Silkworm pupa oil and extracting method and applications

An extraction method and technology of silkworm chrysalis oil, which are applied in the directions of application, production/processing of edible oil/fat, metabolic diseases, etc., can solve the problems of high cost of special equipment, etc., and achieve a structure that is convenient for mass production, protects the double health, and shortens the extraction time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

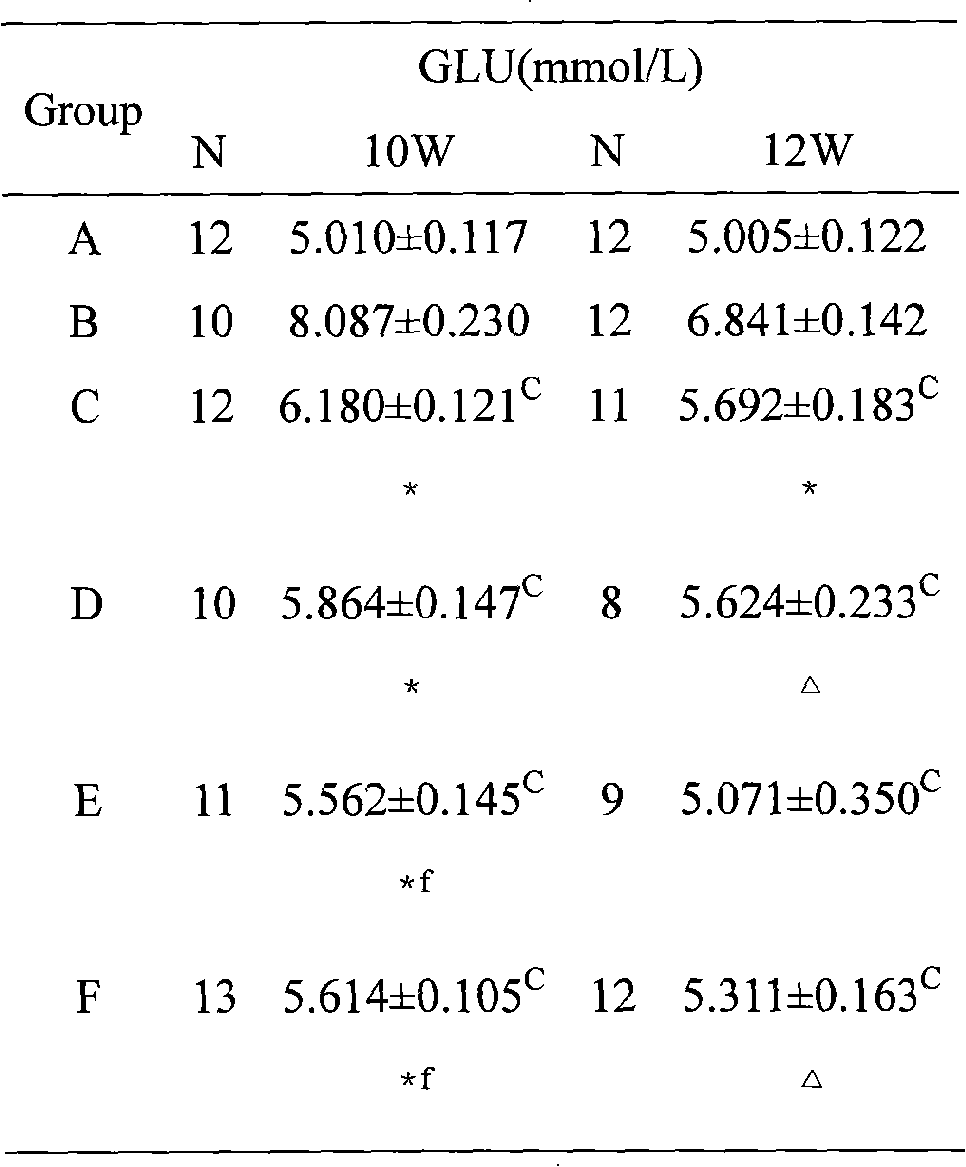

Examples

Embodiment 1

[0029] 1. Microwave extraction: Silkworm chrysalis powder: absolute ethanol (mass: volume) is 1:3 to 1:7, generally 1:5. Add 5.6-22.4 grams of potassium hydroxide per 1000ml of absolute ethanol and put it into a microwave extraction tank. Reaction conditions: 400W-550W, 40-70°C, 20-40min. Suction filtration, rotary evaporation of excess ethanol under reduced pressure, move the reactant to a separatory funnel, add dilute hydrochloric acid of PH=1 to neutralize the excess alkali, and adjust the pH value to neutrality, then use hot saturated sodium chloride solution (temperature 30-40°C or so) to wash away the glycerin. Add anhydrous sodium sulfate to dehydrate and dry to obtain mixed fatty acid ethyl esters.

[0030] 2. Urea clathrate: add a certain proportion of urea-ethanol (100ml ethanol can dissolve 10g urea) saturated solution of mixed fatty acid ester, fatty acid: urea: ethanol is about 1:1:10 (v:m:v). Stir evenly and reflux for 40 minutes; after cooling to room temperat...

Embodiment 2

[0032] 1. Microwave extraction: silkworm chrysalis powder: absolute ethanol (mass: volume) is 1:5, 11.2 grams of potassium hydroxide can be added to every 1000ml of absolute ethanol, and put into a microwave extraction tank. Reaction conditions: 400W~550W, 60 ℃, 20min. Suction filtration, rotary evaporation of excess ethanol under reduced pressure, move the reactant to a separatory funnel, add dilute hydrochloric acid of PH=1 to neutralize the excess alkali, and adjust the pH value to neutrality, then use hot saturated sodium chloride solution (temperature 30-40°C or so) to wash away the glycerin. Add anhydrous sodium sulfate to dehydrate and dry to obtain mixed fatty acid ethyl esters.

[0033] 2. Urea clathrate: add a certain proportion of urea-ethanol (100ml ethanol can dissolve 10g urea) saturated solution of mixed fatty acid ester, fatty acid: urea: ethanol is about 1:1:10 (v:m:v). Stir evenly and reflux for 40 minutes; after cooling to room temperature, place at 0°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com