Distributary seed cotton foreign fiber capturing cleaner

A heterosexual fiber and shunt technology, applied in fiber processing, fiber separation, mechanical processing, etc., can solve problems such as seed cotton clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

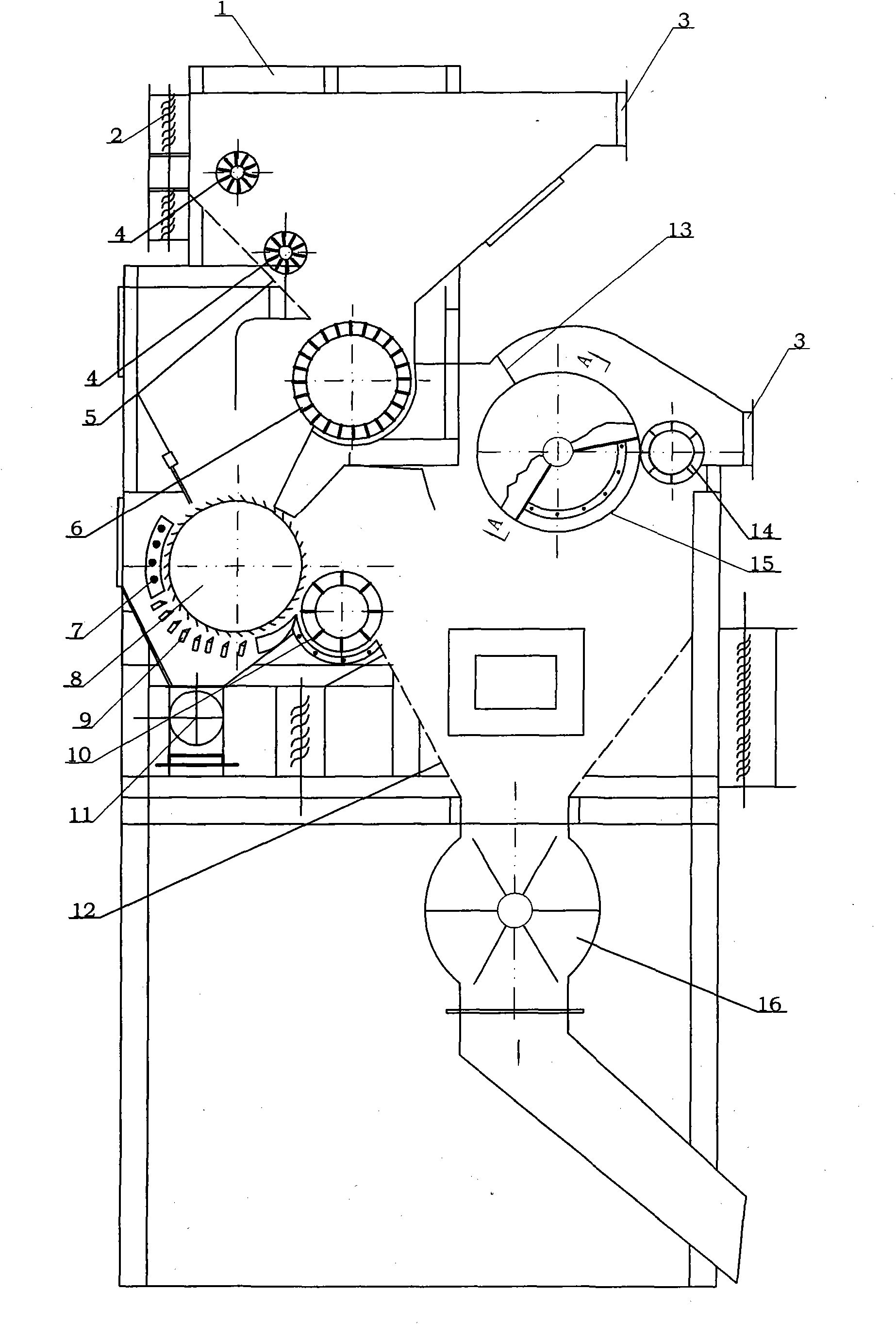

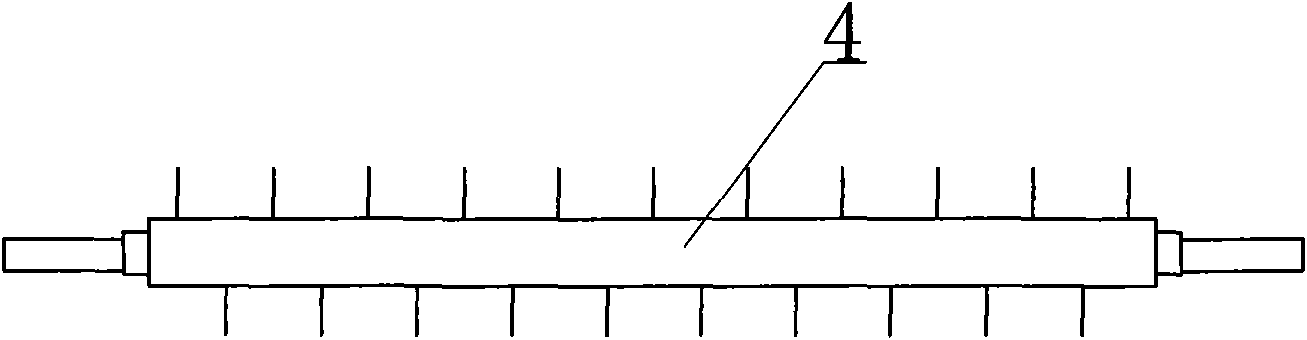

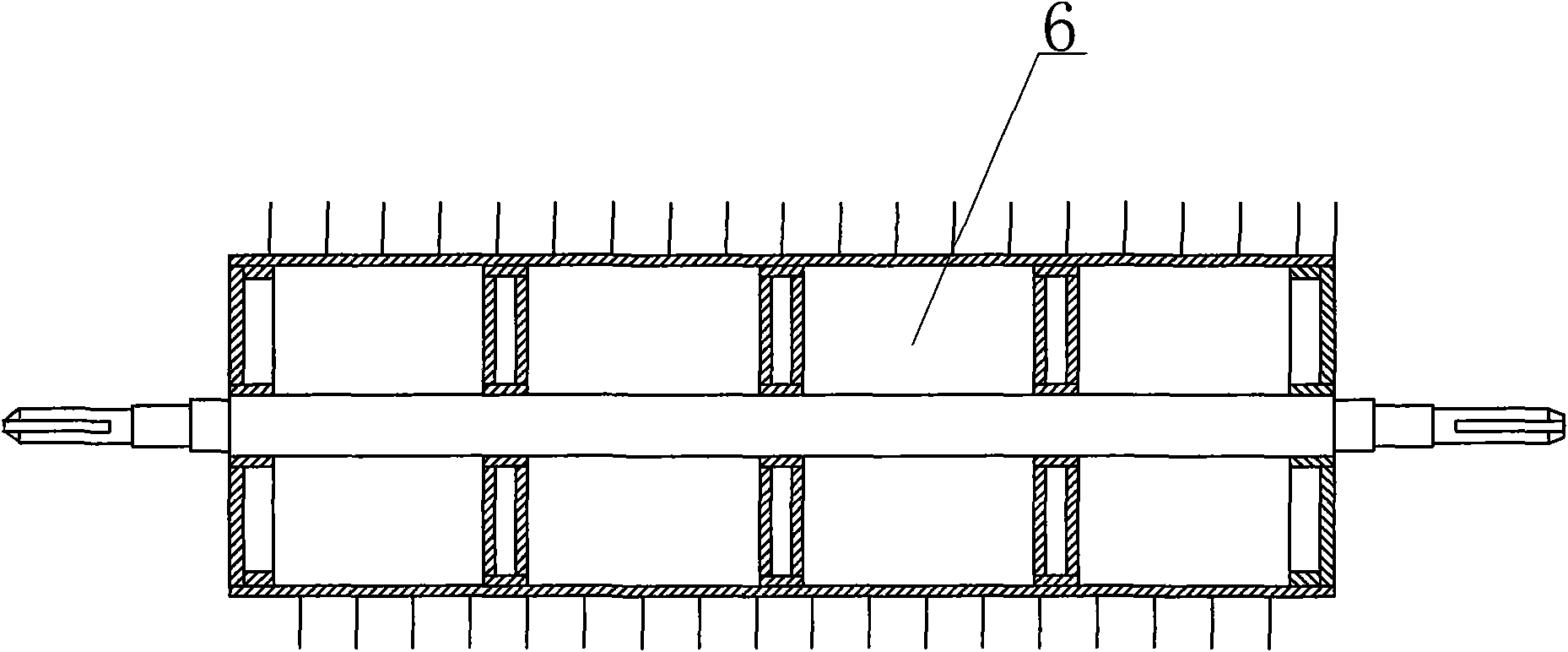

[0015] A split-type seed cotton foreign fiber capture and cleaning machine, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown embodiment 1 comprises the cabinet that has air inlet 2 and air outlet 3, and its top is provided with cotton inlet 1, and winding roller 4 is installed in the cabinet and blower fan is installed on the air outlet 3 of cabinet, has In the first-level cleaning room of the diffusion chamber, two winding rollers 4 are arranged sequentially along the inclined side wall formed by the air inlet mesh plate 5, and an air outlet 3 is arranged on the other side of the diffusion chamber, which is connected with the first-level cleaning room. The secondary cleaning chamber connected to the discharge port is equipped with a spike roller 6 with one side of the roller surface matching the wall of the secondary cleaning chamber. The diameter of the spike roller 6 is larger than that of the winding roller 4. The nail density evenly distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com