Cashmere yarn with high tensile stretch and production technology thereof

A technology with high elongation and production technology, applied in yarn, deburring devices, textiles and papermaking, etc., can solve the problems that cashmere fibers are not suitable for anti-shrinkage treatment, reduce the excellent characteristics of cashmere, and low dimensional stability. Achieve the effects of rough fiber feel, improved environmental conditions, and decreased elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

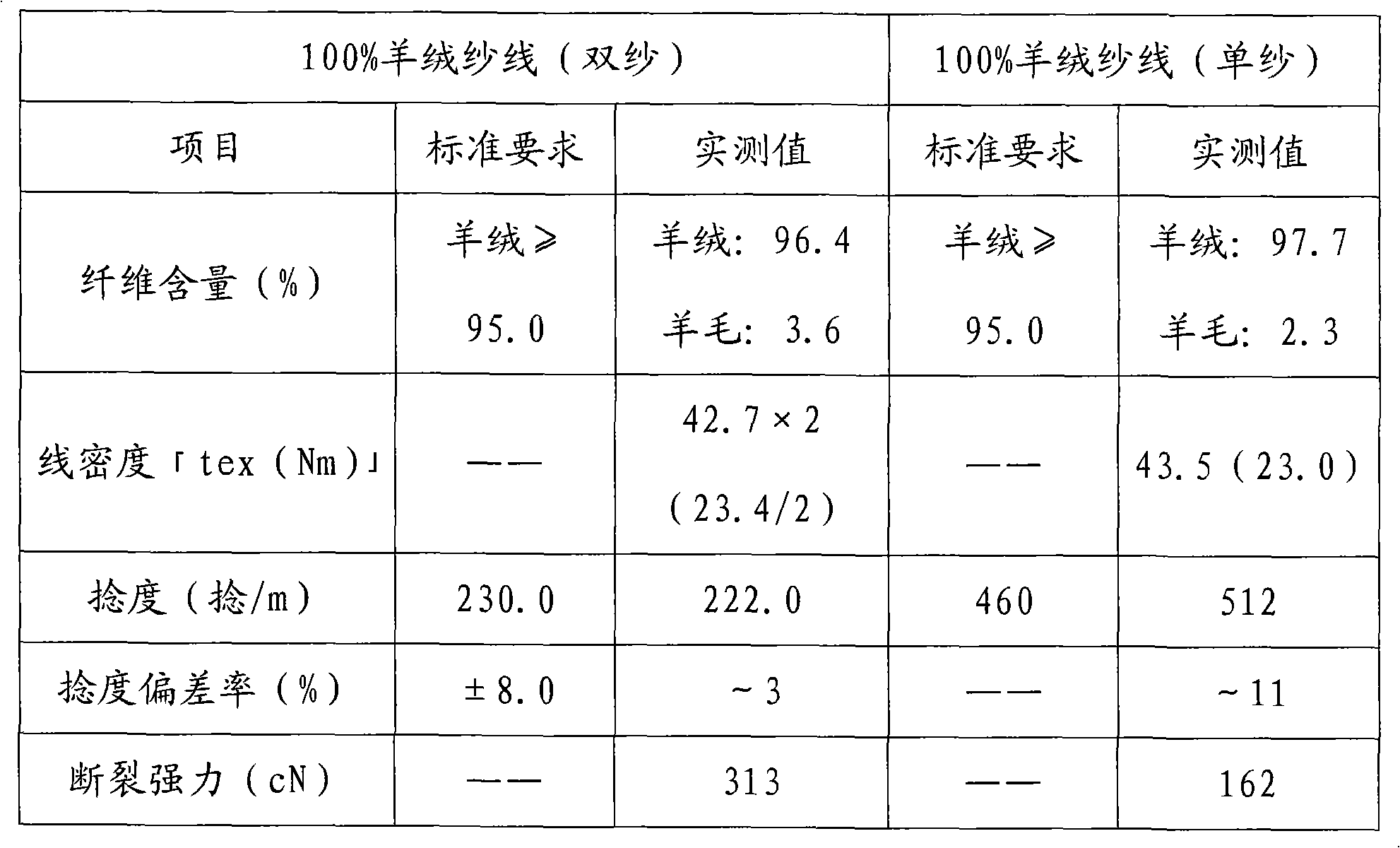

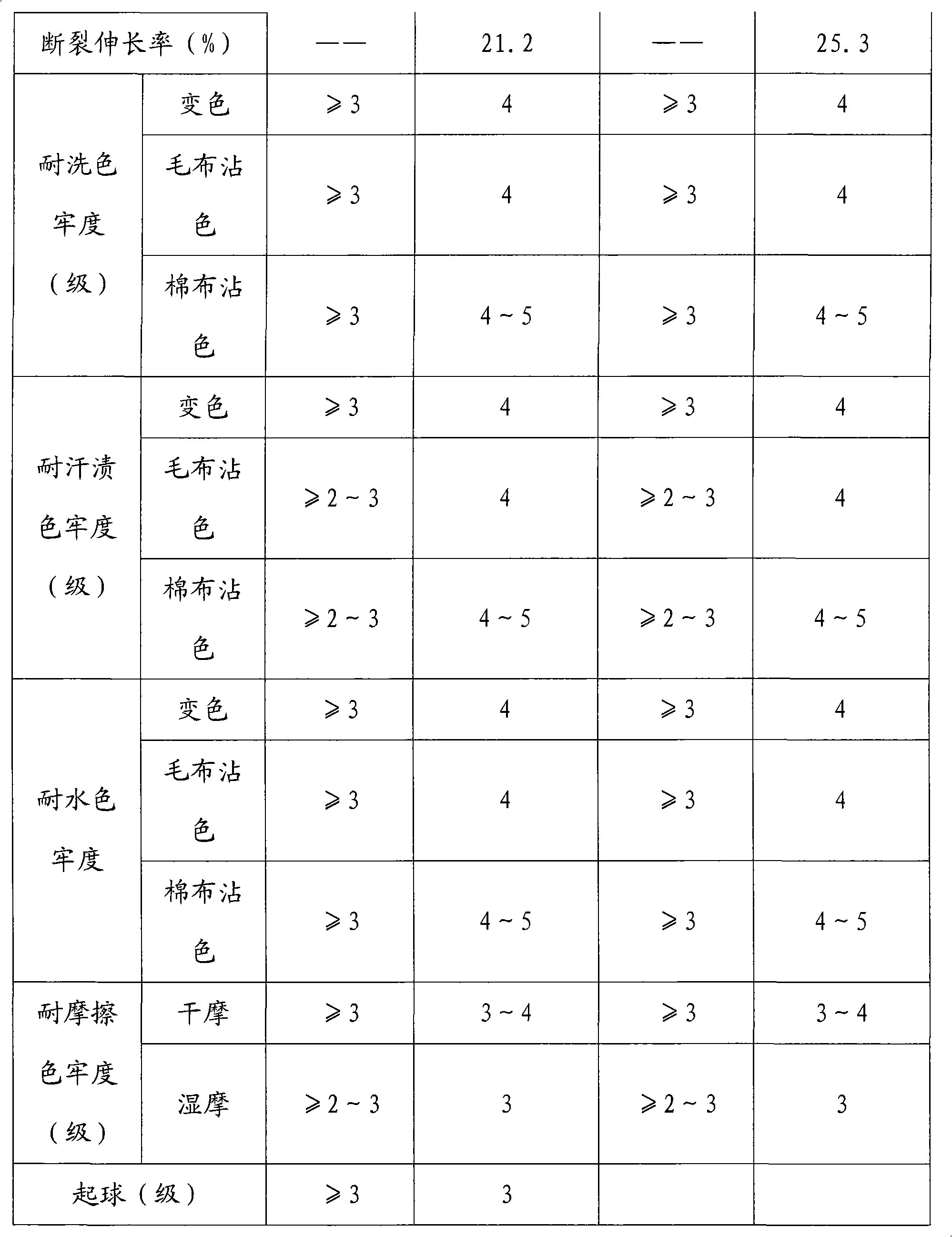

Examples

Embodiment 1

[0023] 1. Material selection: 15.0um medium fineness carded cashmere is preferred as raw material.

[0024] 2. Cashmere washing: three gentle openings are used before washing, the raw cashmere is decomposed in large pieces during the first opening, part of the grass clippings and sediment in the raw cashmere are removed during the second opening, and the focus is removed during the third opening Part of the skin; the three gentle openings make the raw cashmere fully loosen and the fiber damage is small, and the partial removal of impurities reduces the pressure of washing and carding in the subsequent process. Use neutral detergent and low temperature washing wool, lower temperature drying

[0025] 3. Carding: Set two sets of working rollers and plucking rollers on the carding machine. In the traditional carding process, add a dust removal device for falling objects, and add two carding machines to adjust the angle of the carding roller card clothing to 130°.

[0026] 4. Dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com