Isomaltooligosacharide prepared from ginkgo starch as well as preparation method and application thereof

A technology of isomaltooligosaccharide and starch, which is applied in the fields of application, function of food ingredients, food science, etc., can solve the problems of large amount of enzymes, high cost, and unseen problems, so as to simplify the production steps, reduce the types of use, and reduce the Effects of insufficient food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

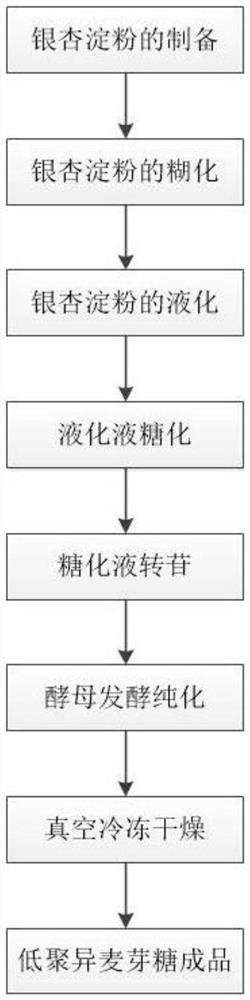

[0044] A method for preparing isomaltooligosaccharide with ginkgo starch, comprising the steps of:

[0045] (1) Preparation of ginkgo starch: shell the ginkgo seeds, remove the endocarp, mash, add 1% NaOH aqueous solution according to the mass ratio of 3:1, soak for 2 hours and centrifuge to get the precipitate, repeat the above method 3 times Combine the precipitates and wash with water until neutral to obtain wet starch, dry the wet starch by freeze-drying, seal it, and store it at room temperature;

[0046] (2) pulping: take by weighing 20g with the ginkgo starch that step (1) makes, join in the PBS damping fluid of 100mL, pH=6.0, be mixed with the ginkgo starch suspension that concentration is 20%, adjust pH to 5.8, Adjust the temperature of the water bath to 95°C, put it into a stirrer and stir for 5 minutes to gelatinize, and obtain a gelatinized liquid;

[0047] (3) Liquefaction: Add high-temperature-resistant α-amylase to the gelatinized liquid prepared in step (2) ac...

Embodiment 2

[0054] A method for preparing isomaltooligosaccharide with ginkgo starch, comprising the steps of:

[0055] (1) Preparation of ginkgo starch: shell the ginkgo seeds, remove the endocarp, mash, add 1% NaOH aqueous solution according to the mass ratio of 3.5:1, soak for 2.5h and then centrifuge to get the precipitate; repeat the above method for 4 times; combine the precipitates and wash to neutral to obtain wet starch, use freeze drying to dry the wet starch, seal it, and store it at room temperature;

[0056] (2) pulping: take by weighing the 25g ginkgo starch that step (1) makes, join in the PBS damping fluid of 100mL, pH=6.0, be mixed with the ginkgo starch suspension that concentration is 25%, adjust pH to 6.0, Adjust the temperature of the water bath to 98°C, put it into a stirrer and stir for 4 minutes to gelatinize to obtain a gelatinized liquid;

[0057] (3) Liquefaction: Add high-temperature-resistant α-amylase to the gelatinized liquid prepared in step (2) according ...

Embodiment 3

[0064] A method for preparing isomaltooligosaccharide with ginkgo starch, comprising the steps of:

[0065] (1) Preparation of ginkgo starch: shell the ginkgo seeds, remove the endocarp, mash, add 1% NaOH aqueous solution according to the mass ratio of 4:1, soak for 3 hours and then centrifuge to get the precipitate; repeat the above method 5 times Combine the precipitates and wash with water until neutral to obtain wet starch, dry the wet starch by freeze-drying, seal it, and store it at room temperature;

[0066] (2) Slurry: Take by weighing 30g of ginkgo starch prepared in step (1), add 100mL, PBS buffer solution of pH=6.0, be mixed with the ginkgo starch suspension that concentration is 30%, adjust pH to 6.2, adjust water bath The temperature of the pot is 100°C, put it into a stirrer and stir for 3 minutes to gelatinize, and obtain a gelatinized liquid;

[0067] (3) Liquefaction: Add high-temperature-resistant α-amylase to the gelatinized liquid prepared in step (2) acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com