A Quantitative Evaluation Method for Center Macro Segregation of Billets

A macro-segregation and quantitative evaluation technology, applied in material inspection products, testing metals, etc., can solve problems such as deviation and inaccurate drilling chemical analysis results, and achieve the effect of avoiding the deviation of the center segregation analysis results of the cast billet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

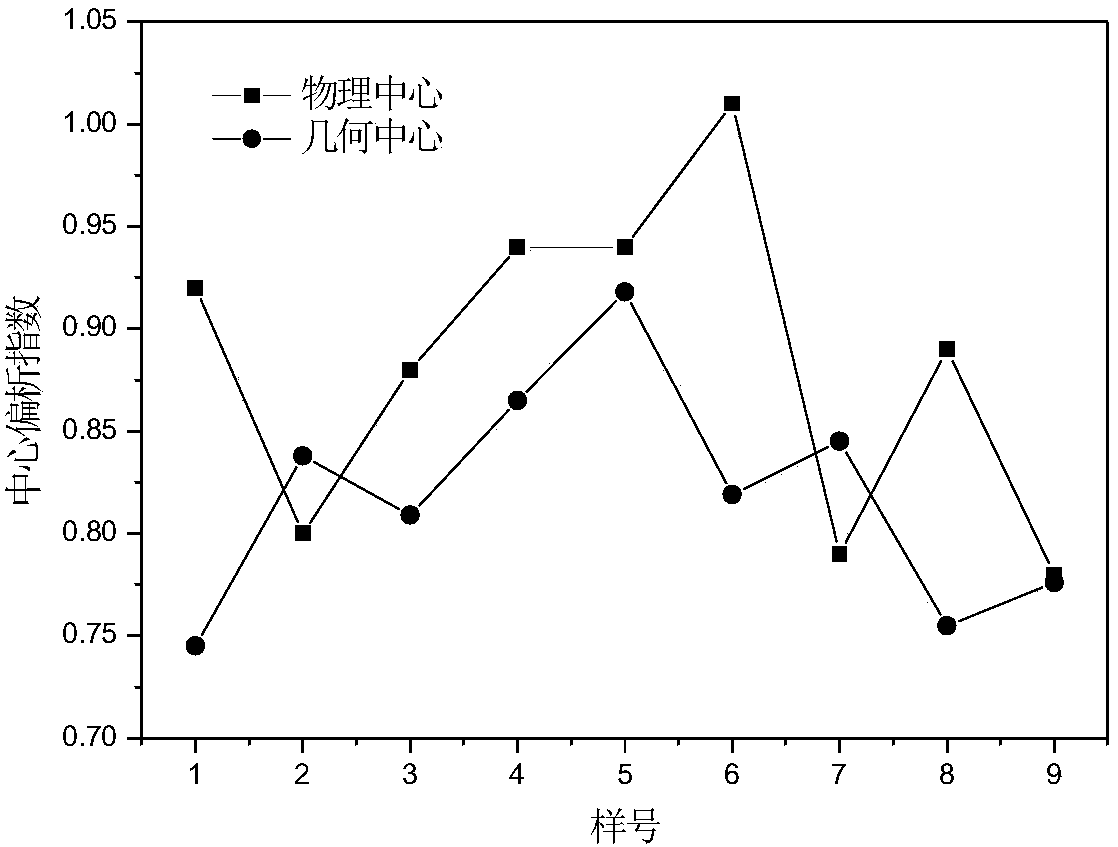

[0023] Using the quantitative evaluation method for billet center macro-segregation provided by the patent of the present invention, the internal quality of the billet SWRH82B billet with a cross-sectional size of 160mm×160mm was evaluated, and compared with the detection results of the geometric center. The specific casting machine mainly The basic parameters and continuous casting process parameters are shown in Table 1:

[0024] Table 1 Basic process parameters of casting machine and continuous casting process

[0025]

[0026] The specific steps and parameters are as follows:

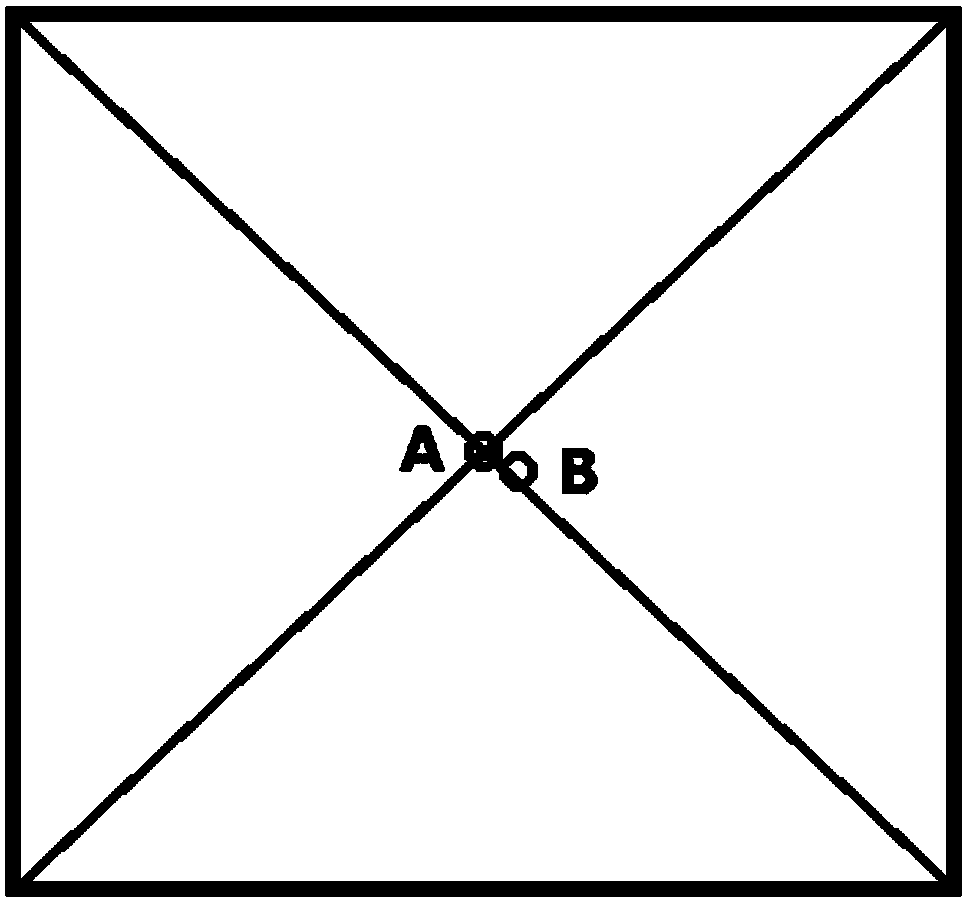

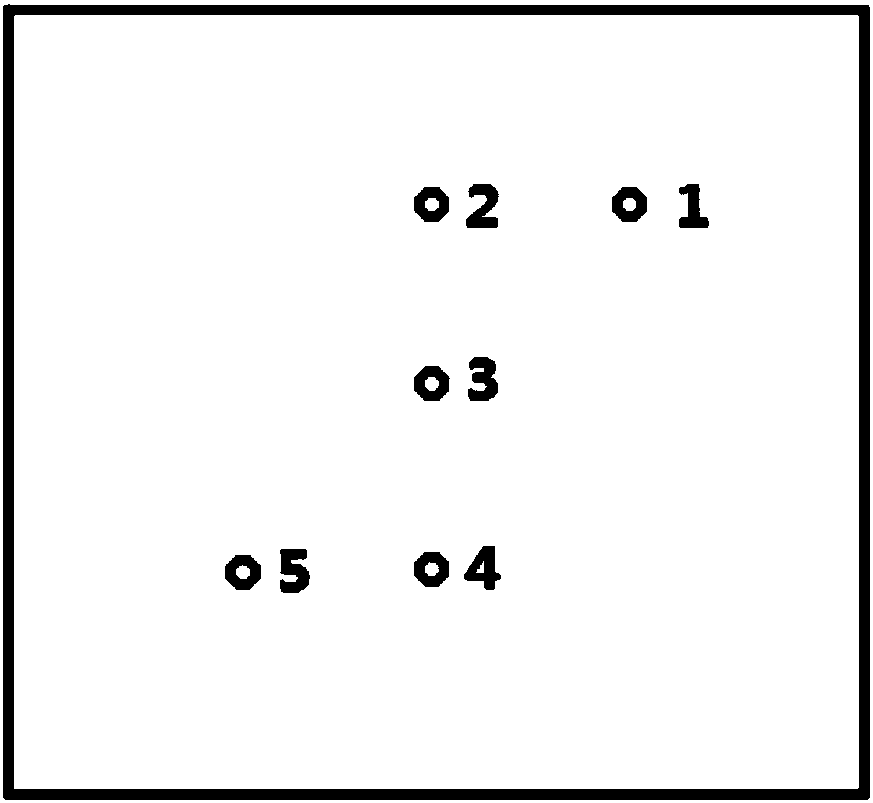

[0027] 1) Find out the solidification physical center of the slab by hot acid etching method, that is, the specific position of the final solidification in the cross section. First, the billet is processed into a 15mm thick low-magnification sample, and the corrosion test is carried out with an industrial hydrochloric acid solution with a volume ratio of 1:1. The temperature of the hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com