A Second Phase Characterization Method of Ferromagnetic Alloy Powder

An alloy powder, ferromagnetic technology, applied in the field of metal materials and their structure characterization, can solve problems such as damage, inability to perform TEM/HRTEM characterization of equipment, and pollution of electron microscope equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

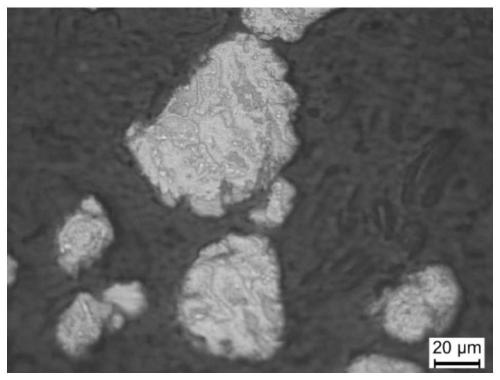

[0068] Example 1: Characterization of the second phase of 14YWT alloy powder

[0069] Step 1: Put ferromagnetic alloy powder (14YWT alloy powder, particle size less than 150 μm) and nickel foam into a beaker filled with absolute ethanol for ultrasonic dispersion for 3 minutes to obtain nickel foam filled with ferromagnetic alloy powder as an electrolytic anode .

[0070] Step 2: Use nickel foam filled with alloy powder as the anode (the pore size of the pores in the foam nickel is less than or equal to 200 μm), and the stainless steel cylinder as the cathode, and put it into the electrolyte to electrolyze the electrolytic anode to separate the second phase from the iron matrix , using a magnet for magnetic separation to obtain an electrolyte solution containing the second phase. The electrolyte used is: 2% tetramethylammonium chloride, 15% acetylacetone, 3% glycerol, and the balance is absolute ethanol. The electrolysis method is: constant voltage electrolysis at room tempera...

Embodiment 2

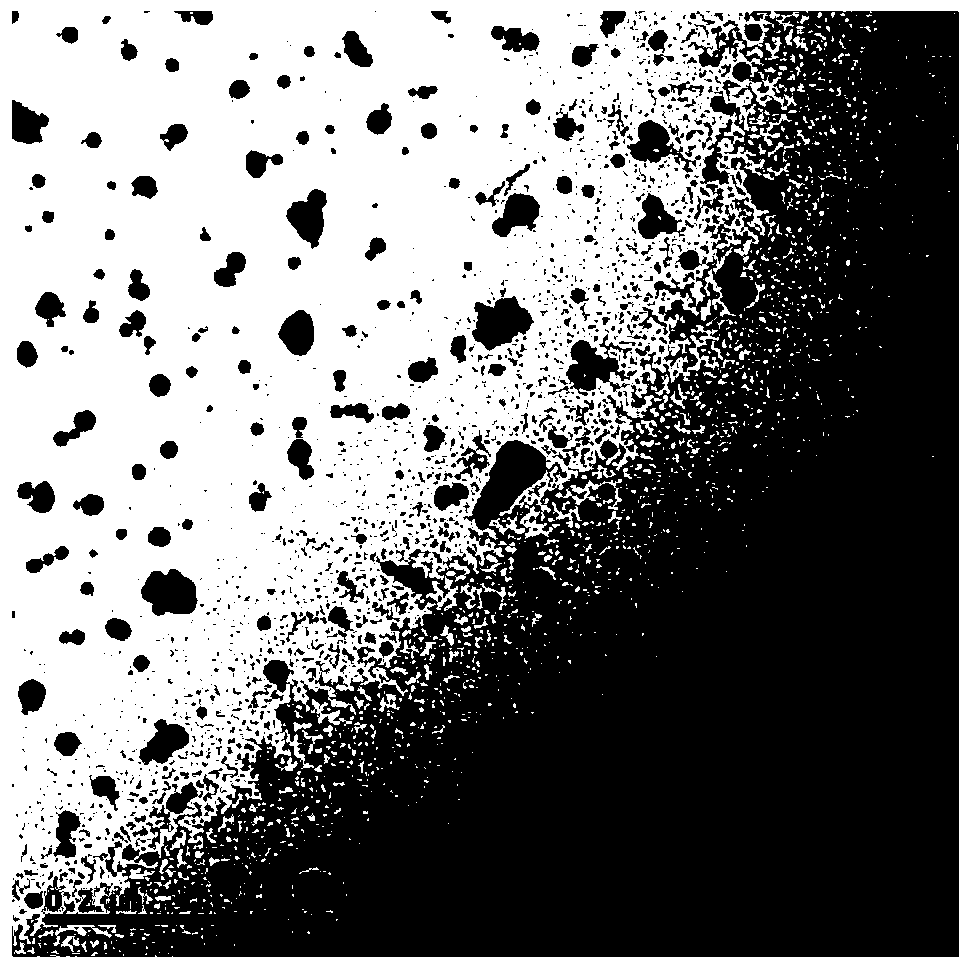

[0078] Embodiment 2: Fe-14Cr-3W-0.4Ti-0.5Y 2 o 3 (wt.%) Second Phase Characterization of Alloy Powders

[0079] Step 1: Ferromagnetic alloy powder (Fe-14Cr-3W-0.4Ti-0.5Y 2 o 3 (wt.%) alloy powder, the particle size is less than 150 μm), and foamed nickel are placed in a beaker filled with absolute ethanol and ultrasonically dispersed for 5 minutes to obtain foamed nickel filled with ferromagnetic alloy powder, which is an electrolytic anode.

[0080] Step 2: Use nickel foam filled with alloy powder as the anode (the pore size of the pores in the foam nickel is less than or equal to 200 μm), and the stainless steel cylinder as the cathode, and put it into the electrolyte to electrolyze the electrolytic anode to separate the second phase from the iron matrix , using a magnet for magnetic separation to obtain an electrolyte solution containing the second phase. The electrolyte used is: 2% tetramethylammonium chloride, 3% cetyltrimethylammonium chloride, 15% acetylacetone, 5% ...

Embodiment 3

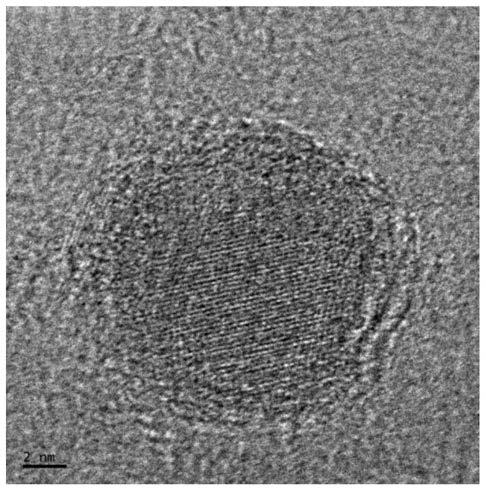

[0087] Embodiment 3: Fe-14Cr-3W-0.4Ti-5Y 2 o3 (wt.%) Second Phase Characterization of Alloy Powders

[0088] Step 1: Ferromagnetic alloy powder (Fe-14Cr-3W-0.4Ti-5Y 2 o 3 (wt.%) alloy powder, the particle size is less than 150 μm), and foamed nickel are put together into a beaker filled with absolute ethanol for ultrasonic dispersion for 3 minutes to obtain foamed nickel filled with ferromagnetic alloy powder, which is an electrolytic anode.

[0089] Step 2: Use nickel foam filled with alloy powder as the anode (the pore size of the pores in the nickel foam is less than or equal to 200 μm), and the stainless steel cylinder as the cathode, and put it into the electrolyte to electrolyze the electrolytic anode to separate the second phase from the iron matrix , using a magnet for magnetic separation to obtain an electrolyte solution containing the second phase. The electrolyte used is: 2% tetramethylammonium chloride, 15% acetylacetone, 3% glycerol, and the balance is absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com