Method for quantitative analysis of continuous casting sheet billet gross segregation by image analysis method

A quantitative analysis and image analysis technology, applied in the field of metallurgy, can solve problems such as the uniformity of the mechanical properties of the steel plate, the delamination of the steel plate, the adverse effects of the welding performance and corrosion resistance of the steel plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

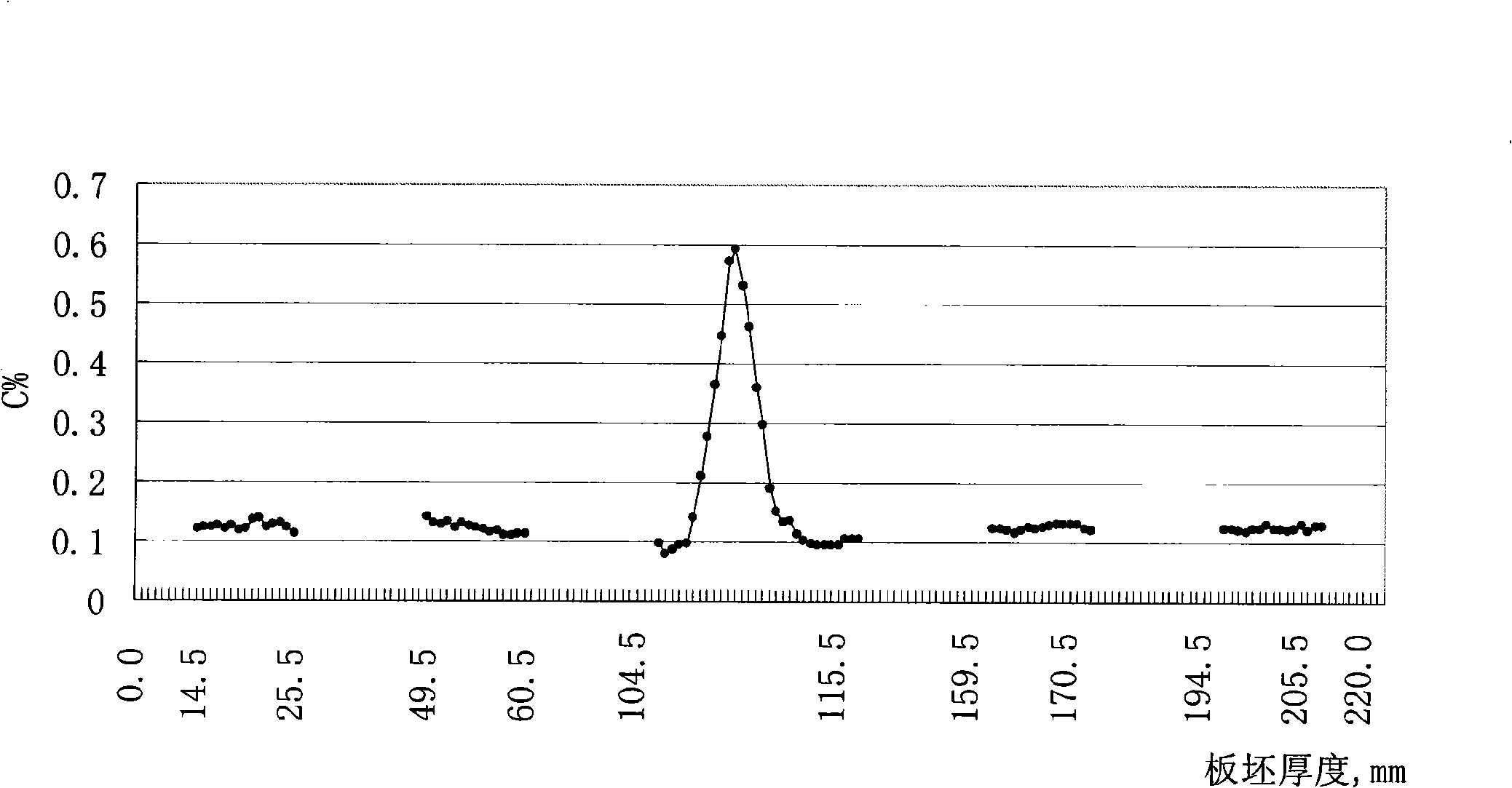

[0029] The slab used in the analysis is ship slab, and its composition is shown in Table 1.

[0030] Table 1 Chemical composition of test slabs (tundish analysis) %

[0031]

[0032] At 1 / 4 of the width of the slab, cut 5 samples of 11mm×11mm×10mm along the length direction at 5 positions 20, 55mm from the upper and lower surfaces and the thickness center, and obtain 2 groups of 10 samples along the length direction. samples, and each set of samples includes the above 5 positions.

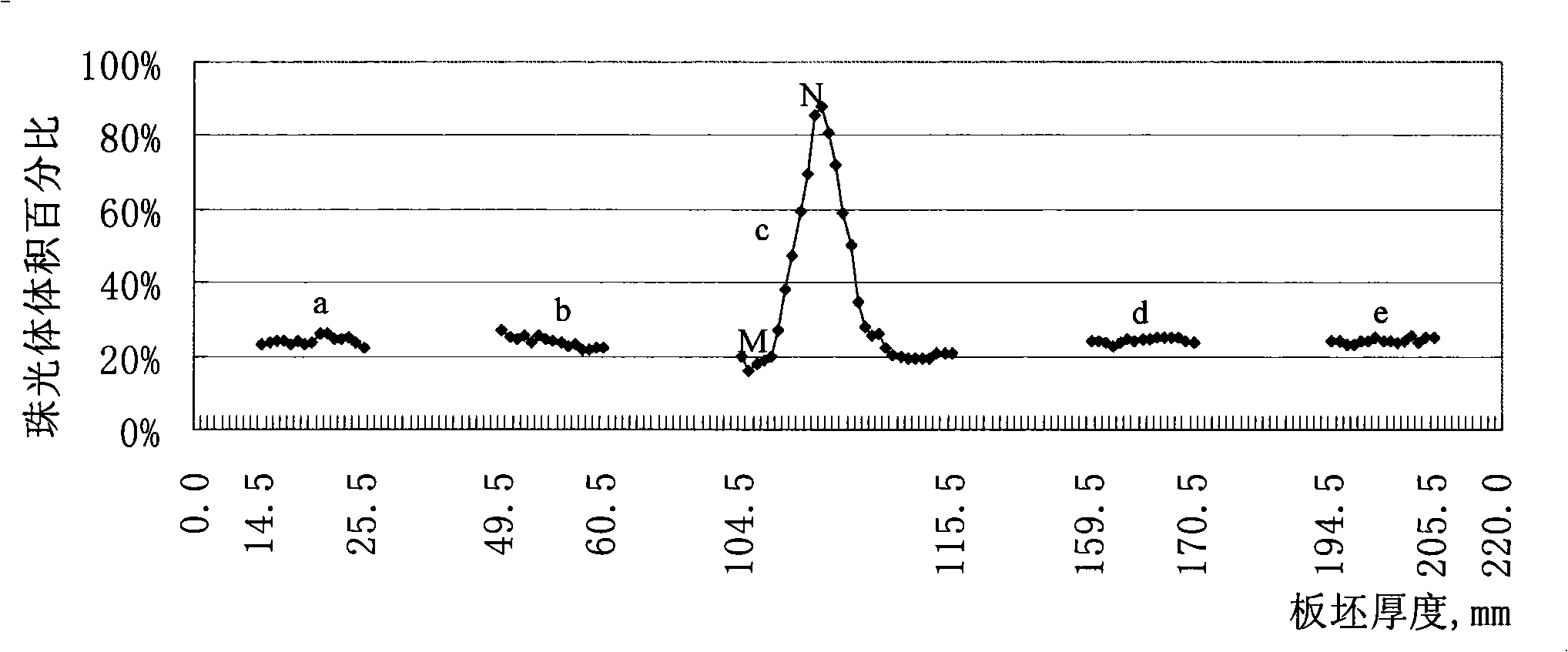

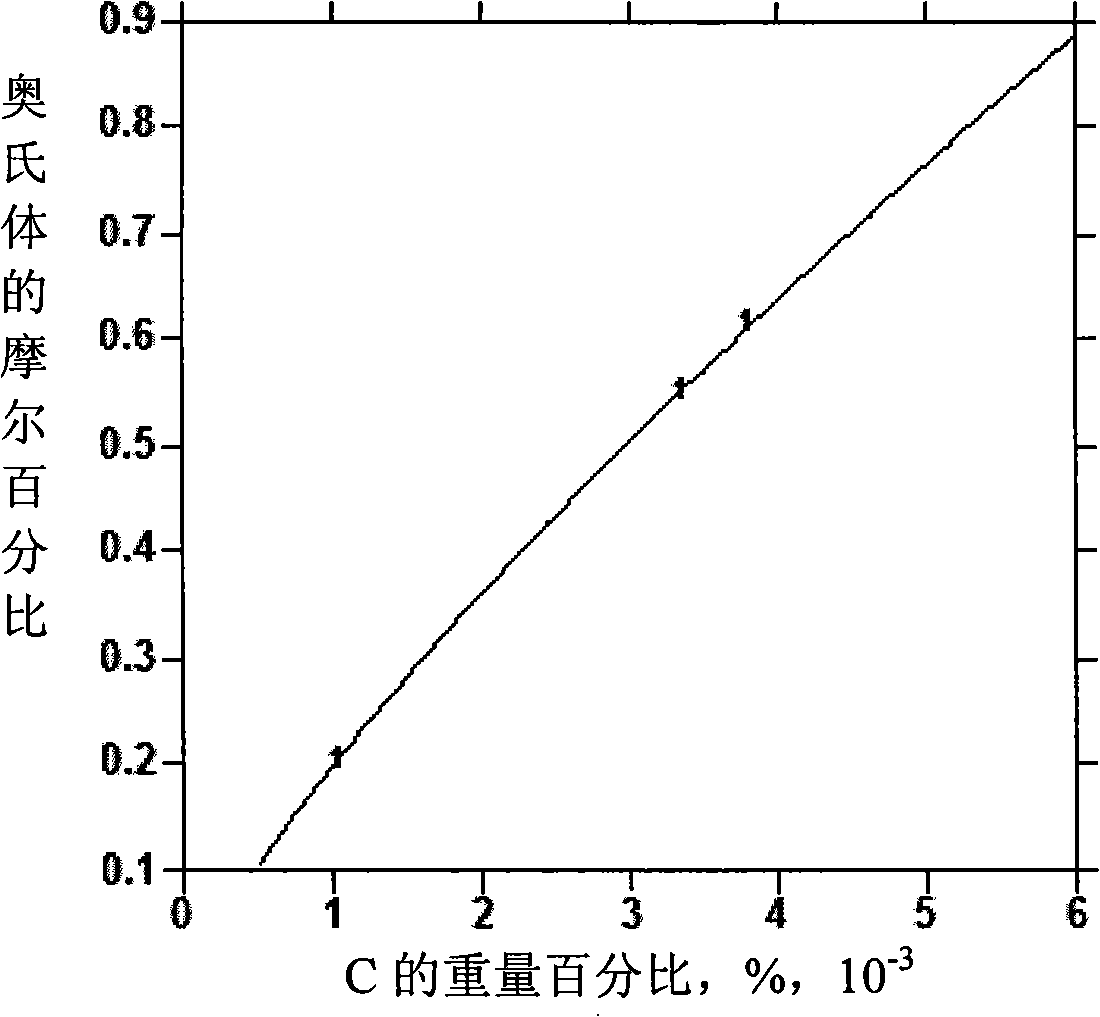

[0033] The samples were etched with 2% nitric acid alcohol solution after inlaying and polishing. For each sample, 7 columns of observation areas are randomly selected along the width direction of 11 mm, and the magnification of X100 is used, and the calculation and analysis of 30 continuous areas are carried out in each column along the thickness direction (the length and width of each analysis area are both less than 1 mm ). The tissue change in each thickness direction adopts the average v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com