of rare earth oxide, calcium oxide, magnesium oxide and barium oxide in rare earth concentrate

InactiveCN106053718BRealize continuous measurementEasy to masterWeighing by removing componentChemical analysis using titrationMetallurgical assayEngineering

The invention discloses a method for continuously measuring rare earth oxide, calcium oxide, magnesium oxide and barium oxide in a rare earth ore concentrate, and belongs to the technical field of metallurgical analysis methods. The invention aims at providing a method for continuously measuring rare earth oxide, calcium oxide, magnesium oxide and barium oxide in the rare earth ore concentrate with short analysis time, accurate measurement result, and low detection cost. The method disclosed by the invention comprises the following steps: 1, preparing a sample; 2, implementing primary sedimentation; 3, implementing secondary sedimentation; 4, preparing measurement; 5, measuring the content of calcium oxide; 6, measuring the total content of calcium oxide and magnesium oxide; 7, measuring the content of rare earth oxide; 8, measuring the content of barium oxide; 9, calculating the contents of rare earth oxide, calcium oxide, magnesium oxide and barium oxide. The method is easy to master, is high in result accuracy, and can be popularized in and applied to production. The method is suitable for rapid continuous measurement of rare earth oxide, calcium oxide, magnesium oxide and barium oxide in the rare earth ore concentrate.

Owner:包钢勘察测绘研究院

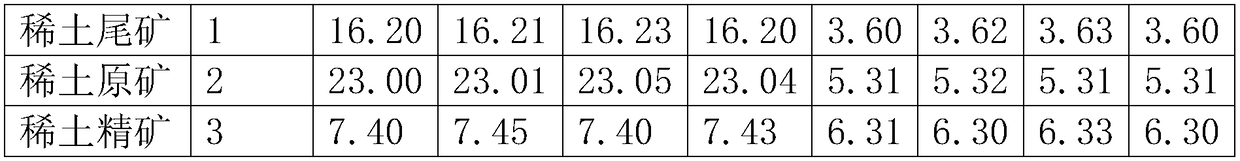

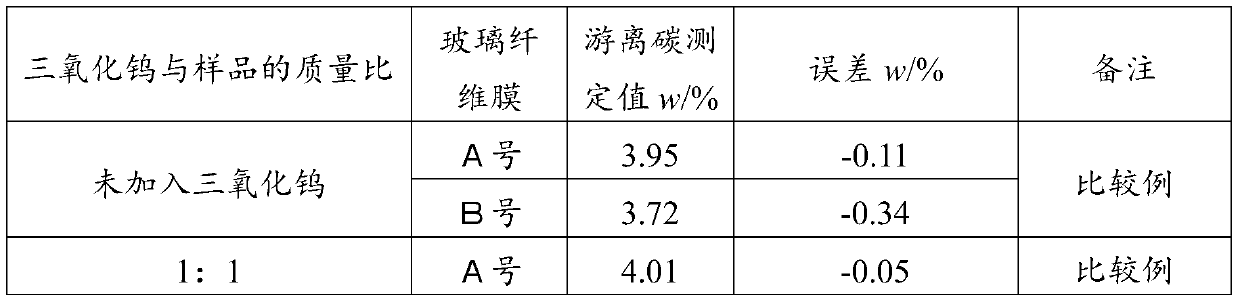

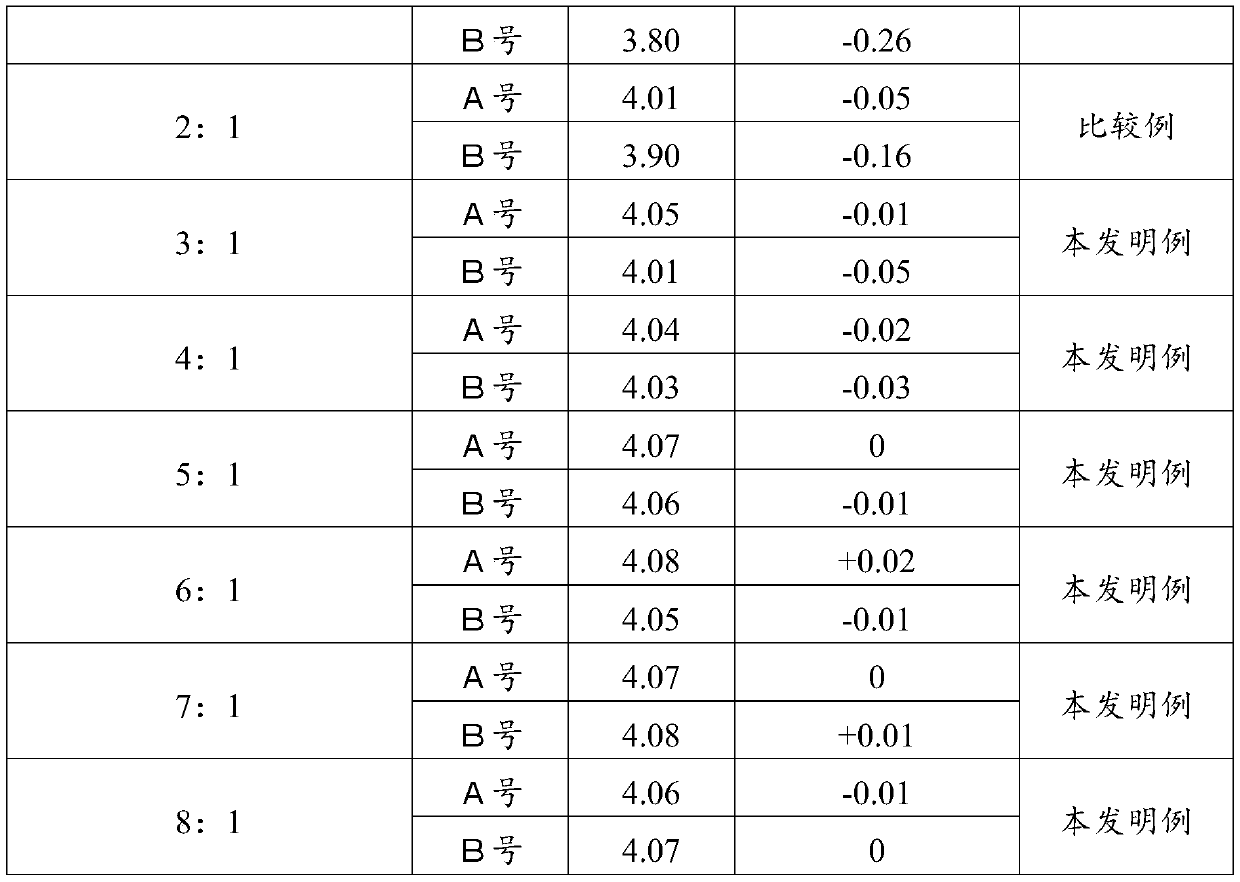

A method for filtering the decomposition liquid of continuous casting mold slag

ActiveCN107764622BImprove analysis efficiencyReduce usagePreparing sample for investigationMetallurgical assaySlag

The invention relates to a filter method of decomposition liquid of continuous casting mold flux, which relates to the field of metallurgic analysis chemistry. The filter method comprises the following steps: after acid oxide powder is dispersed on a fibrous membrane, performing the suction filtering for decomposition liquid of the continuous casting mold flux. By adopting the method, the loss offree carbon can be avoided, and the yield of the free carbon in the continuous casting mold flux is increased. Meanwhile, the carcinogenicity substances such as acid-washed asbestos can be avoided, and the health state of the working personnel is facilitated.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

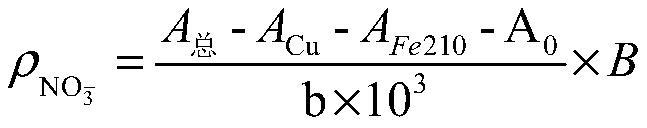

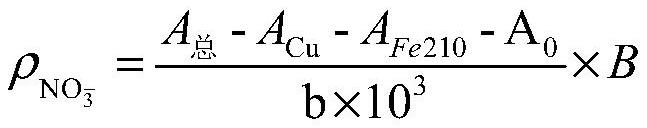

Method for determining nitrate ions in high-iron and copper matrix samples

PendingCN114018845AHigh analysis test speedHigh precisionColor/spectral properties measurementsCu2 ionsMetallurgical assay

The invention discloses a method for determining nitrate ions in high-iron and copper matrix samples, relates to the technical field of metallurgical analysis, and solves the problem of inaccurate nitrate ion determination caused by iron and copper interference in the analysis and determination process of the nitrate ions in the high-iron and copper matrix samples. The determination method comprises the following steps: selecting a sample determination system as a sulfuric acid system, selecting a dual-wavelength method with wavelengths of 210 nm and 275 nm, successfully deducting the interference of the iron matrix, deducting the interference of the copper matrix at the nitrate determination wavelength of 210 nm and within a certain concentration range and the absorbance of the copper ions conform to the Lambert-Beer law, and finally calculating the concentration of the nitrate ions through a formula. According to the determination method provided by the invention, the determination interference of copper and iron matrixes on the nitrate ions is successfully deducted, an analysis method which meets the process requirements and can realize rapid determination of the nitrate ions is developed, and the determination method has the characteristics of high analysis and test speed, low cost, good stability, high accuracy and convenience in operation.

Owner:金川镍钴研究设计院有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com