Method for preparing ecological materials through steam explosion and refining of bamboo and recycling bamboo

An ecological material, energy-based technology, applied in the separation of plant raw materials, fibers, chemical post-processing of fibers, etc., to achieve the effect of reducing energy consumption, saving processes, improving utilization rate and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

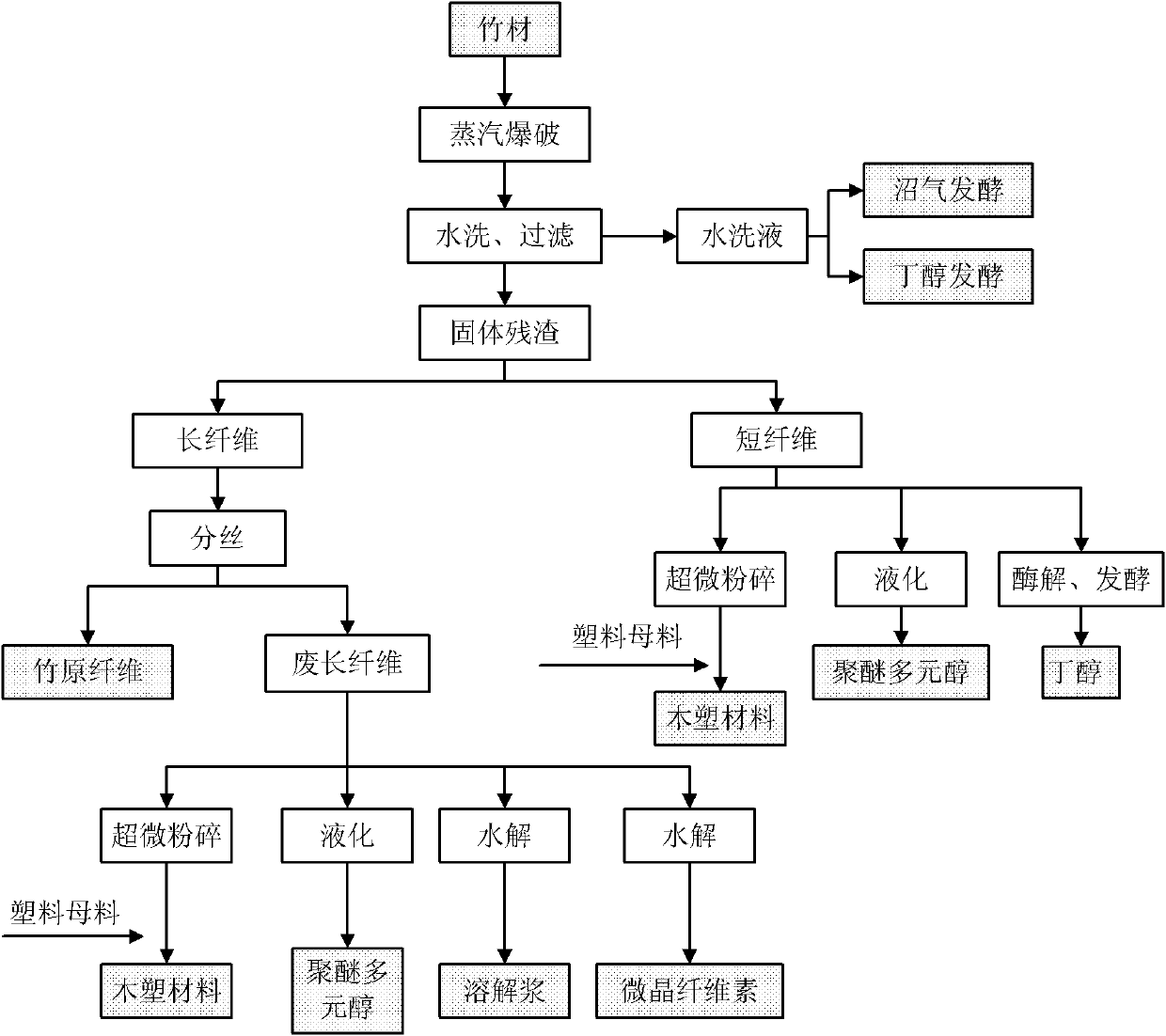

Image

Examples

Embodiment 1

[0029] ① Bamboo steam explosion pretreatment: After the bamboo is cleaned, arranged and dried, it is made into bamboo strips; placed in a steam explosion treatment device, maintained at 12MPa saturated steam pressure for 5 minutes, and the bamboo chip raw material is subjected to steam explosion treatment;

[0030] ②Biogas fermentation of steamed firecracker material washing liquid: the total sugar content in the steam firecracker material washing liquid is about 23g / L, and the fiber material after washing is separated by a fiber carding device to obtain short fibers less than 5cm and Long fibers larger than 5cm; add 25ml of activated sludge and 0.1g of beef extract to 100ml of washed sugar solution, adjust the pH to 6.5, ferment at 50°C, and collect gas;

[0031] ③Prepare bamboo fibers from long fibers and separate waste long fibers: use a fiber splitting device to decompose the steamed bamboo material coarse fibers into thinner fibers, and obtain long fibers with strong tough...

Embodiment 2

[0034] ① Bamboo steam explosion pretreatment: After the bamboo is cleaned, arranged and dried, it is made into bamboo strips; placed in a steam explosion treatment device, maintained at 12MPa saturated steam pressure for 5 minutes, and the bamboo chip raw material is subjected to steam explosion treatment;

[0035] ②Butanol fermentation of the steamed firecracker material washing liquid: the total sugar content in the steamed firecracker material washing liquid is about 23g / L, and the fiber material after washing is separated by a fiber carding device to obtain short fibers less than 5cm according to the length of the steam firecracker material fiber And long fibers larger than 5cm; the washing solution is treated with 7.5% activated carbon at 30°C and 150rpm for 12h, then adjusted to pH 6.5, sterilized at 121°C for 15min, and after cooling to room temperature, add 10% (v / v) Clostridium acetobutylicum ATCC 824 seed culture medium, static anaerobic culture at 37°C, and the tota...

Embodiment 3

[0040] ① Bamboo steam explosion pretreatment: After the bamboo is cleaned, arranged and dried, it is made into bamboo strips; placed in a steam explosion treatment device, maintained at 12MPa saturated steam pressure for 5 minutes, and the bamboo chip raw material is subjected to steam explosion treatment;

[0041] ②Biogas fermentation of steamed firecracker material washing liquid: the total sugar content in the steam firecracker material washing liquid is about 23g / L, and the fiber material after washing is separated by a fiber carding device to obtain short fibers less than 5cm and Long fibers larger than 5cm; add 25ml of activated sludge and 0.1g of beef extract to 100ml of washed sugar solution, adjust the pH to 6.5, ferment at 50°C, and collect gas;

[0042] ③Prepare bamboo fibers from long fibers and separate waste long fibers: use a fiber splitting device to decompose the steamed bamboo material coarse fibers into thinner fibers, and obtain long fibers with strong tough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com