Method for separating feather fibers from poultry feather raw material

A feather fiber and feather technology, applied in the field of fiber preparation, can solve the problems of large fiber damage, insufficient use of raw materials, and affecting product quality, etc., and achieve the effect of simple steps, easy separation operation, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

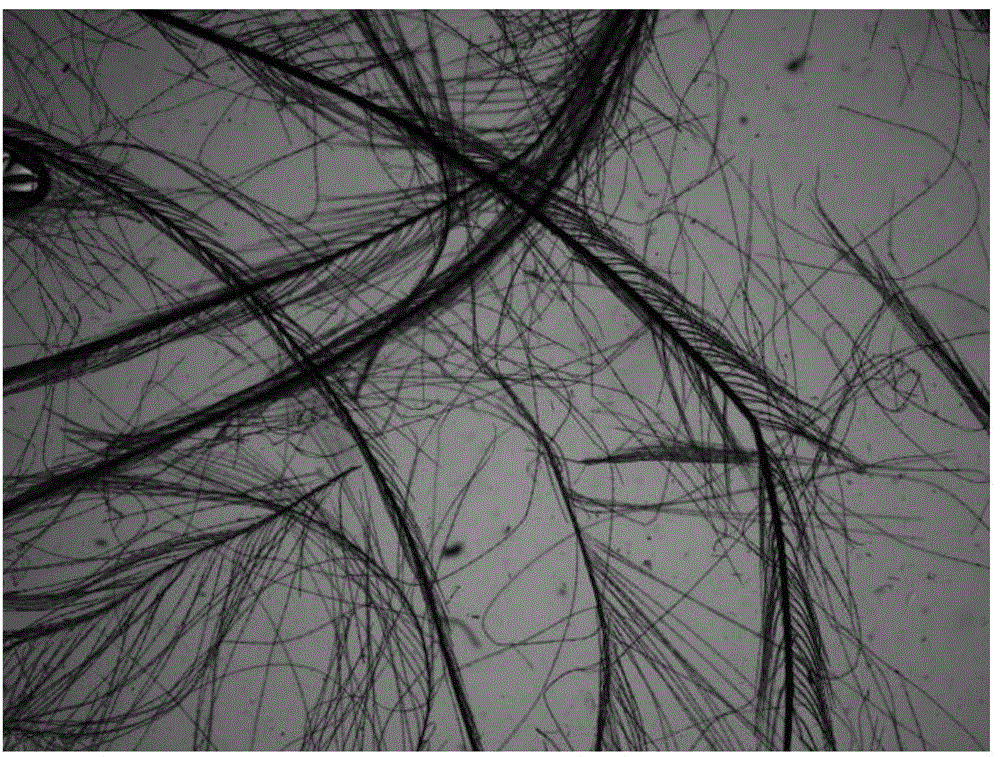

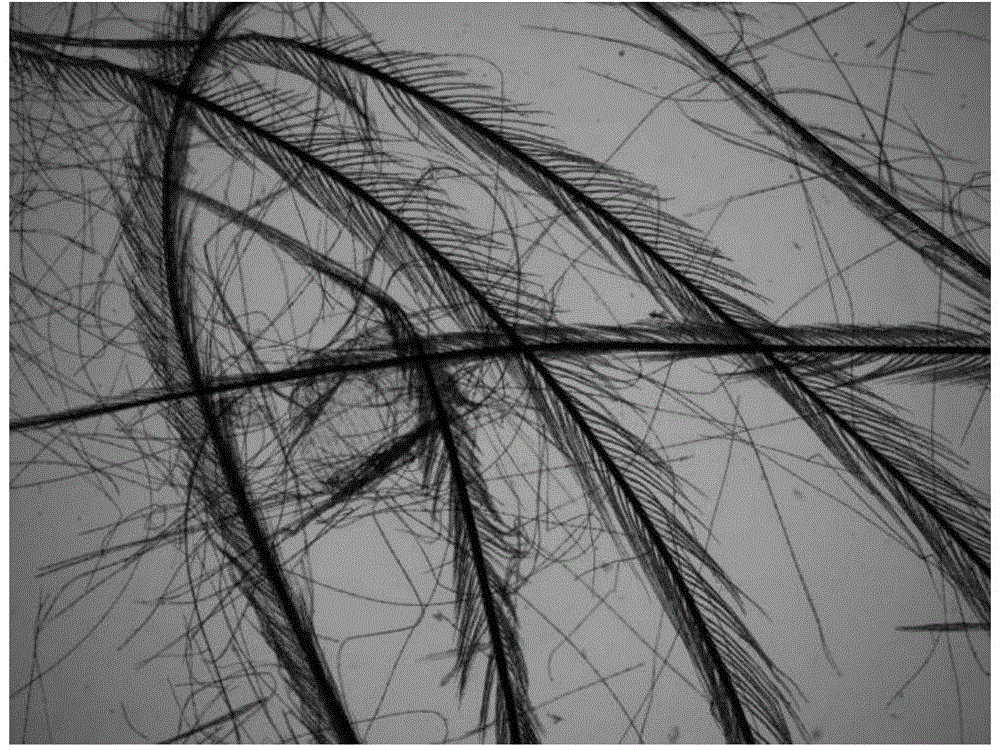

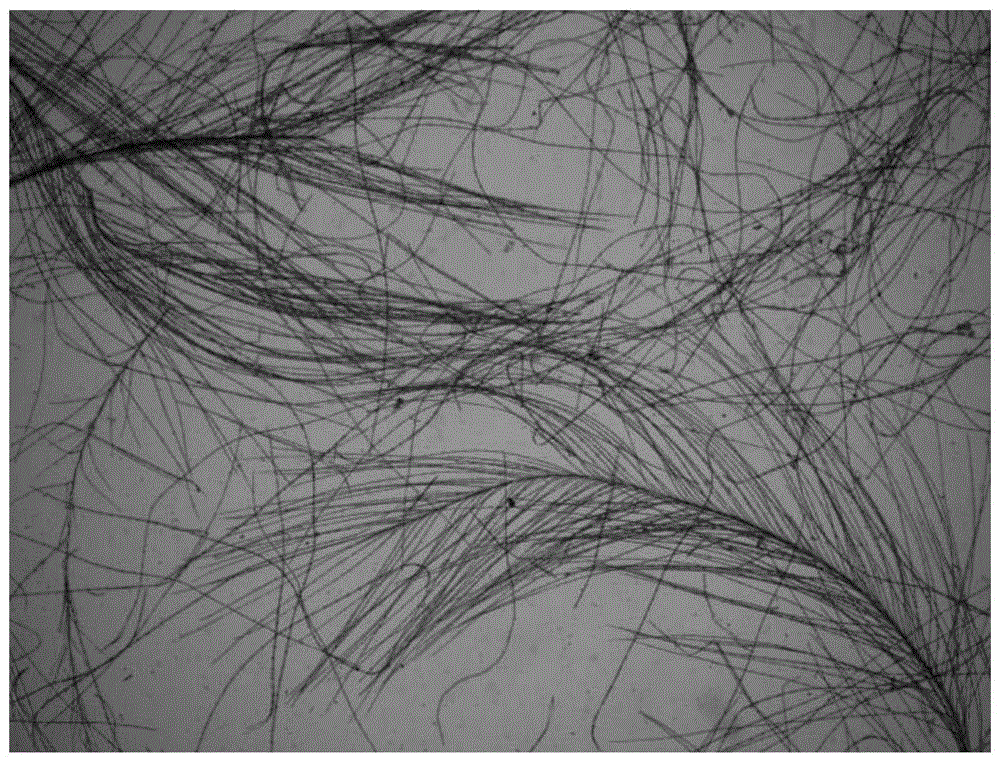

Image

Examples

Embodiment 1

[0026] (1) Clean the poultry feather raw material, and degrease and disinfect the feather during cleaning, and finally carry out gravity dehydration to the feather;

[0027] (2) Place the feathers treated in step (1) in water so that the mass ratio of feathers to water is 1:50, the water temperature is controlled at room temperature, and continuously stirred at a rate of 10,000 rpm for 20 minutes to obtain water and feather fibers mixture;

[0028] (3) The mass ratio of water and feather fiber is readjusted so that the mass percentage of feather fiber is 4%, and then the mixture of water and feather fiber is passed through a slotted sieve, and the sieve slot width is 0.35mm, and the rachis is divided by the sieve Based on the generally relatively coarse feather fiber fraction (ie, the feather fibers that do not pass through the sieve slots and remain on the sieve plate), a generally relatively fine feather fiber fraction 1 (ie, the feather fibers that pass through the sieve sl...

Embodiment 2

[0031] (1) Use a mesh sieve to screen out impurities such as sandstone, dust and dander entrained in the poultry feather raw material;

[0032] (2) further cleaning the poultry feather raw materials, and degreasing and disinfecting the feathers during the cleaning process, and finally pressing and dehydrating the feathers;

[0033] (3) Place the feathers treated in step (2) in water so that the mass ratio of feathers to water is 1:200, the water temperature is 90°C, and the water and feather fibers are obtained by stirring continuously at a rate of 25,000 rpm for 2 minutes. mixture;

[0034] (4) The mass ratio of water and feather fiber is readjusted so that the mass percentage of feather fiber is 0.5%, and then the mixture of water and feather fiber is passed through a slotted sieve, and the width is 0.20mm, 0.15mm and 0.10mm. sieve slots, and generally relatively thick feather fiber components (feather fibers that did not pass through the 0.20mm sieve slot) mainly composed ...

Embodiment 3

[0037](1) Use a mesh sieve to screen out impurities such as sandstone, dust and dander entrained in the poultry feather raw material;

[0038] (2) further cleaning the raw material of poultry feathers, and degreasing and disinfecting the feathers during the cleaning process, and finally carrying out centrifugal dehydration to the feathers; repeating this step once to make the purification effect more sufficient;

[0039] (3) Place the washed and dehydrated feathers in water, the mass ratio of feathers to water is 1:10, the water temperature is 60°C, and the mixture is continuously stirred at a rate of 1000 rpm for 120 minutes to obtain a mixture of water and feather fibers;

[0040] (4) the mass ratio of water and feather fiber is readjusted, and the mass percentage of feather fiber is 2.5%, and the slotted sieve that the mixture of water and feather fiber is passed through the sieve width of 0.25mm afterwards is screened out by rachis The generally relatively coarse feather f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com