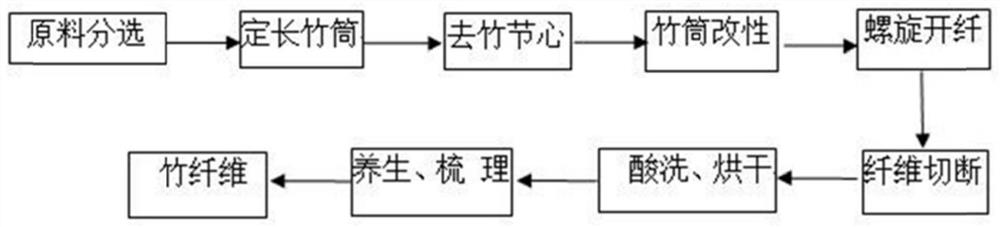

A kind of bamboo tube continuous spiral opening equipment and bamboo fiber acquisition method

A continuous spiral and bamboo tube technology, which is applied in the field of bamboo tube continuous spiral opening equipment and bamboo fiber acquisition, can solve the problems of uneven separation of bamboo fibers, strength damage, etc. Processed fiber neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

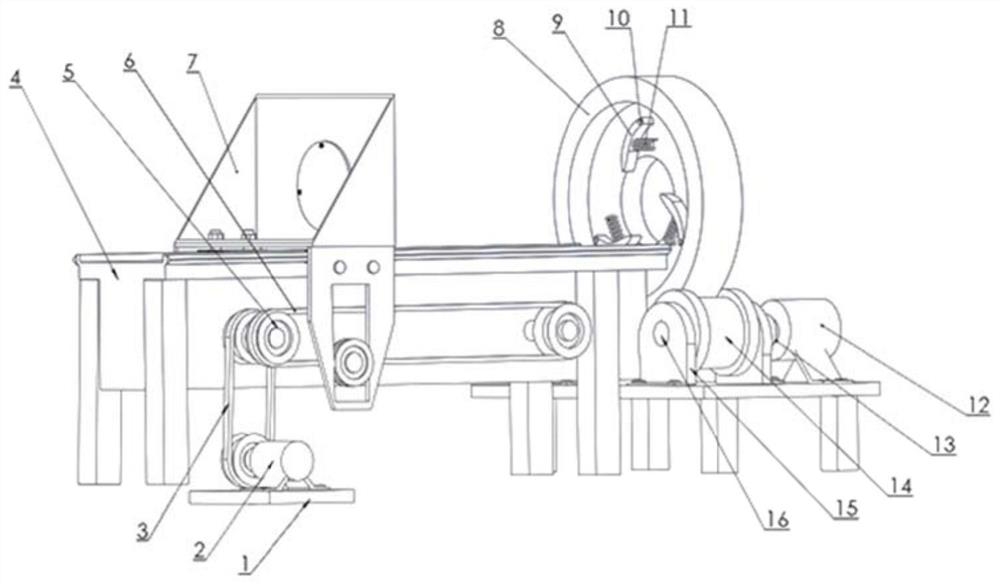

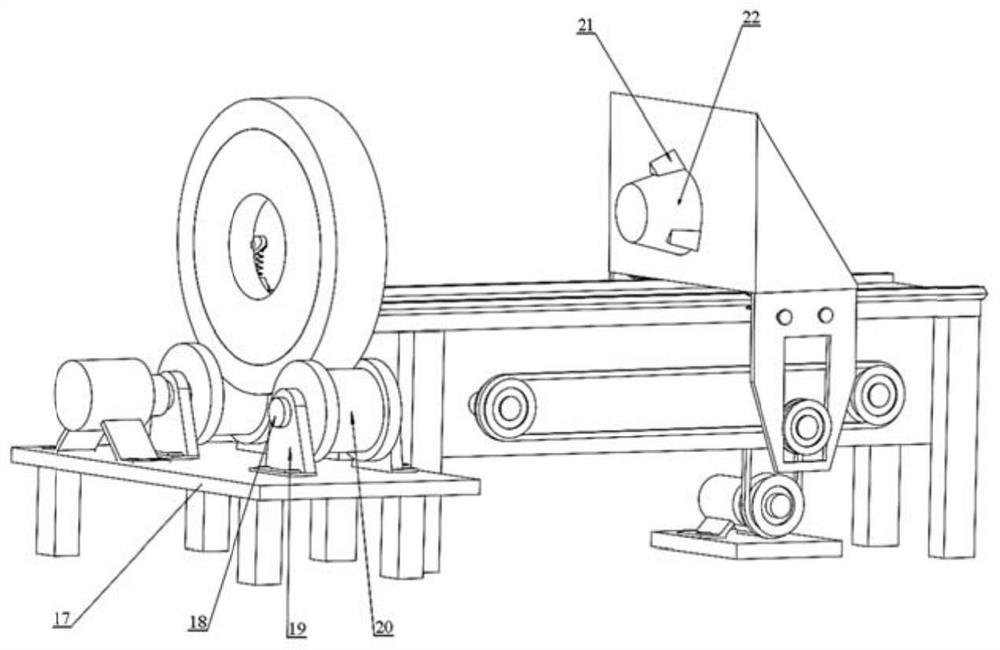

[0034] The present invention will be further elaborated and described below with reference to the accompanying drawings and specific embodiments. The technical features of the various embodiments of the present invention can be combined correspondingly on the premise that there is no conflict with each other.

[0035] Bamboo is essentially a kind of non-uniform fiber reinforced gradient composite material, which has the characteristics of laminated structure; the strength modulus of bamboo fiber is much larger than that of the matrix material, and the fiber bundles are arranged in parallel in the longitudinal direction. According to the structural characteristics and mechanical properties of bamboo, the invention studies the principle of fiber separation, and proposes to separate bamboo fibers by making the modified bamboo tube perform a controllable compound helical motion. Torque is applied to one end of the bamboo tube, and axial load is applied to the other end, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com