Preparation method of high-orientation Ca0.4Sr0.6Bi4Ti4O15 template grain film

A high-orientation, template technology, applied in electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve problems such as unfavorable applications, difficulty in non-destructive separation of films and substrates, and difficulty in tailoring ferroelectric films. Achieve the effect of low cost, smooth grain and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

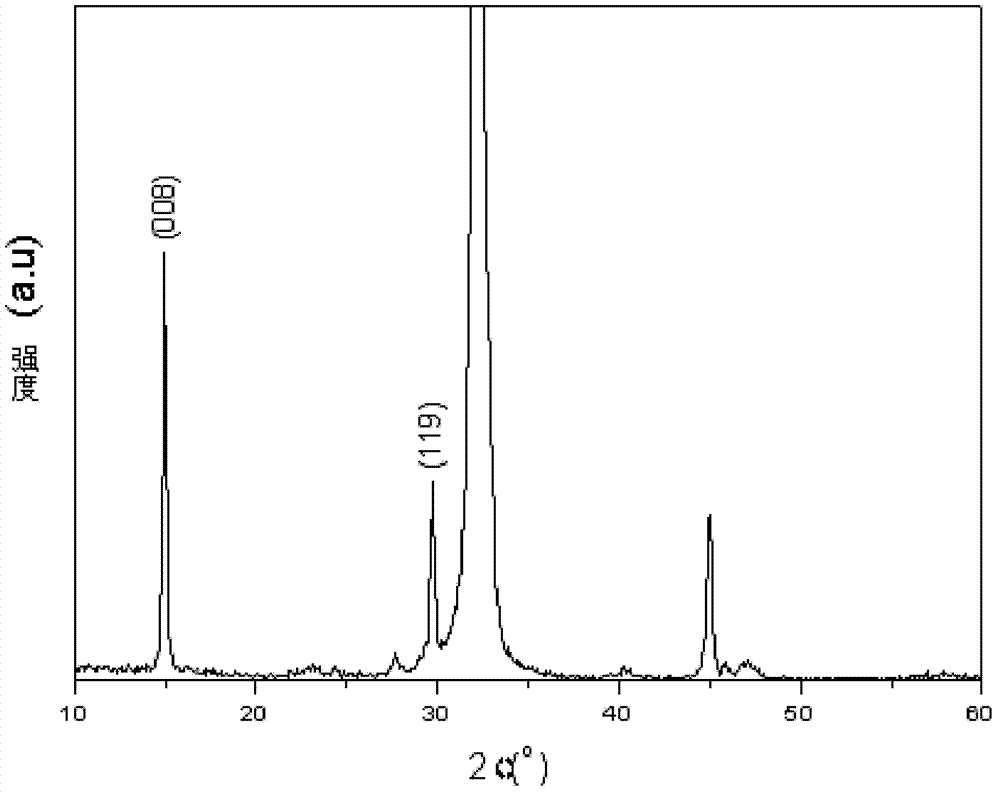

[0025] A highly oriented Ca 0.4 Sr 0.6 Bi 4 Ti 4 o 15 The preparation method of the template grain film, the specific steps are as follows:

[0026] (1) Prepare solution A by mixing 10ml of tetrabutyl titanate and acetylacetone at a ratio of 1:1 by volume, put the beaker containing the solution in 0°C ice water and stir for 12h to obtain a clear yellow-brown transparent A solution; Weigh bismuth nitrate (15.5224g), strontium acetate (0.9465g), calcium nitrate (0.6870g) and join in the solvent ethylene glycol (52ml), stir 12h on the magnetic stirrer, obtain clear and transparent B solution. Then slowly add solution B into solution A, and stir the mixed solution thoroughly for 48 hours to obtain pale yellow Ca 0.4 Sr 0.6 Bi 4 Ti 4 o 15 Precursor solution C, the C solution is equally divided into two parts D and E;

[0027] (2) Using the method of self-propagating combustion (the temperature causing combustion is 300°C, the specific operation is: pour the solution evenly...

Embodiment 2

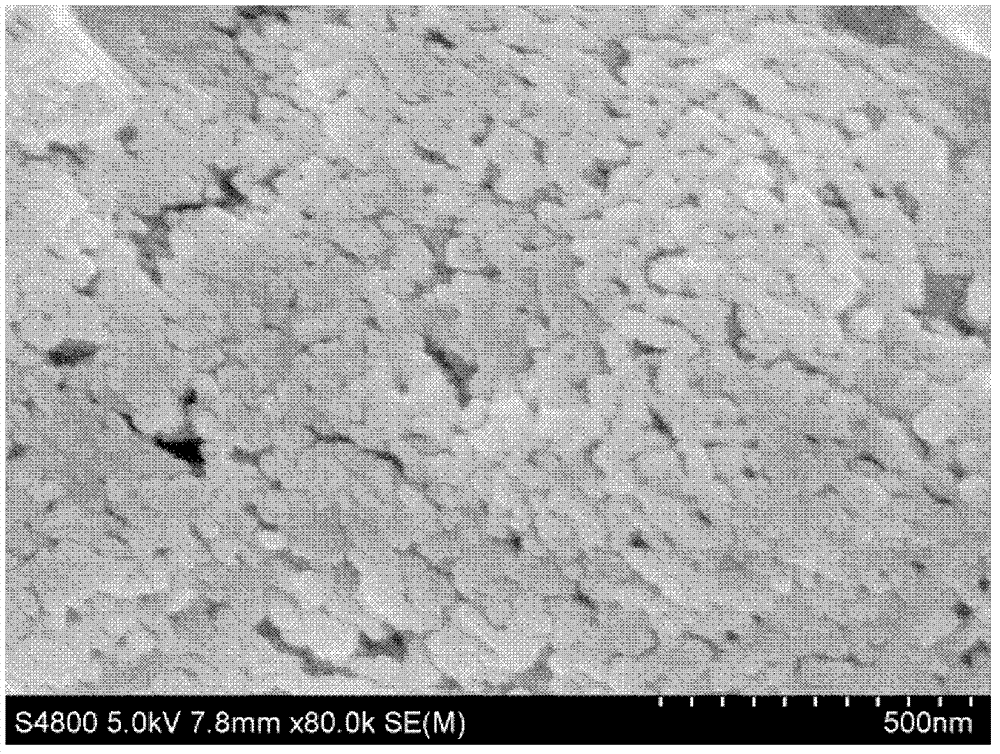

[0033] The preparation method is the same as in Example 1, and the rotating speed of the glue homogenizer in step (3) is adjusted, adopting the glue homogenization speed of 3250r / min and the glue homogenization time of 30s, and all the other conditions are the same as in Example 1. When the Ca 0.4 Sr 0.6 Bi 4 Ti 4 o 15 The SEM photo of the template grain film is as follows figure 2 As shown, the surface of the film has no cracks, the particles are clear, and the crystal grains are well crystallized. A high-quality template grain film was successfully prepared on the soluble substrate NaCl.

Embodiment 3

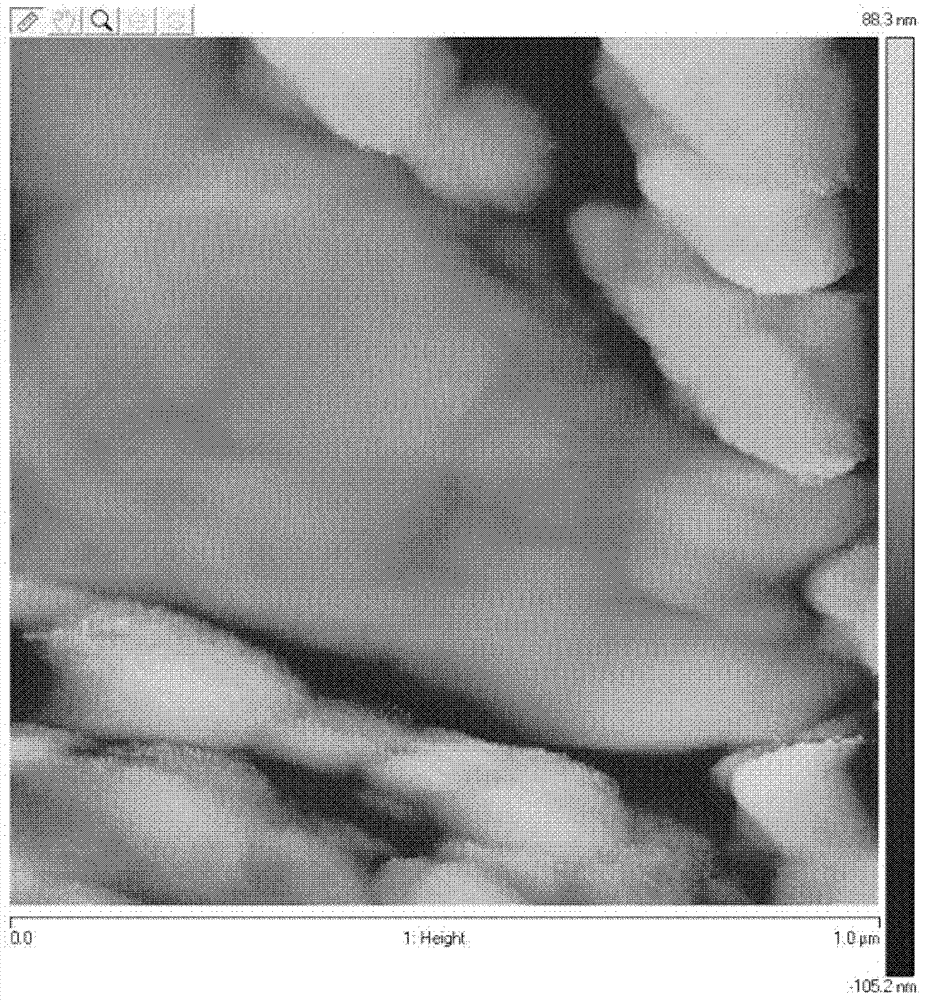

[0035] The preparation method is the same as in Example 1, the layer-by-layer annealing heat treatment process in step (4) is adjusted, and the thermal decomposition temperature and annealing temperature in the heat treatment process are changed. When the temperature is 700°C and the annealing time is 300s, other conditions are the same as in Example 1. The prepared Ca 0.4 Sr 0.6 Bi 4 Ti 4 o 15 The atomic force of the template film is as image 3 As shown, the crystal grains on the surface of the template grain film are relatively smooth, and the orientation of the grain crystals is better. A highly oriented template grain film was successfully prepared on the soluble substrate NaCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com