Multi-channel electrostatic separation device for foreign fibers in machine-harvested seed cotton

An electrostatic separation and channel machine technology, which is applied in the separation of plant fibers from seeds, fiber separation, and fiber processing, can solve problems such as limited sorting efficiency, improve processing efficiency and economic benefits, and improve quality and market prices. , the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

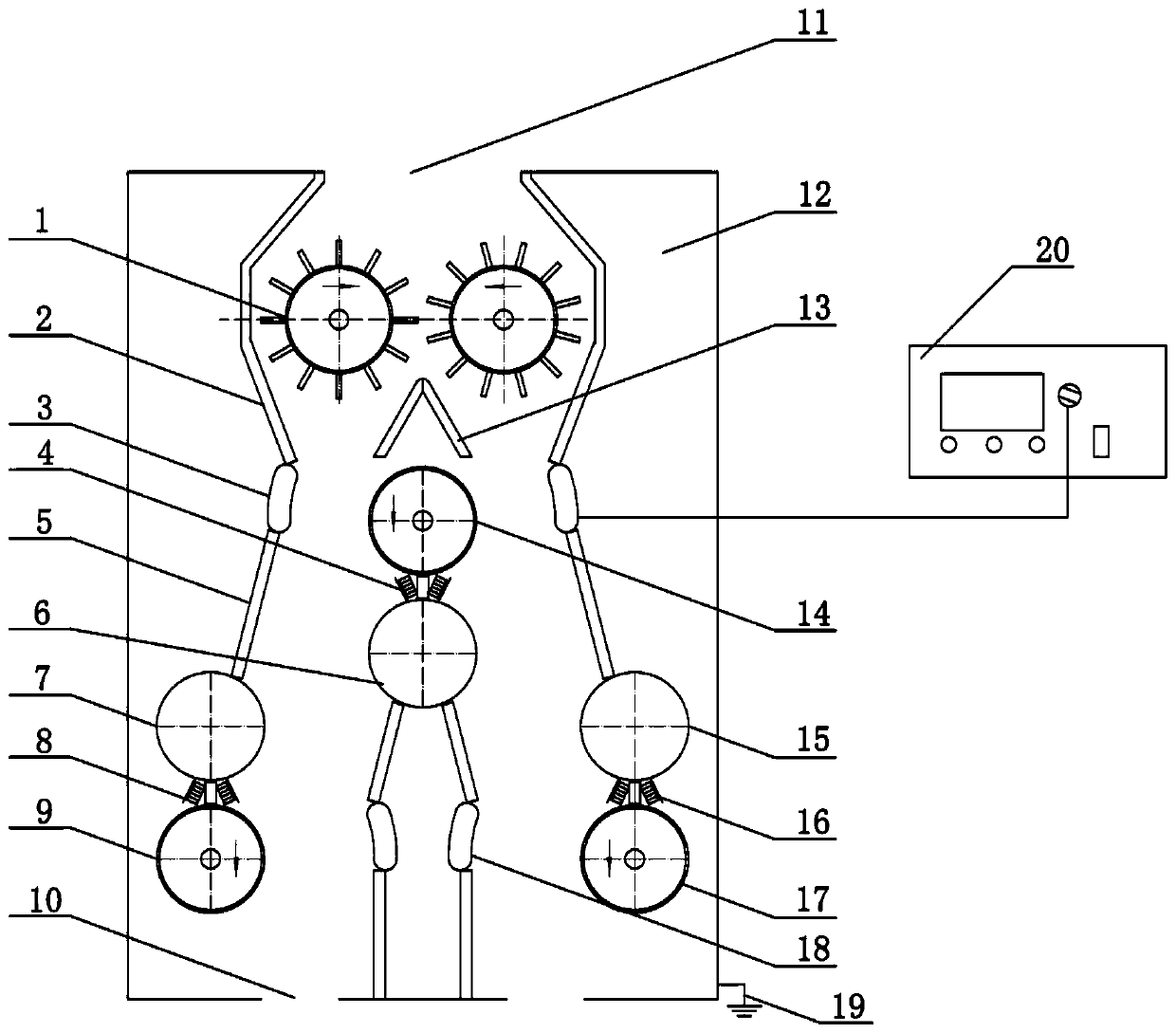

[0013] A multi-channel electrostatic separation device for machine-picked residual cotton film, comprising an electrostatic separation shell, a seed cotton sub-channel device, and an electrostatic separation device.

[0014] The seed cotton sub-channel device is composed of a feeding port (11), a flower feeding roller (1) and a sub-channel baffle (13); the uppermost part of the electrostatic separation device housing (12) is provided with the feeding Feeding mouth (11), two flower feeding rollers (1) are fixed on the shell (12) of the electrostatic separation device through bearings with seats, and two flower feeding rollers (1) are arranged in parallel on the side of the feeding mouth (11). Directly below, and the two flower feeding rollers (1) rotate relatively inward; the sub-channel baffle (13) is fixed by the baffle bracket and the baffle fixing plate, and the baffle fixing plate is fixed on the electrostatic separation device shell ( 12), the sub-channel baffle (13) is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com