A method for continuous determination of rare earth oxide, calcium oxide, magnesium oxide and barium oxide in rare earth concentrate

A technology of rare earth oxides and rare earth concentrates, applied in the direction of measuring devices, preparation of test samples, weighing by removing certain components, etc., can solve the problem of high measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

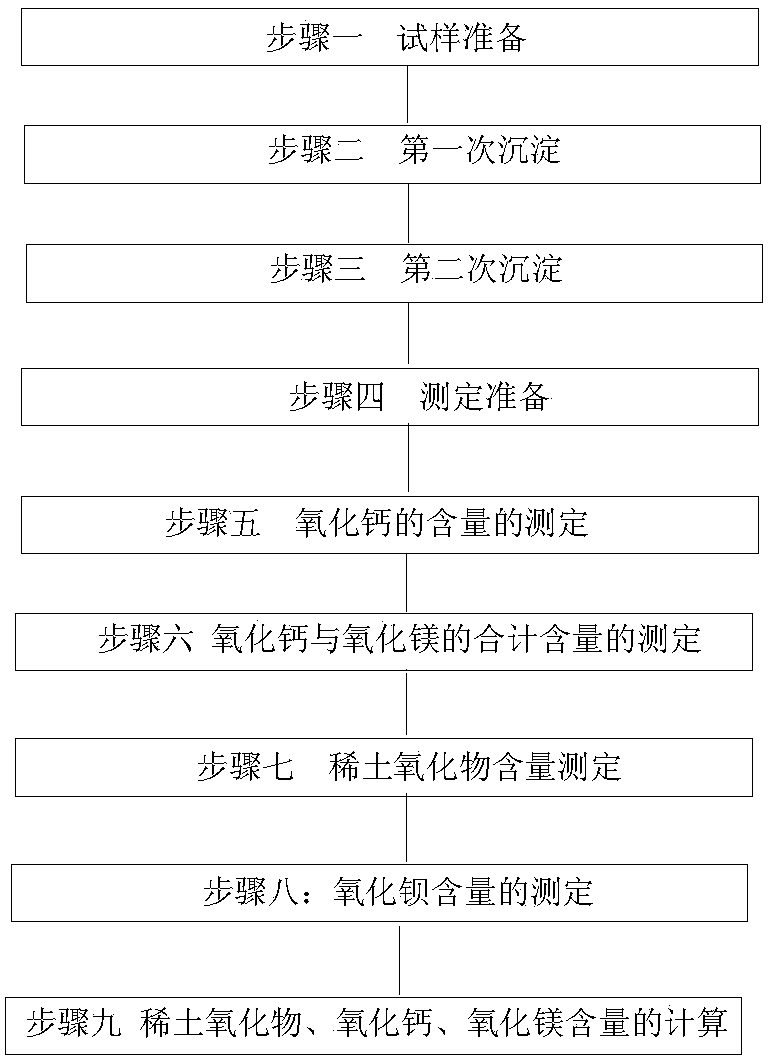

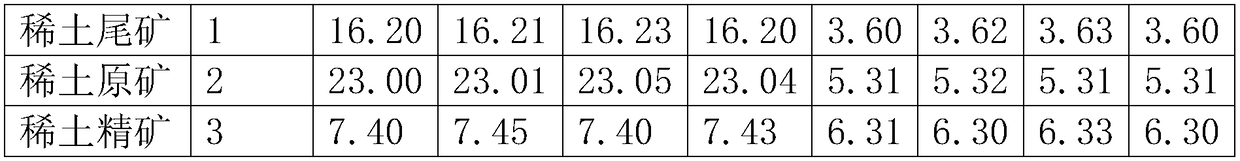

[0064] The method steps of this specific embodiment are as figure 1 As shown, three kinds of samples were selected, namely rare earth tailings, labeled 1, rare earth raw ore, labeled 2, and rare earth concentrate labeled 3. The samples were prepared according to the iron ore sampling standard, and each sample was separately Do 4 sets of comparative experiments according to the following method. The basic process of the determination method is: melt the sample with alkali, and separate interfering elements such as iron, aluminum, and manganese in the triethanolamine solution. After removing silicon dioxide, elements such as calcium and magnesium are precipitated and separated with ammonia water, and rare earths are precipitated with oxalic acid in a slightly acidic solution with pH=2. Burn into rare earth oxides and weigh. Concentrate the filtrate separated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com