Seed cotton isomerism defibrator

A foreign fiber and separator technology, applied in the field of machinery, can solve the problems of inability to guarantee the use requirements, poor picking effect, high labor intensity, etc., and achieve the effects of shortening downtime, high equipment operation rate, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

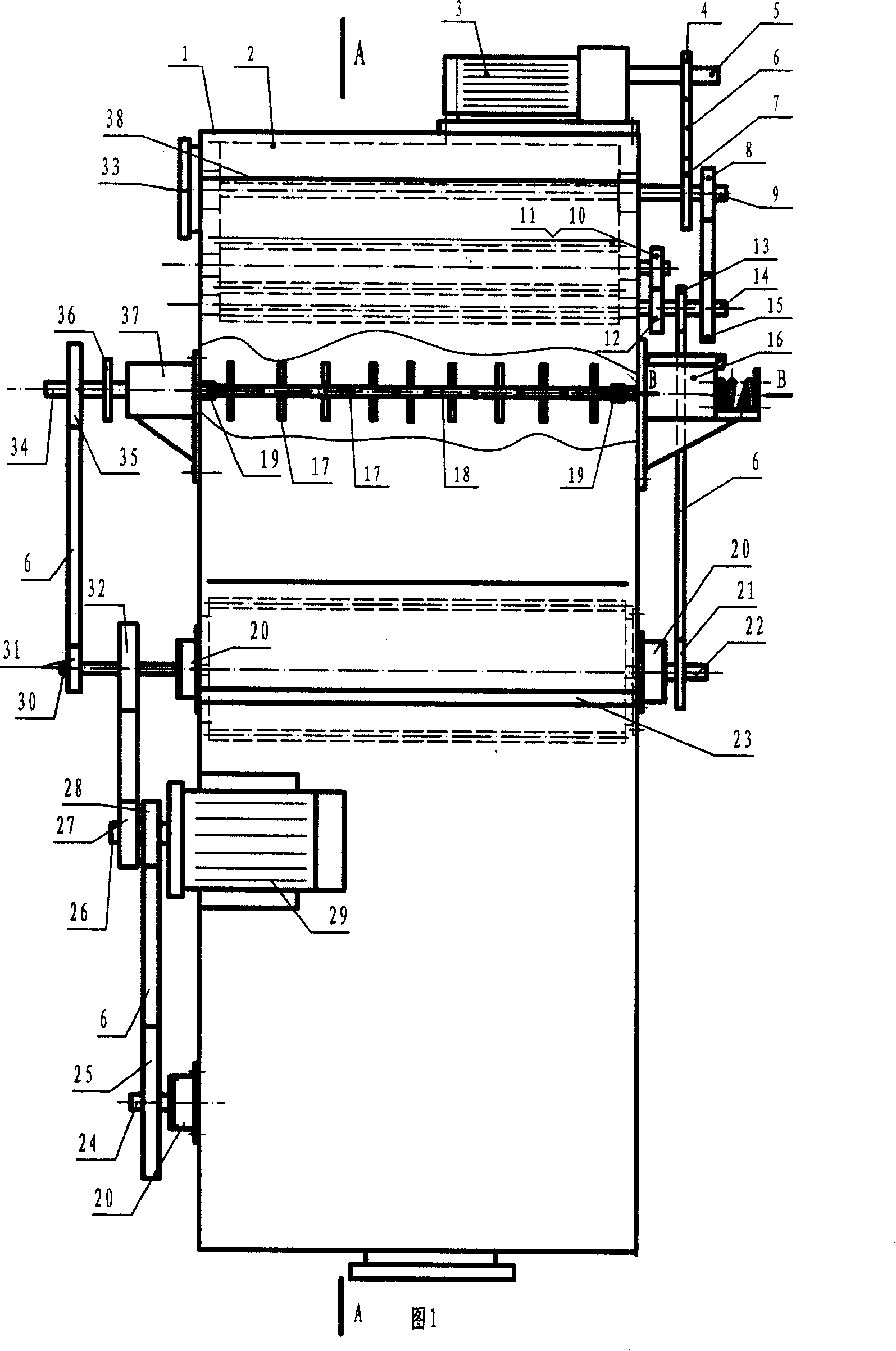

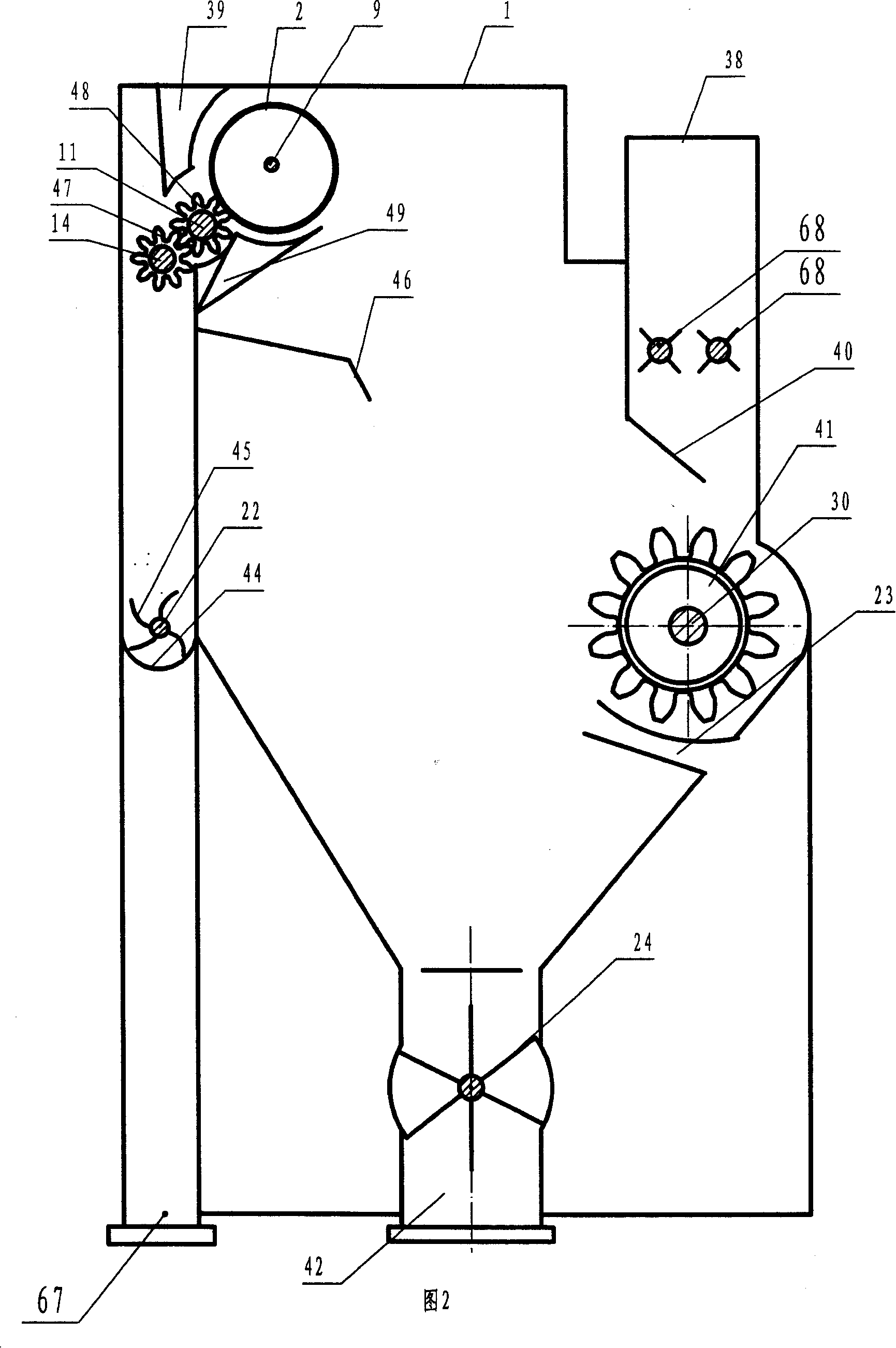

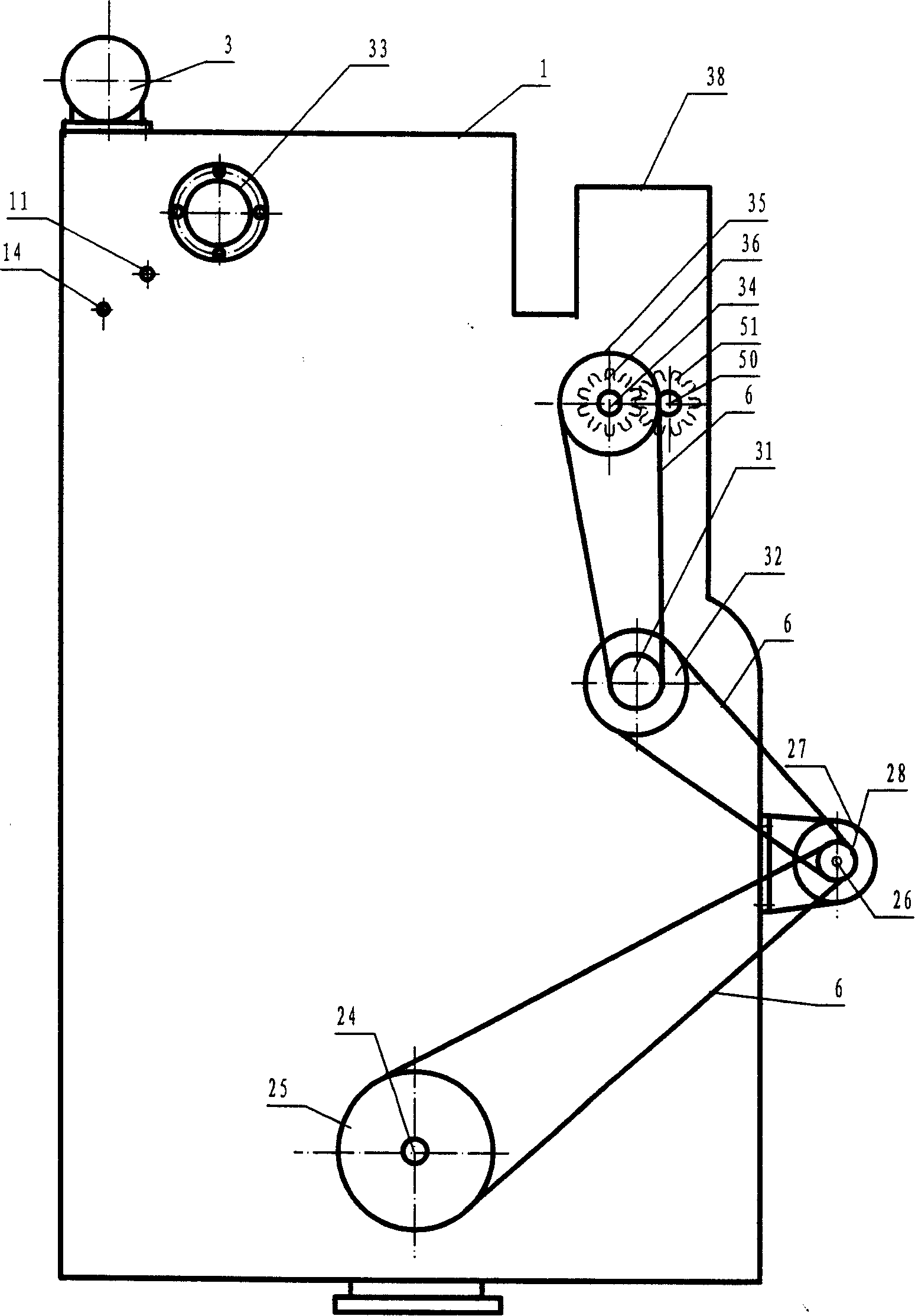

[0018] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0019] Figure 1- Figure 4 As shown, a seed cotton inlet 38 is provided on one side of the body 1, and two winding rollers 68 are arranged in the inner cavity below the inlet 38. The two ends of the winding roller shaft 18 on the winding roller 68 are equipped with spline sleeves 19, A number of winding teeth 17 are provided on the winding roller shaft 18, and each pair is arranged at 180° on the winding roller shaft 18. The winding teeth 17 and the adjacent pair of winding teeth 17 cross in a cross shape; as shown in Figure 5, One side of the body 1 is equipped with a fiber winding roller shaft seat 37, and a transmission shaft 34, a bearing 61, a bearing cover 62 and a connecting piece are arranged in the fiber winding roller shaft seat 37, and the end of the transmission shaft 34 stretches out of the seat body On, be equipped with the gear 36 that drives a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com