Standard sample for spectroscopic analysis of welding wire steel ER50-6

A technology of spectral analysis and standard samples, which is applied in the field of standard samples for spectral analysis of welding wire steel ER50-6, can solve problems affecting test results, spectral interference, etc., and achieve the effects of low impurity content, good stability, and good physical standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

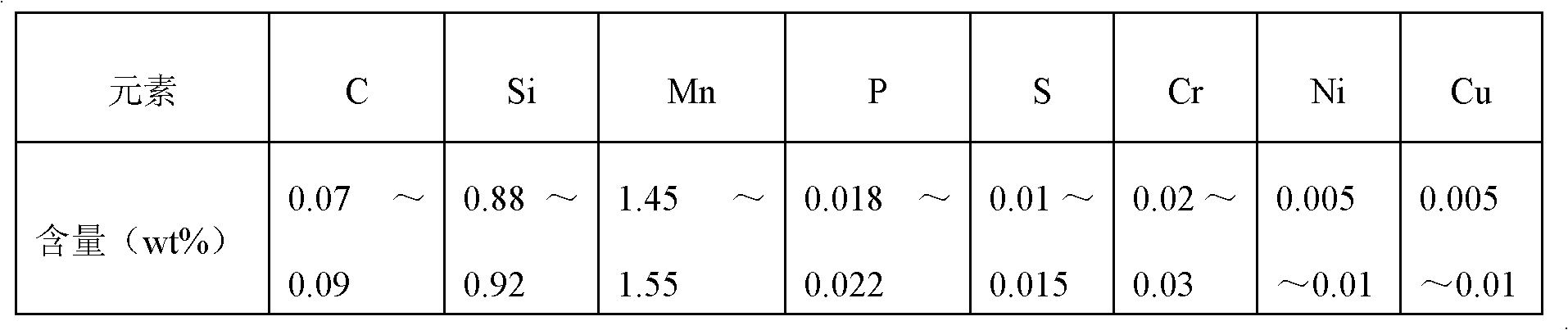

[0014] 1. Composition design: iron is the matrix component, the composition and content of alloy elements are shown in Table 1, and the content of other impurity elements are all <0.005wt%.

[0015] 2. Preparation method:

[0016] (1) According to the designed ingredients, 500kg intermediate frequency induction furnace is used for smelting, and induction magnetic stirring is used to ensure uniform composition of molten steel. The deoxidizer is made of pure aluminum, and the φ180mm ingot-shaped metal mold is used for pouring molding;

[0017] (2) The steel ingot is forged after being held at 1100°C-1200°C for 3 hours, forged into a 80mm×80mm×2000mm billet, and air-cooled; then the main elements are segregated, and the results are judged by the range method. -1100℃ for 1 hour, hot rolling into Φ45mm×1000mm round bar;

[0018] (3) The rolled round bars are numbered, descaled, flattened, and processed into Φ40mm×40mm spectral blocks.

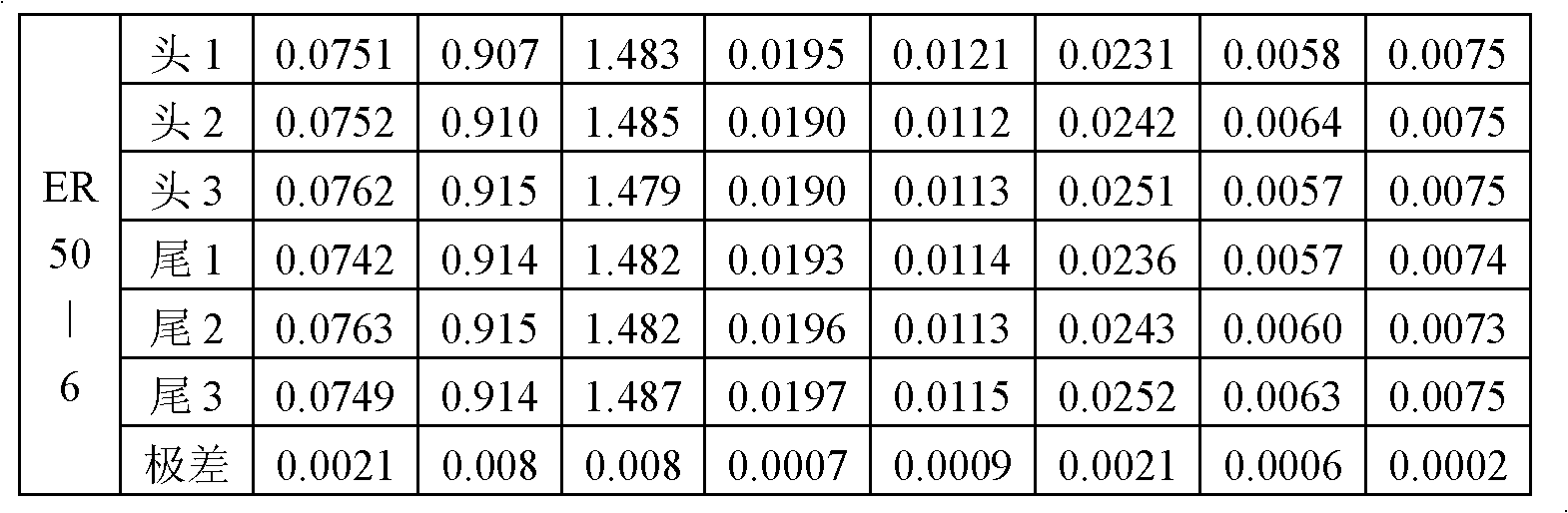

[0019] 3. Homogeneity inspection of standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com