Patents

Literature

153results about "Fibre separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

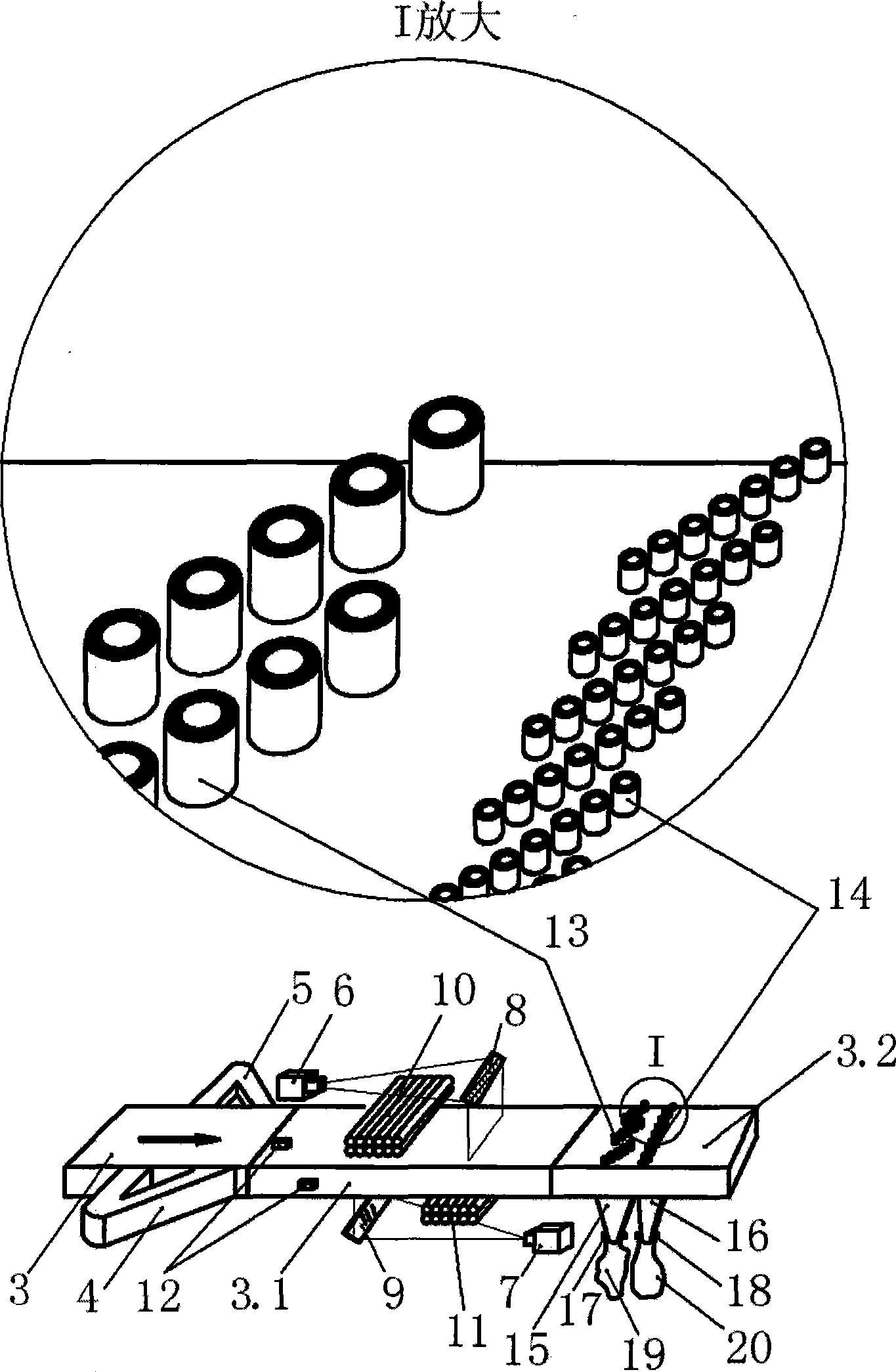

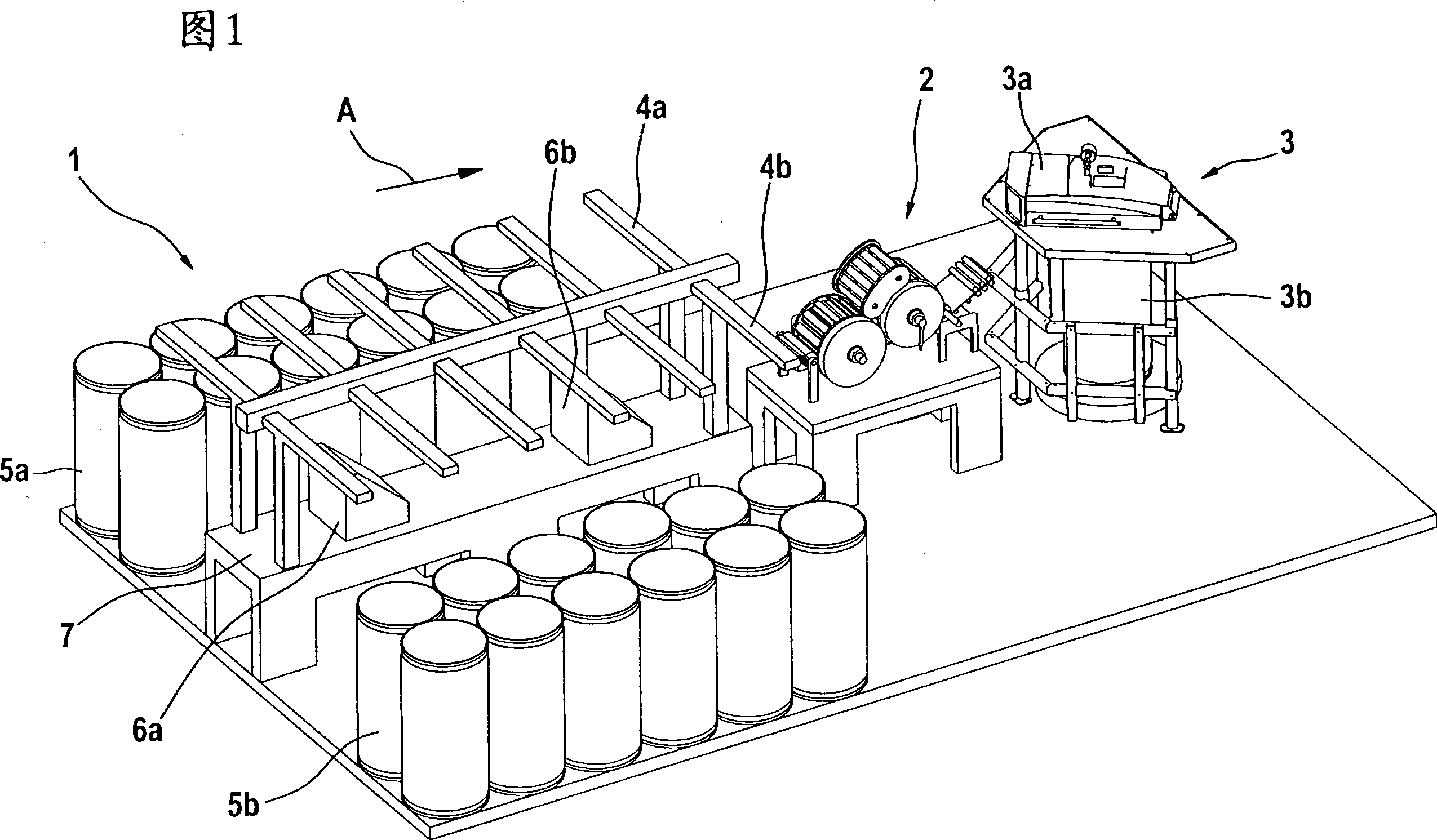

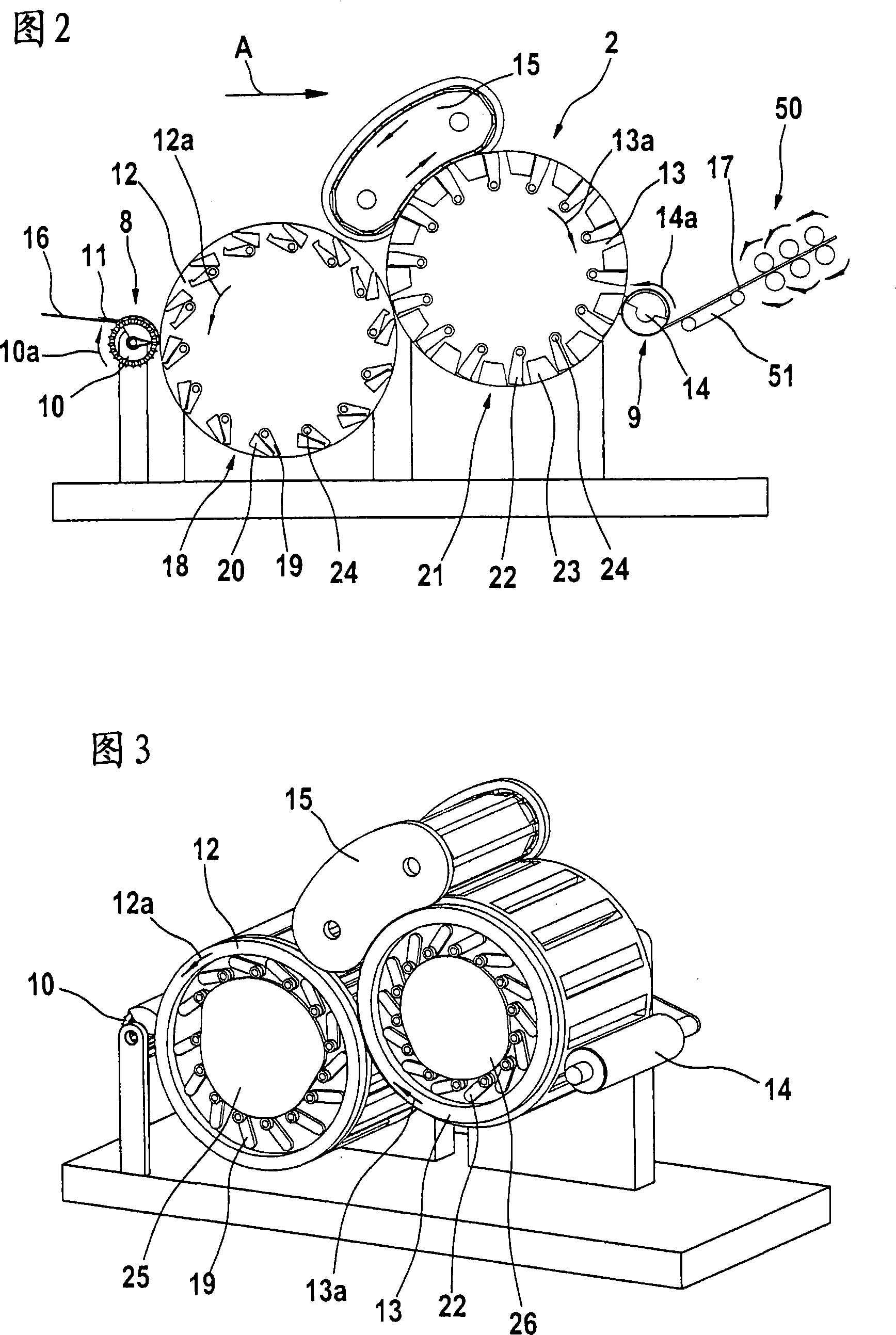

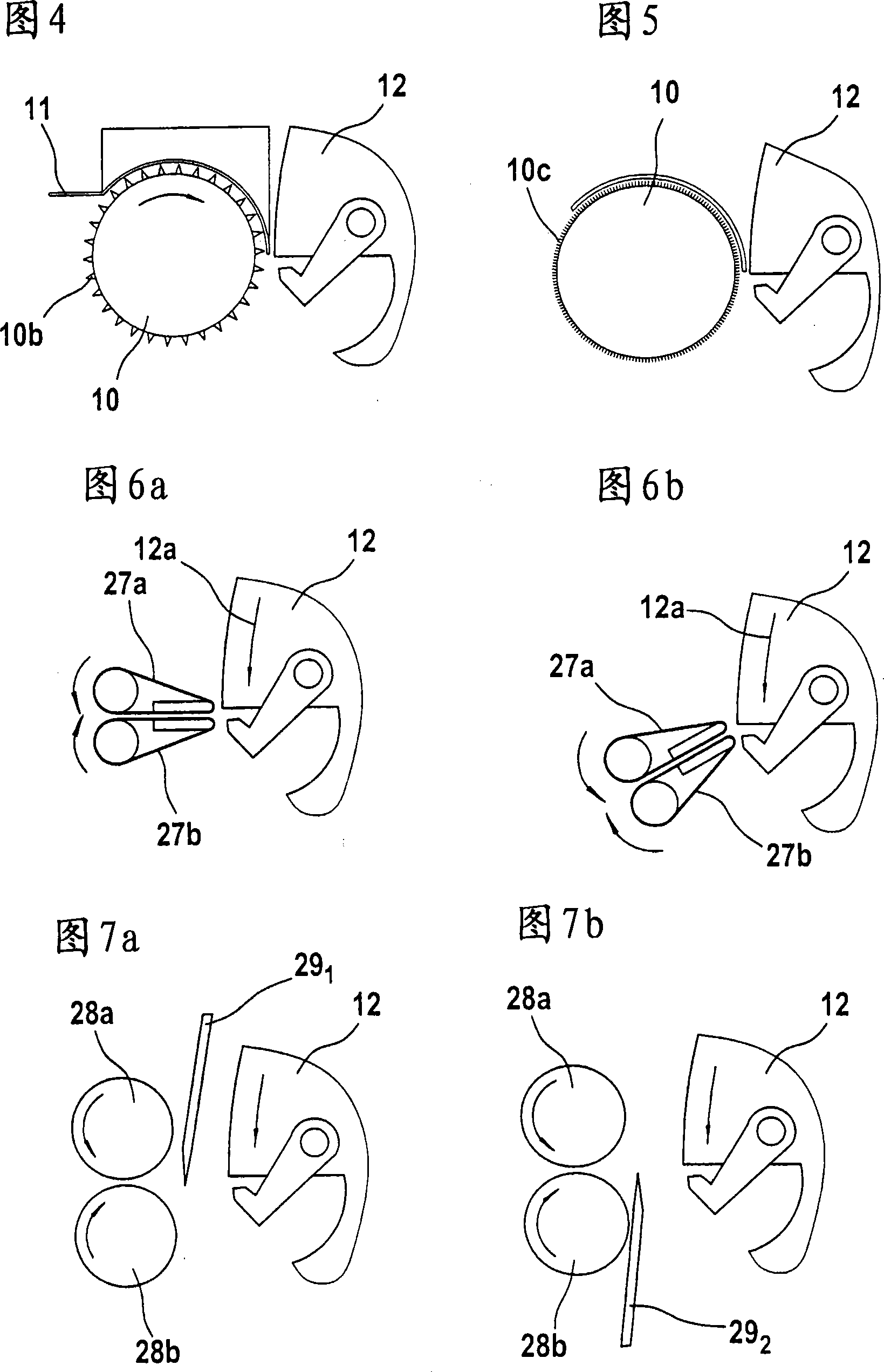

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000079A1Improved sliverIncrease volumeCombing machinesFibre separationProduction rateFiber bundle

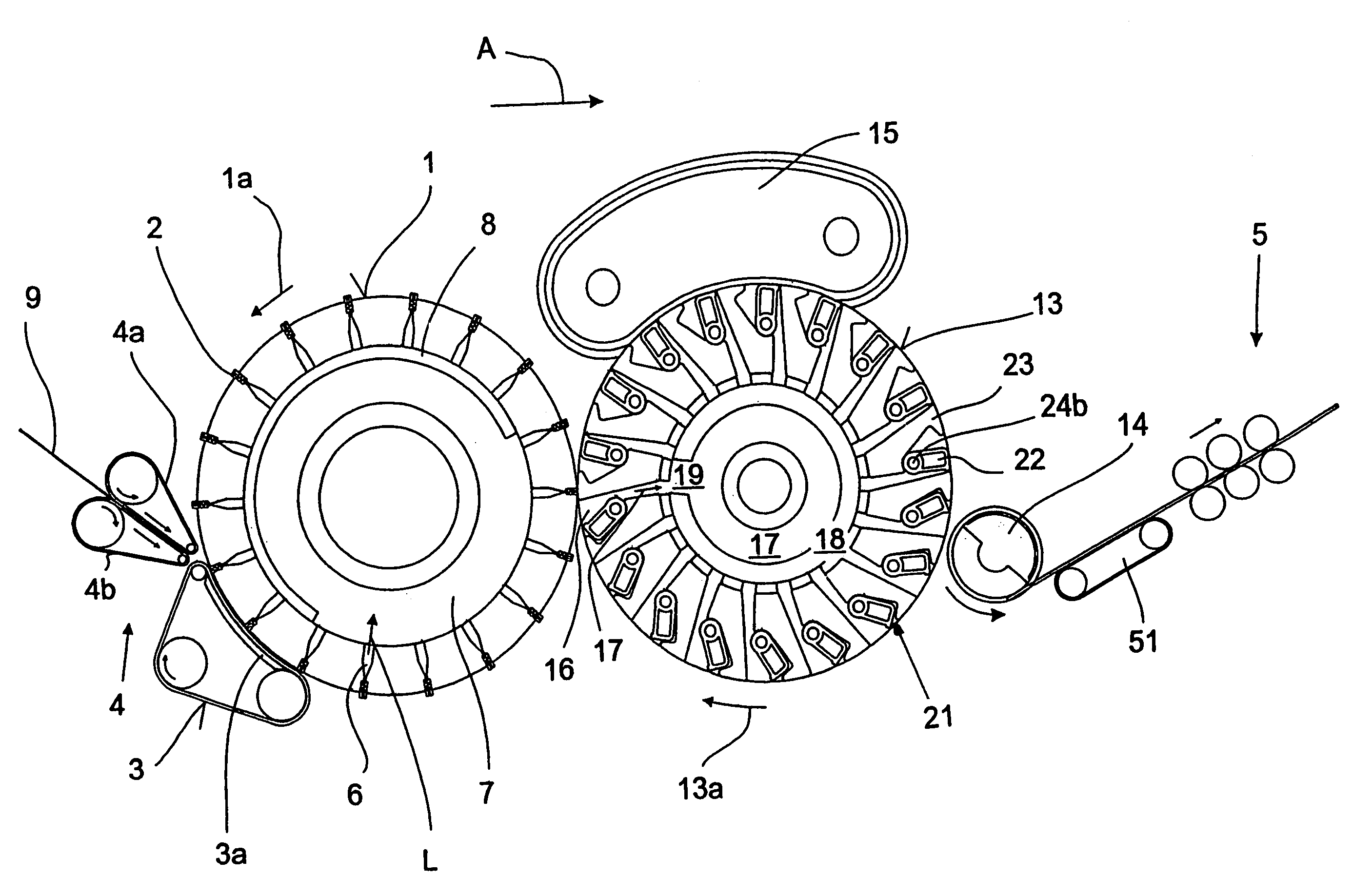

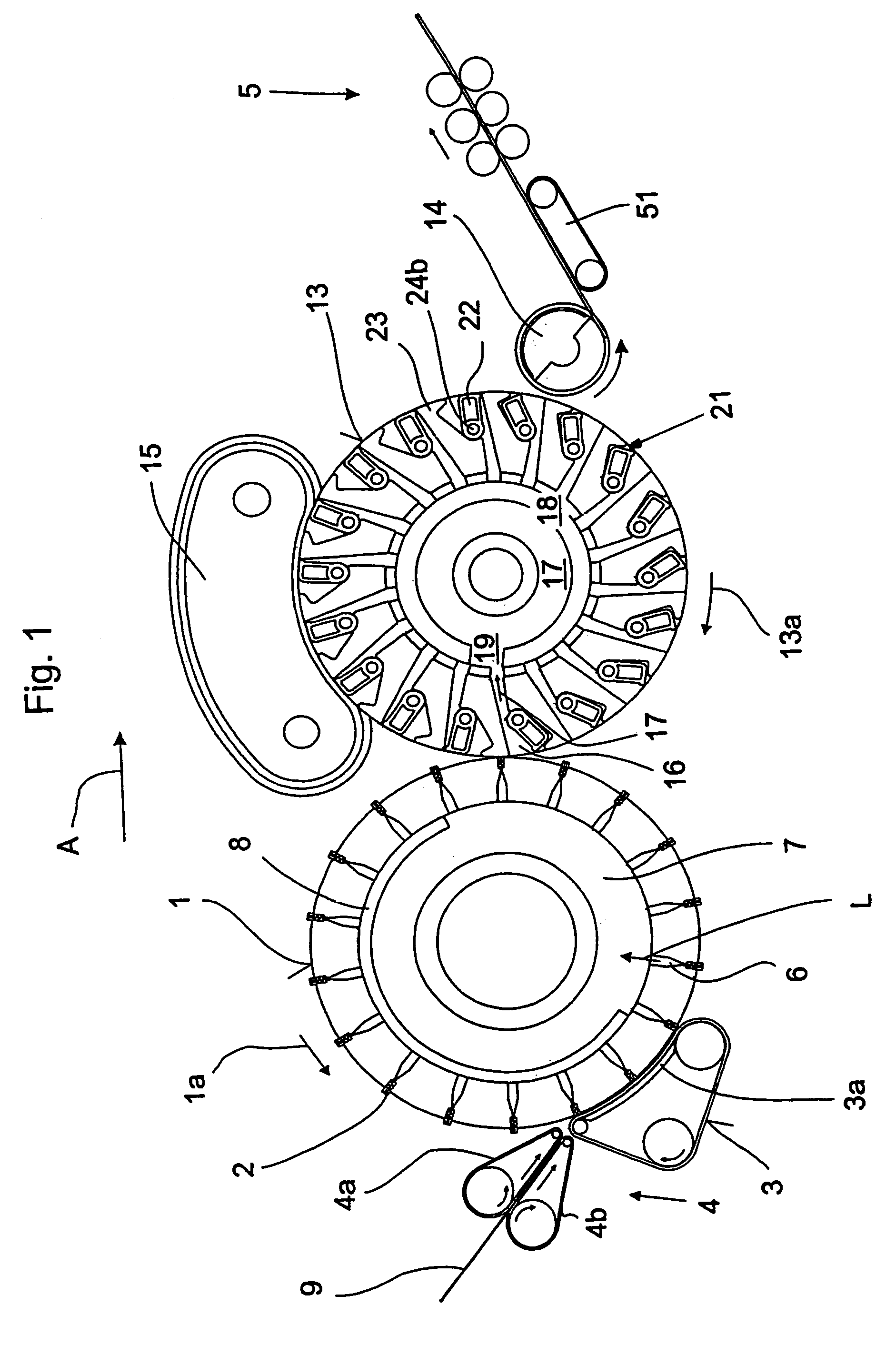

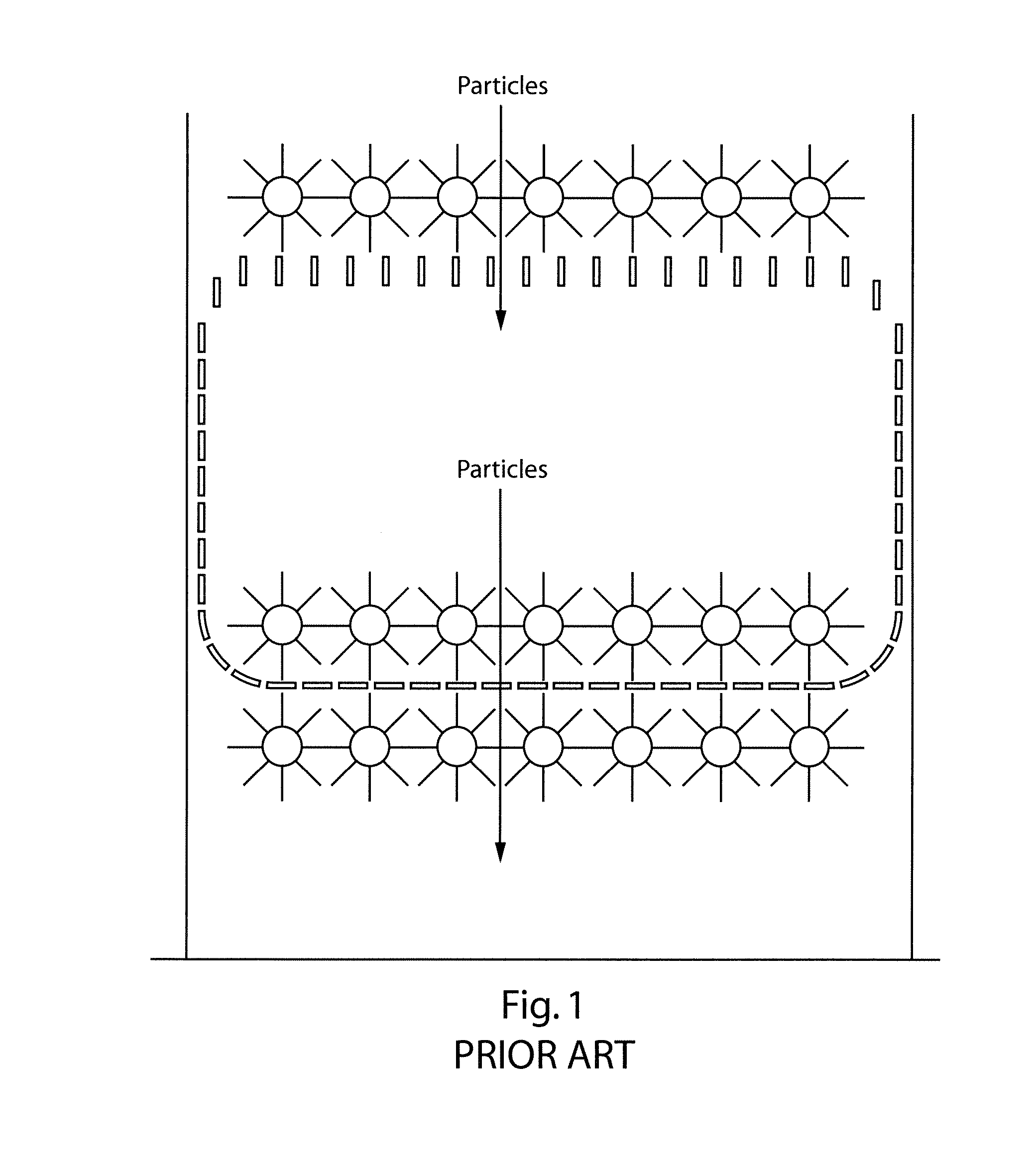

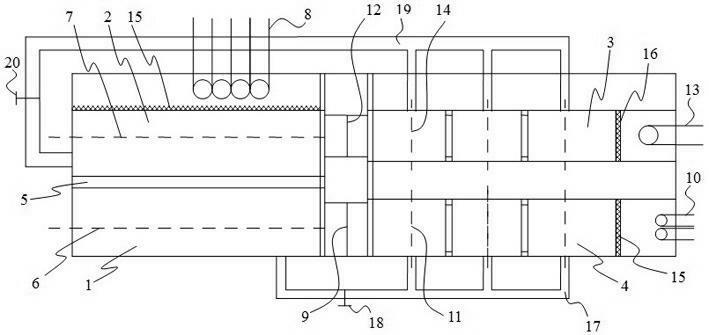

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device, in which a mechanical device is present which generates a combing action to loosen and remove non-clamped constituents, and a clamping element is present for transfer of the supplied fibre material. To enable productivity to be increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged two rotatably mounted rollers, which are provided with clamping devices for the fibre material having clamping elements that are distributed spaced apart in the region of the roller periphery and co-operate with counter-elements, the counter-elements in the case of the first roller being arranged opposite the roller periphery and in the case of the second roller on or in the roller.

Owner:TRUETZSCHLER GMBH & CO KG

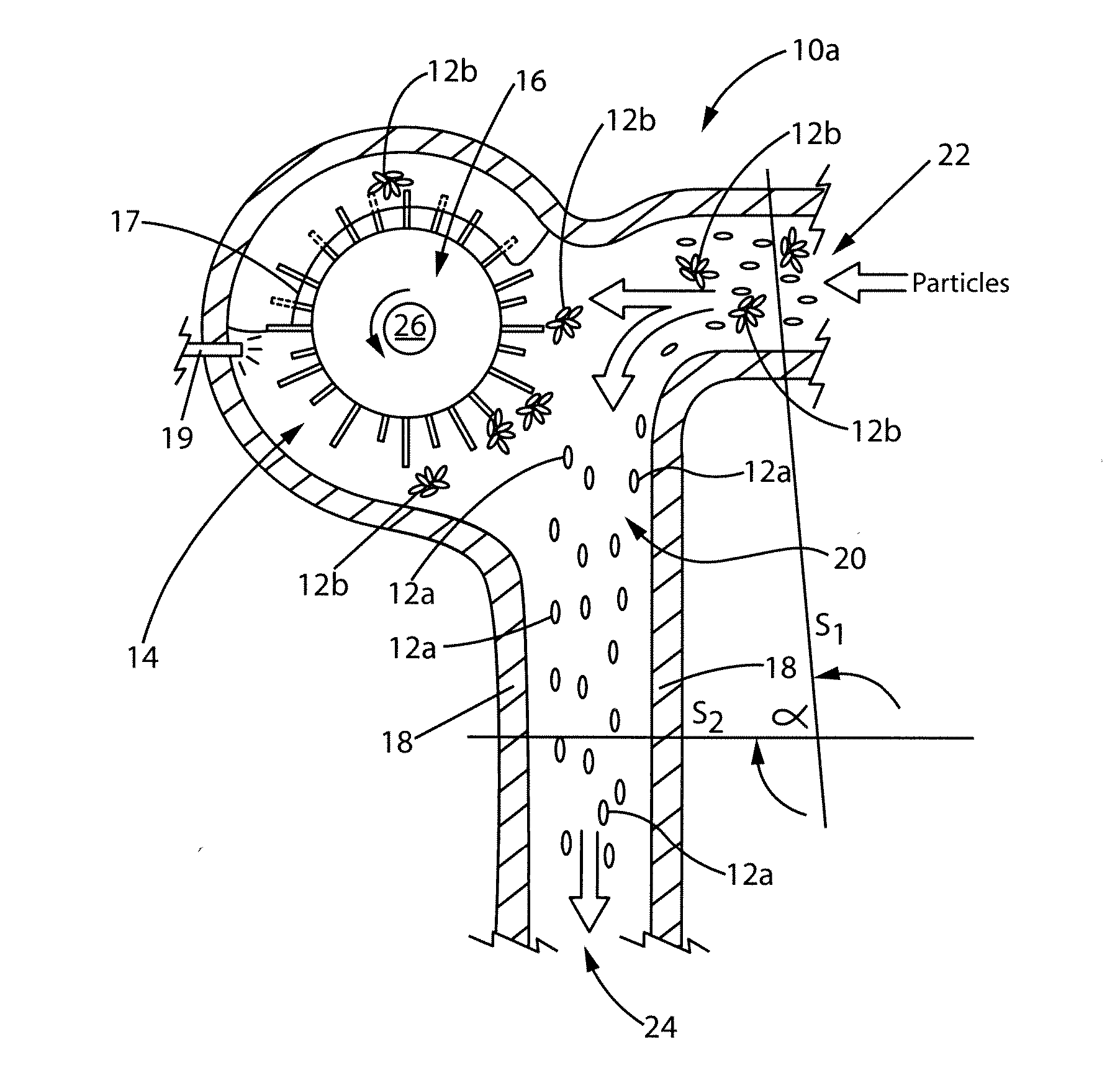

Apparatus for separating particles and methods for using same

Owner:THE PROCTER & GAMBLE COMPANY

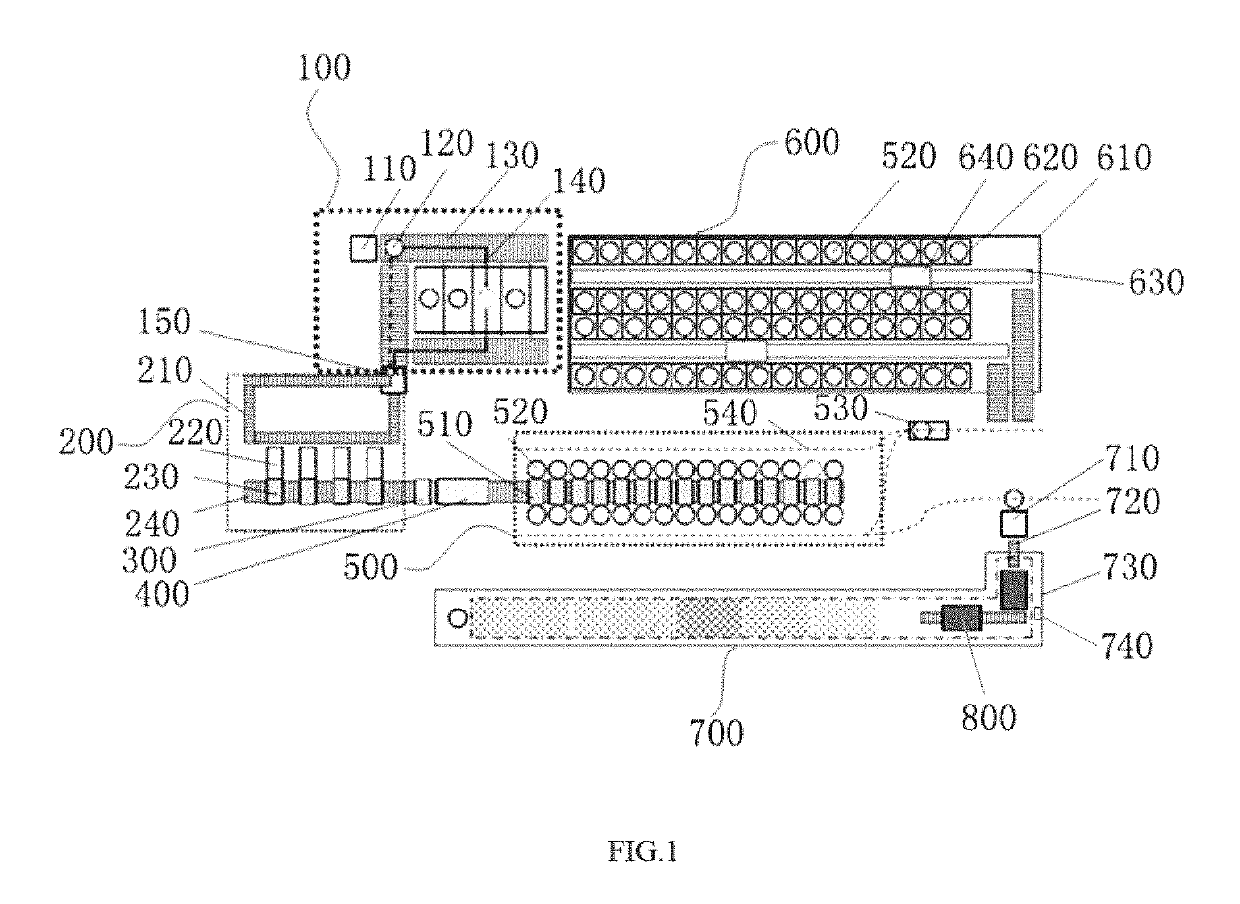

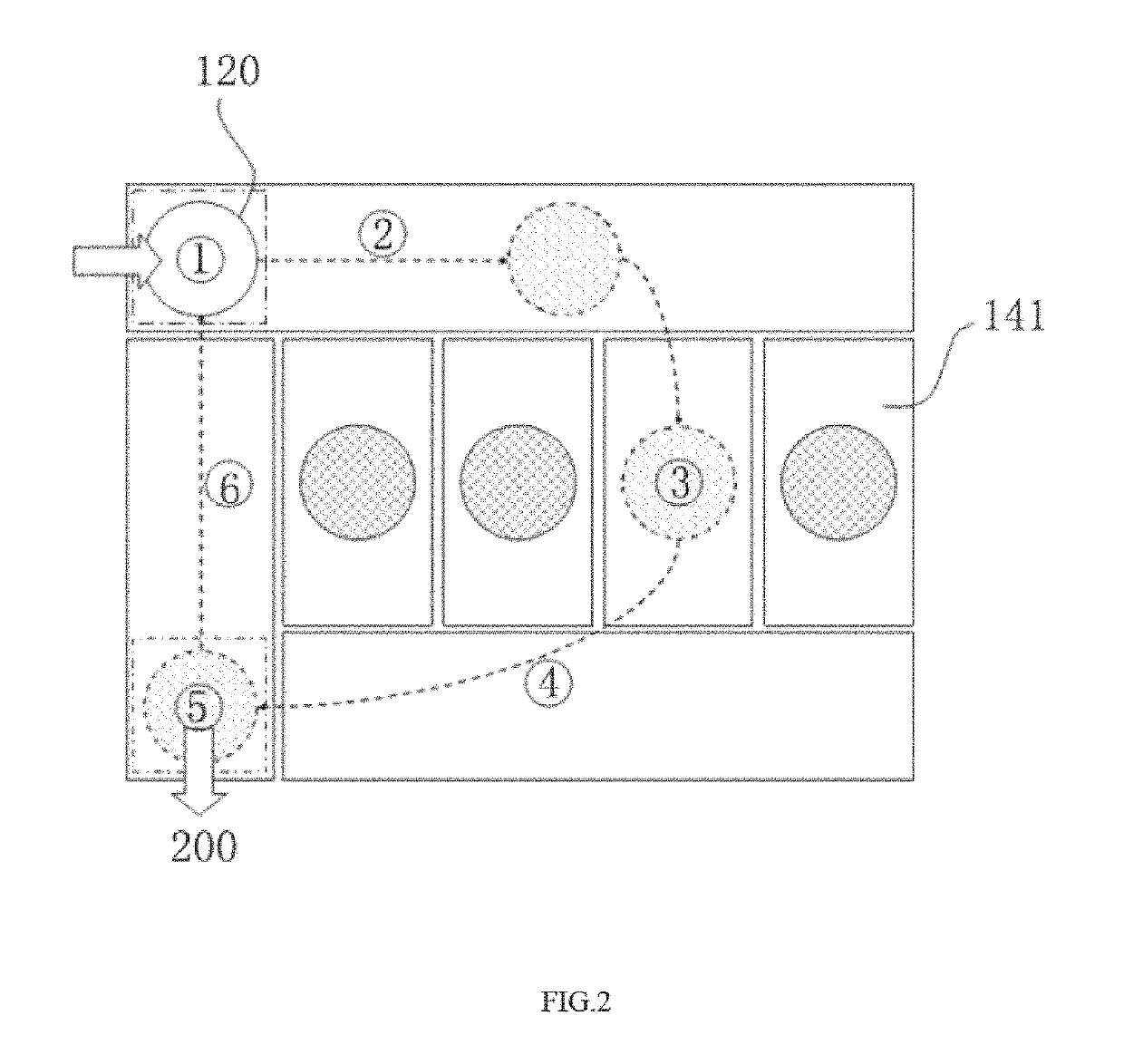

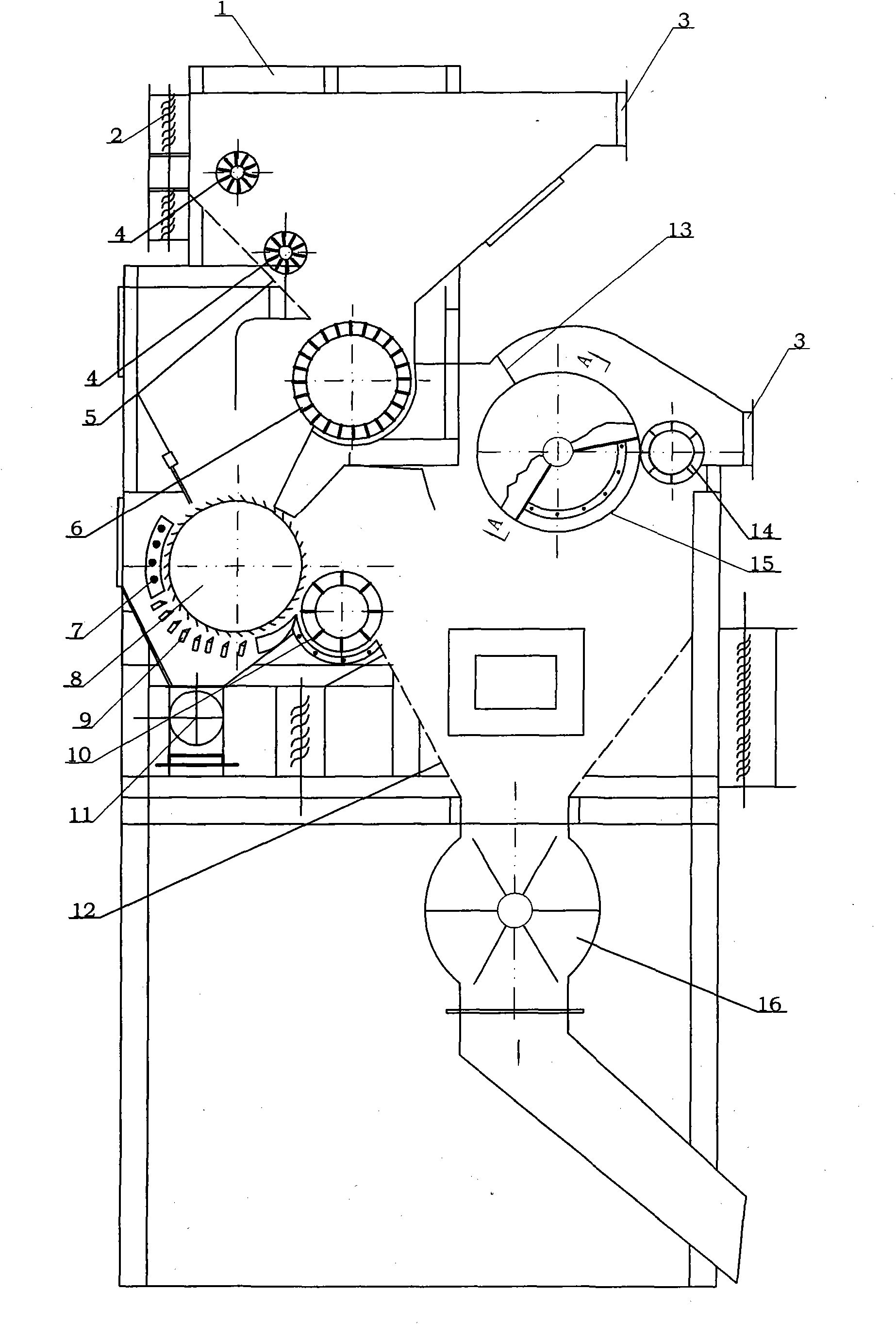

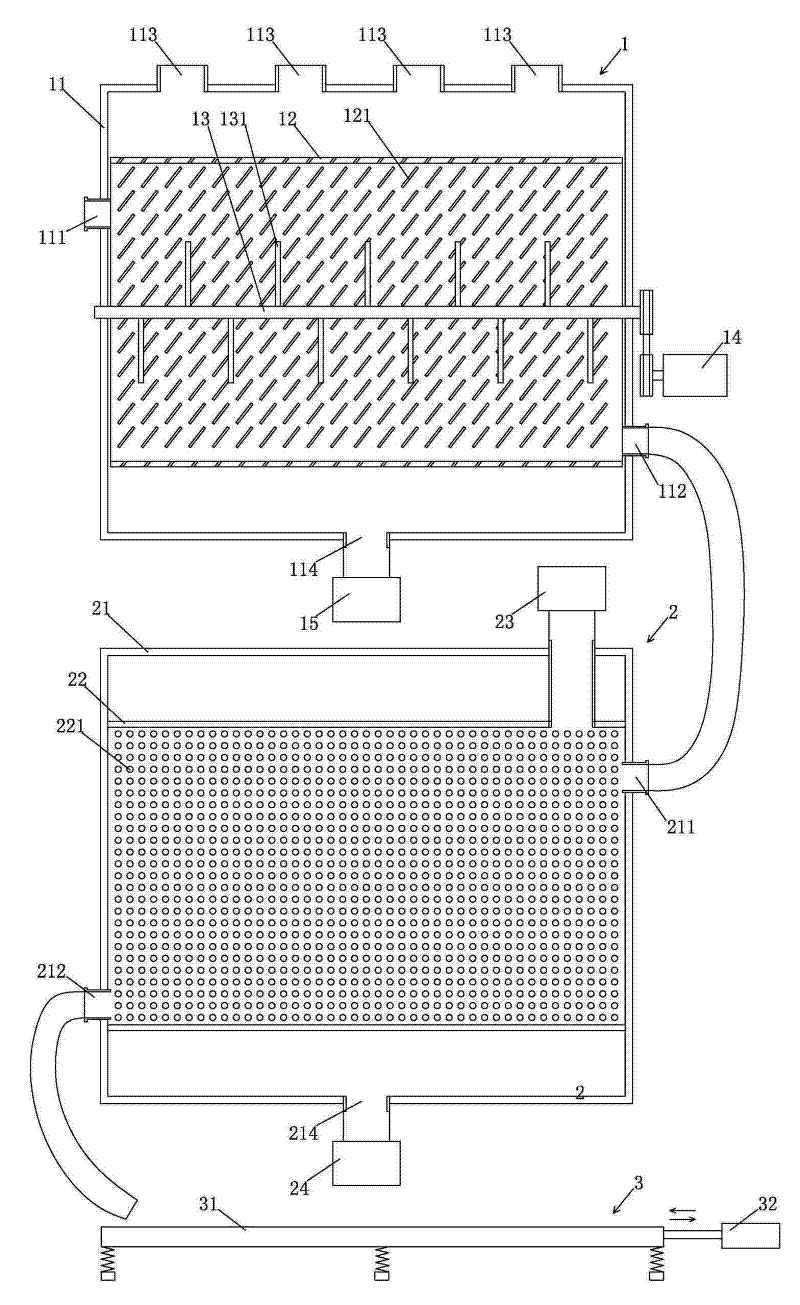

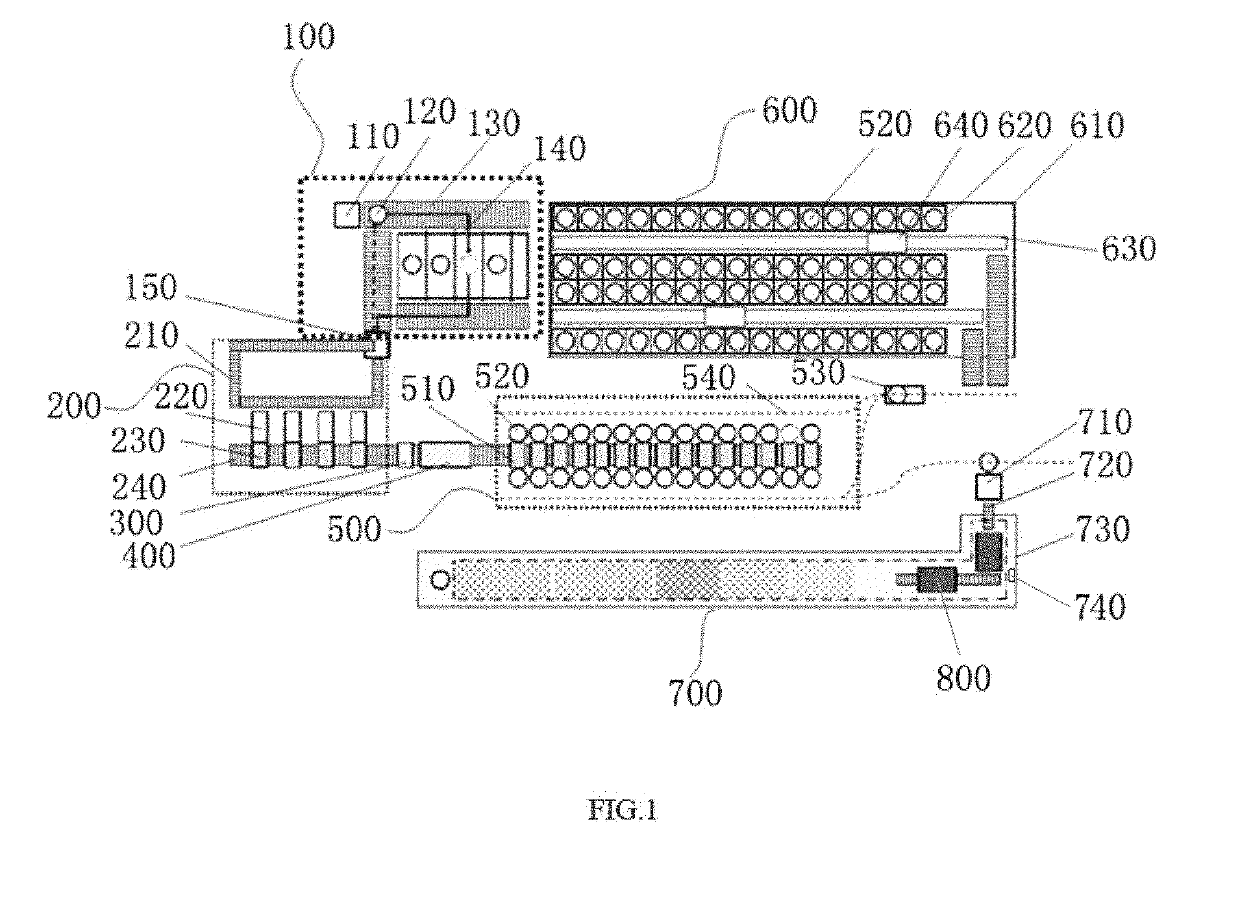

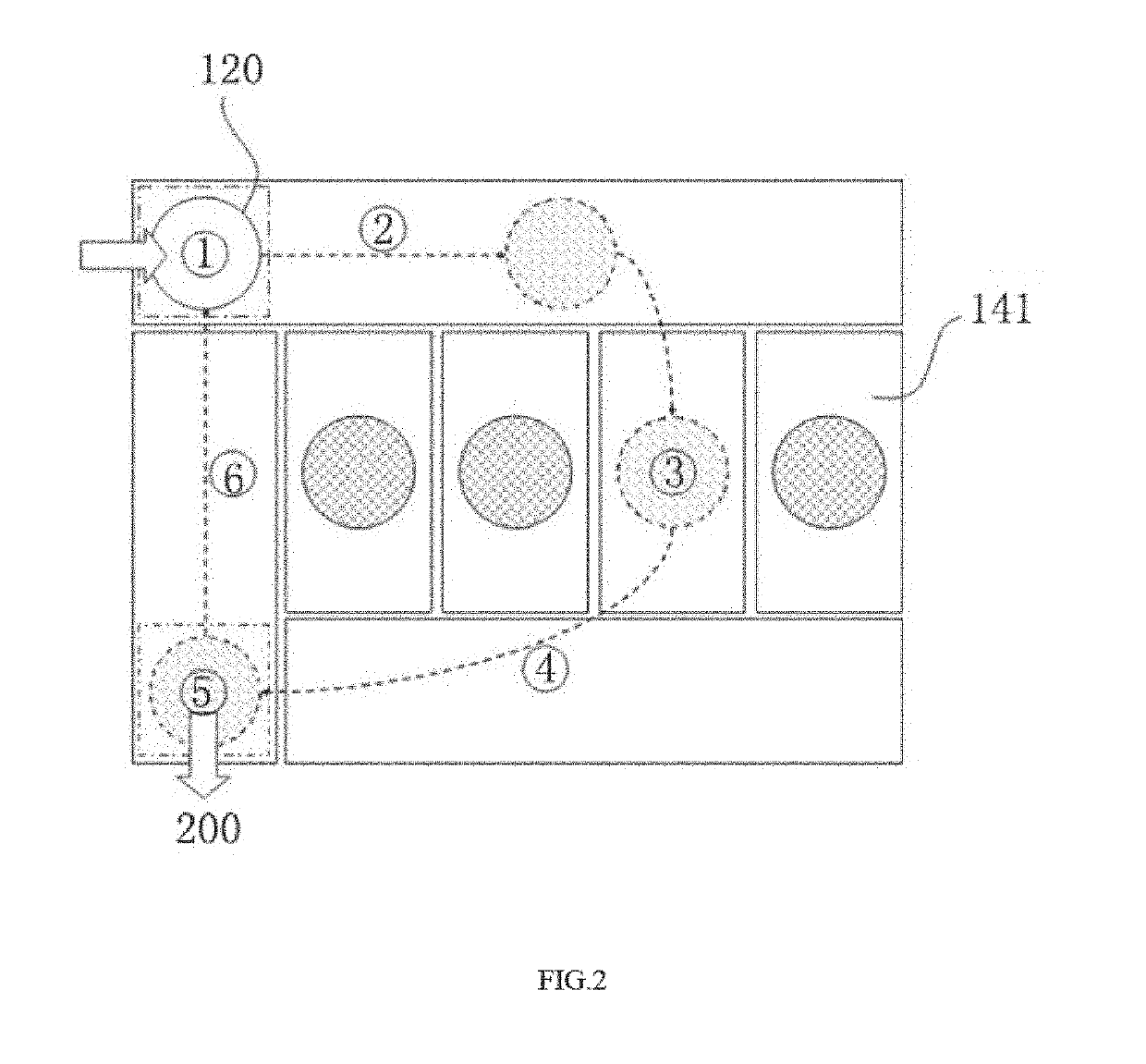

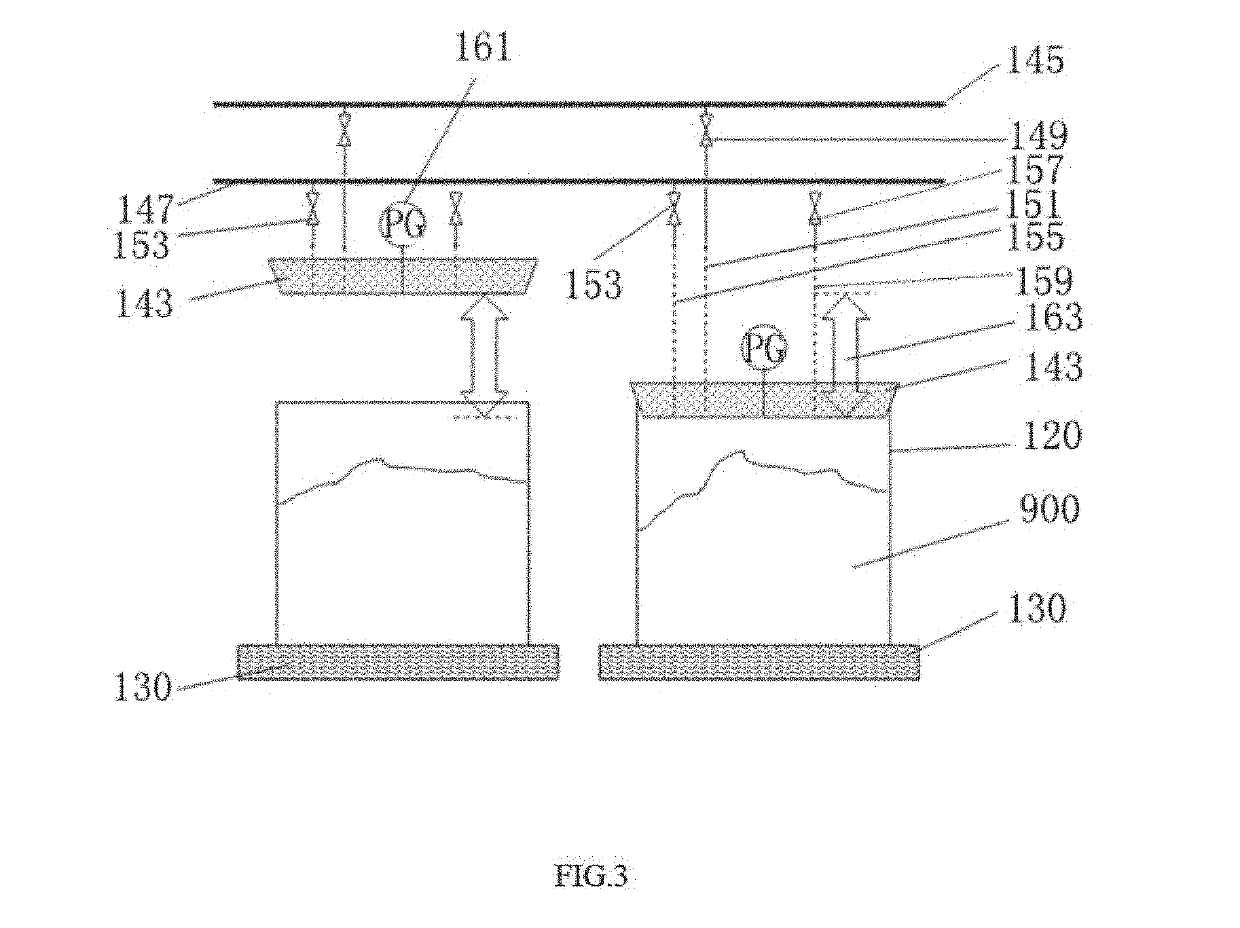

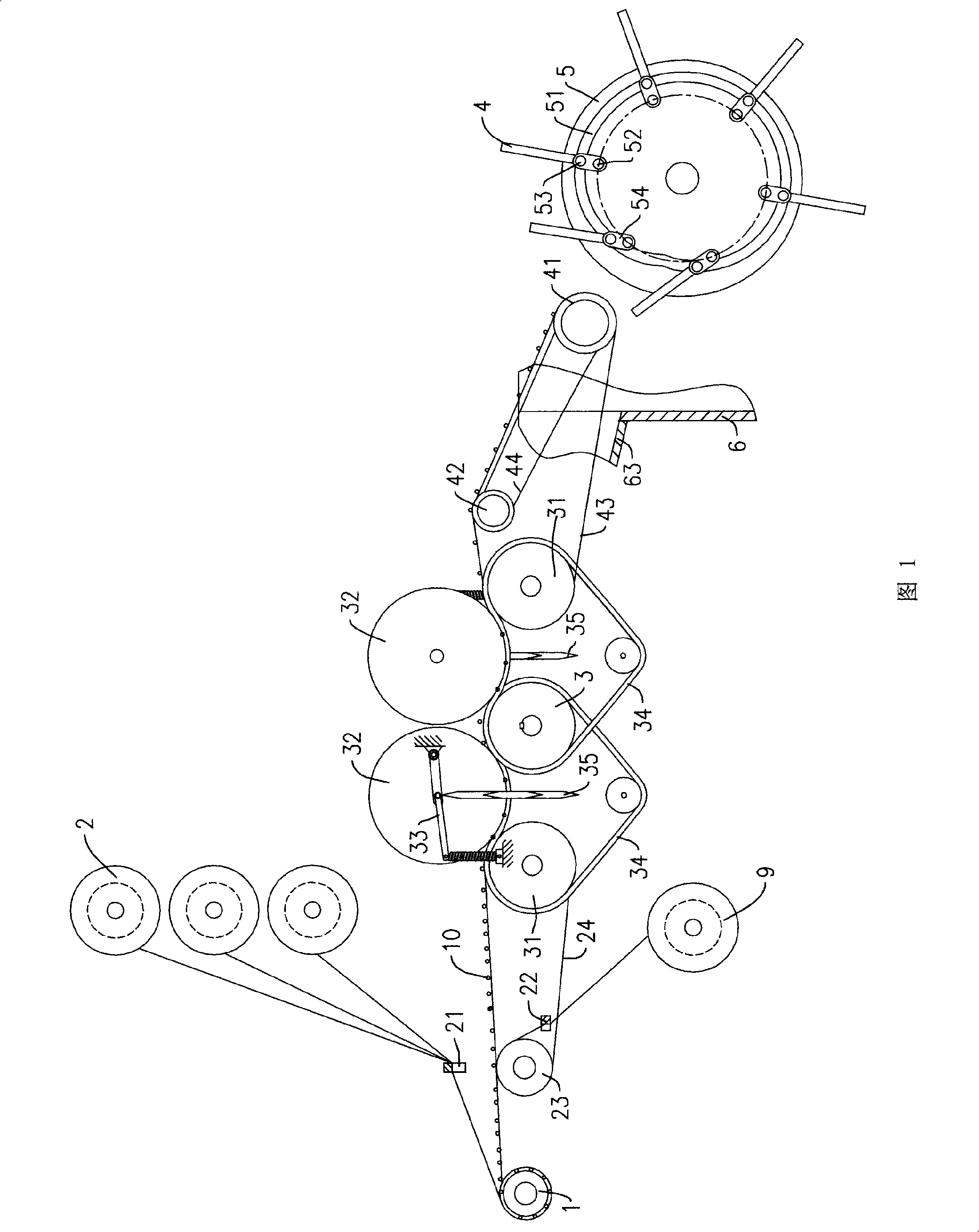

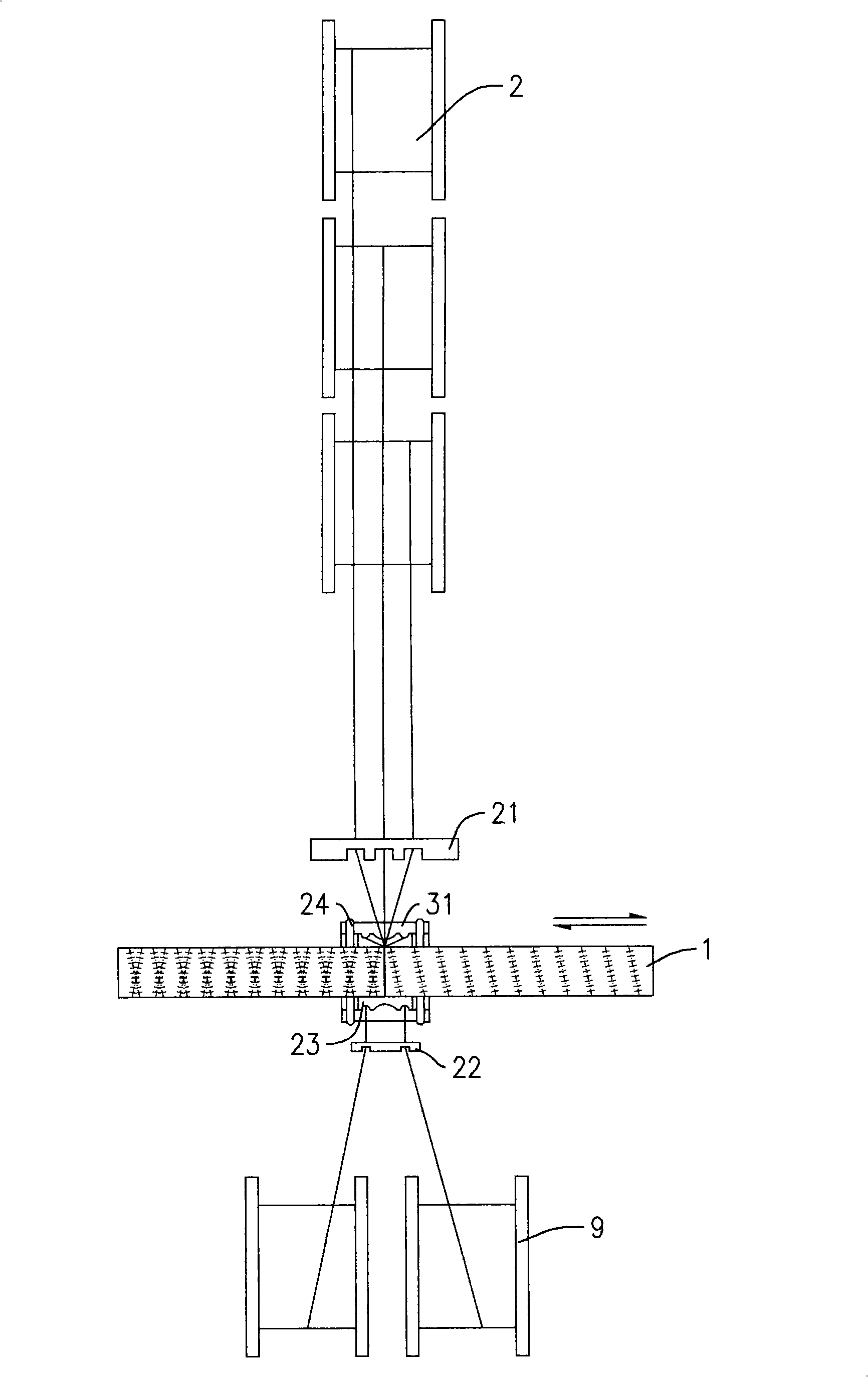

System and method for recycling fibers from textiles waste

ActiveUS10458047B2Fibre cleaning and opening machine combinationsSolid waste disposalFiberPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

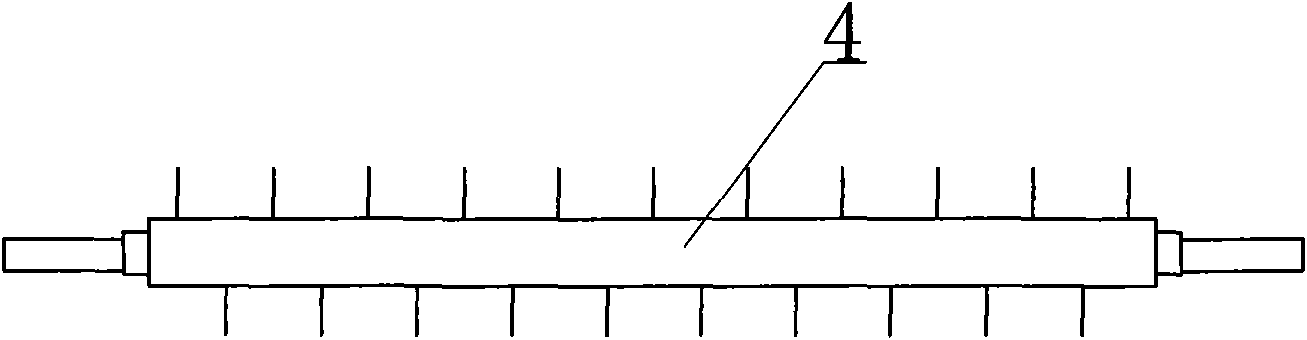

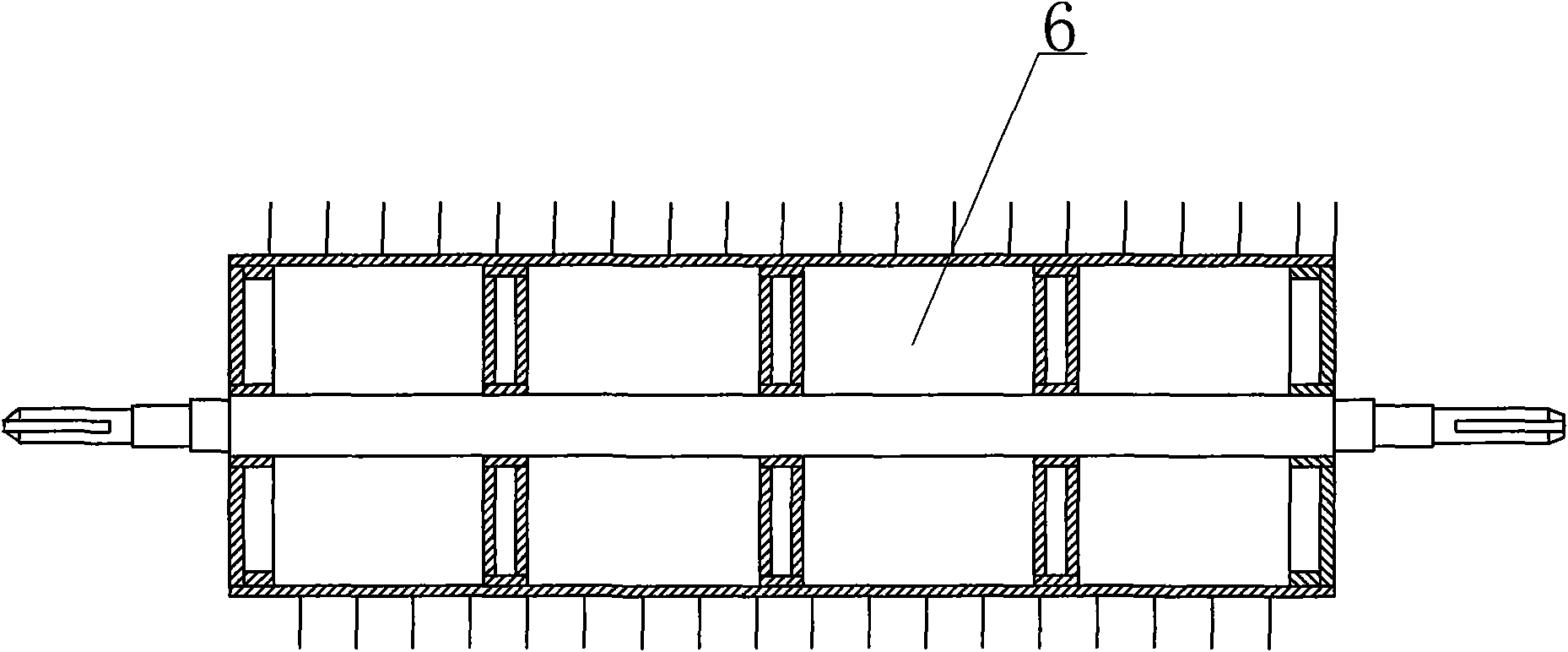

Production technology of the best down feather hanging down feather and hanging down feather screening device

The invention belongs to the technical field of down feather deep processing and particularly relates to a production technology of the best down feather hanging down feather and a hanging down feather screening device. The hanging down feather screening device is provided with a screening box body, a roller screen is arranged inside the screening box body, a blowing leakage tube is arranged in the middle of the roller screen, two ends of the roller screen are connected with a drive motor through a rolling shaft, at least one of two ends of the blowing leakage tube is connected with an air blower, screening holes are evenly formed in the surface of the roller screen, and air leakage holes are evenly formed in the surface of the blowing leakage tube. The feather and down feather row materials are sequentially processed by a preliminary classification process, a dust removing process, a water washing process, a drying process and a hanging down feather screening process. On the basis of the existing down feather processing technology, technological innovation is conducted to be combined with the hanging down feather screening technology, the down feather produced by white gooses in western Anhui is used as raw materials, and thereby down feather content of the screened hanging down feather is close to 100%, wherein the down feather has unique qualities such as big down feather flower, high bulkiness and extremely good quality.

Owner:六安皖智知识产权运营有限公司

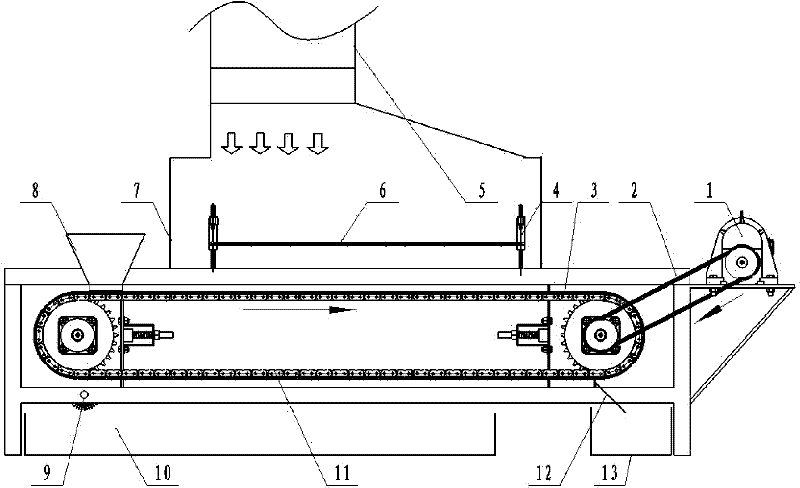

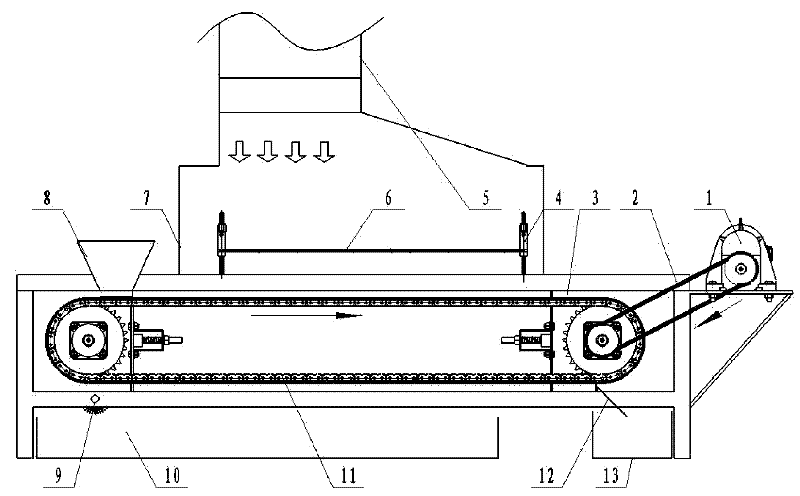

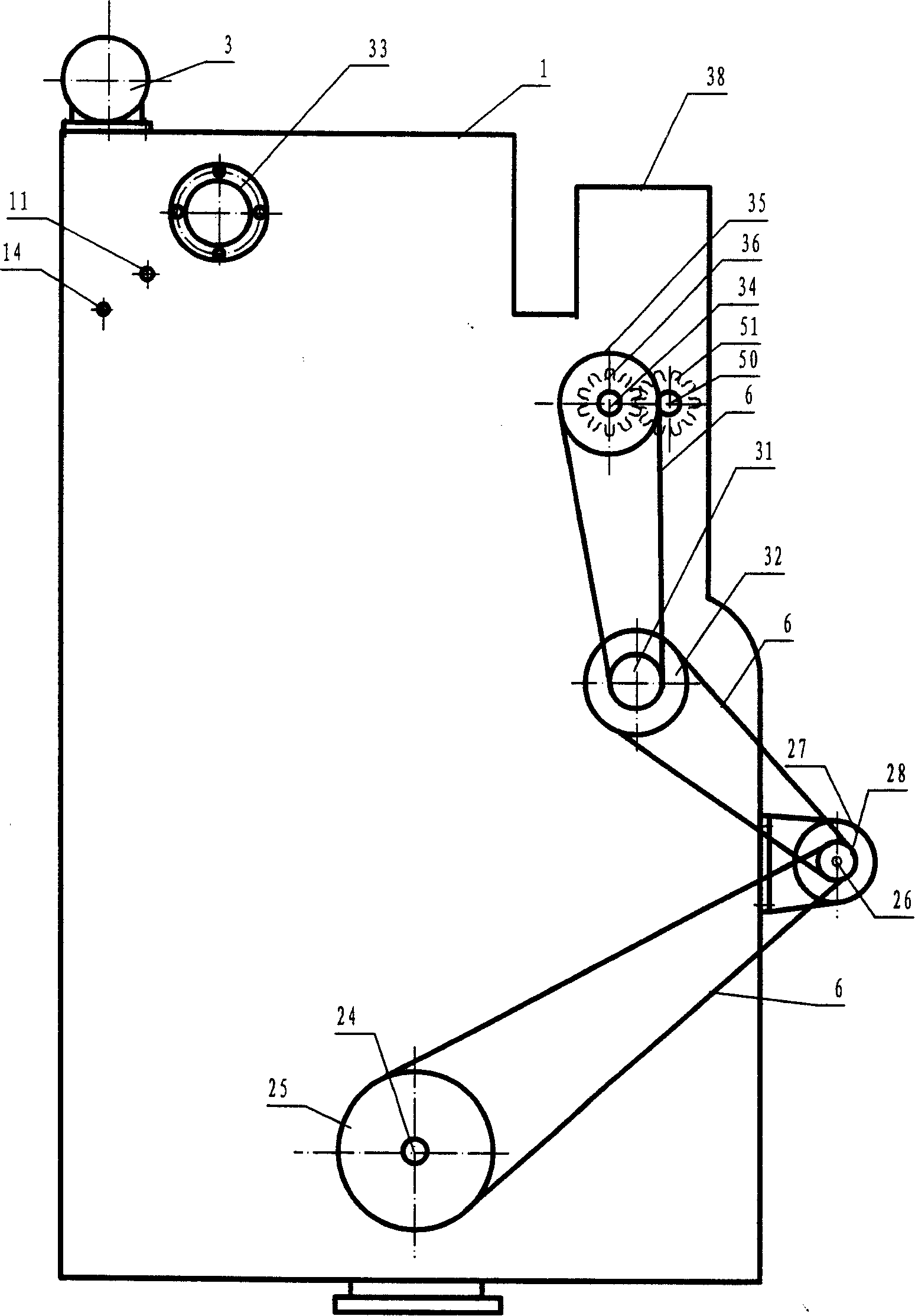

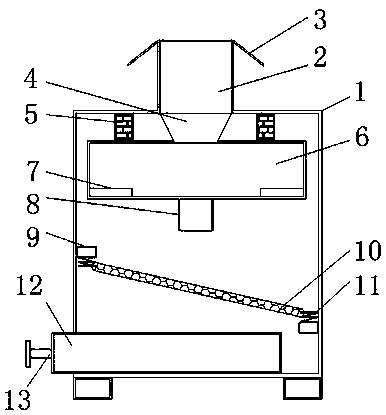

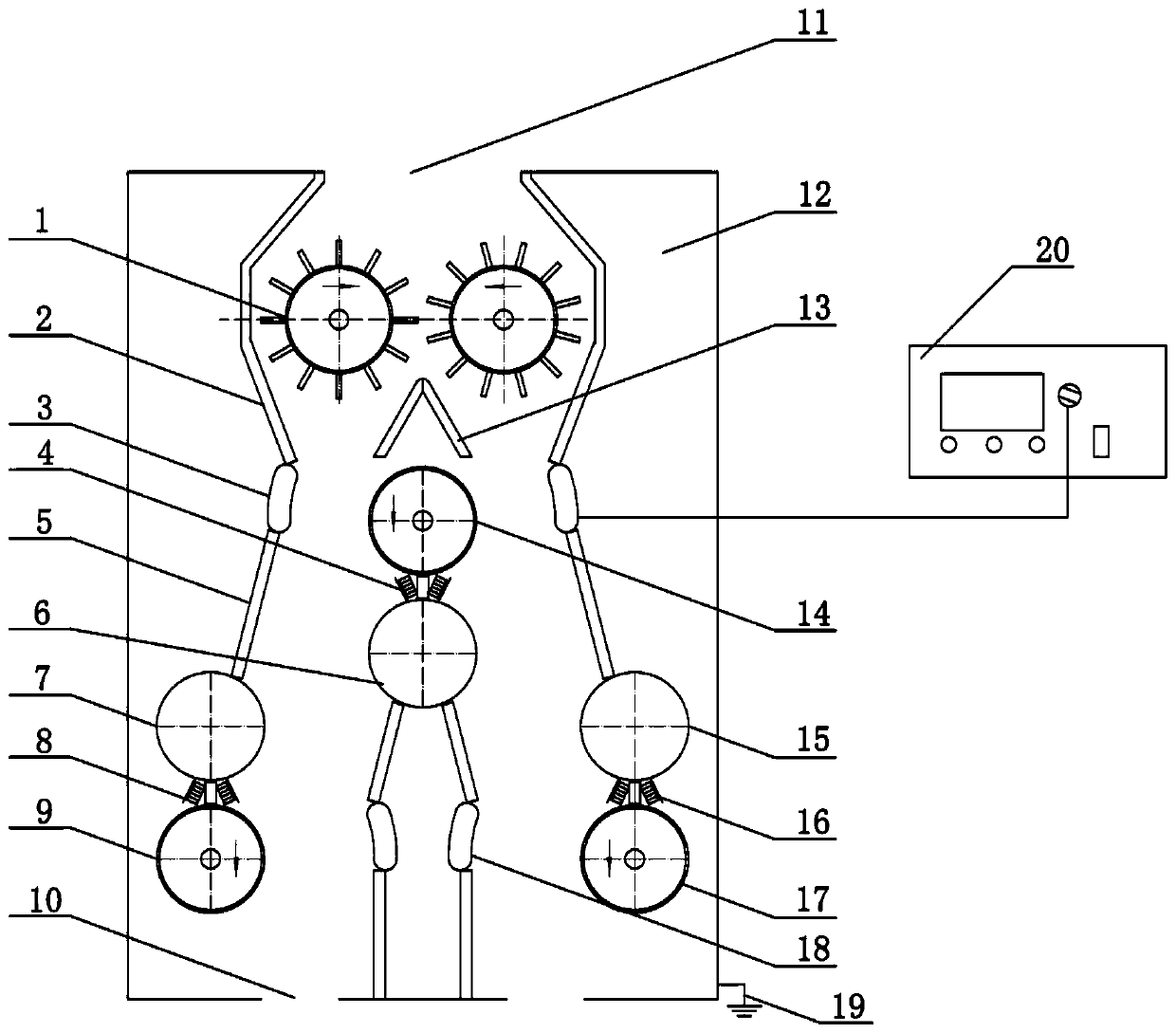

Static wind power type foreign fiber separation device

ActiveCN102505192AEfficient removalUniform electric fieldFibre separationFiberAgricultural engineering

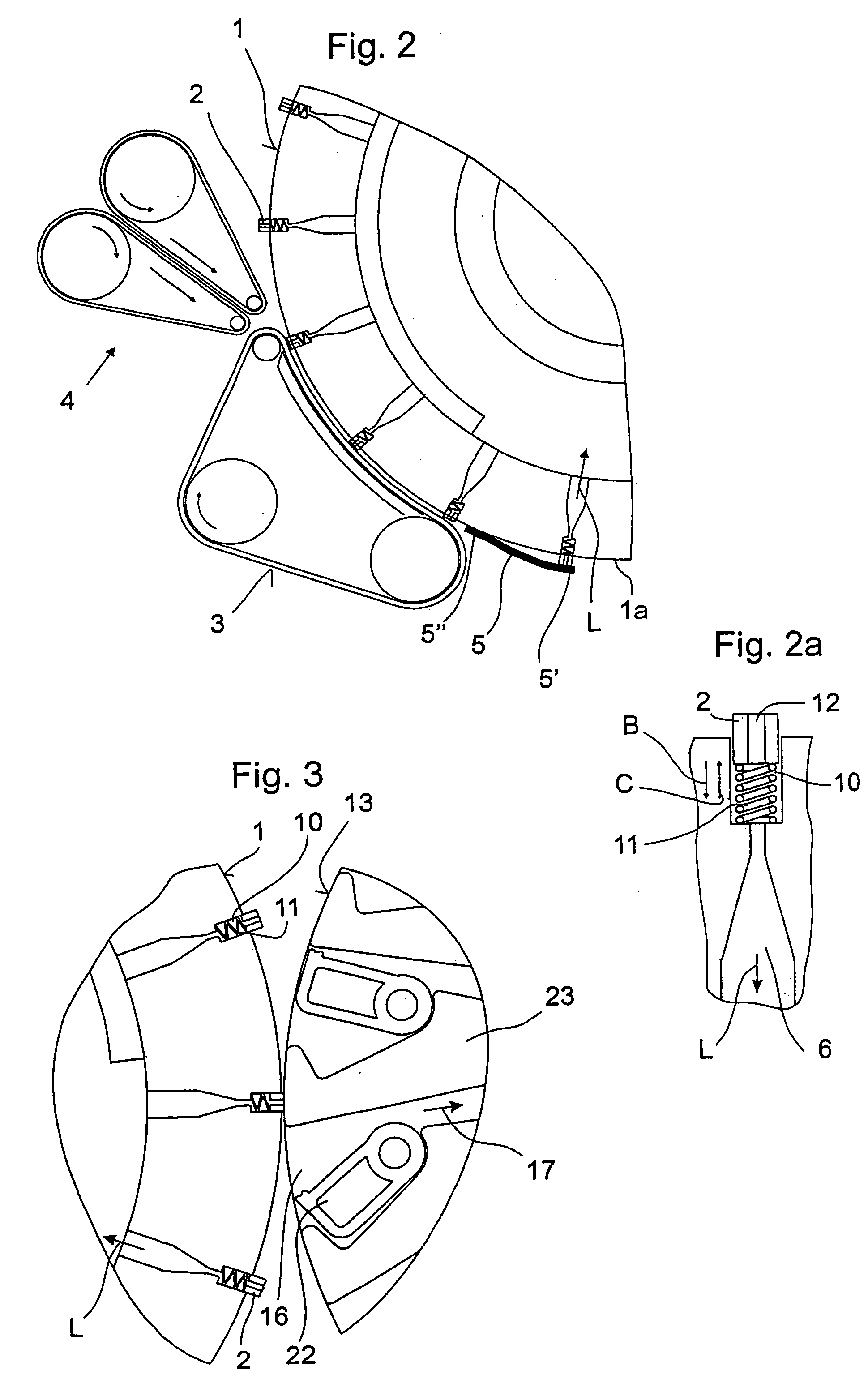

The invention discloses a static wind power type foreign fiber separation device, which belongs to the field of agricultural machinery and comprises a machine frame, a motor, a belt, a conveying system, a feeding opening, a hair brush, a foreign fiber recovery box, a seed cotton outlet baffle plate, a seed cotton collecting box and a separation chamber, wherein the separation chamber comprises a separation chamber case, a blowing centrifugal fan, a high-voltage electrode and an electrode plate support component, the high-voltage electrode and the electrode plate support component are arranged inside the separation chamber case and are connected, the blowing centrifugal fan is fixedly arranged at the upper part of the separation chamber case, the high-voltage electrode comprises an insulation bar provided with a deep groove and a sawtooth-shaped electrode fixedly arranged in the deep groove, one end of the upper part of the machine frame is fixedly provided with the motor, the motor is connected with the conveying system through the belt, the conveying system is fixedly arranged at the side surface of the machine frame, the feeding opening is fixedly arranged at the other end of the upper part of the machine frame, the lower end of the separation chamber is fixedly arranged between two ends of the upper part of the machine frame, and the seed cotton outlet baffle plate, the seed cotton collecting box, the foreign fiber recovery box and the hair brush are respectively and fixedly arranged at the lower part of the machine frame. The static wind power type foreign fiber separation device can be used for effectively removing foreign fibers mixed in various substances.

Owner:SHIHEZI UNIVERSITY

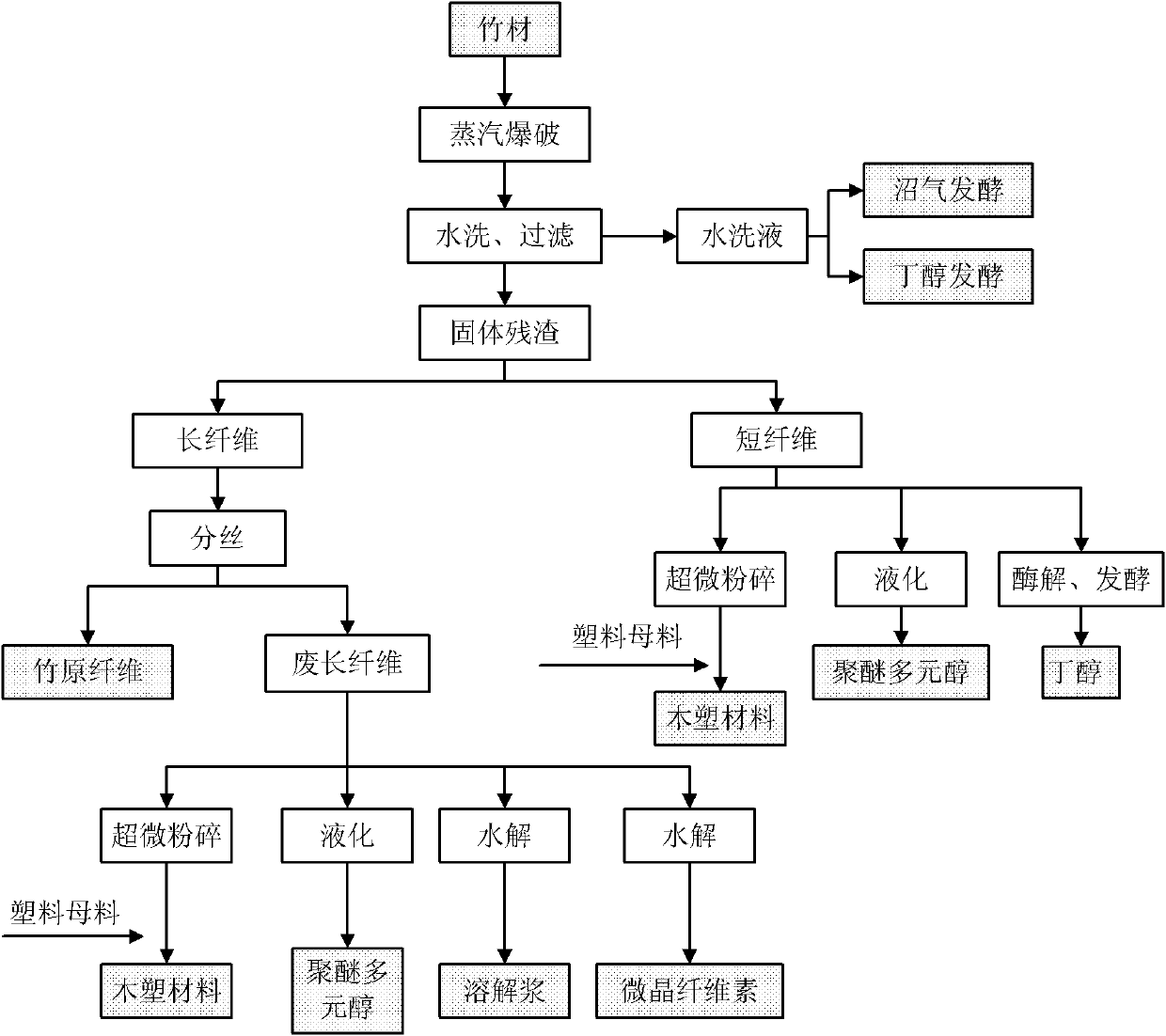

Method for preparing ecological materials through steam explosion and refining of bamboo and recycling bamboo

InactiveCN102140699AIncrease profitIncrease added valueFibre separationVegetable materialFiberProcess systems

The invention belongs to the field of utilization of bamboo resources, relates to a method for preparing ecological materials through steam explosion and refining of bamboo and recycling the bamboo, and mainly aims to comprehensively utilize the bamboo resources in an environment-friendly high-value mode and co-produce biobased ecological materials such as bamboo fibers, a wood-plastic material and the like, and clean energy such as biogas and the like. The technical scheme comprises the following steps that: (1) the bamboo is subjected to steam explosion, and washed and filtered so as to obtain washing solution and a fiber material, and the washing solution is used for fermenting bioenergy such as the biogas, butanol and the like; (2) waste long fibers produced in the process of preparing the bamboo fibers from long fibers can be used for preparing the ecological materials such as the wood-plastic material, microcrystalline cellulose, dissolving pulp, liquefied polyether polyol and the like; and (3) short fibers are subjected to enzymolysis and fermentation for fermenting biological butanol, and also can be used for preparing the ecological materials such as the wood-plastic material, the liquefied polyether polyol and the like. Through the technical scheme, the utilization rate and the added value of the bamboo resources are high, and a bamboo refining process system is low in energy consumption, simple in process, clean and environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

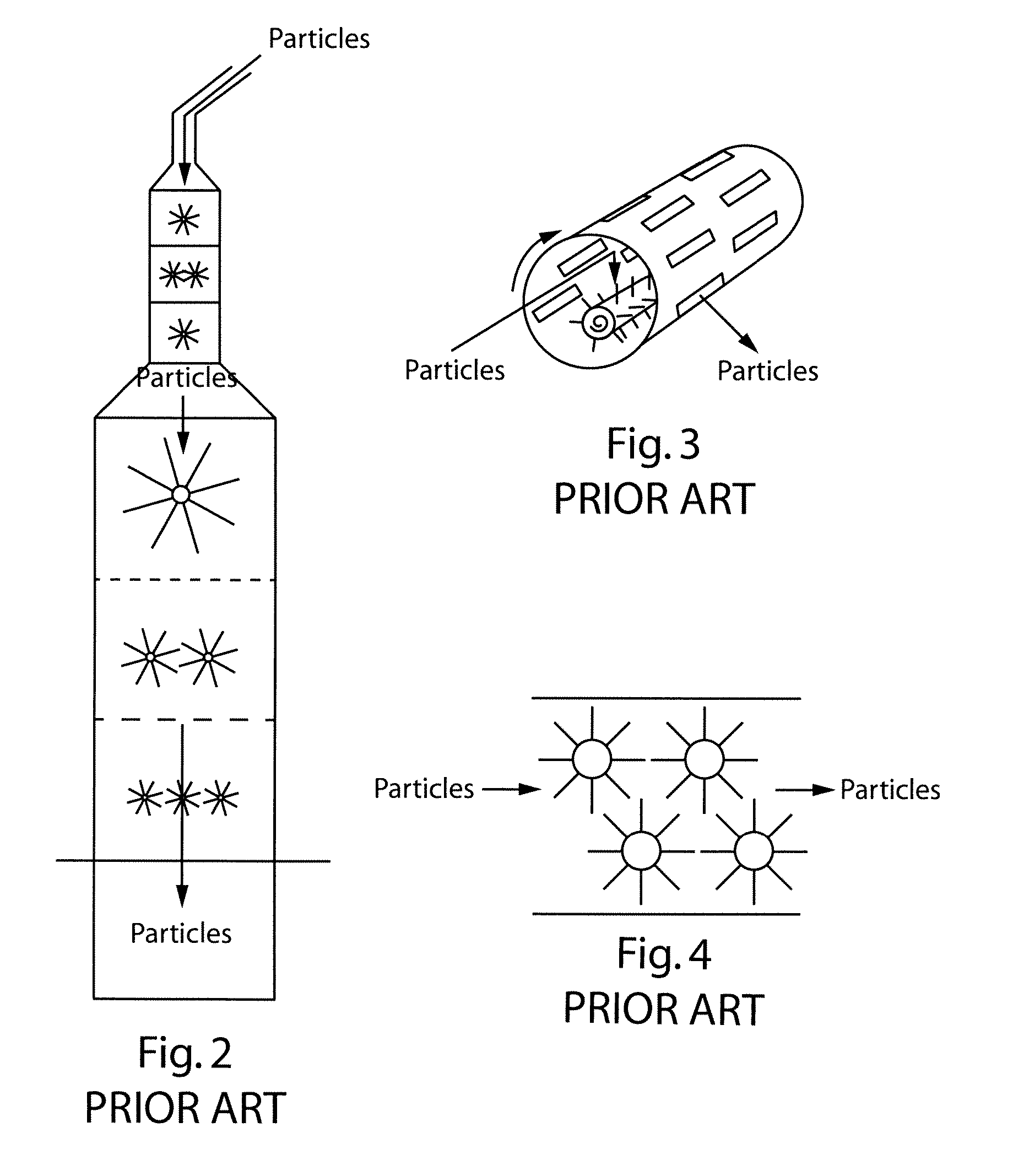

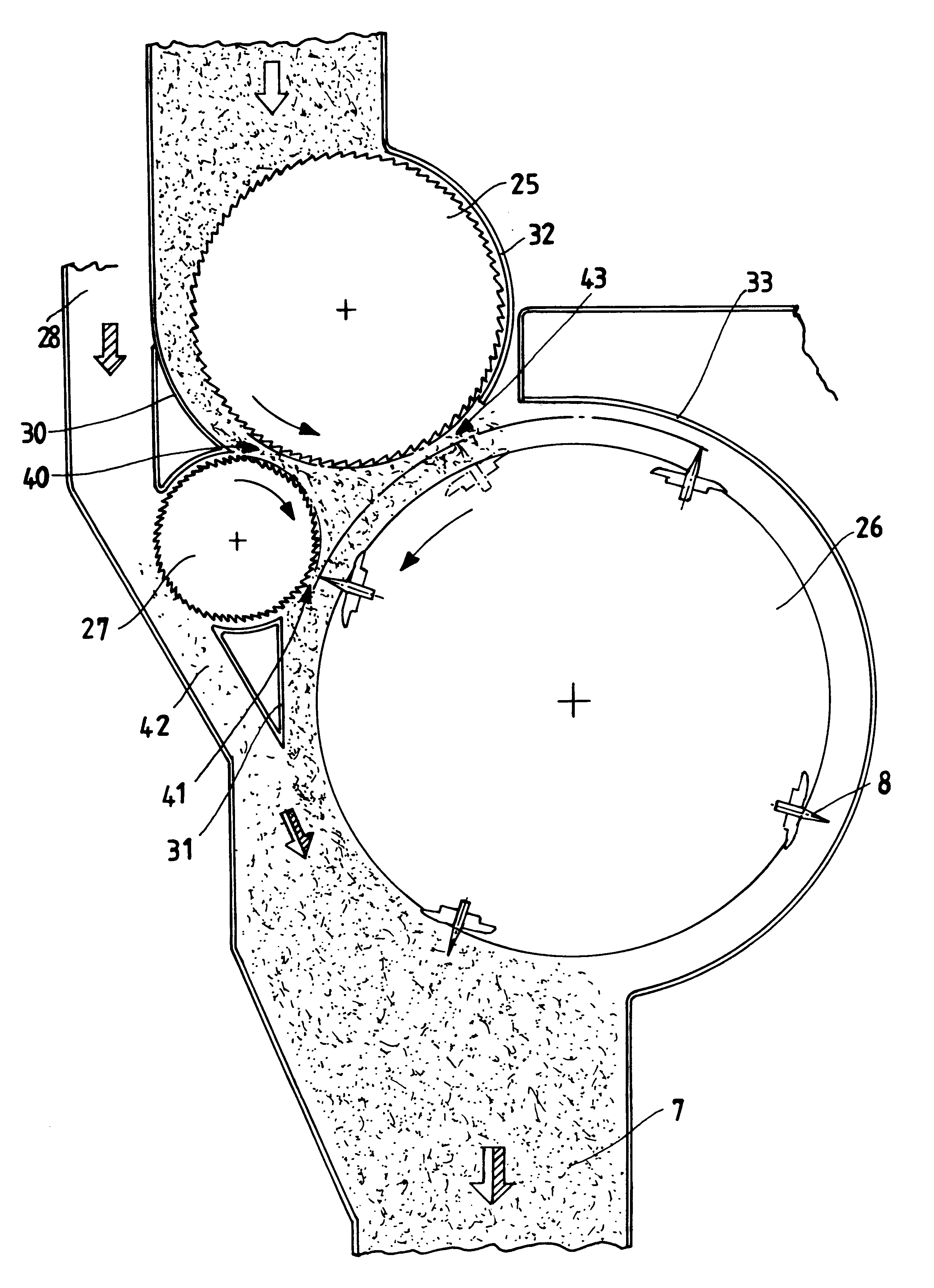

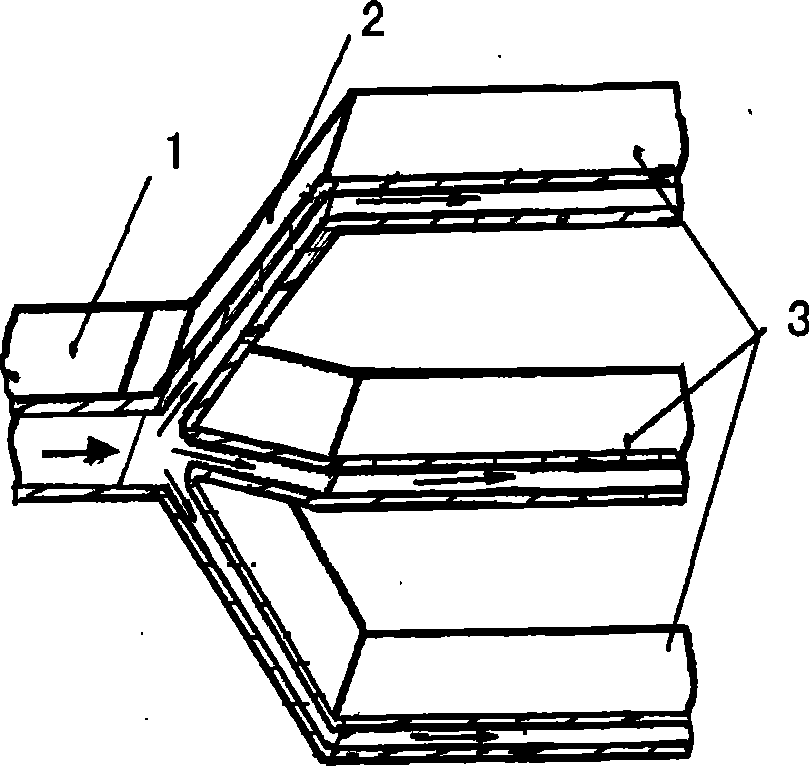

Device for preparation and opening of flock fibers to be supplied to a carder

InactiveUS6195841B1Mechanical impurity removalFibre cleaning/opening by toothed membersFiberEngineering

Silo for supply of flock fibers to a carder, which silo is subdivided into superimposed chambers, between which there is interposed a set of rollers which regulate the descending flow, and carry out breaking and separation of the fibrous material, in which a supply roller, an auxiliary supply roller and a breaker roller are disposed in a triangle, in which the surface of the auxiliary roller opposite that which is tangent to the supply roller is exposed to the flow of air which descends downwards, together with the fibers worked by the breaker roller.

Owner:MARZOLI

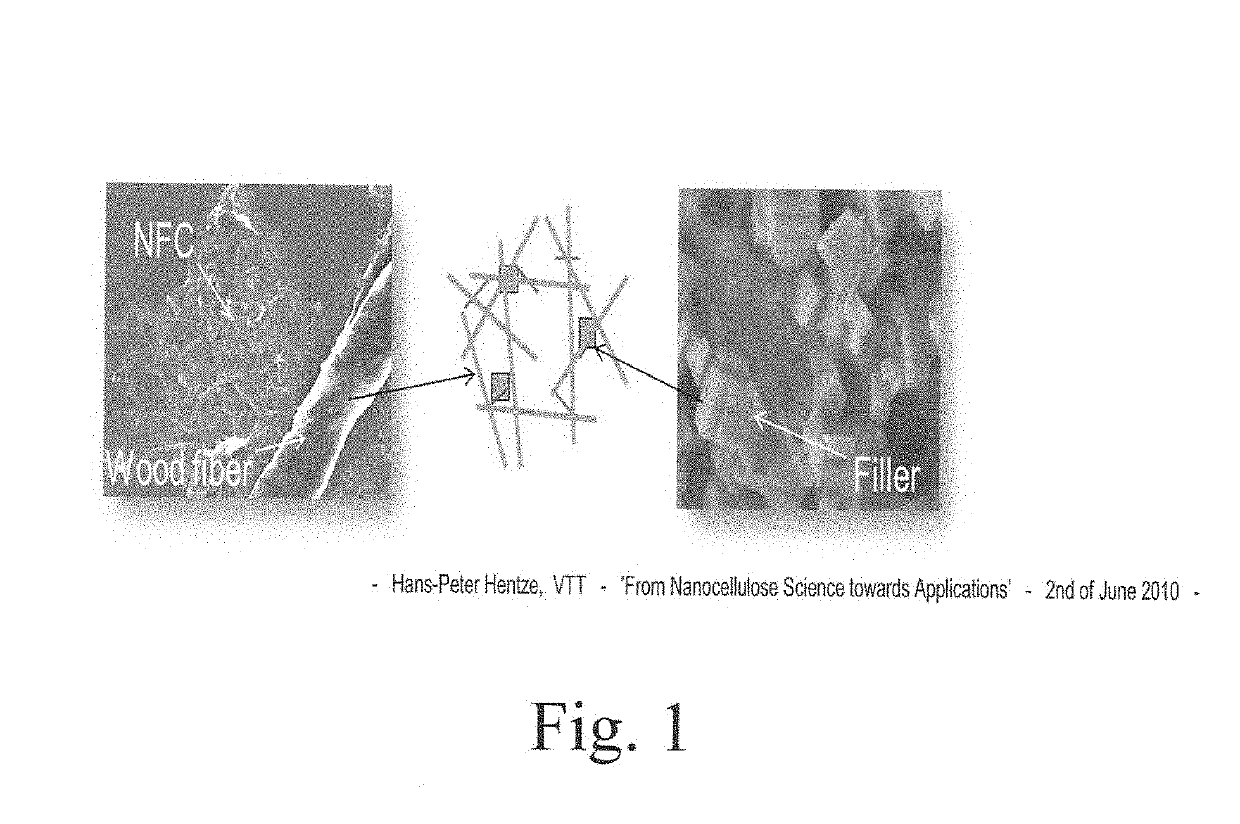

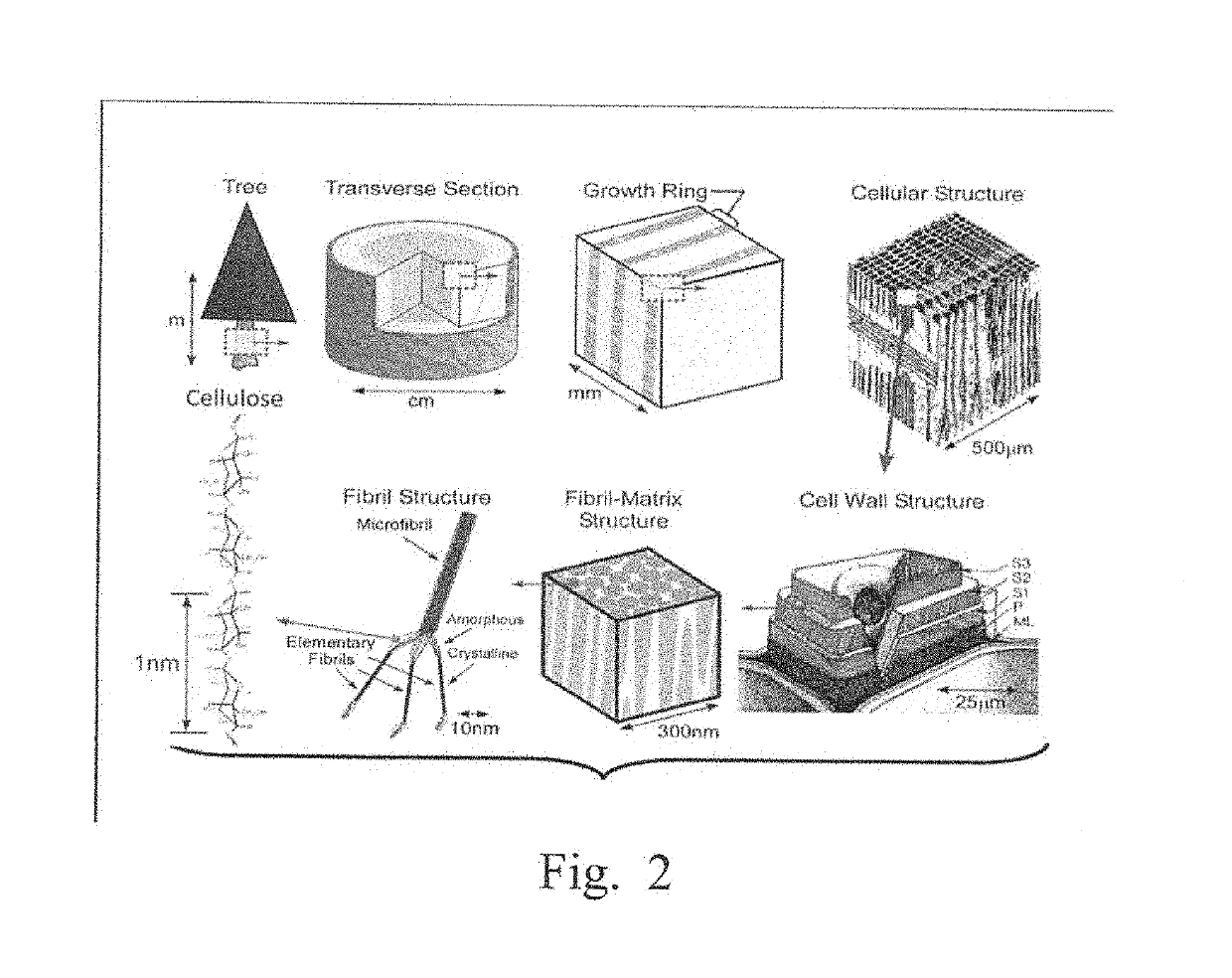

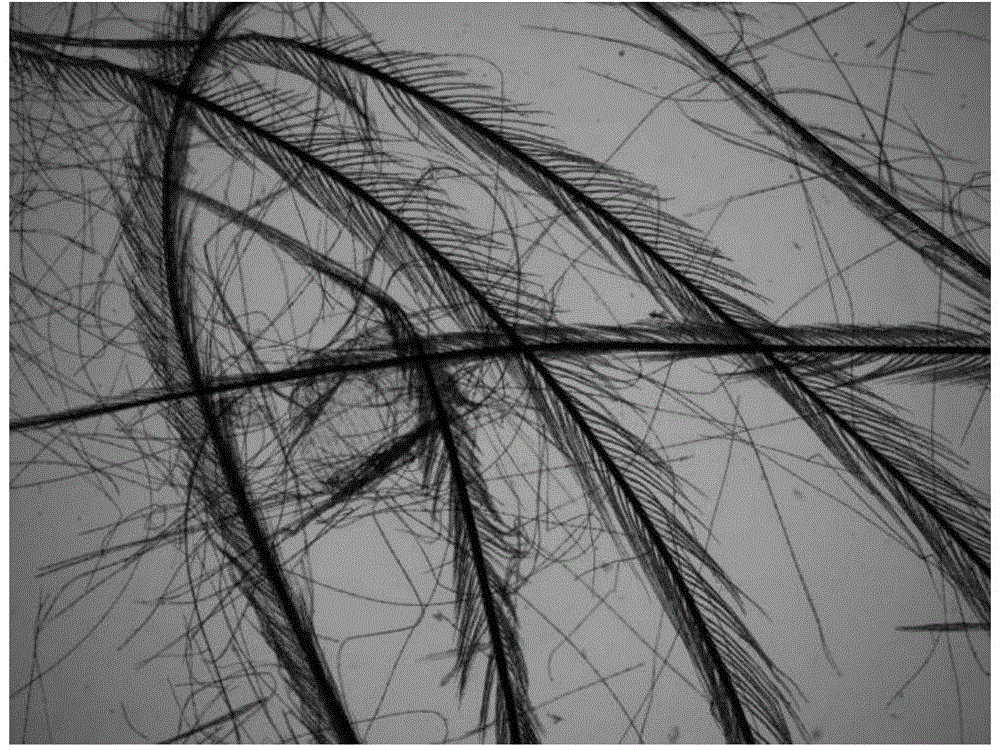

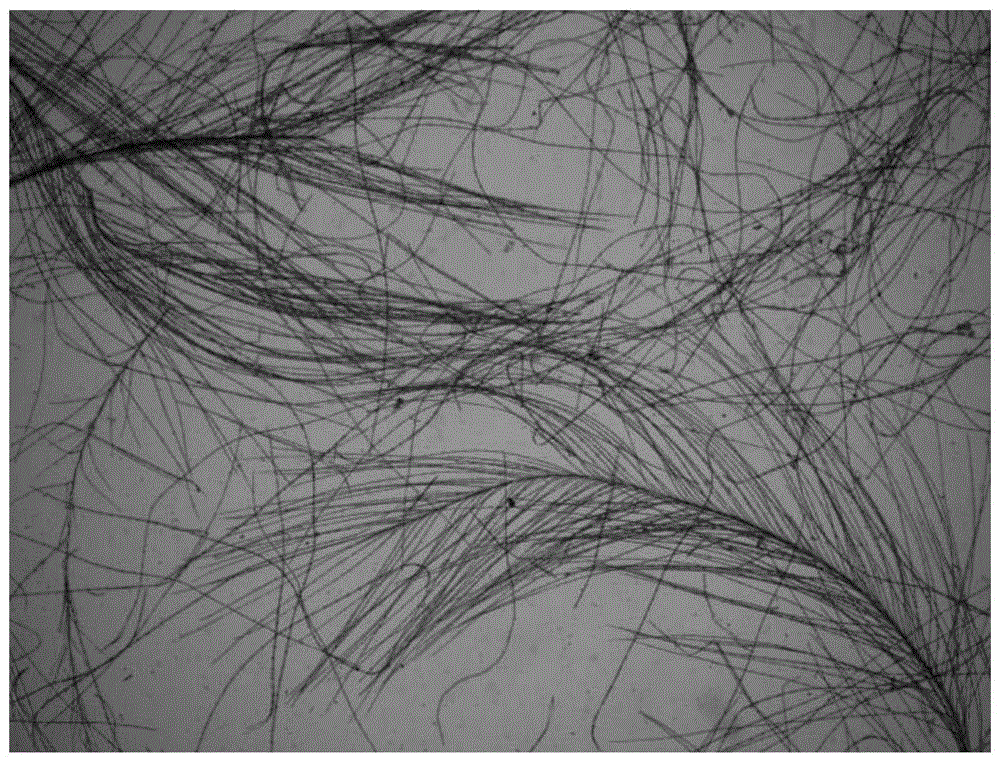

Processes for improving high aspect ratio cellulose filament blends

ActiveUS20190316293A1High aspect ratioDegradation of particle levelCellulosic pulp after-treatmentMonocomponent cellulose artificial filamentCelluloseOrganic chemistry

A process for improving high aspect ratio cellulose filament blends comprising the steps of: a) providing a blend of cellulose nano-filaments or blend of cellulose micro-filaments; b) diluting the blend of cellulose nano-filaments or the blend of cellulose micro-filaments to a target consistency; c) fractionating the diluted blend of cellulose nano-filaments or the diluted blend of cellulose micro-filaments from the step c); and, d) collecting the fraction of the diluted blend of cellulose nano-filaments or the diluted blend of cellulose micro-filaments from the step c) having an average length of greater than at least about 25 μm.

Owner:MERCER INT

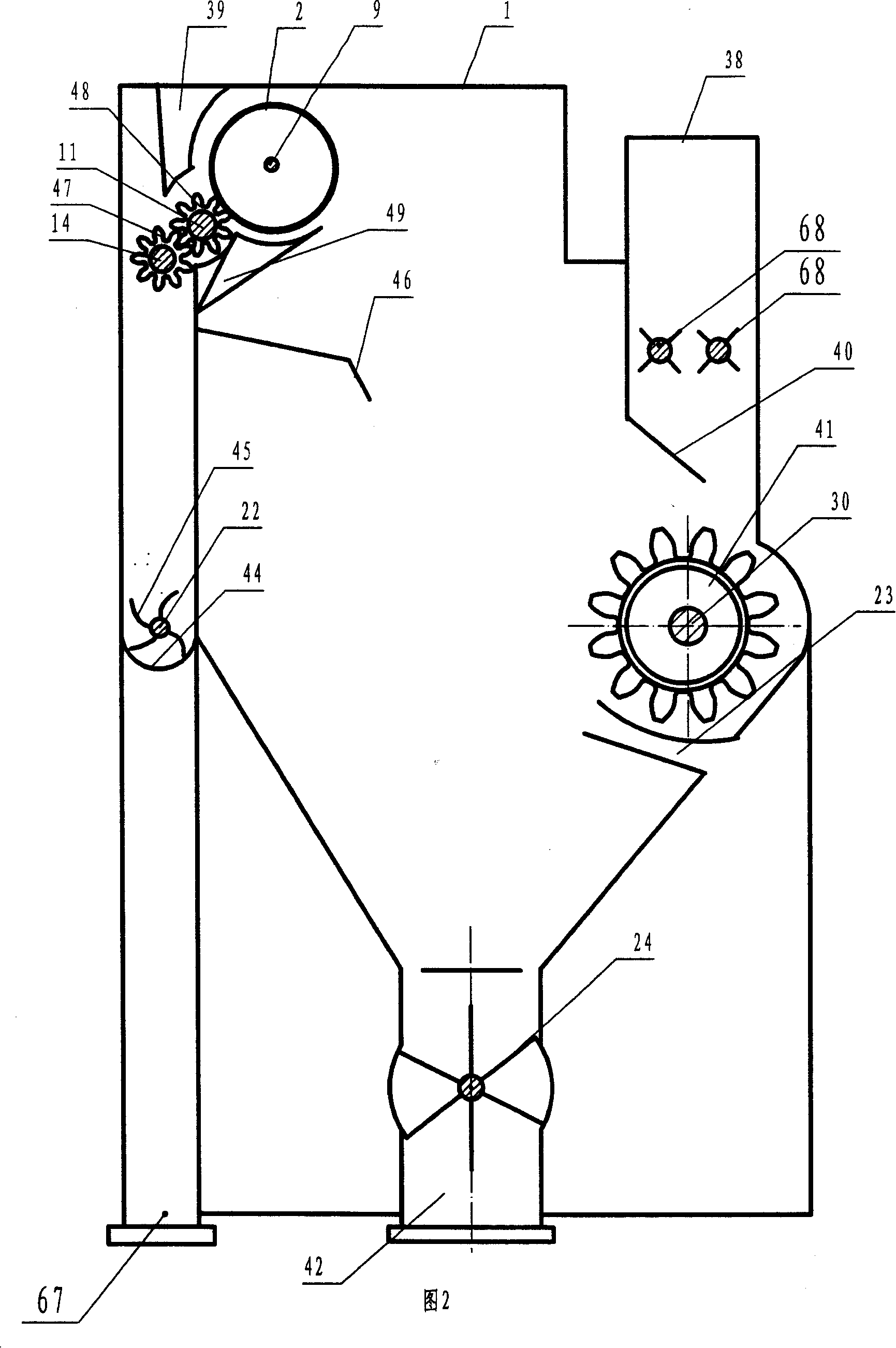

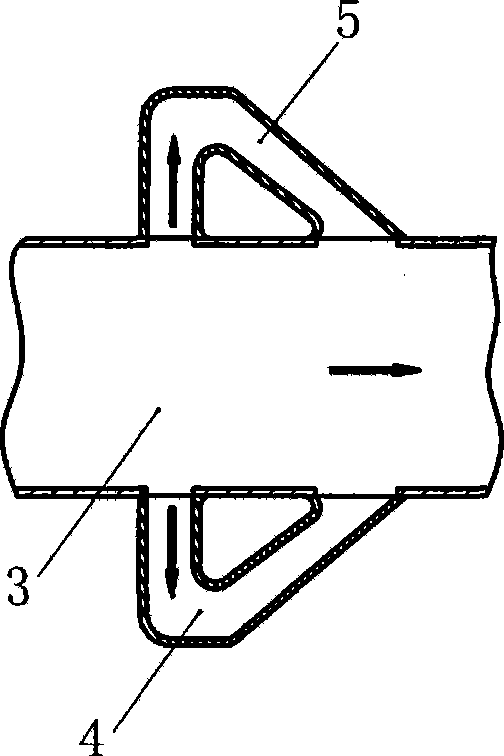

Distributary seed cotton foreign fiber capturing cleaner

InactiveCN101597803AEfficient exclusionReasonable structural designFibre separationMechanical treatmentFiberEngineering

The invention belongs to a mechanism for removing impurities in seed cotton, in particular to a distributary seed cotton foreign fiber capturing cleaner. In a first-grade cleaning chamber, two winding rollers are arranged on an inclined lateral wall formed by an air inlet screen plate; a feeding hole of a second-stage cleaning chamber connected with the first-grade cleaning chamber is provided with a barbed nail roller of which one lateral roller surface is matched with the inner wall of the second-stage cleaning chamber; a trash outlet of the barbed nail roller is provided with a sawtooth roller of which the roller surface is evenly distributed with sawteeth; one side of the sawtooth roller is sequentially provided with a trash grid rod and a trash grid plate which are matched with the sawtooth roller, and the other side of the sawtooth roller is provided with a cotton brushing roller; two lateral walls of a third-stage cleaning chamber connected with the second-stage cleaning chamber is formed by an air inlet mesh screen plate; a foreign light fiber separating roller is arranged at the upper part of the third-stage cleaning chamber; an airflow baffle is arranged at the upper part of the separating roller; the cotton brushing roller arranged at an air outlet of third-stage cleaning chamber is matched with the separating roller; and a discharging hole of the third-stage cleaning chamber is provided with a star stripper. The invention can effectively remove various foreign fibers and impurities mixed in the seed cotton, improve the quality and the grade of ginned cotton and achieve high production efficiency.

Owner:王礼华

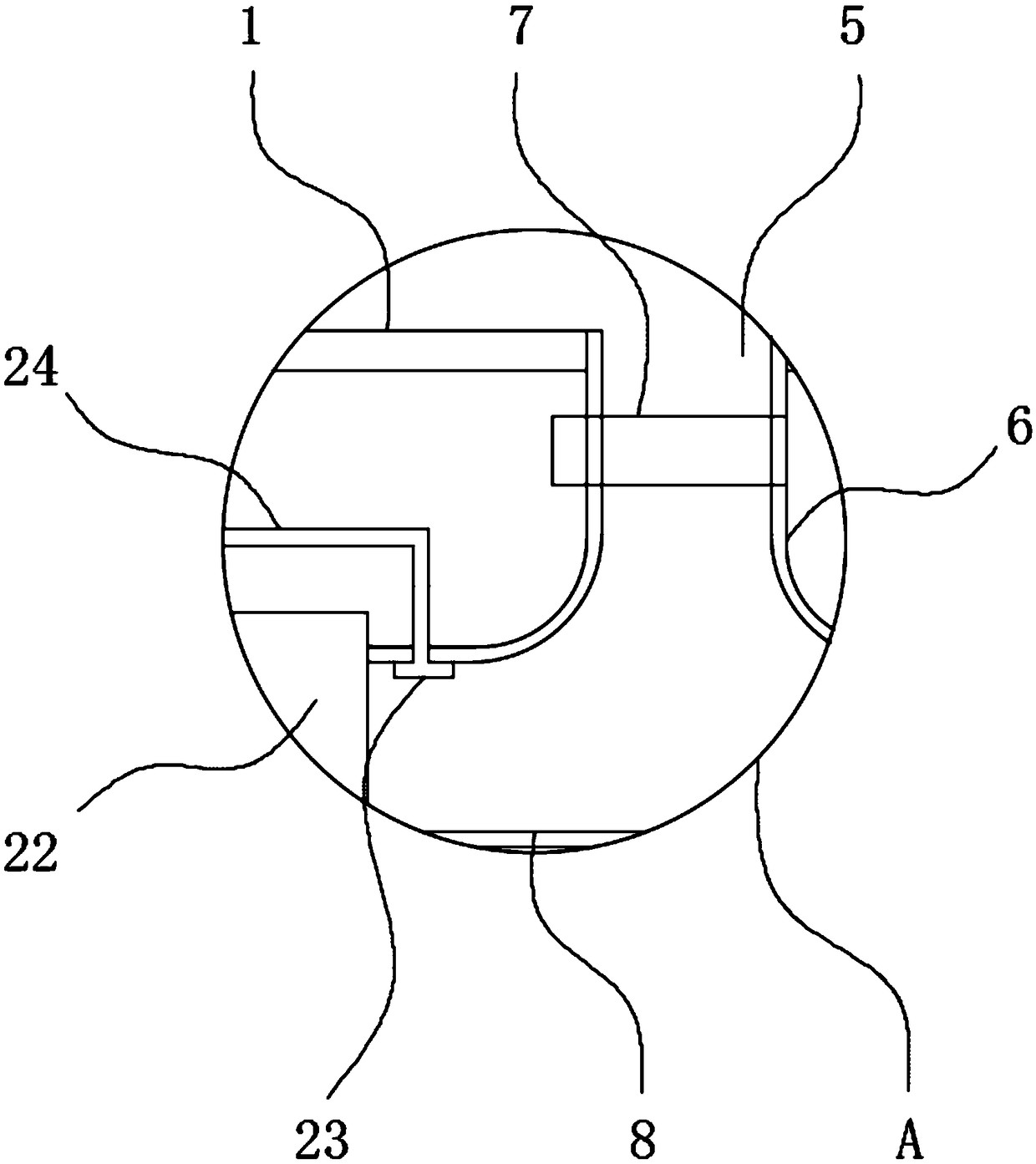

Seed cotton isomerism defibrator

InactiveCN101173370AIntegrity guaranteedEnsure comprehensivenessVegetable fibre separation from seedsFibre separationIsomerismsPulp and paper industry

The invention relates to a machine used for separating foreign fibre from seed cotton, which is characterized in that a plurality of winding rollers are arranged inside the intra-cavity under the inlet of the body and a guide plate is arranged on a longitudinal side of the winding rollers, a mass ejection roller is arranged under the outlet of the guide plate, and a makeup air port is arranged under the mass ejection roller; a net cage, a removing roller and a poking roller are arranged on the other side of the intra-cavity of the body, a wind screen and a wind limited plate are respectively arranged at the upper side and the lower side of the net cage and the removing roller, a back partition board is arranged under the wind limited plate, a screw conveyor and a screw conveyor groove are arranged under the poking roller, and a channel communicated with the foreign fibre outlet is arranged at the bottom of the screw conveyor groove; the lower part of the intra-cavity is funnel-shaped, and an airlock is arranged between the upper and lower ends of the lower outlet of the body. The invention has the advantages of significantly decreasing the textile cost, ensuring the continuity of scale production, sky-high running rate of equipments, consumedly reducing the human labor intensity, consumedly shortening the downtime, and significant rising of quality index of the produced lint cotton compared with other removing methods.

Owner:周义

Down feather processing technology

InactiveCN103484944AAvoid interferenceSorting went wellAnimal fibre deburring machinesWool fibre washing/scouringTruckMechanical engineering

The invention relates to a down feather processing technology. The down feather processing technology comprises the following steps of (1) selection, (2) suction, (3) washing, (4) dehydration, (5) drying, (6) cooling, (7) packing, (8) sorting, (9) static electricity elimination, (10) boxing and (11) truck loading. The down feather processing technology has the advantages of being reasonable in step setting, facilitating manufacture and the like, smooth performing of down feather processing can be ensured, and static electricity interference on down feather can be avoided.

Owner:安徽万利达羽绒制品有限公司

Sorting device for facilitating rough division of feathers in feather production

The invention discloses a sorting device for facilitating the rough division of feathers in feather production. The device comprises a feeding box. The top of the feeding box is threadingly connectedto a sealing cover, a feeding tube is fixedly connected at the center of the sealing cover, the feeding box is provided with a stirring mechanism, the bottom of the feeding box is provided with a blanking opening, a blanking pipe is fixedly connected in the blanking opening, the blanking pipe is provided with a first electromagnetic valve, and one end of the blanking pipe away from the blanking opening is fixedly connected to a connection pipe. According to the sorting device, by setting the stirring mechanism in the feeding box, through the rotation of rubber strips, feathers and plumes are separated, thus the separation of the plumes is facilitated, an atomization nozzle is set to carry out static electricity removing on raw materials, by setting three sorting nets inside a sorting box,feathers of different sizes can be stopped, then the feathers of different sizes can be stopped and sent to different sorting chambers, and the recycling is carried out.

Owner:安徽华隽羽绒制品有限公司

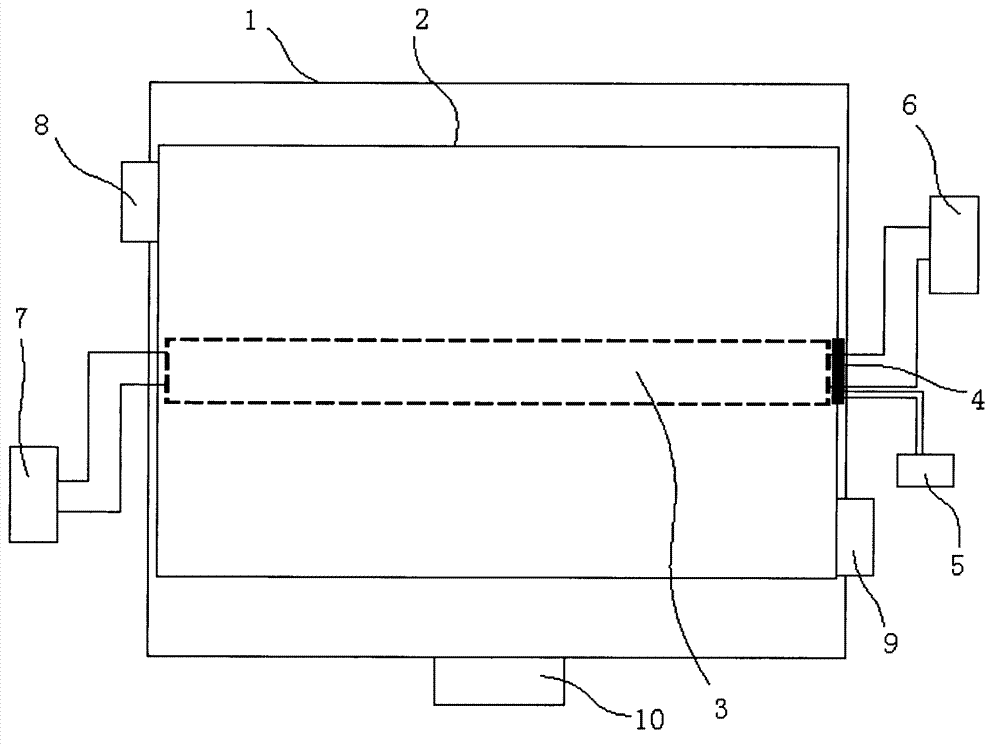

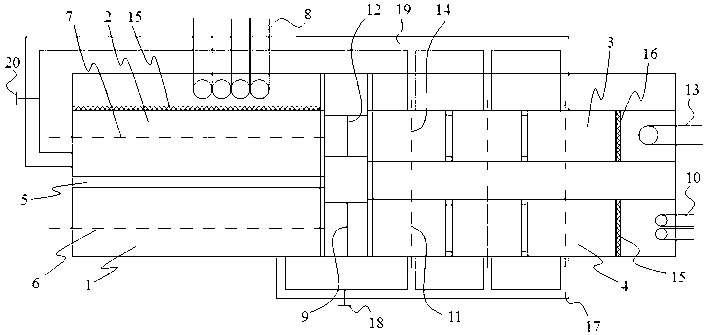

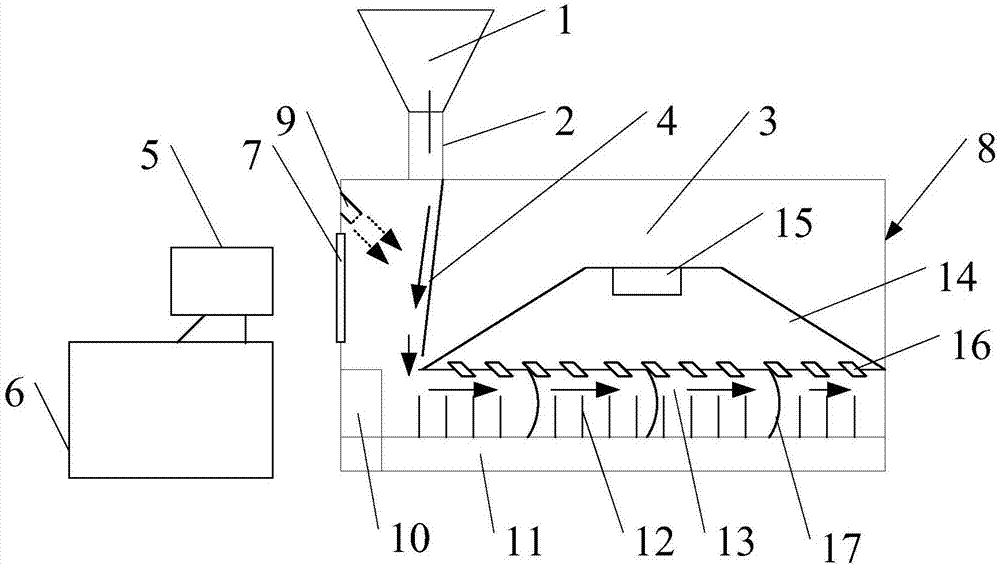

Cotton foreign fiber eliminating system

InactiveCN101387020AEvenly distributedAccurate calculation of timeFibre cleaning/openingFibre separationProduction lineFiber

The invention discloses a cotton foreign fiber removing system, which belongs to the technical field of agricultural mechanization. The system mainly comprises a layering device, a layering pipe, a teaser pipe, a high-speed CCD color video camera, a reflecting mirror, a light source, an ultrasonic air velocity transducer, an air nozzle set, a high-speed snifting valve set, a compressor, a cloth bag and so on. In the invention, the cotton current is layered by the layering device, teased by the teaser pipe and identified by the high-speed CCD color video camera; when the foreign fiber is found, the running speed of the foreign fiber is detected by the ultrasonic air velocity transducer, and the foreign fiber is ejected by the air nozzle set in lattice arrangement. The invention provides the foreign fiber removing system which is matched with a cotton production line, thereby improving the removing rate of the foreign fiber; by utilizing two groups of air nozzles with different diameters, the cotton foreign fiber removing system can reduce the unnecessary loss of cotton while removing the foreign fiber; and, due to the adoption of the cloth bag and a disk, the power loss of the whole system can be effectively reduced.

Owner:CHINA AGRI UNIV

Fiberizing, retexturing and recycling technology of fabric rags

InactiveCN101906691AAvoid secondary pollutionReduce usageWeft knittingWarp knittingYarnDying processes

The invention discloses a fiberizing, retexturing and recycling technology of fabric rags, in particular to a fiberizing, retexturing and recycling technology of denim fabric rags. In a treating and recycling process flow, color cotton fiber is directly produced without a bleaching process and spun after compounding cotton and mixing colors to produce dyed yarn in the same confirm color. The dyed yarn is made into chaine and is directly overdyed in a dying process to save a bottom color dying process, reduce the dye consumption, shorten production flows, save water and electricity costs, and take the favorable effects of saving energy and reducing consumption. Meanwhile, the invention can be used for producing overdyed denim fabrics of various color styles.

Owner:开平富琳纺织制衣有限公司

Four-compartment feather separating device

The invention discloses a four-compartment feather separating device, which comprises a material charging compartment, a classification compartment, an inferior feather classification compartment and a superior feather classification compartment that are connected and realize rough classification and fine classification for feathers through baffles. The four-compartment feather separating device is also provided with a recovery passage that can recover feathers in the compartments to the last classification step for second classification. As a new attempt and improvement on the feather classification at present, the four-compartment feather separating device enables all compartments to maintain different pressures through control on the wind speed of the vacuum blower so as to realize fine classification for feathers, and recovers the classified heavier feathers at the same time, thereby greatly increasing the collected feathers and improving the profits of manufacturers.

Owner:句容市红掌食品有限公司

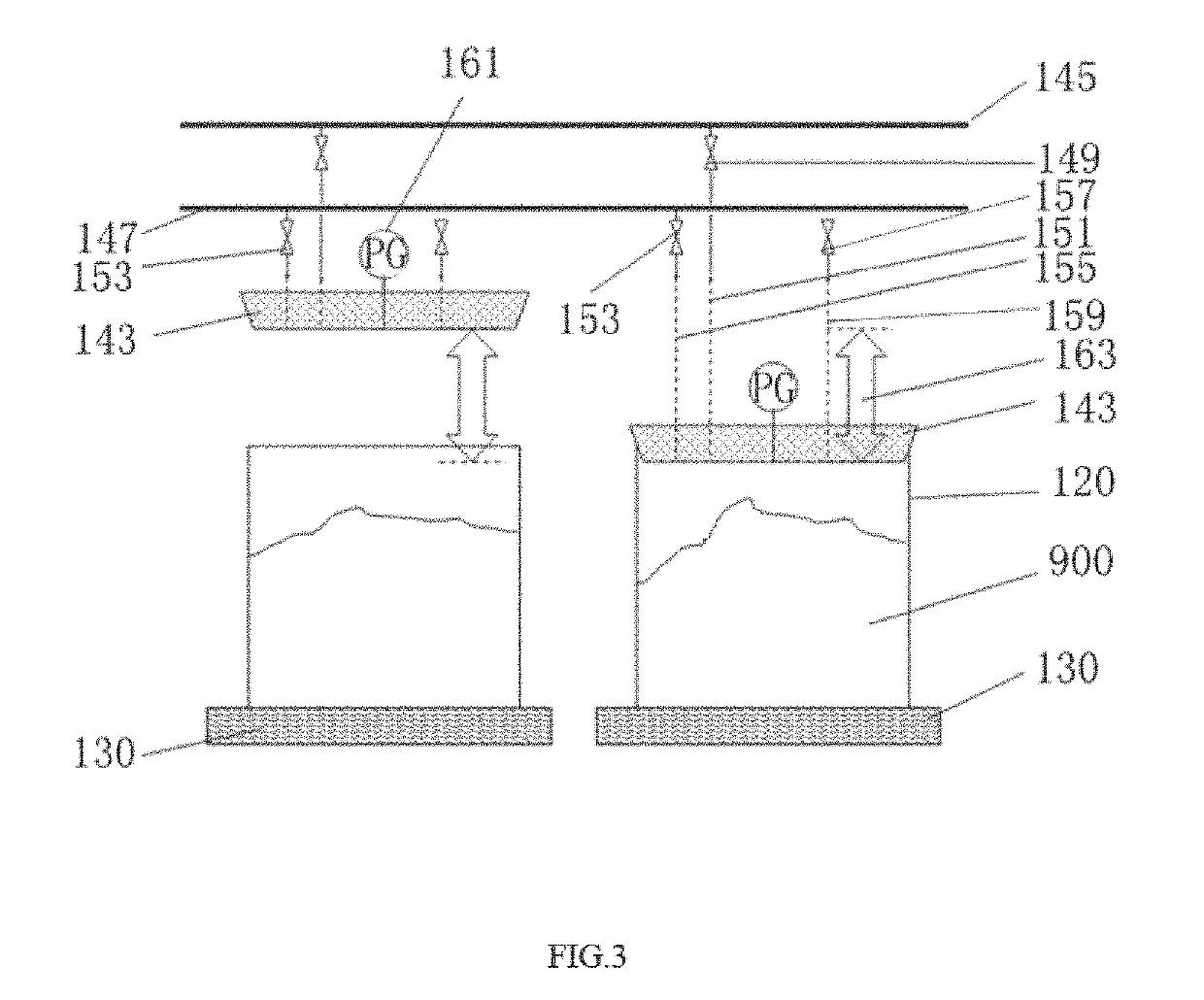

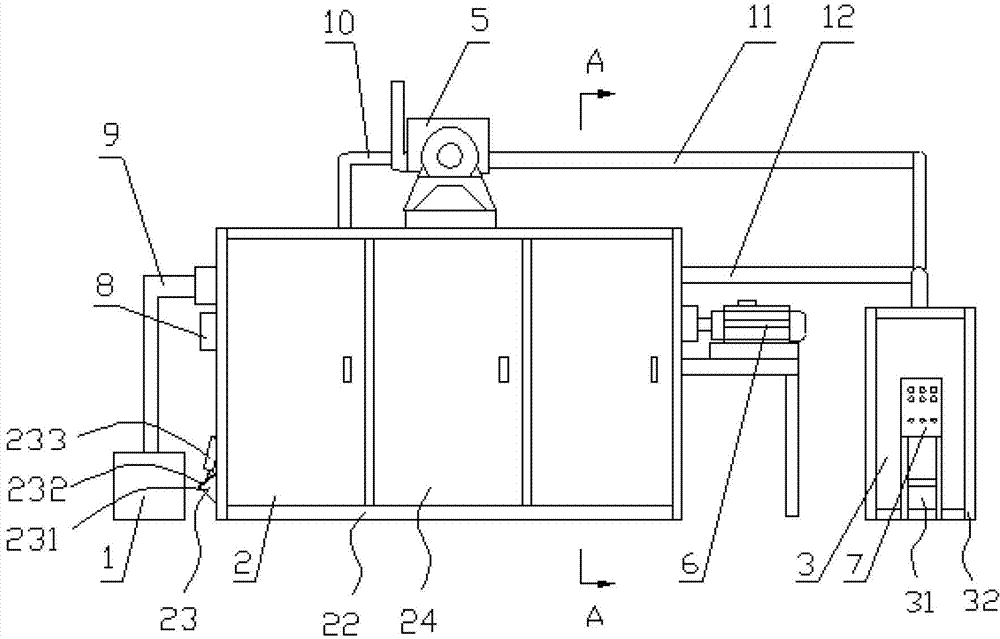

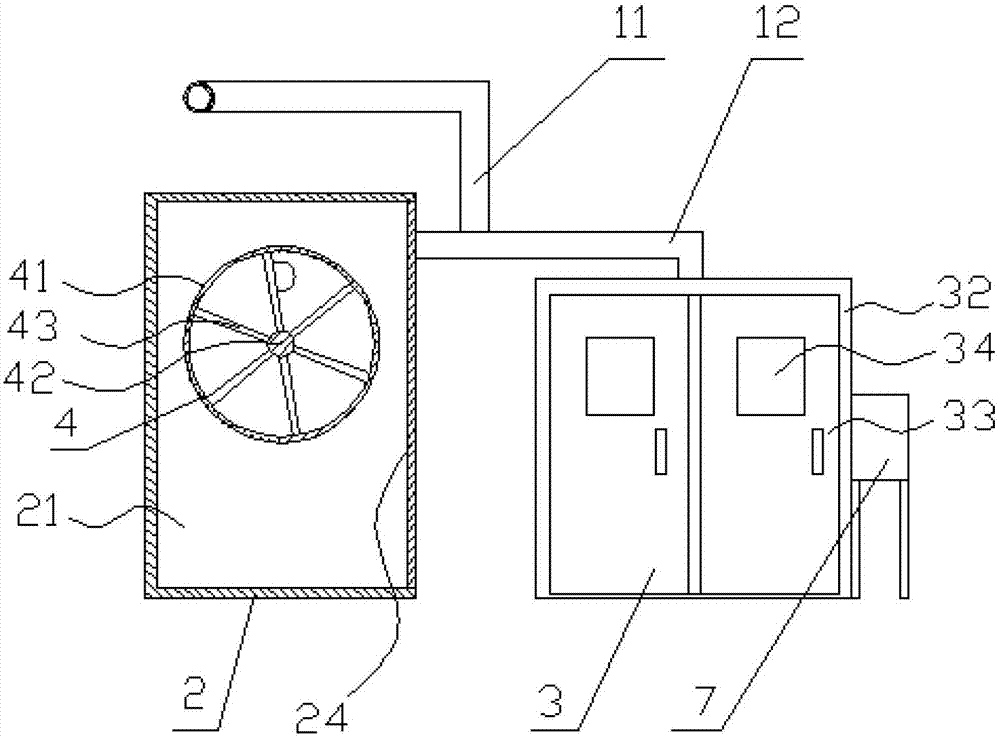

Large-down separation unit

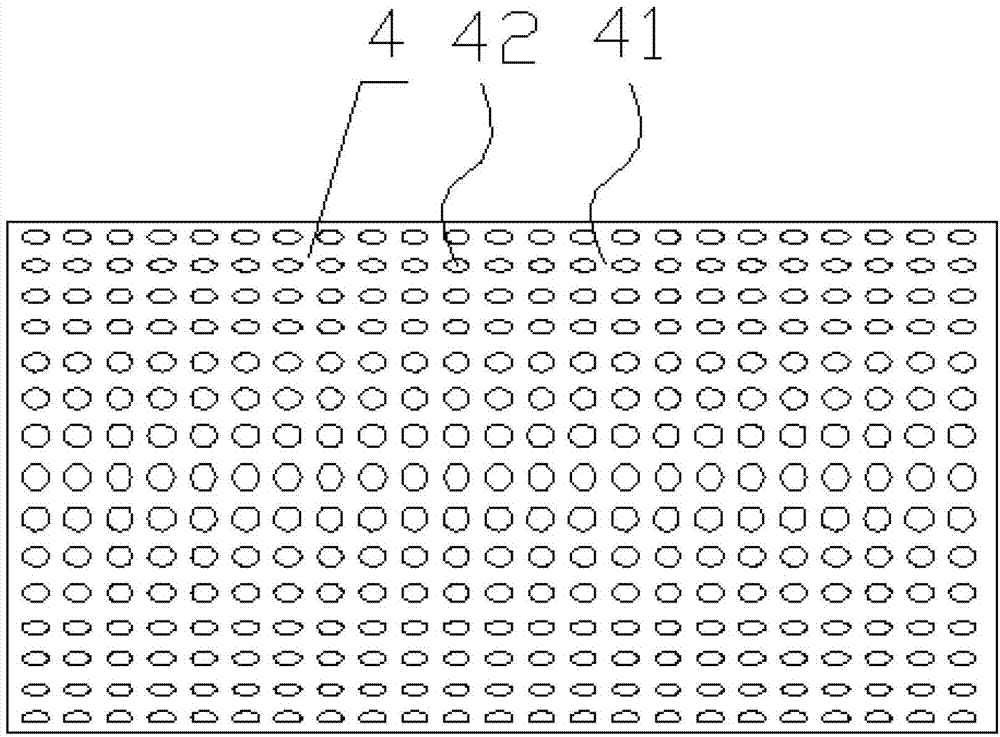

A large-down separation unit relates to the technical field of down feather production and separation equipment and is characterized by comprising a material bin, a separation chamber, a collecting chamber, a separation drum, a fan, a transmission motor and a control cabinet. The separation drum is arranged inside the separation chamber. Transmission shafts are arranged on two sides of the separation drum. A feed pipe is disposed in the material bin. The feed pipe connected with the separation chamber extends into a separation barrel. The fan is disposed at the top of the separation chamber. The fan is connected inside the separation chamber through a first delivery pipe. The collecting chamber is connected with the fan through a second delivery pipe. The collecting chamber is connected with the separation chamber through a third delivery pipe. The third delivery pipe extends into the separation barrel and is connected with the second delivery pipe. The transmission motor is disposed at the end of the separation chamber and is connected with the transmission shaft. The large-down separation unit is reasonable in structure, low in manufacturing cost, convenient to control and capable of effectively separating to obtain high-quality large down.

Owner:安徽明牛羽绒有限公司

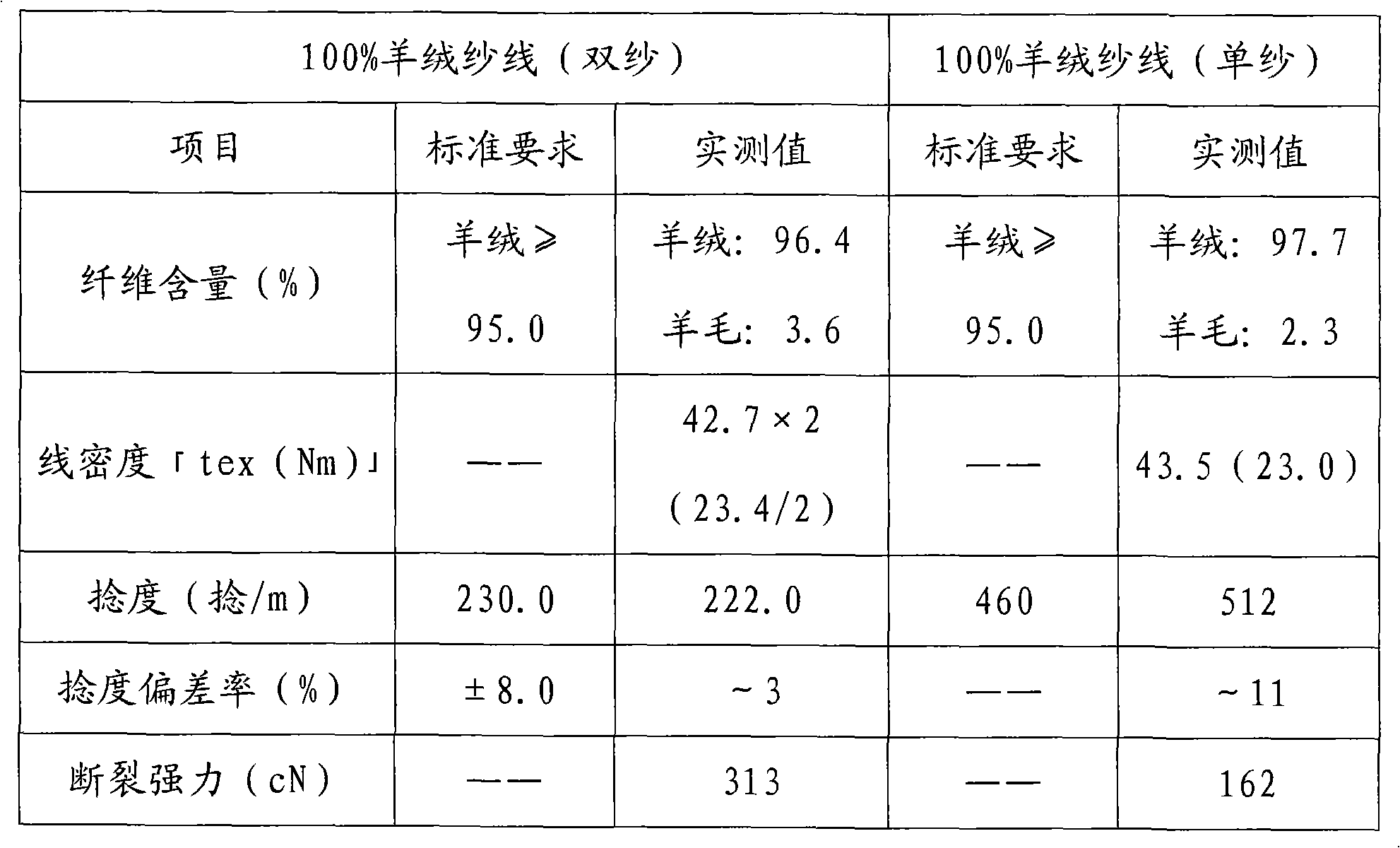

Cashmere yarn with high tensile stretch and production technology thereof

ActiveCN101586278AAvoid damageHigh elongation at breakFibre cleaning/openingWool fibre washing/scouringYarnSingle fiber

The invention belongs to the technical field of knitting yarns and production technology thereof, in particular relates to a cashmere yarn with high tensile stretch and production technology thereof. The production technology of the cashmere yarn with high tensile stretch includes the followings: in cashmere washing step, drying is carried out at the low temperature of 40 DEG C to 50 DEG C so as to reduce the power damage of cashmere single fiber; in carding step, the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG so that the striking point direction of cubing rolls is changed and the length damage of cashmere is reduced; in dying step, drying is carried out at the low temperature of 50 DEG C to 70 DEG C so as to further reduce the power damage of cashmere single fiber; in spinning step, the twist factor of the single yarn used is 90% to 98%. In the invention, drying is carried out at the low temperature of 40 DEG C to 50 DEG C both in cashmere washing step and in dying step, and the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG in carding step, thereby reducing the damage of cashmere to the maximum and guaranteeing high breaking elongation, rebound degree and force of cashmere.

Owner:湖州珍贝羊绒制品有限公司

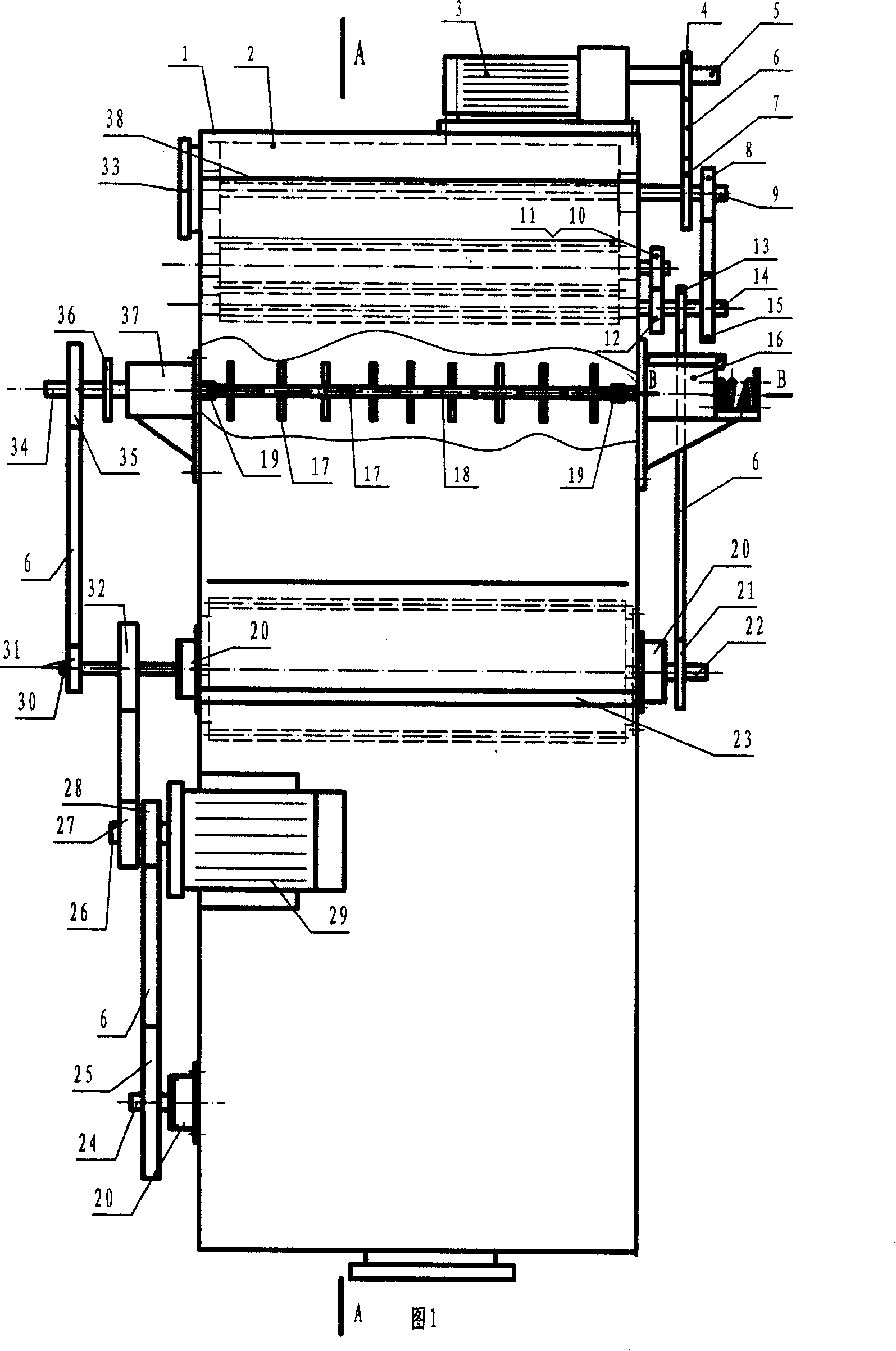

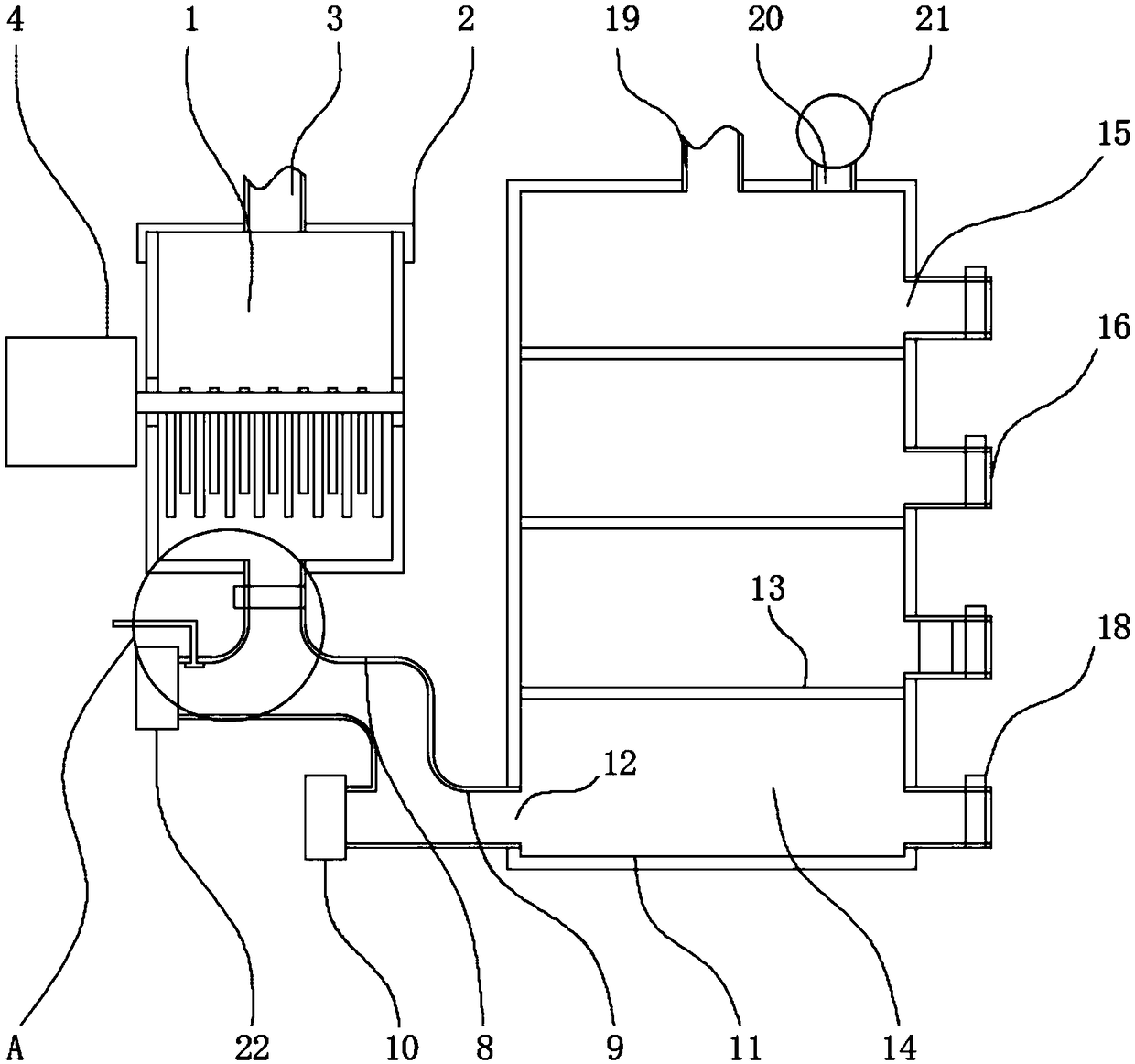

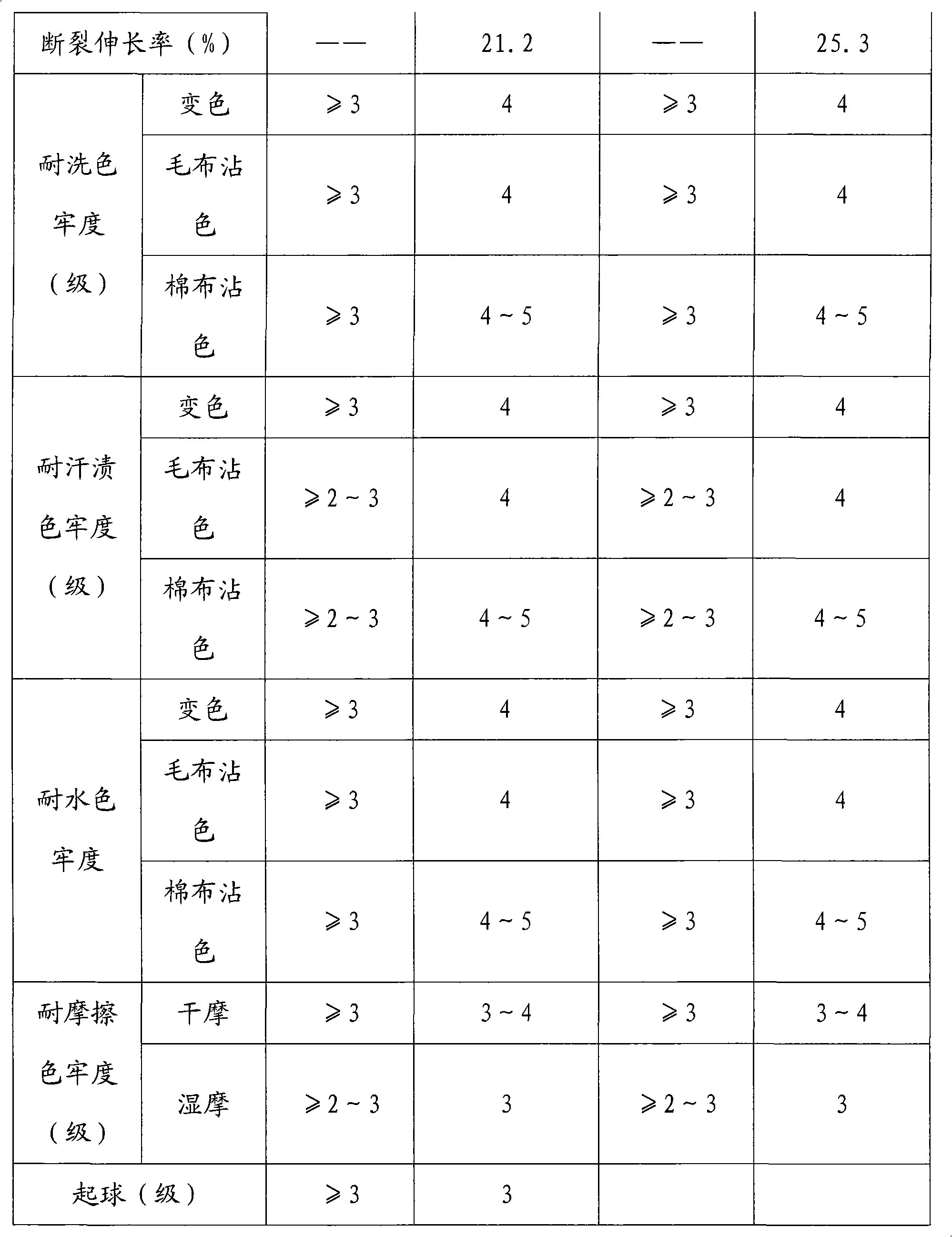

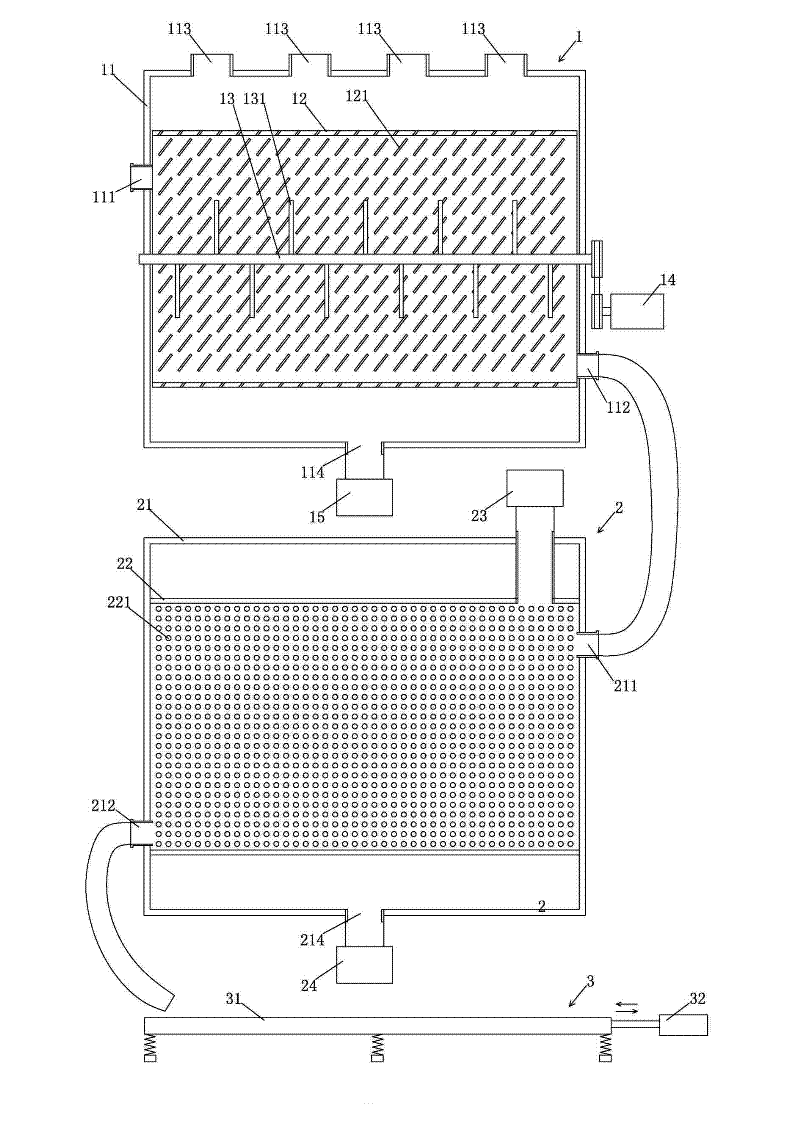

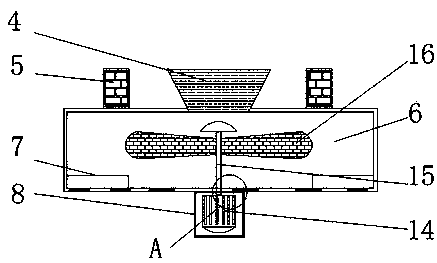

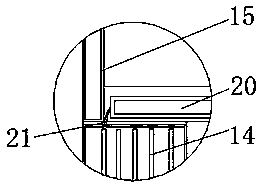

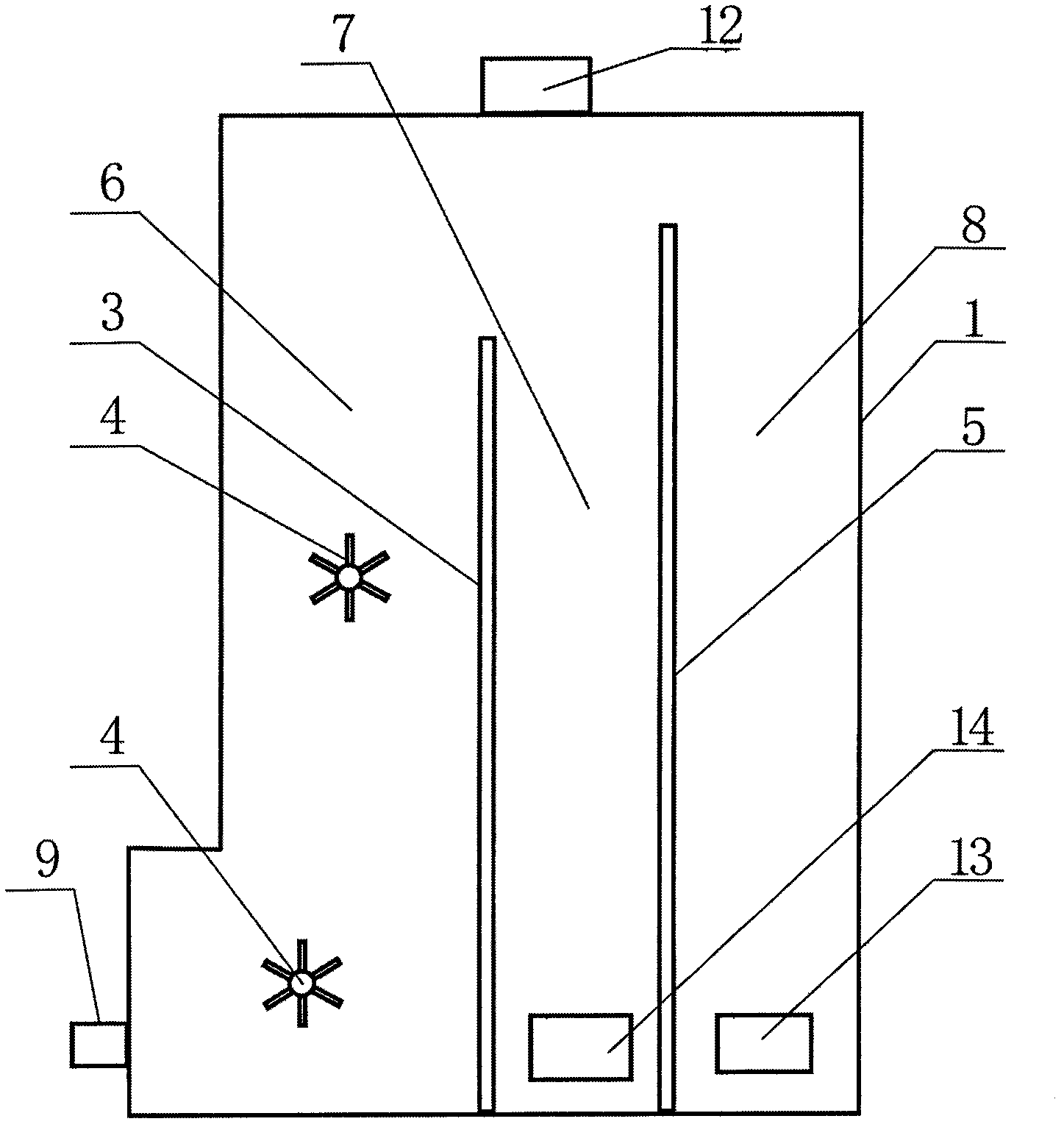

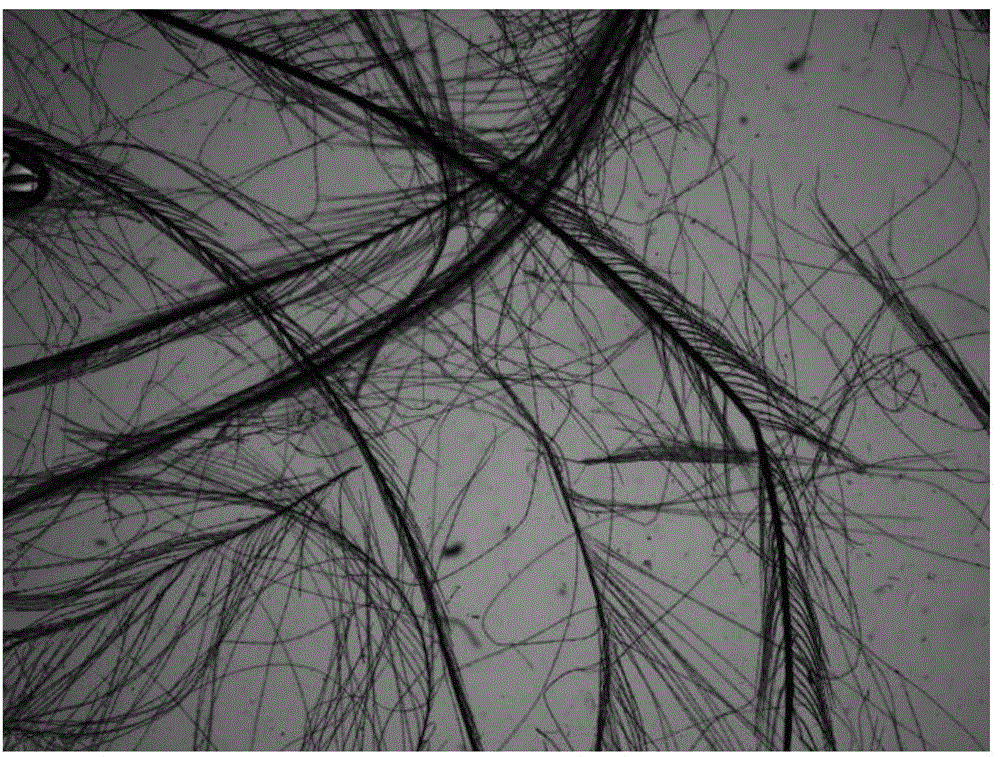

Device and method for extracting sticky down by deeply processing down

ActiveCN102242420ATo achieve the purpose of sterilization and deodorizationEliminate odorHeating/cooling textile fabricsFibre separationYarnWater vapor

The invention discloses a device and a method for extracting sticky down by deeply processing down. The device for extracting the sticky down by deeply processing the down comprises a feather yarn separation box (1), a neck feather yarn separation box (2) and a down flying yarn separation sieve (3) which are connected in turn. The method comprises the following steps of: 1) disinfecting, sterilizing and deodorizing feathers by using a high temperature of 120 DEG C generated by water vapor and pressurizing to make the feathers separated to form the down; 2) putting the down into the feather yarn separation box through a feeding hole for processing to separate feather yarns; 3) putting the down in a sieve barrel into the neck feather yarn separation box through a discharging opening for processing to separate neck feather yarns; and 4) putting the down in an inner box body into the down flying yarn separation sieve for processing to separate down flying yarns. By the device and the method, the feather yarns, the neck feather yarns and the down flying yarns can be efficiently separated to extract the sticky down with the down content of 97 percent.

Owner:广东鸿凌羽绒有限公司

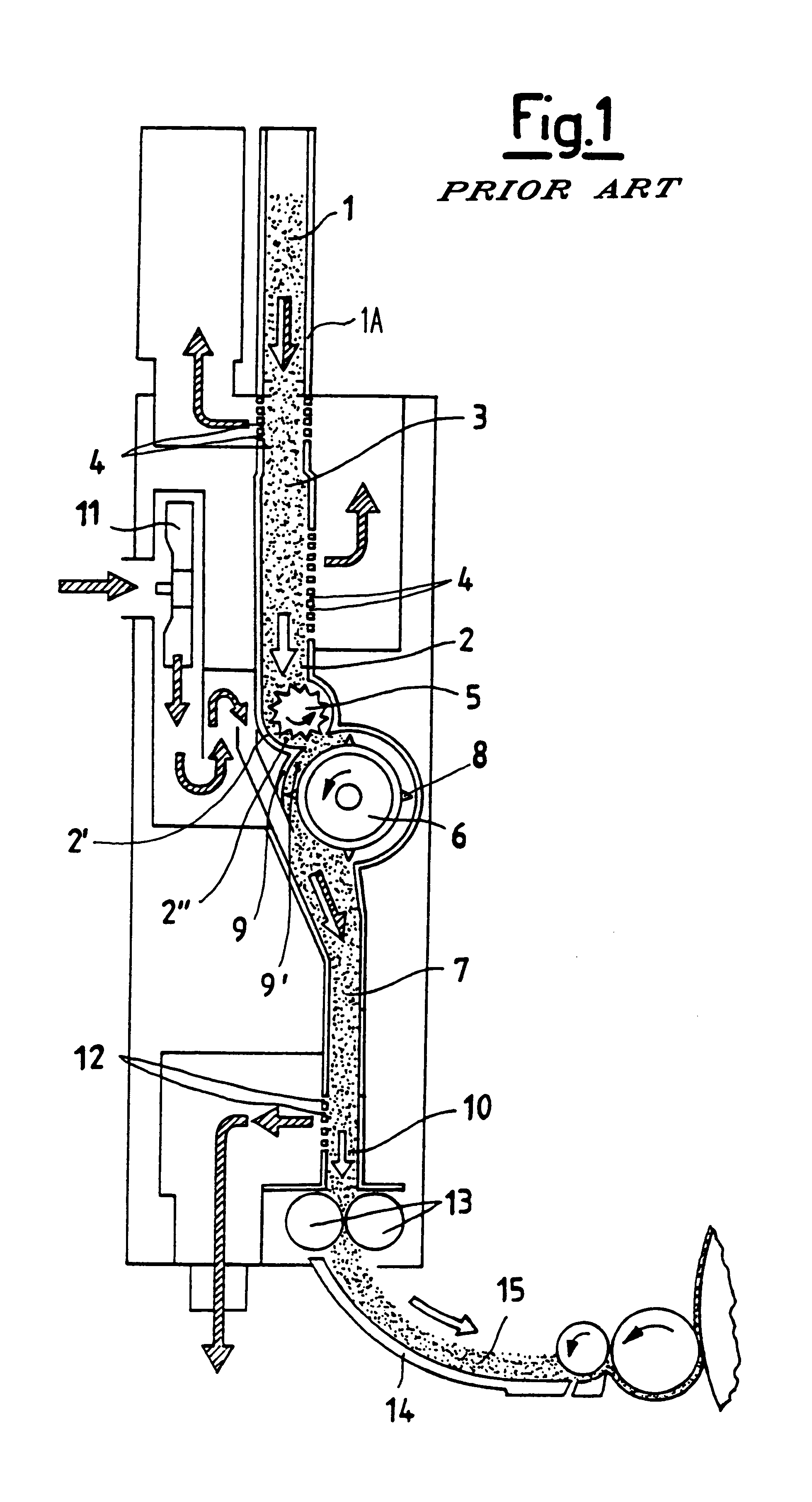

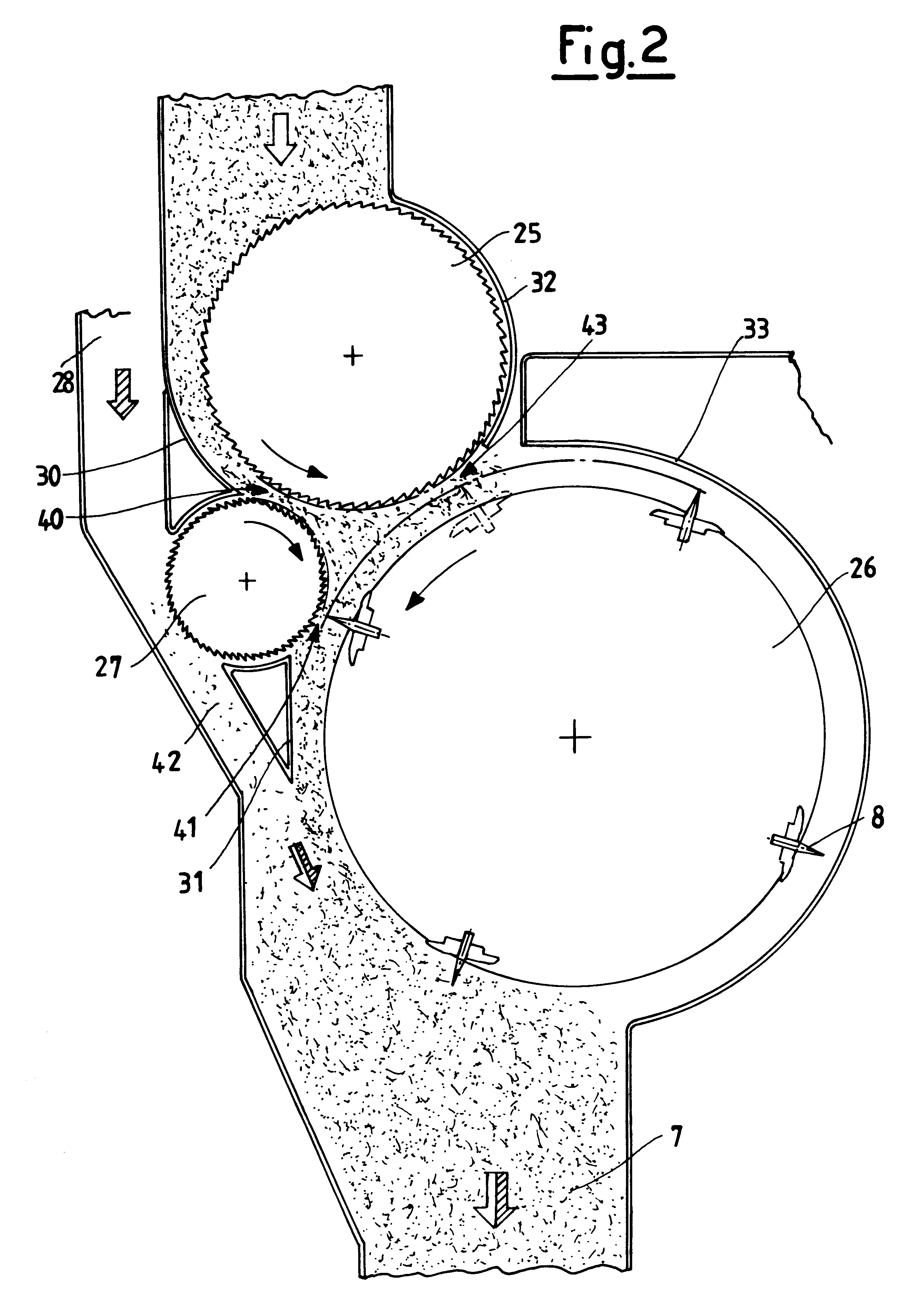

Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

InactiveCN101165239AIncrease supplyEasy to separateCombing machinesCarding machinesTextile fiberMechanical engineering

An apparatus is used for carrying out fiber finishing or fiber selecting on fiber strip. Especially in an apparatus for combing, the fiber strip is supplied to a fiber finishing device by supply device; especially the combing device includes clamping device clamping the fiber strip on the certain distance far away from the free end thereof, a device for generating combing effect from clamping point to the free end of the fiber strip to loose and remove nor-clamping composition, such as short fiber, hair knot, dust and so on from the free end. At least one roller capable of rotating is installed on the upstream of the supply device in order to improve the amounts (productivity) generated each hour and obtain improving fiber strip. The clamping equipment used in the fiber strip is set on the roller, the periphery of which is distributed with interval around the stone roller. And the device (combing element) for generating combing effect is connected with the periphery of the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Integral vibration type down screening machine for down processing

InactiveCN108221092AImprove bulkImprove processing efficiencyFibre separationDrive motorPulp and paper industry

The invention discloses an integral vibration type down screening machine for down processing. The machine comprises a screening machine main body, a connecting rubber tube, a first fixed block, a second fixed block, a filter screen, a pull handle, a driving motor, a connecting wire and a moving groove; a feed inlet is formed in the screening machine main body, feed bin doors are arranged at the two ends of the feed inlet, the connecting rubber tube is arranged at the bottom of the feed inlet, a stirring box is arranged at the bottom of the connecting rubber tube, the screening machine main body and the stirring box are welded to the two ends of the first fixed block respectively, a discharge through hole is formed in the stirring box, a driving box is arranged at the bottom of the stirring box, the second fixed block is arranged in the screening machine main body, fixed springs are fixed to the bottom of the second fixed block through welding, and the fixed springs are fixed to the two ends of the filter screen through binding connection. The integral vibration type down screening machine for down processing is provided with the feed bin doors, the overall tightness of the devicecan be improved, and the raw material processing efficiency is effectively improved.

Owner:ZHANJIANG ZIJIN DOWN PROD

System and method for recycling fibers from textiles waste

ActiveUS20190226125A1Fibre cleaning and opening machine combinationsSolid waste disposalFibre treatmentPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

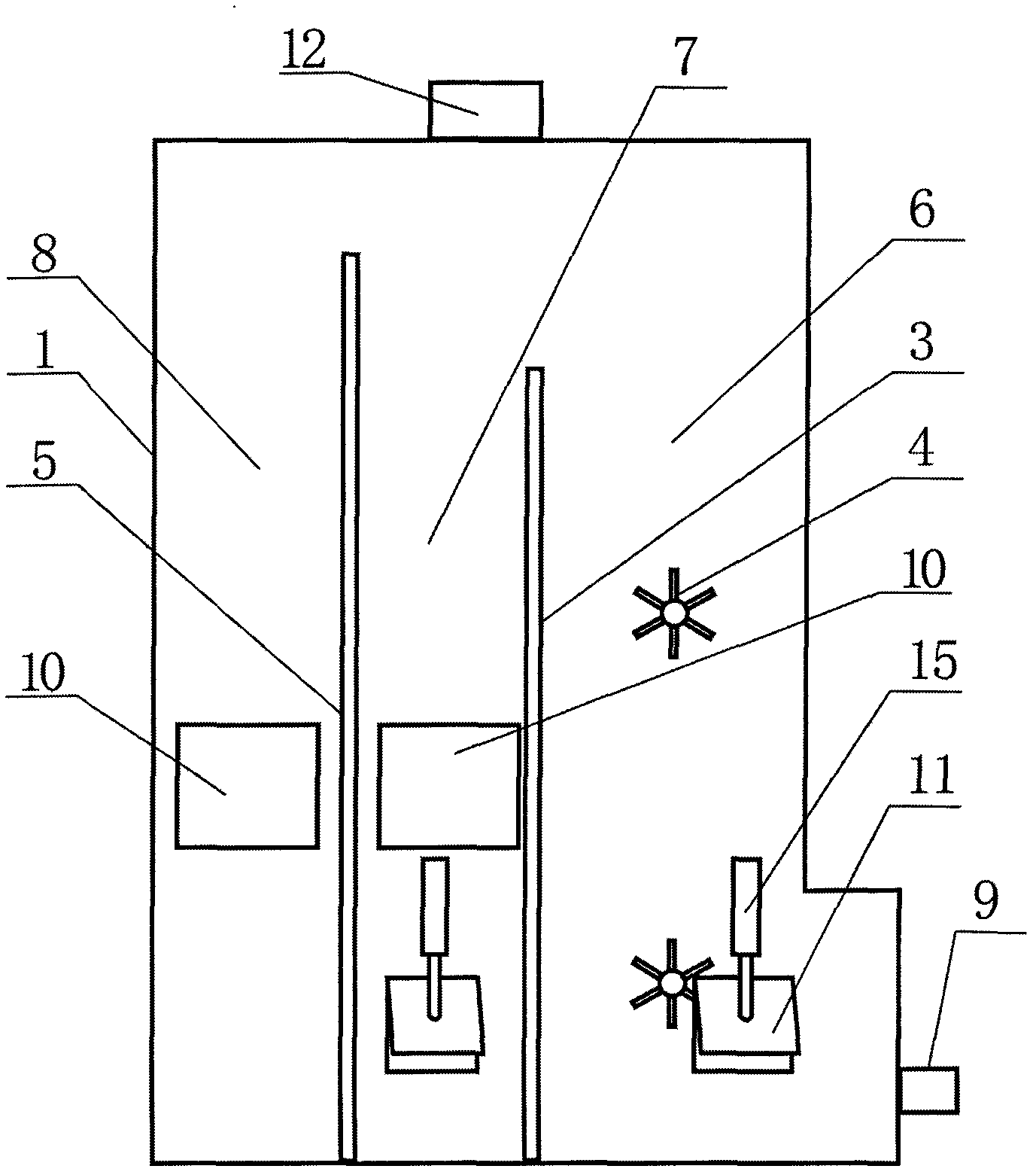

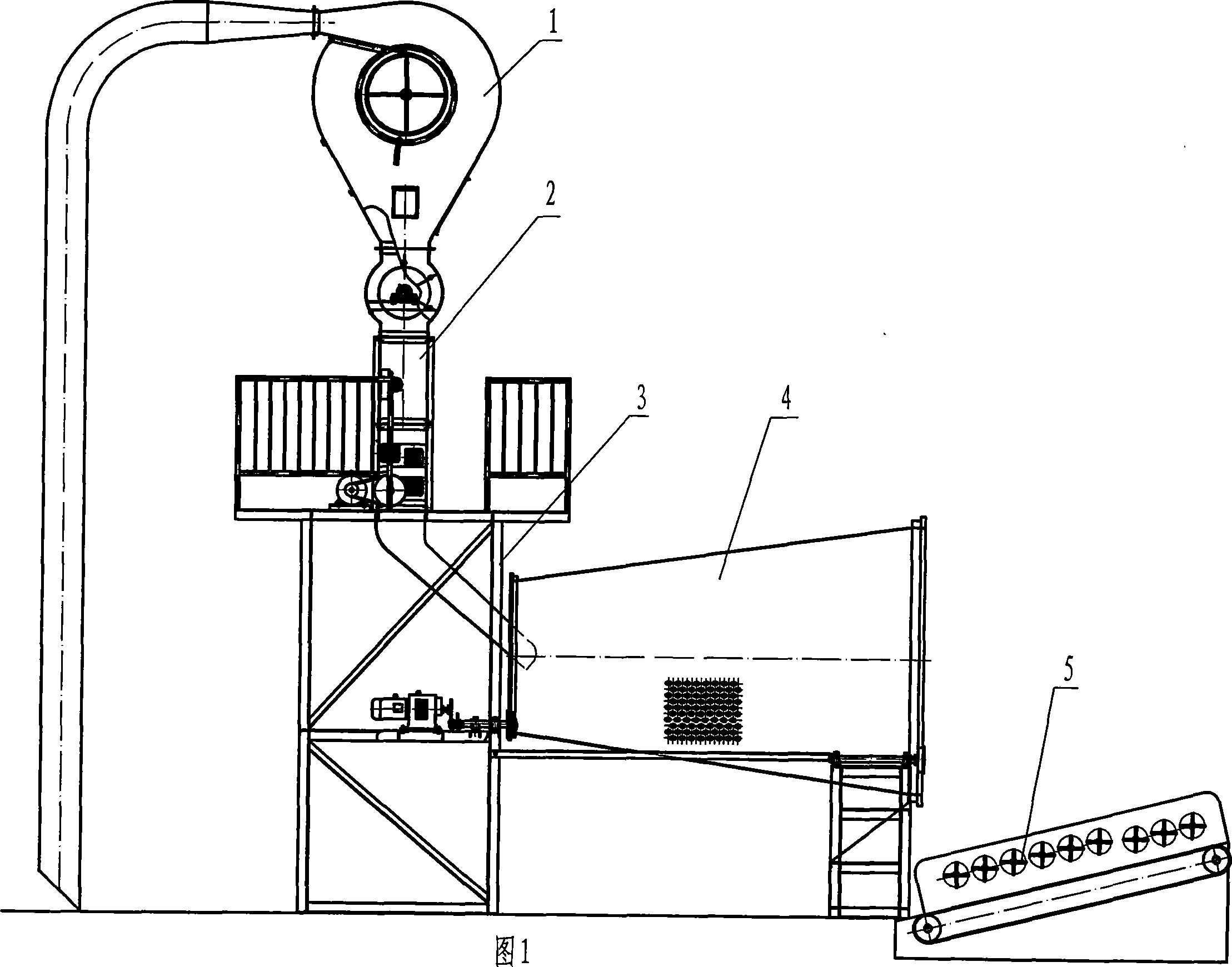

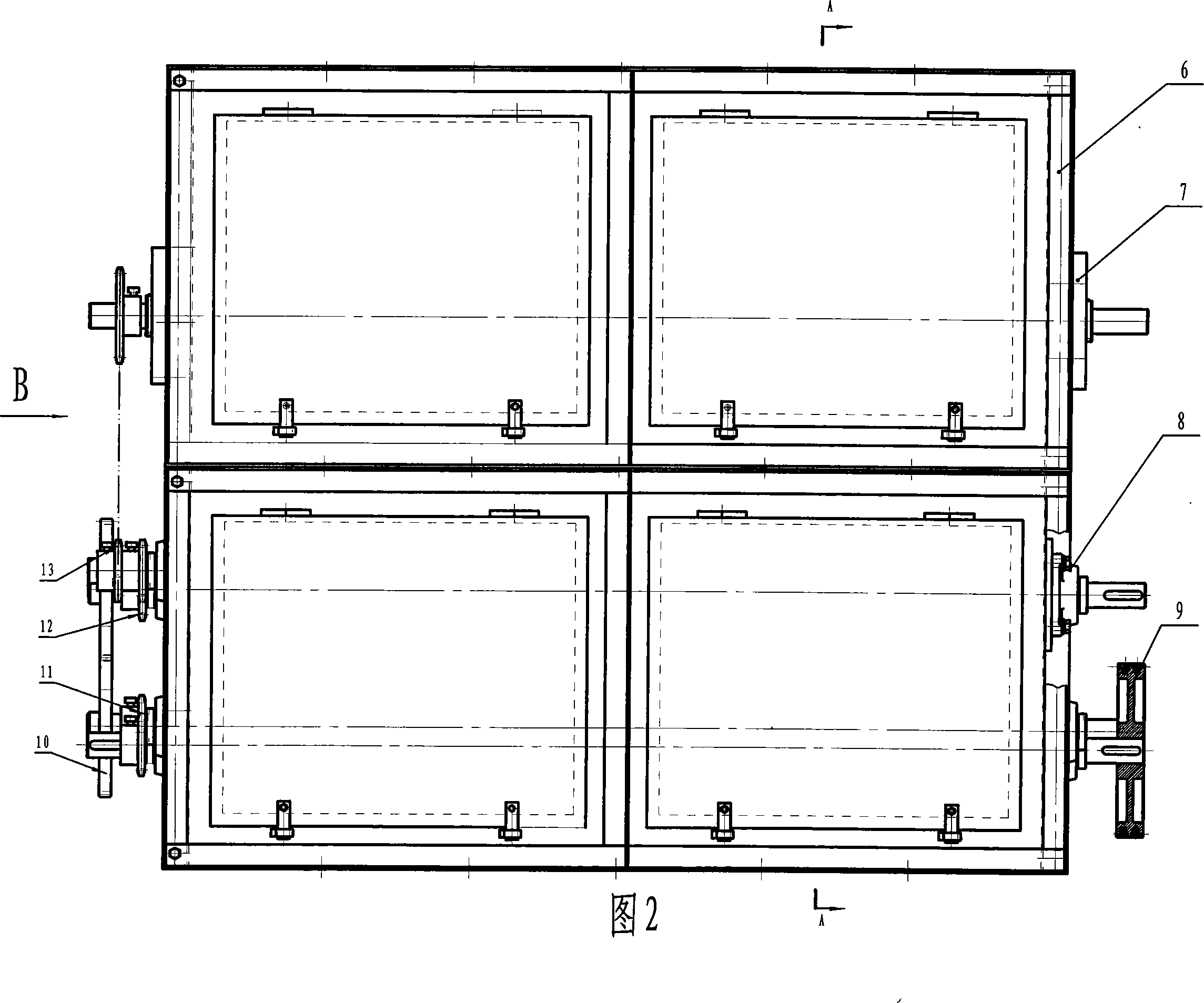

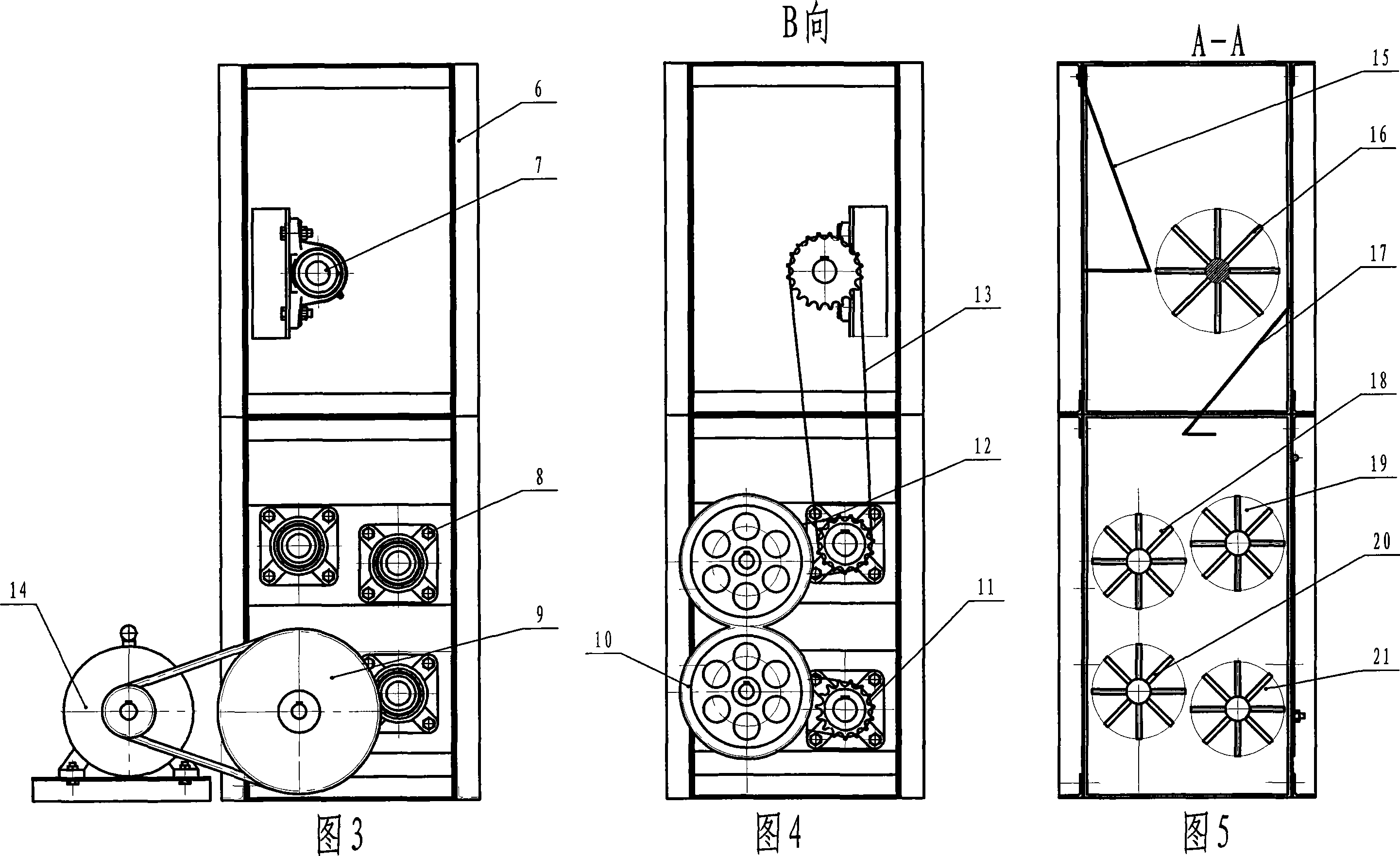

Efficient energy-saving environment-protection type velvet product refining sorting machine

InactiveCN102367597AImprove qualityHigh failure rateFibre cleaning/openingFibre separationSocial benefitsYarn

The invention discloses an efficient energy-saving environment-protection type velvet product refining sorting machine, which comprises a box body, a stirring device and a motor, wherein the motor drives the stirring device arranged in the box body to rotate through a transmission mechanism, a separation plate A and a separation plate B in vertical placement are arranged in the box body, the box body is sequentially separated into a raw material scattering box, a crude velvet gathering box and a fine velvet gathering box by the separation plate A and the separation plate B, gaps are formed between the upper ends of the two separation plates and the top of the box body, the height of the separation plate A is lower than the height of the separation plate B, and the stirring device is arranged in the raw material scattering box. The efficient energy-saving environment-protection type velvet product refining sorting machine has the advantages that the fine velvet with the lightest weight in the velvet products can be separated from velvet yarns and dust, the quality of the velvet products is improved in the separation process through regulating the air flowing speed and the stirring rotating speed, the raw materials can also be separated into different specifications, the problems of low technical efficiency, high electric consumption and the like in the prior art are solved, and the efficient energy-saving environment-protection type velvet product refining sorting machine has the advantages that the environment protection effect is realized by the whole machine, the energy consumption is little, the fault rate is low, safety and reliability are realized, the social benefits and the economic benefits are obvious, and the like.

Owner:程启标

Seed cotton long-different fiber and deadlocked valvula cleaning machine

InactiveCN101250773AReduce varietyReduce in quantityFibre cleaning/openingFibre separationFiberEngineering

The invention provides seed cotton long foreign fiber and a dead boll cleaning machine, which relates to a cotton processing device, in particular to a device for cleaning the long foreign fiber and the dead boll in original seed cotton, which comprises a seed cotton discharger and a foreign fiber bar grizzly machine and is characterized in that the device further comprises a rotating mesh type seed cotton cleaning machine, at least two foreign fiber bar grizzlie machines, wherein the seed cotton discharger is fixedly connected on the top of an A-degree foreign fiber bar grizzly machine, a feed opening of the A-degree foreign fiber bar grizzly machine is inserted into a feed inlet of the rotating mesh type seed cotton cleaning machine, a B-degree foreign fiber bar grizzly machine is arranged on the lower side of a discharge hole of the rotating mesh type seed cotton cleaning machine, the rotating mesh type seed cotton cleaning machine at least comprises a power machine, a drive mechanism and a rotating mesh, wherein the rotating mesh is in shape of trumpet, long shaped meshes whose major diameters are 18-40mm are homogeneously distributed on the rotating mesh, the rotating mesh rotates around the axial cord of the rotating mesh through the driving of the drive mechanism by the power machine, and mechanization and automatization of the original seed cotton cleaning machine are realized.

Owner:大丰市供销机械厂有限公司

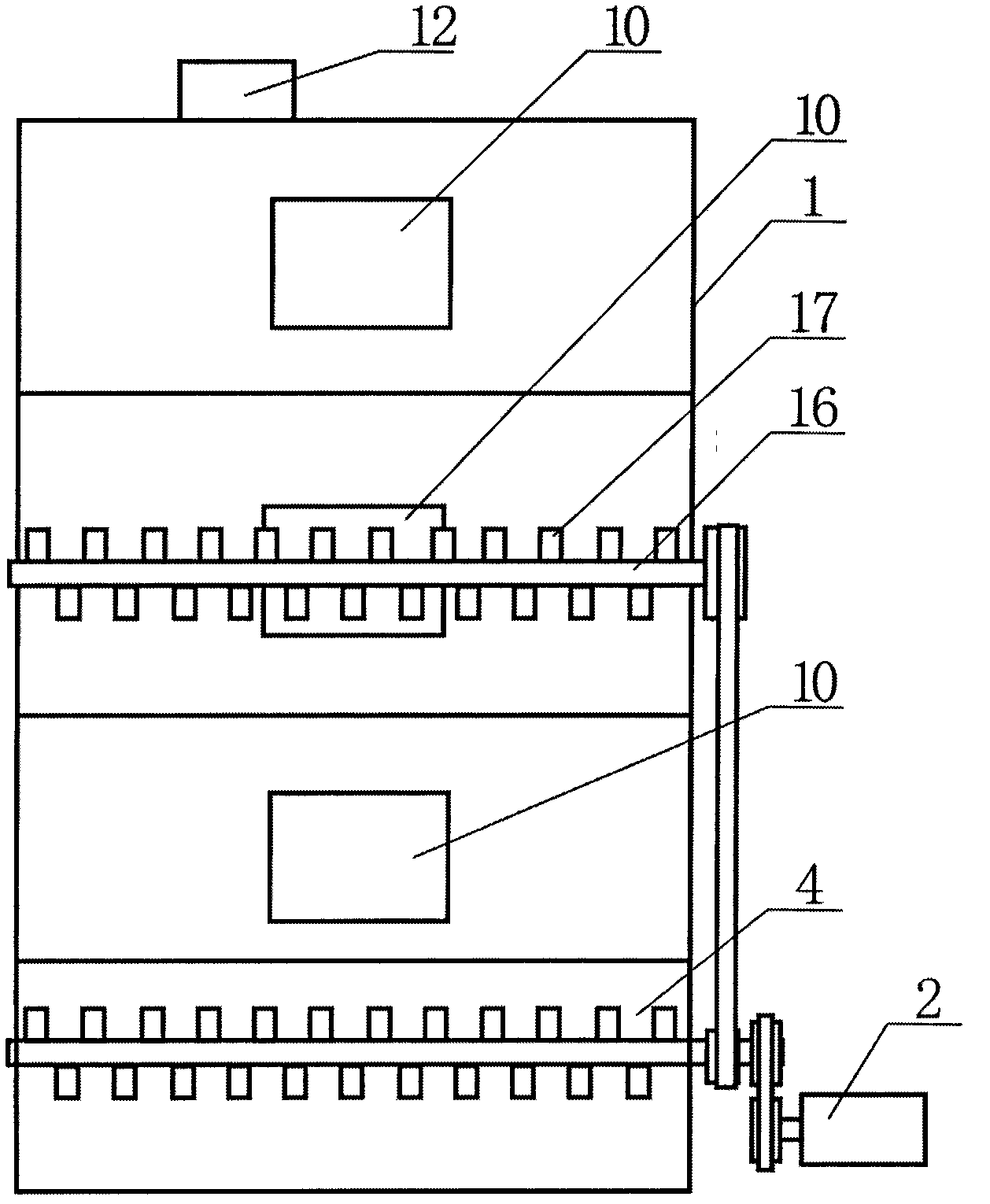

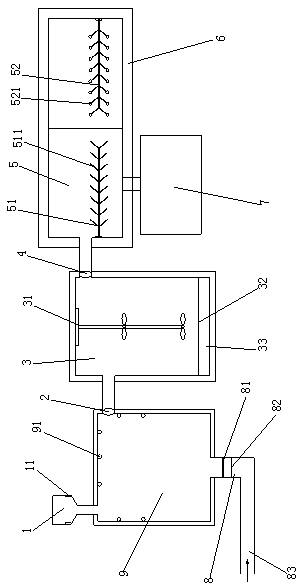

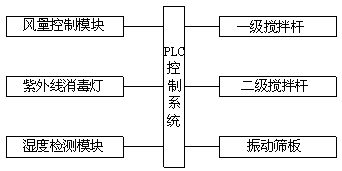

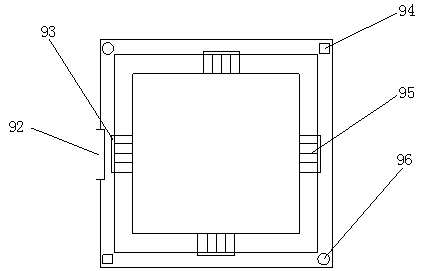

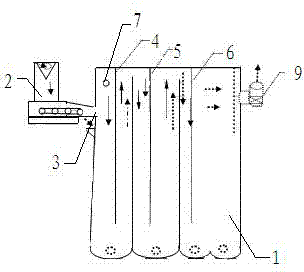

Down feather separation system based on PLC

ActiveCN108893805AGuaranteed separation efficiencyMeet separation requirementsDrying gas arrangementsFibre separationControl systemUv disinfection

The invention relates to a down feather separation system based on a PLC. The system comprises a pretreatment chamber, a dust removal chamber, a motor, a down feather channel and a PLC control system,wherein the pretreatment chamber comprises a feed port and a drying system, the feed port is internally provided with a humidity detection module, the drying system comprises a drying chamber and a ventilation pipeline, the inner wall of the drying chamber is equidistantly provided with ultraviolet disinfection lamps, and a first suction ventilator is arranged above the drying chamber; the firstsuction ventilator is arranged at one end of the dust removal chamber, and the dust removal chamber is internally provided with a stirring motor; a second suction ventilator is arranged above the other end of the dust removal chamber, the second suction ventilator is arranged at one end of the down feather channel; the PLC control system controls running of the humidity detection module, the ultraviolet disinfection lamps, the first suction ventilator, the second suction ventilator, a first-grade stirring rod and a second-grade rod respectively. The down feather separation system based on thePLC has the advantages that the pretreatment, dust removal and separation are combined together to form the continuous down feather separation system, thereby greatly improving the speed and quality of down feather separation, reducing the labor amount of manual separation and shortening the separation time.

Owner:WEST ANHUI UNIV +2

Method for separating feather fibers from poultry feather raw material

InactiveCN104651983AAchieve fine separationEasy separationMechanical impurity removalFibre separationFiberMaterials science

The invention provides a method for separating feather fibers from a poultry feather raw material. The method comprises four steps, namely washing, stripping, carrying out multistage separation and drying, wherein in the step of multistage separation, the feather fibers are subjected to multistage separation by using slit type screens of different screen slit widths, the fine separation of the feather fibers is realized, more choices are provided for the further full utilization of the feather fibers, and thus, the application is more convenient. In addition, the method provided by the invention only comprises four steps, each step is simple and feasible and does not need complicated and expensive equipment, embodied in that only the step (3) of the four steps adopts the slit type screens as a multistage separation device for the feather fibers, and the slit type screens are common devices for papermaking and are simple in structure, so that the separating operation is simple, convenient and feasible.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

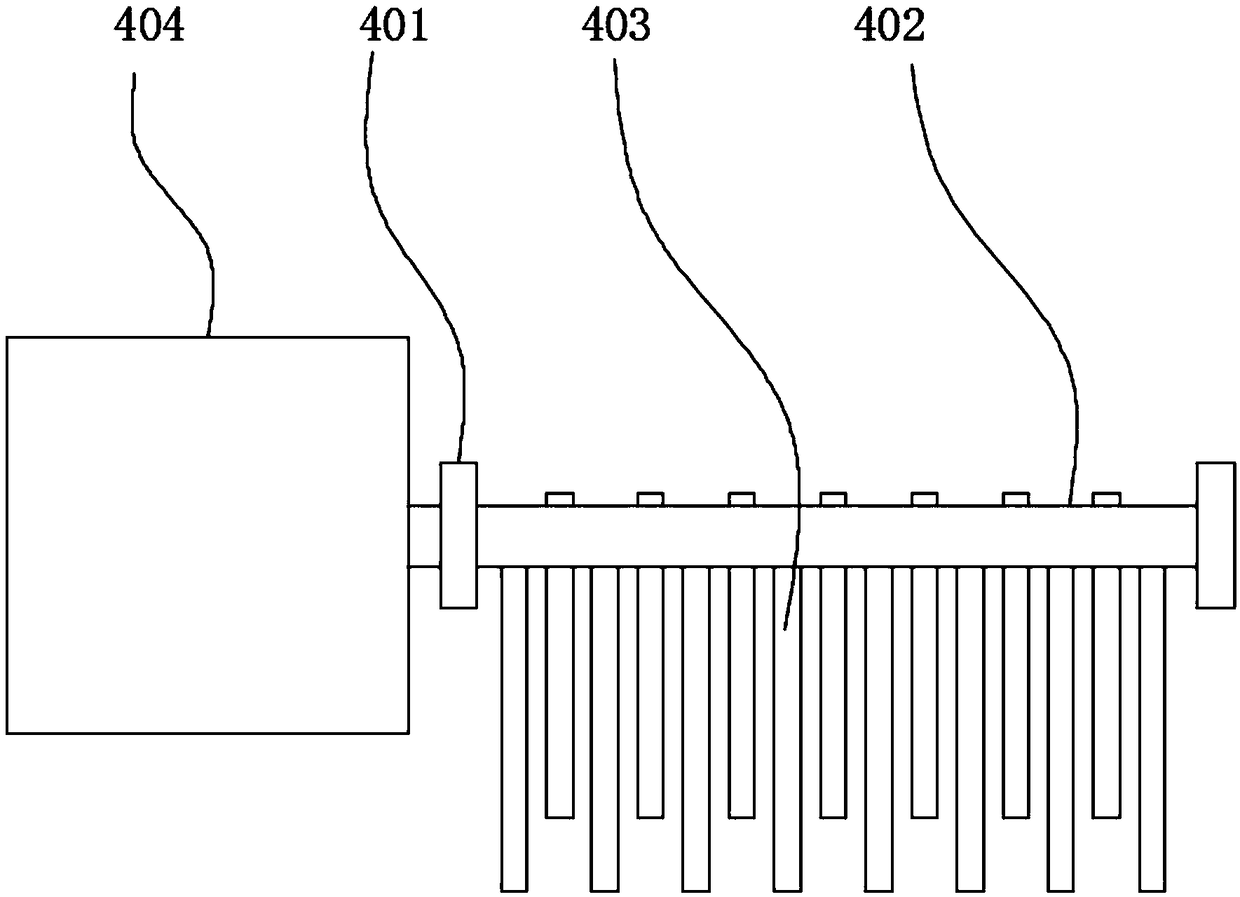

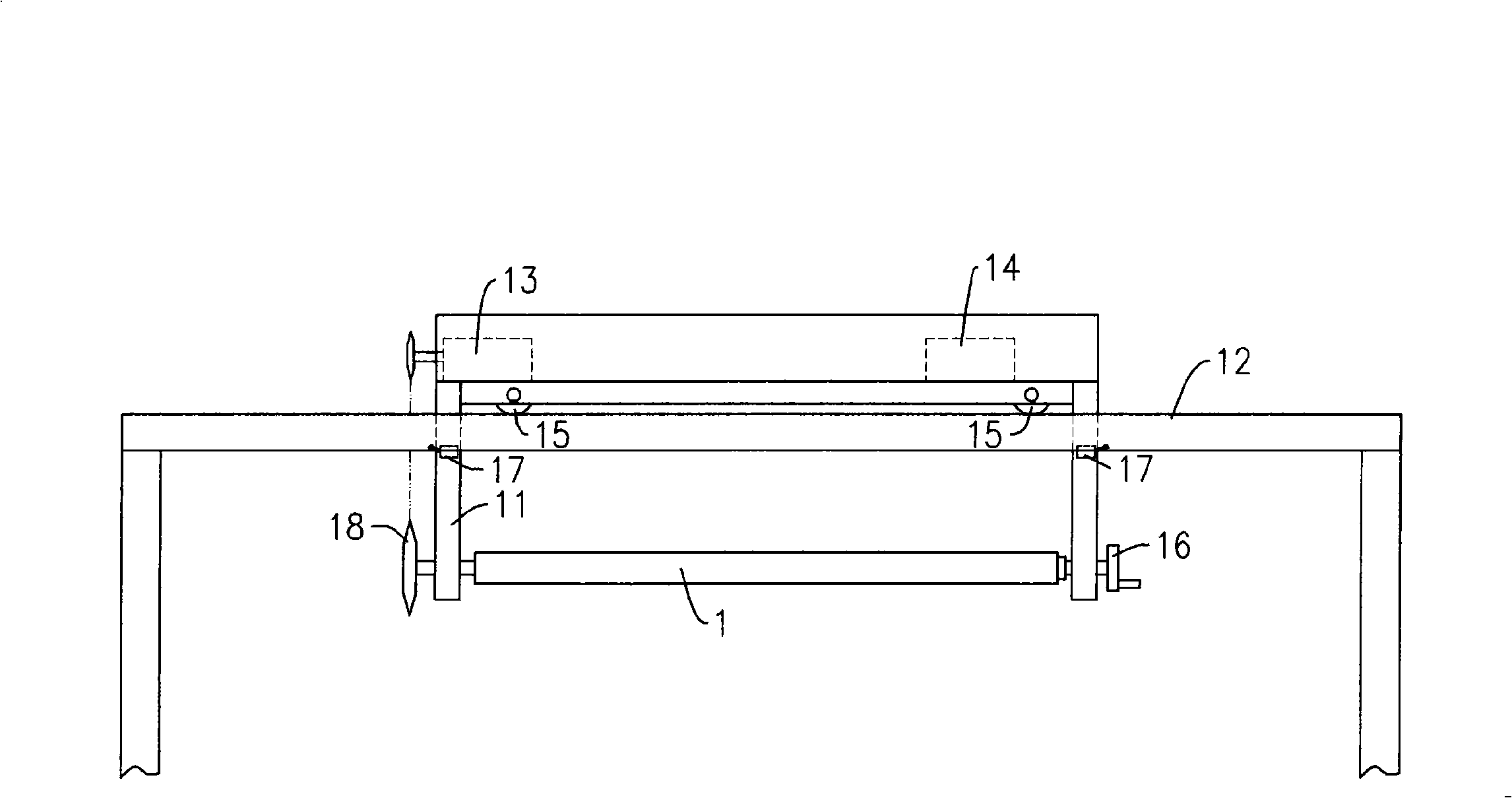

Bristle automatic hair wrapping machine

InactiveCN101283858AEasy to wrapEasy to operateContinuous processingFibre rougheningWinding machineBristle

The invention discloses an automatic bristle winding machine, which comprises a bristle pickup device for picking up soaked bristles, a bristle combing device for combing the bristles picked by the pickup device, and a bristle winding device for clamping the combed bristles by a clamper wire and winding the bristles, which are arranged sequentially. The bristle winding device comprises a main body provided with a winding roller rotating and simultaneously making reciprocating movement along the axis thereof, and the bristles combed by the bristle combing device are clamped by the clamper wire and are wound on the winding roller. The automatic bristle winding machine has the advantages of convenient operation, high mechanization and automation degree, greatly improved bristle shaping efficiency and lowered labor intensity.

Owner:孙文乐

Collecting and separating system for cotton fiber waste treatment

ActiveCN107974735ARealize automatic detection and analysisCarding machinesFibre separationCardingImaging analysis

The invention relates to a collecting and separating system for cotton fiber waste treatment. The collecting and separating system comprises a collector, a first camera shooting device used for continuously acquiring a plurality of images of waste falling into the collector, a second camera shooting device used for collecting an image of cotton fiber carded by a carding device, a data processing module, a separating channel, a first draught fan, a card clothing plate, a second draught fan, an air inlet pipe and a plurality of collecting nets, wherein the data processing module comprises an image analysis module and a storage module; the storage module is used for storing a fiber contrast image and an impurity image in advance; the image analysis module is used for recognizing a fiber partand an impurity part; the separation channel is arranged in a square box; the needle clothing plate is arranged in the separating channel; the air supply pipe is provided with a plurality of air inlets, and the periphery of the air inlets is connected with an air guide pipe; the collecting nets are arranged in the separating channel at intervals, and each collecting net is of a net structure wovenfrom metal. According to the system, automatic detection and analysis of waste components in the carding process are achieved.

Owner:NANJING ZHIQIAO AGRI CO LTD

Novel antistatic feather separator

InactiveCN102787366AExtended separation timeIncrease humidityWool fibre washing/scouringFibre separationEngineeringWater pipe

The invention provides a novel antistatic feather separator. The novel antistatic feather separator comprises a box body, wherein a feed opening is formed in the box body; a feather storage box is arranged at one end of the box body and connected with the feed opening; a first interactive baffle, a second interactive baffle and a third interactive baffle are arranged in the box body; a water pipe is arranged at the upper end in the box body of the feather separator; innumerous water pores for spraying water into mist are formed on the water pipe; and a blower is arranged at the other end of the box body. According to the invention, the three interactive baffles are blown to move by the blower, so that down feather and feathers are dispersed; as the feathers are easy to generate static electricity in winter, the water pipe arranged in the box body increases the humidity of the feathers, static electricity is reduced, the separation between the feathers and the down feather is accelerated, and the production efficiency is improved; and the novel antistatic feather separator has a simple structure, is convenient to manufacture, reduces static electricity and improves both the production efficiency and the product quality.

Owner:江苏欣隆羽绒有限公司

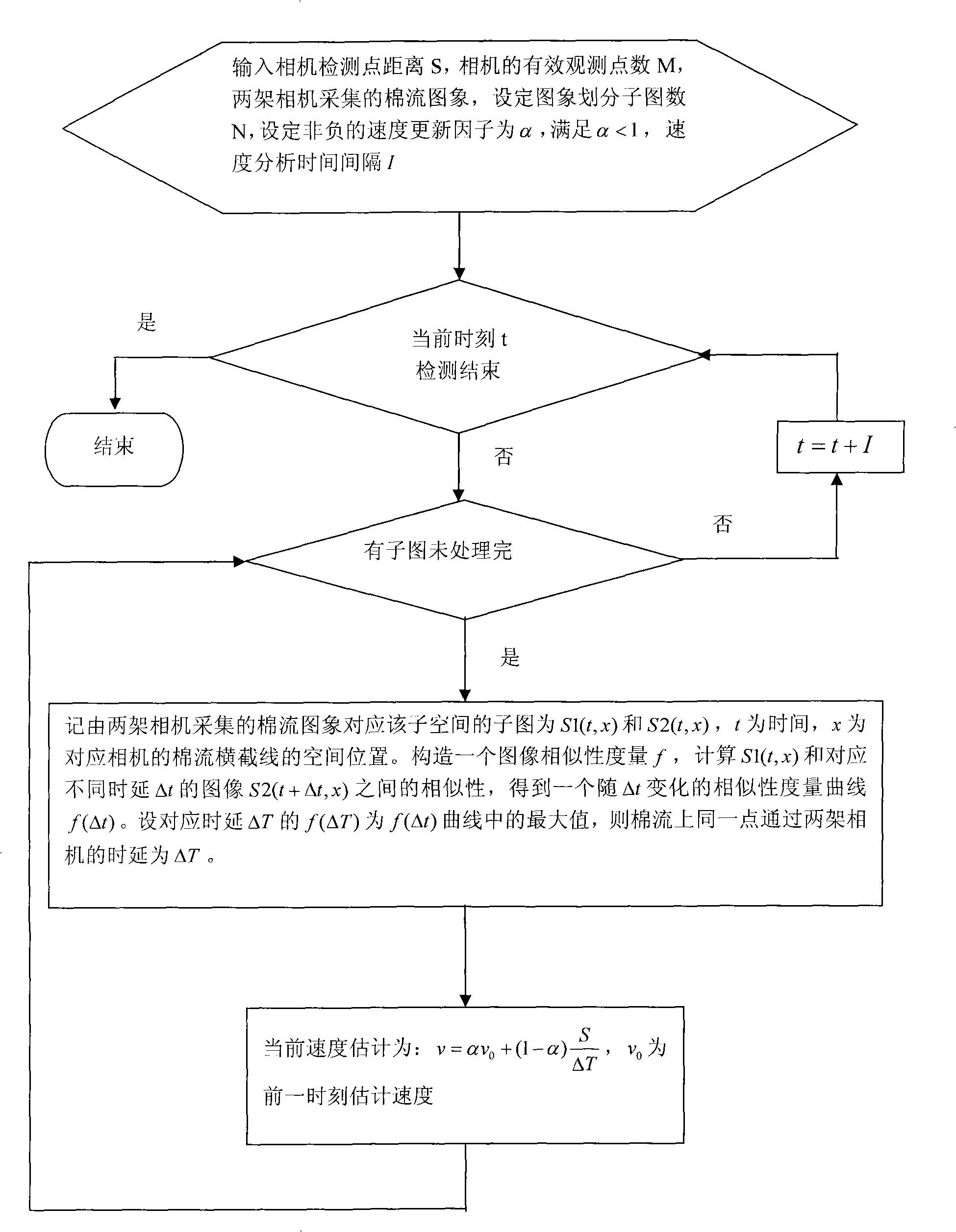

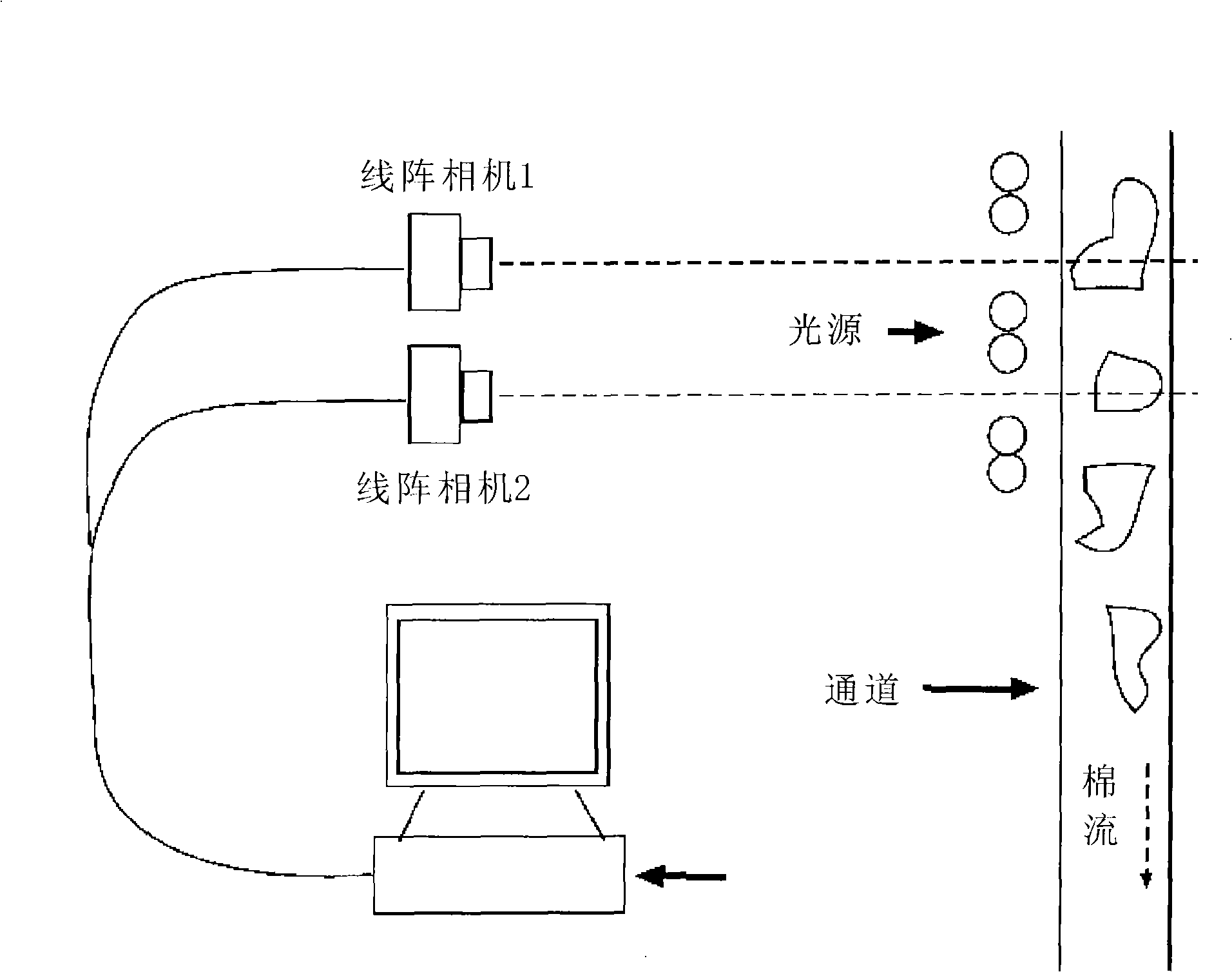

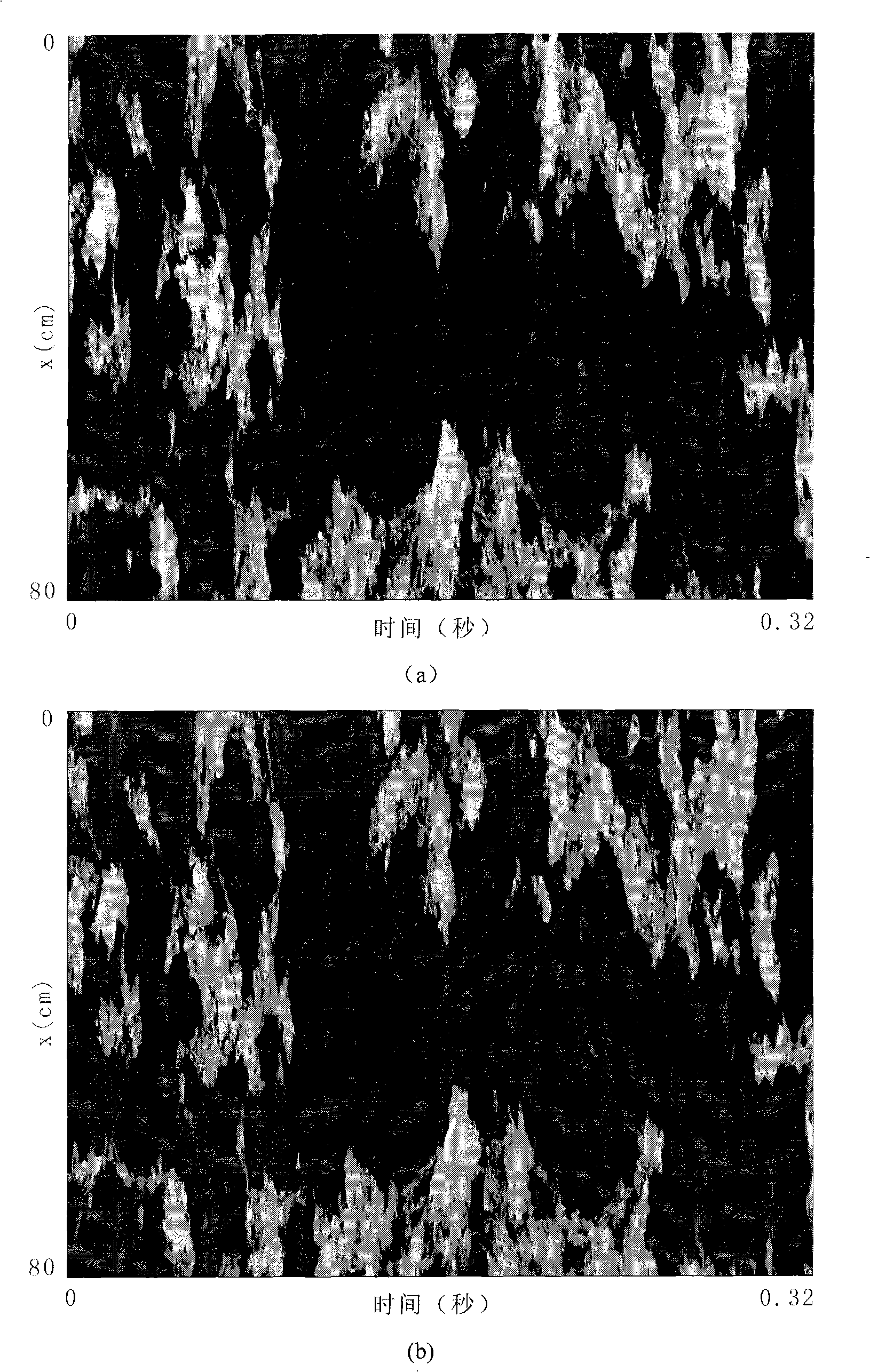

Cotton stream velocity on-line estimation method using video to measure speed in isomerism fibre sorting system

InactiveCN101281208ASpeed tracking is accurate in real timeAverage false blow rate reductionImage analysisLinear/angular speed measurementFiberMachine vision

The invention pertains to the industry testing technique field based on machine vision, which is characterized in that two linear array cameras with a setting distance are utilized to respectively extract images in which the cotton stream is partly superposed in the setting equal sampling period, according to cotton streams doing a speed changing rectilinear movement along the channel, and the image are divided into a plurality of cotton stream sub-graphs along a direction perpendicular to the cotton stream cross section direction; according to each sub-graph, the similarity between the sub-graph picked up by a linear array camera 1 and the linear array camera 2 with a different time delay delta t, thereby a similarity curve f(delta t) varying with delta t is obtained, and then calculating a time delay delta T corresponding to the maximum value f(delta T) of the curve f(delta t), namely the time delay of a same point on the cotton stream passing through two linear array cameras; and then based on the setting distance between the two linear array cameras, the cotton stream online speed distributed along the cotton stream transversal, under the condition that the cotton stream velocity will not abruptly change in the setting sampling time delay. the invention can be used to realize accurate sorting of isomerism fiber in the cotton stream.

Owner:TSINGHUA UNIV +1

Multi-channel electrostatic separation device for foreign fibers in machine-harvested seed cotton

PendingCN110747515AAchieve lossless separationImprove qualityVegetable fibre separation from seedsFibre separationFiberElectrostatic separation

The invention relates to a multi-channel electrostatic separation device for foreign fibers in machine-harvested seed cotton, which mainly comprises an electrostatic separation device shell, a cottonfeeding roller, a channel partition retainer, a composite electrode, a separation roller, a negative pressure conveying pipeline, a high-voltage electrostatic generator and a grounding terminal. Compared with the prior art, the multi-channel electrostatic separation device for foreign fibers in machine-harvested seed cotton has the multi-stage separation roller arranged in the electrostatic separation device shell, provides multi-channel separation for the machine-harvested seed cotton and foreign fibers through the cotton feeding roller and the channel partition retainer, so that the removalrate of foreign fibers from the seed cotton is greatly increased, especially residual mulch, effective separation of the foreign fibers from the seed cotton, such as the residual mulch, is achieved, and the multi-channel electrostatic separation device for foreign fibers in machine-harvested seed cotton is suitable for removal of the foreign fibers during cotton processing.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com