Analysis method for determining primary and secondary components in composite vanadium-nitrogen alloy

A vanadium-nitrogen alloy and analysis method technology, which is applied in the field of ICP-AES analysis, can solve the problems of cumbersome operation, long analysis process, and large consumption of reagents, and achieve the effect of less operation steps, saving analysis time and being easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

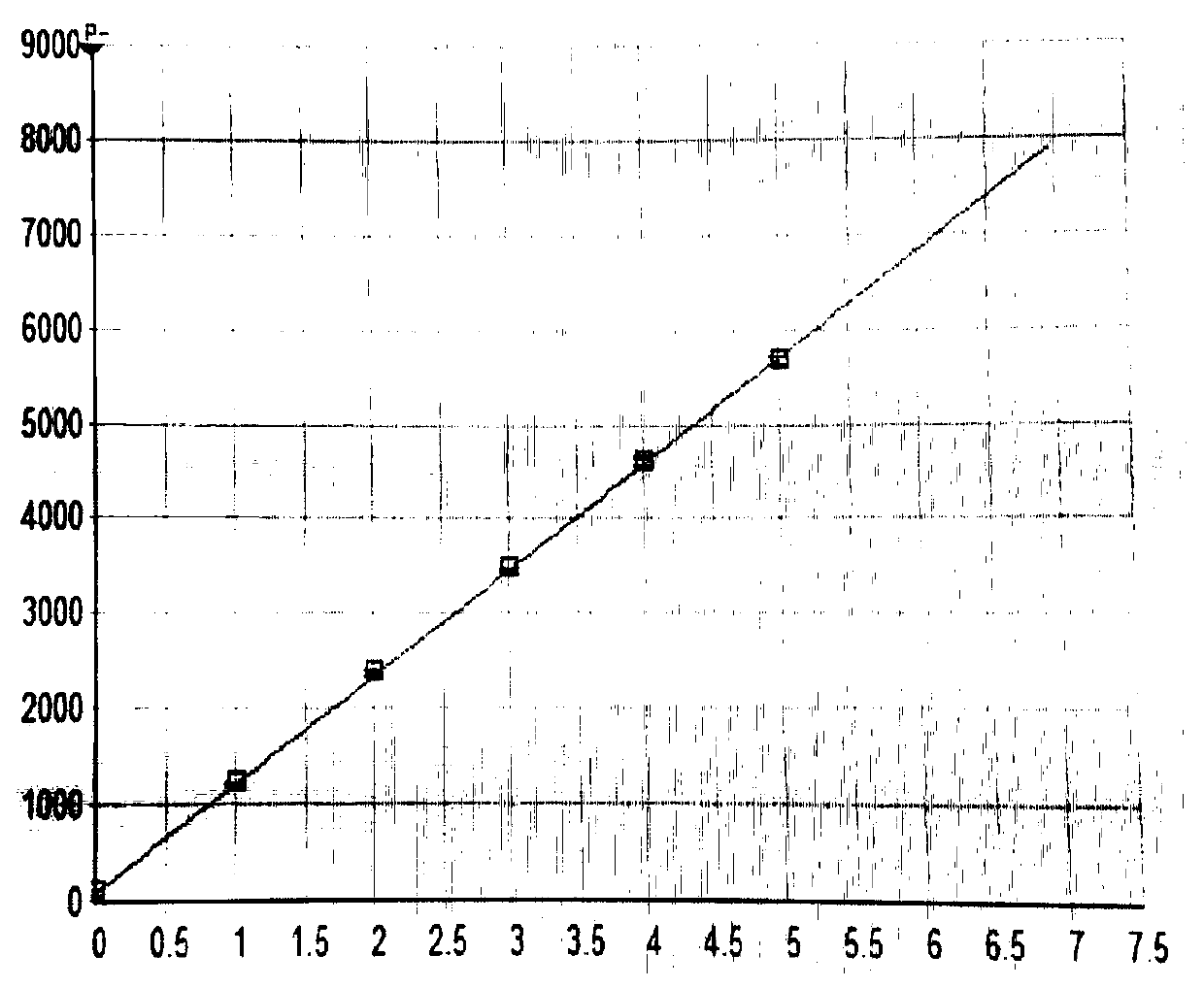

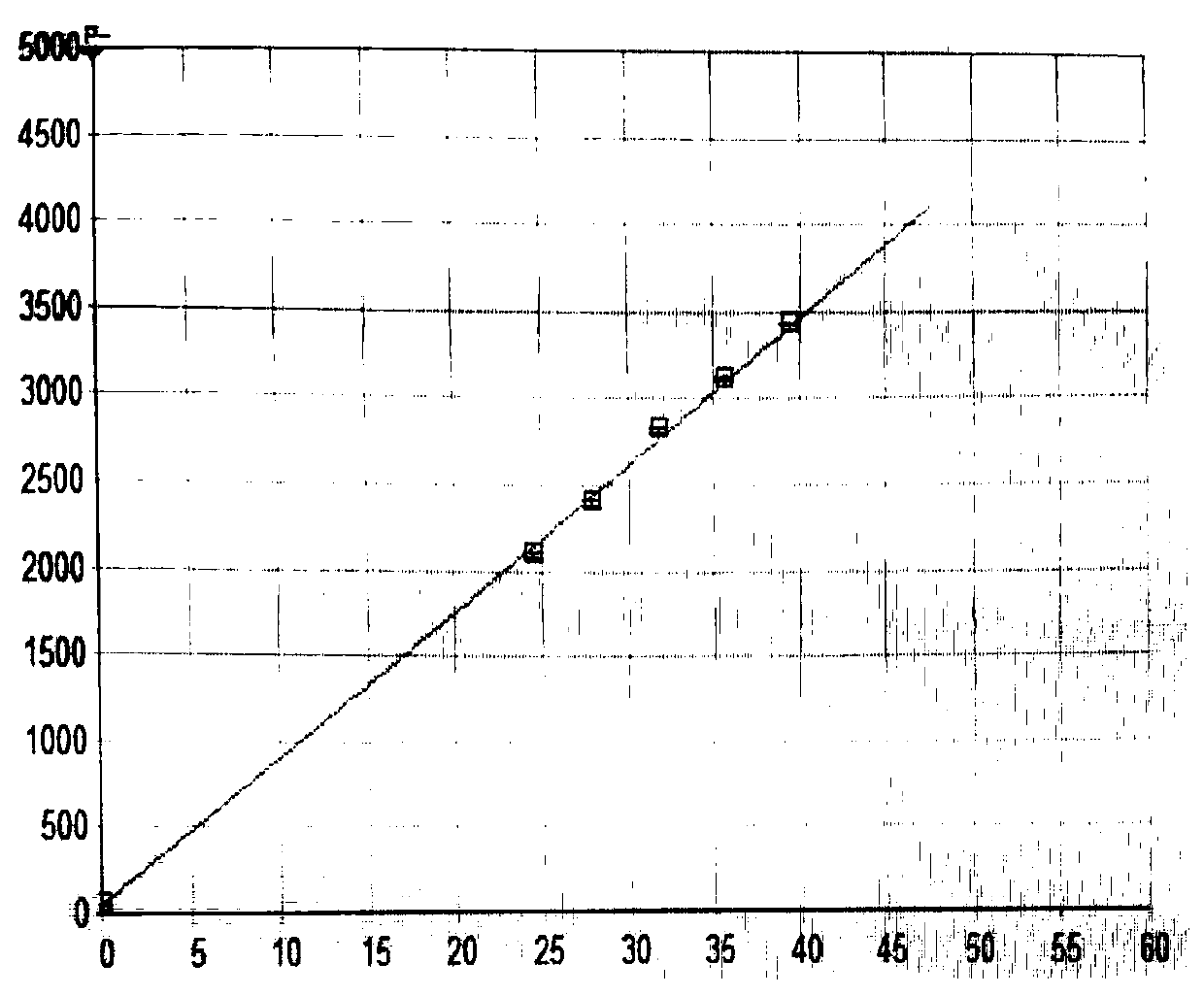

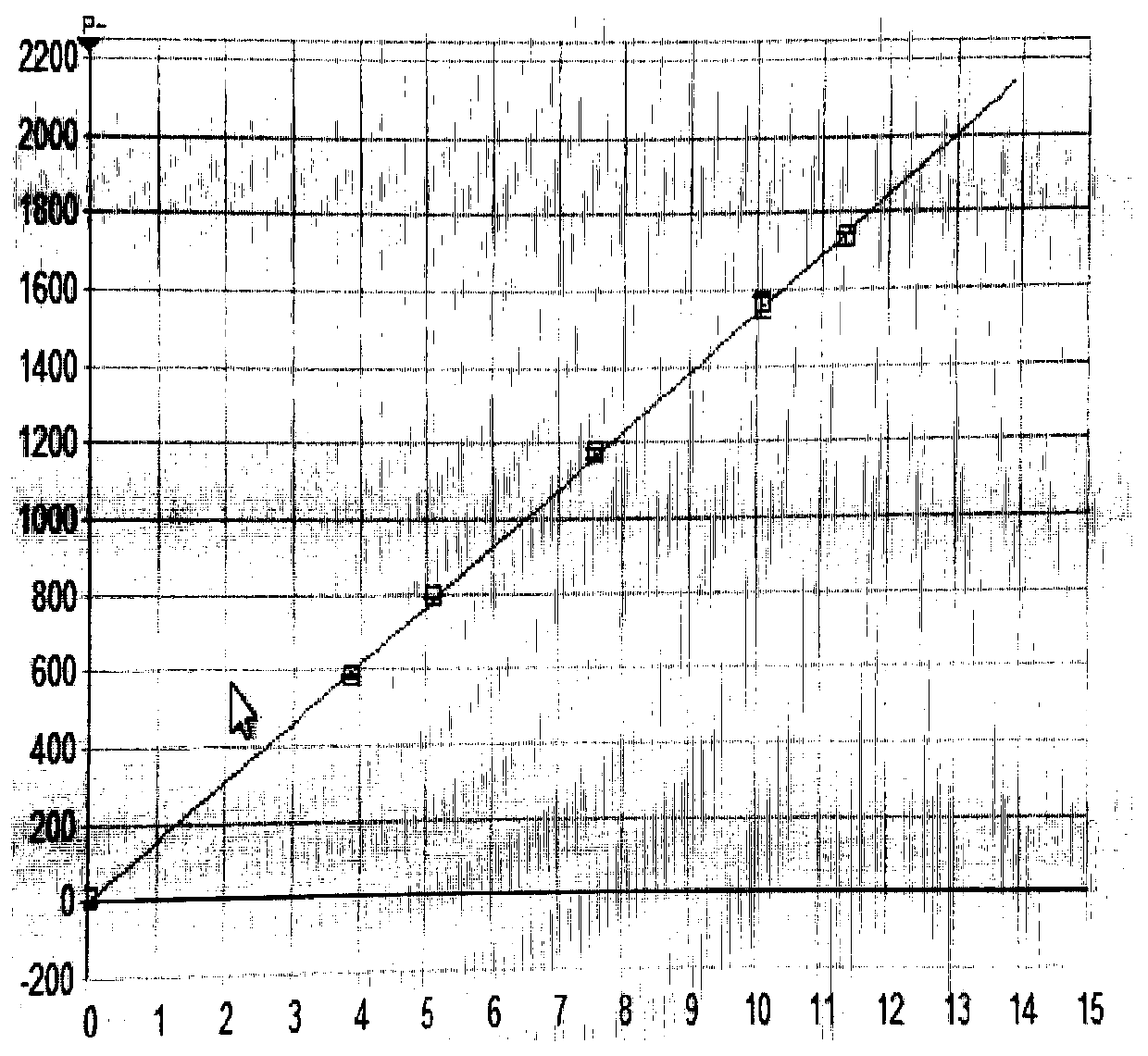

Image

Examples

Embodiment 1

[0021] An analytical method for determining primary and secondary components in a composite vanadium-nitrogen alloy is characterized in that it comprises the following steps:

[0022] 1) Grinding:

[0023] The composite vanadium-nitrogen alloy samples were ground with a grinding machine. According to experimental analysis, when it is ground to pass 180 mesh (particle size 0.08mm), the bonding effect with boric acid is better, showing that the surface of the sample is smooth and not easy to fall off.

[0024] 2) Tablet:

[0025] Using boric acid as a binder, the composite vanadium-nitrogen alloy sample was subjected to X-ray fluorescence compression treatment.

[0026] 3) Qualitative analysis:

[0027] Use the ELTER nitrogen analyzer to analyze the N in the sample, and the measured N mass fraction is about 20%-26%; use the Uniquant software of the Thermo Fisher ARL9900 fluorescence spectrometer to conduct semi-quantitative analysis on the composite vanadium nitrogen sample, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com