A device and method for ultrasonically inspecting the grain size of high-temperature fasteners in thermal power plants

A thermal power plant, ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices, etc. It can solve the cumbersome, manpower-consuming and time-consuming metallographic inspection steps, etc. problems, to achieve the effect of high sampling efficiency, convenient operation and use, and simple test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

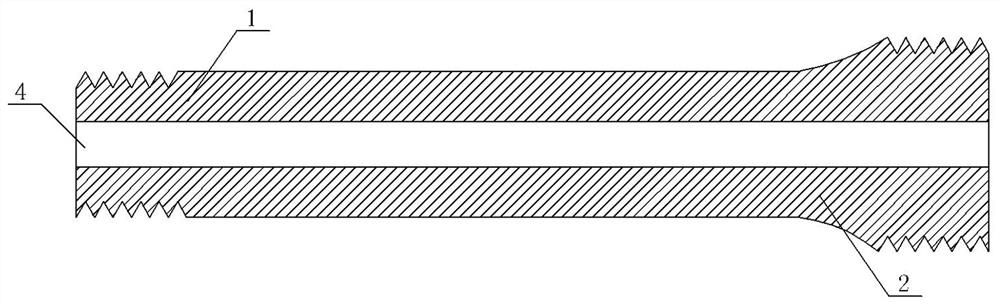

[0045] Such as figure 1 As shown, Embodiment 1 discloses a device for ultrasonically inspecting the grain size of high-temperature fasteners in thermal power plants, which includes an ultrasonic flaw detector and a bolt test block.

[0046] The ultrasonic flaw detector is a Shantou ultrasonic CTS-1008 digital ultrasonic flaw detector, which includes a probe 3, and the probe 3 includes a first probe, a second probe and a third probe, and the first probe is a 51MHz shear wave oblique probe , the second probe is a 36MHz shear wave oblique probe, and the third probe is a 25MHz shear wave oblique probe.

[0047] As shown in Table 2, the bolt test blocks include comparison bolt test blocks of grades 3, 15, and each grade has a comparison bolt test block, which are the comparison bolt test blocks of the third grade and the comparison bolt test blocks of the fourth grade. The test block and the comparison bolt test block of the fifth grade. The comparison bolt test block of the thir...

Embodiment 2

[0050] Such as figure 1 , shown in table 2, embodiment 2 discloses a kind of device of ultrasonic inspection thermal power plant high-temperature fastener grain size, and it comprises ultrasonic flaw detector and bolt test block.

[0051] The ultrasonic flaw detector is Shantou Ultrasonic CTS-1008 digital ultrasonic flaw detector, which includes a probe 3, and the probe 3 includes a first probe, a second probe and a third probe, and the first probe is a 51MHz shear wave oblique probe , the second probe is a 36MHz shear wave oblique probe, and the third probe is a 25MHz shear wave oblique probe.

[0052] The bolt test blocks include the first comparison bolt test block, the second comparison bolt test block and the third comparison bolt test block of grades 3-5, wherein each comparison bolt test block includes rigid end bolts 1 and The flexible end bolt 2, the rigid end bolt 1 and the flexible end bolt 2 are connected as a whole, and the thread profile angle 5 of each comparis...

Embodiment 3

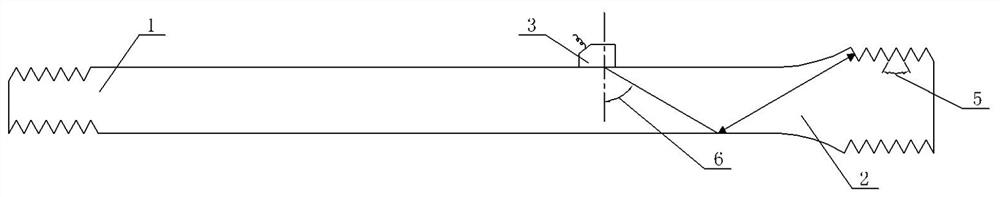

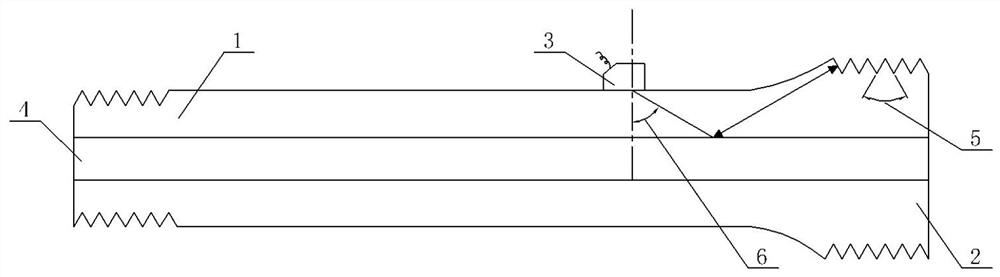

[0054] Such as figure 1 , image 3 As shown, embodiment 3 discloses a kind of method of ultrasonic inspection thermal power plant high-temperature fastener grain size, and it uses the device of embodiment 1, comprises the steps:

[0055] S1 Select the comparison bolt test block

[0056] The bolt to be tested is a flexible bolt with a diameter of 64mm and a length of 800mm. The diameter of the central hole 4 is 20mm. The comparison bolt test block is used as the comparison bolt test block, that is, the second comparison bolt test block of the fifth level is selected as the comparison bolt test block;

[0057] S2 Measure the amplitude of the reflected wave of the threads of the comparison bolt test block

[0058] Using the ultrasonic flaw detector and the comparison bolt test block in step S1, place the first probe on the flexible end bolt 2, adjust the refraction angle 6 of the ultrasonic wave in the comparison bolt test block and the comparison bolt test block The thread p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com