Efficient energy-saving environment-protection type velvet product refining sorting machine

A high-efficiency, energy-saving and environment-friendly technology, applied in fiber separation, textile and papermaking, fiber treatment, etc., can solve the problems of numerous processes, large investment in equipment, high energy consumption, etc., and achieve significant economic benefits, low solution efficiency, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

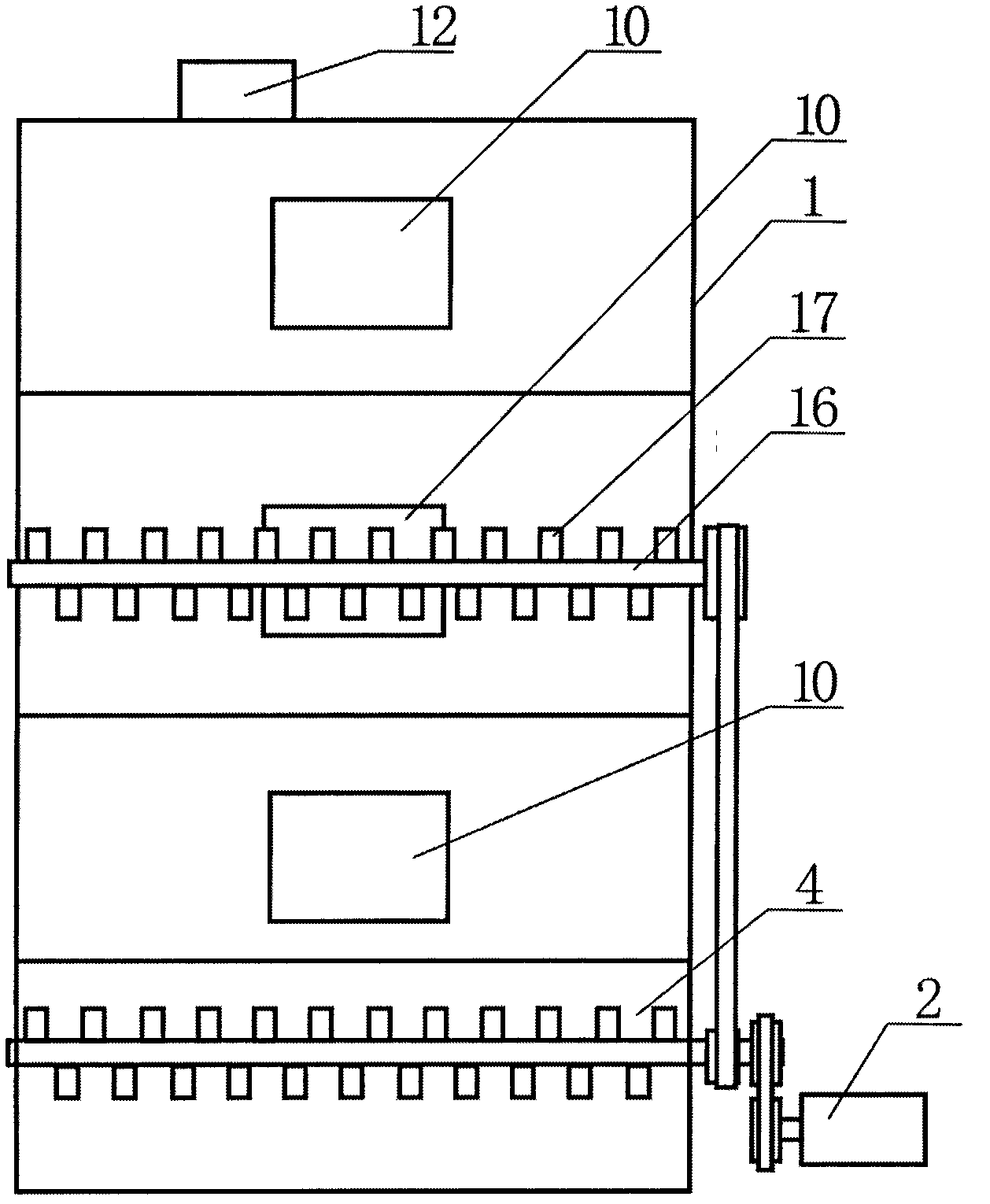

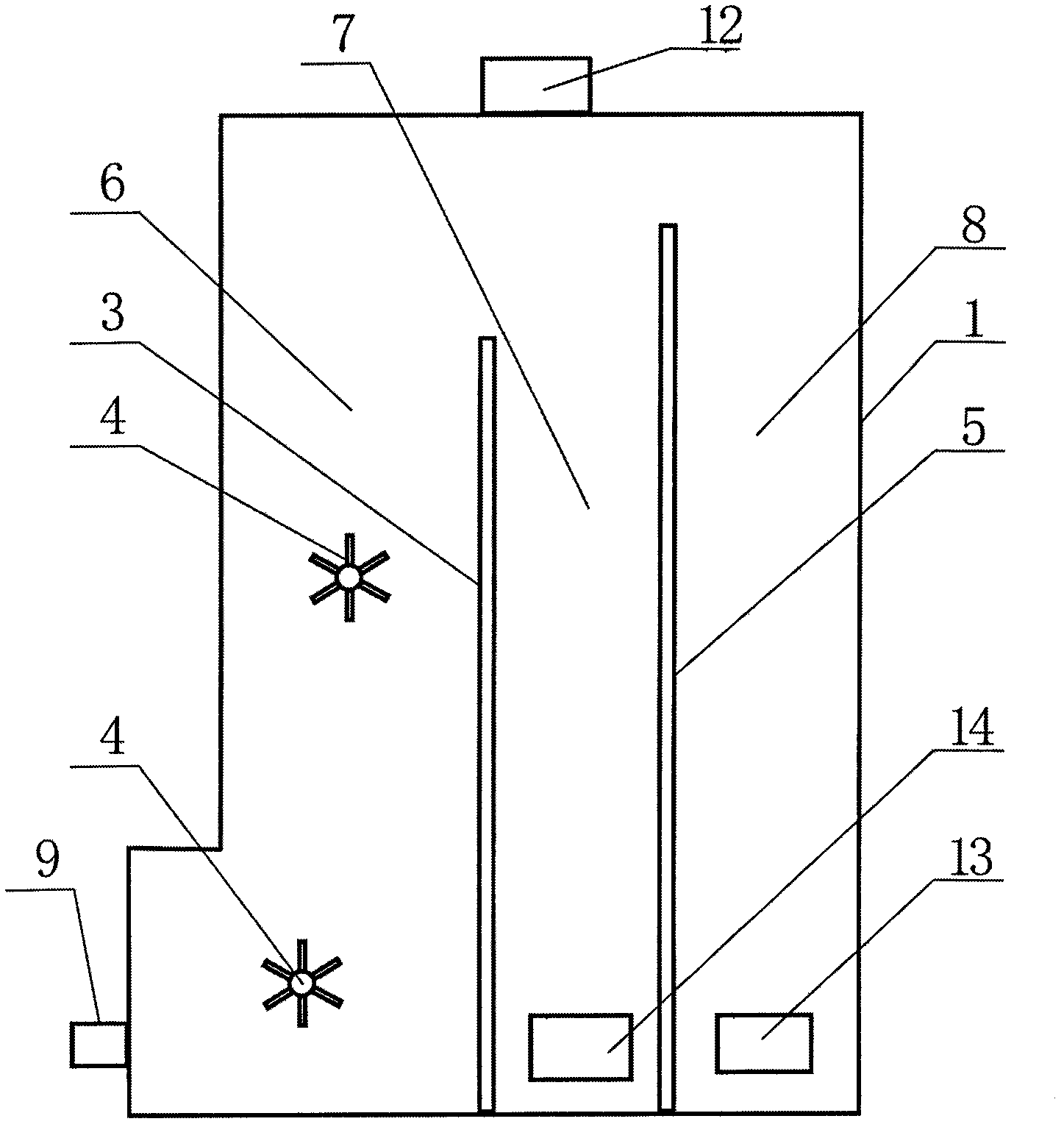

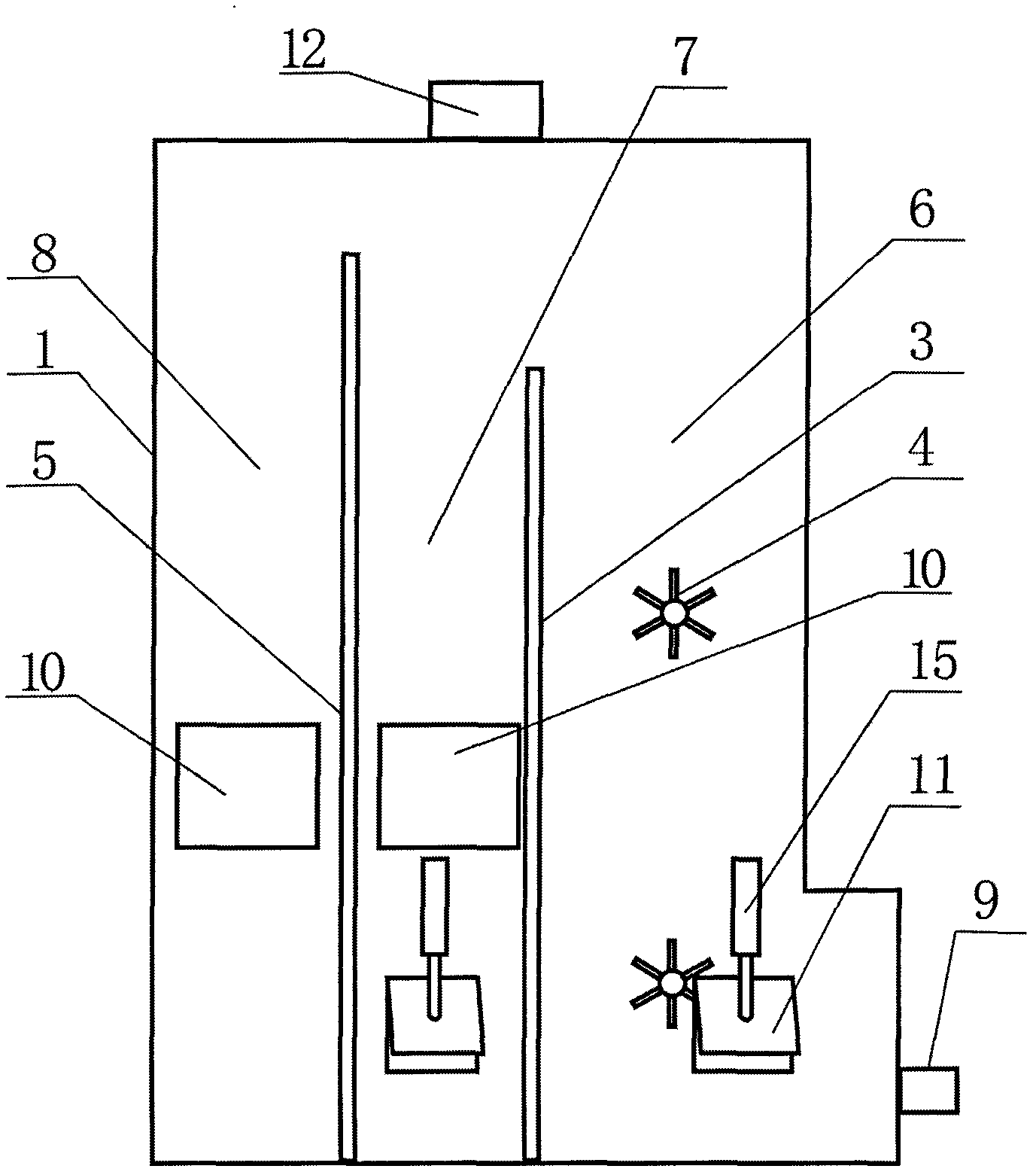

[0015] Such as figure 1 , 2 As shown in 3, the high-efficiency, energy-saving and environmentally-friendly fleece product selection sorter includes a box body 1, a stirring device 4, and a motor 2. The box body 1 is provided with vertical partitions A3 and B5, The partition A3 and the partition B4 divide the box body 1 into the raw material dispersing box 6, the coarse pile collection box 7 and the fine pile collection box 8, in turn, between the upper ends of the partition A3 and the partition B4 and the top of the box body 1. There is a gap, and the height of the partition A3 is lower than the height of the partition B4; there are two stirring devices 4, one stirring device 4 is located in the middle of the raw material dispersing box 6, and the other stirring device 4 is located in the raw material dispersing At the bottom of the box 6, the stirring device 4 includes a stirring shaft 16 and a plurality of stirring cups 17 distributed on the stirring shaft 16, and the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com