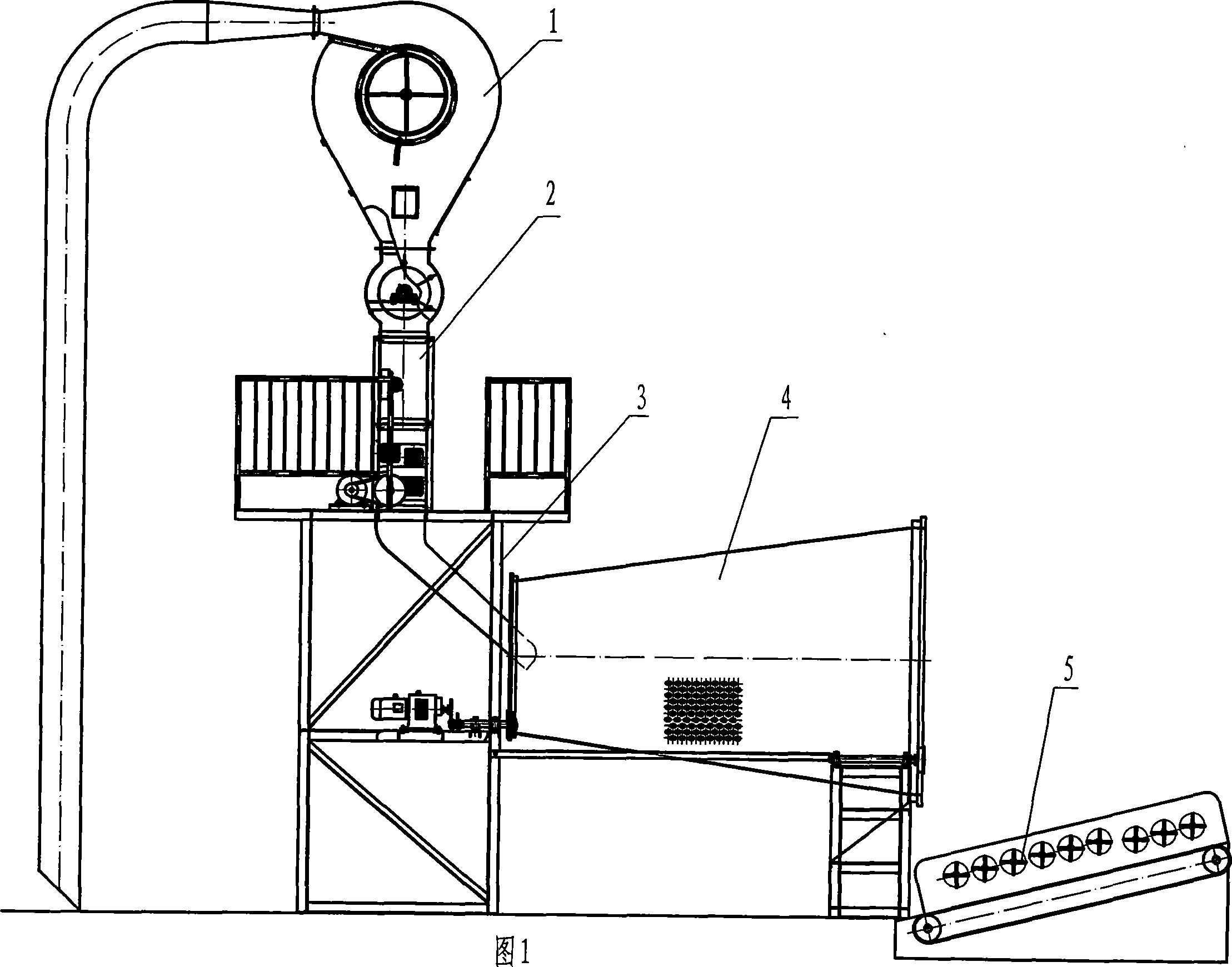

Seed cotton long-different fiber and deadlocked valvula cleaning machine

A technology of cleaning machine and foreign fibers, applied in the direction of fiber processing, fiber cleaning, mechanical treatment, etc., can solve the problems of high foreign fiber content and increase cost, and achieve the effect of reducing production cost, variety and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The rotary net type seed cotton cleaning machine (4) comprises motor (26), gear transmission mechanism (25), support friction wheel (24) and rotary net (22), and rotary net (22) is trumpet shape, and rotary net (22) The two ends are respectively provided with raceways (23), the raceways (23) cooperate with the supporting friction wheels (24), the rotating net (22) is supported on the supporting friction wheels (24), and the motor (26) passes through the gear transmission mechanism (25 ) drives the supporting friction wheel (24), and the supporting friction wheel (24) drives the rotating net (22) to rotate, and the even densely covered oval mesh on the rotating net has an aperture of 18 × 25 millimeters.

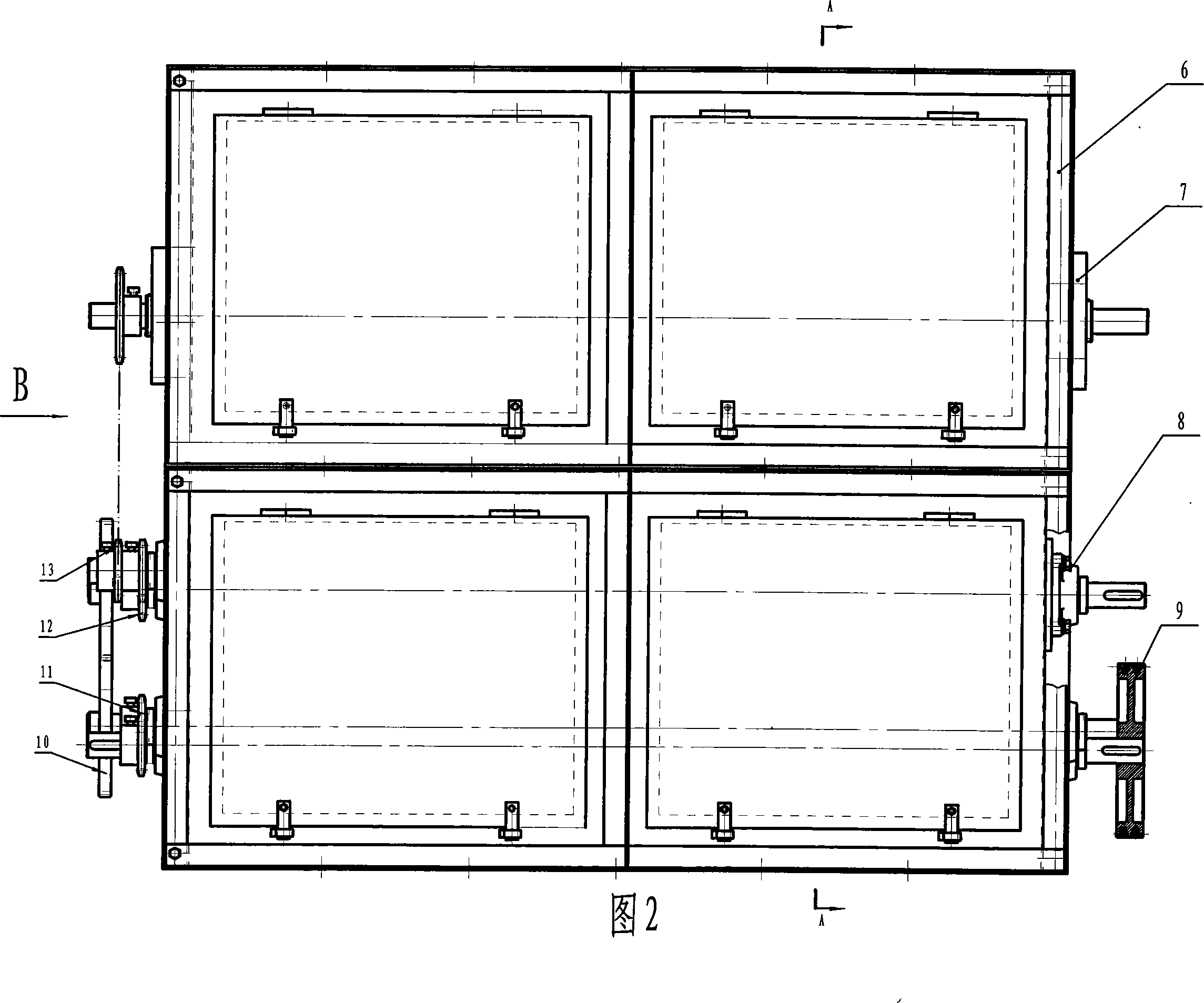

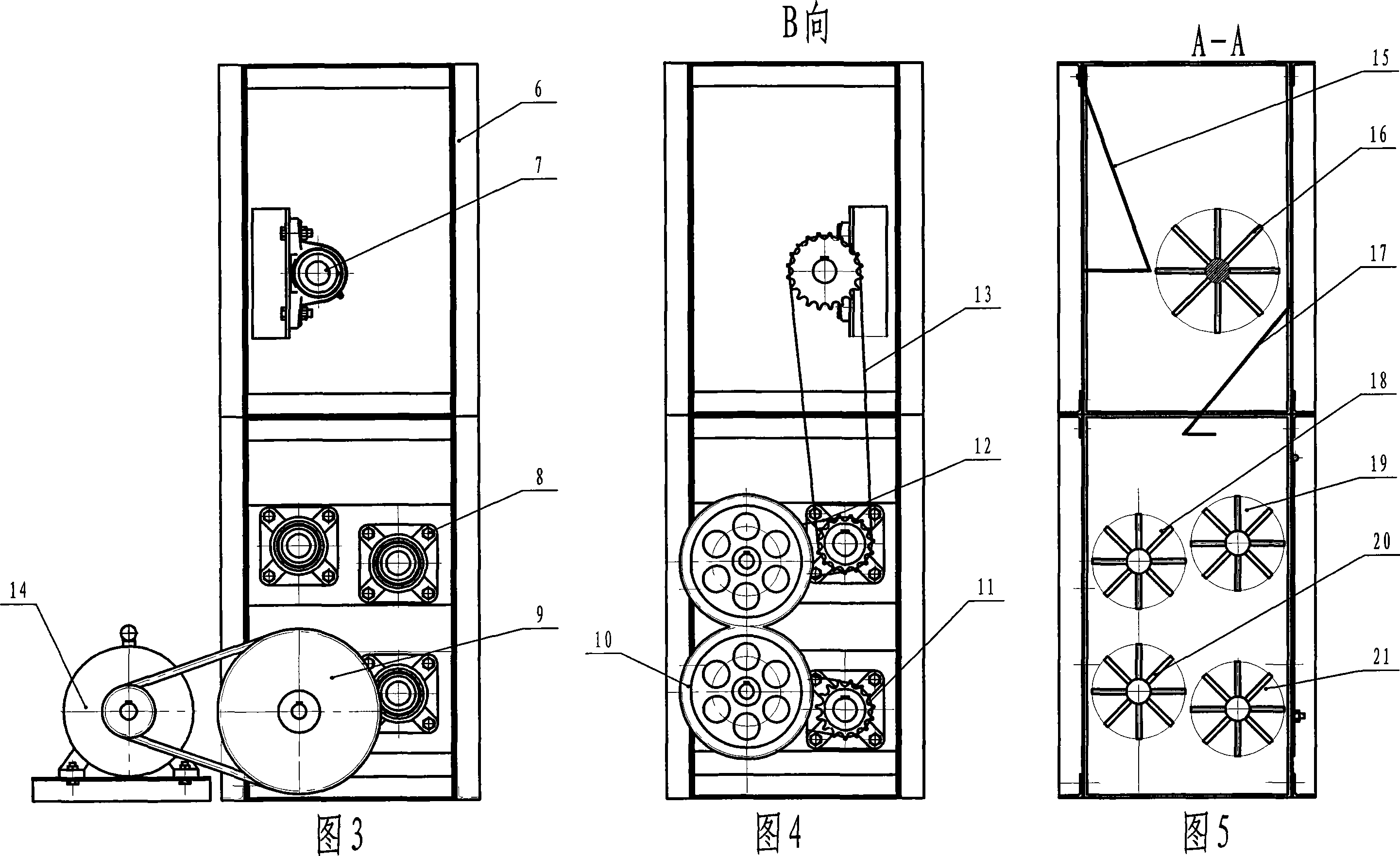

[0021] The vertical five-roller foreign fiber rod machine (2) is composed of a motor (14), a transmission mechanism, a box (6) and five recovery rollers, and an upper soft special recovery roller (16) is erected through a bearing seat (7) On the upper part of the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com