Cotton foreign fiber eliminating system

A foreign fiber and cotton technology, applied in the field of cotton foreign fiber removal system, can solve the problems of residual, re-detection of foreign fibers, poor removal of foreign fibers, etc., and achieve the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

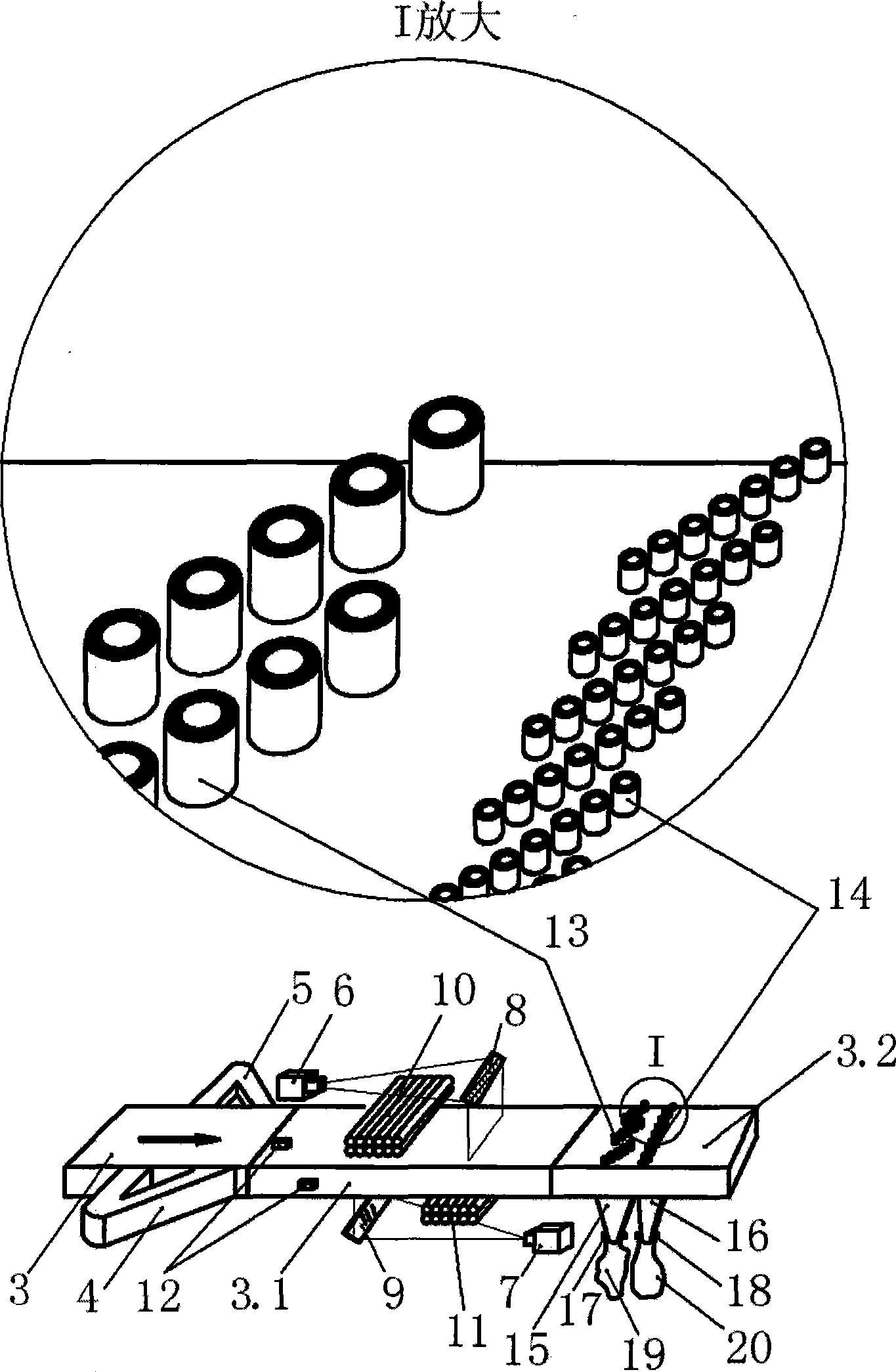

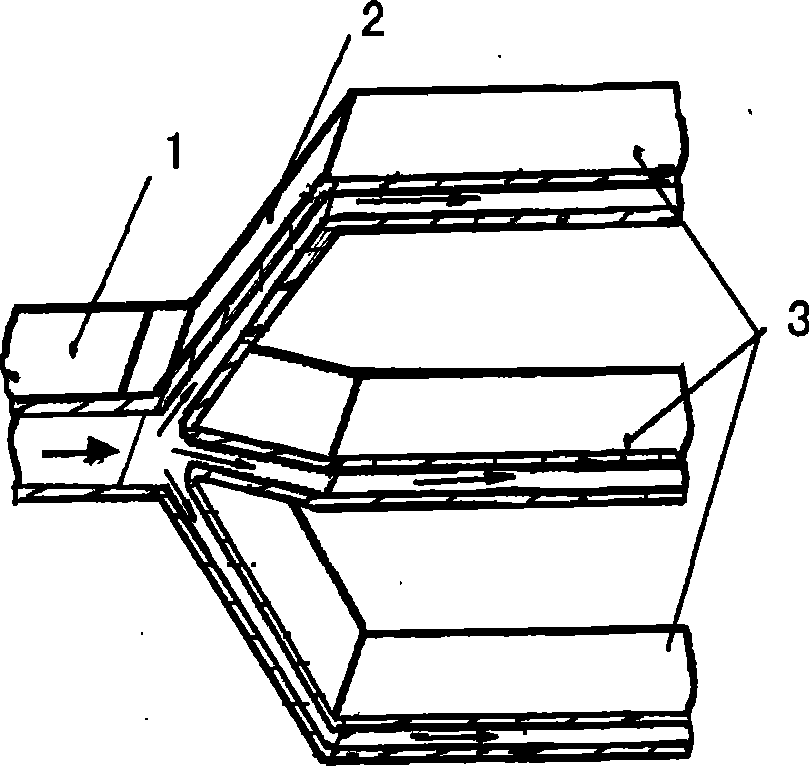

[0032] The invention provides a cotton foreign fiber removing system used in a production line. In the cotton foreign fiber removal system, the main cotton flow pipeline 1 is connected to the layering device 2, and each branch of the layering device 2 is connected to each layer of the cotton flow layering pipeline to form a cotton flow channel.

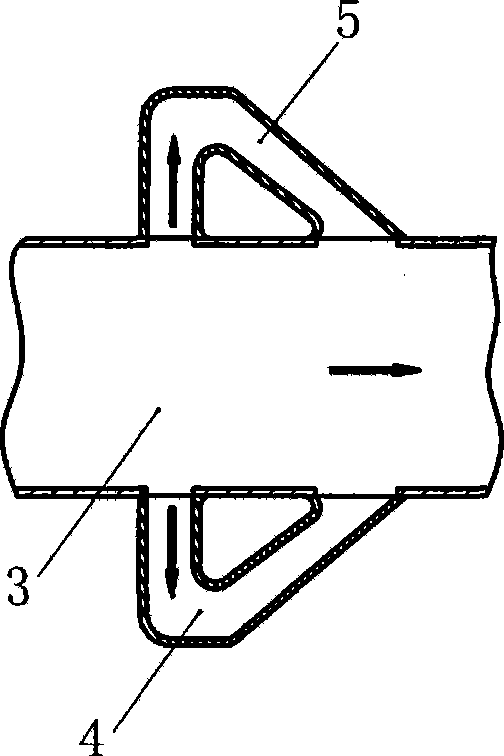

[0033] figure 1 Shown is the cotton flow layered pipeline of the cotton foreign fiber rejecting system, which is formed by sequentially connecting the layered pipeline 3, the first section of pipeline 3.1 and the second section of pipeline 3.2. Insert the first opening pipe 4 on one side of the layered pipe 3, and insert the second opening pipe 5 on the other side; place a high-speed CCD upper color camera 6, upper reflection on the top and outside of the first section pipe 3.1 Mirror 8 and upper light source 10, place high-speed CCD lower color camera 7, lower reflective mirror 9 and lower light source 11 on the outside below it. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com