A combined double-layer rolling separator

A combination and separator technology, applied in solid separation, filter screen, grille, etc., can solve problems such as pollution, waste, and environmental impact, and achieve huge economic benefits, easy transportation and maintenance, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

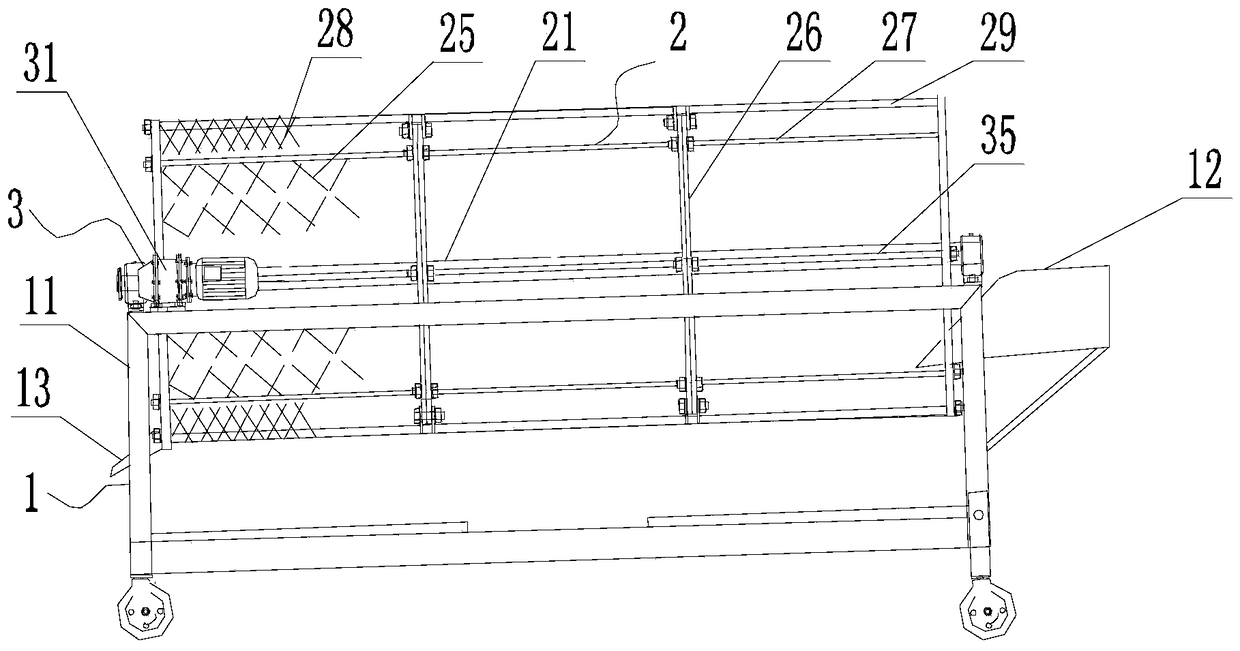

[0032] The invention provides a combined double-layer rolling separator, such as Figure 1 to Figure 4 As shown, it includes a frame assembly 1, a separation assembly 2 for separating seed hulls, and a transmission assembly 3 for driving the separation assembly 2. The frame assembly 1 includes a frame 11, a feed hopper 12, a peel hopper 13 and a grain receiving material Device 14; Transmission assembly 3 comprises the speed reducer 31 that is fixed on the frame 11, the driving wheel 32 that is fixed on the speed reducer 31, the driven wheel 33, the transmission chain 34 that connects driving wheel 32 and driven wheel 33, and is installed in The transmission shaft 35 on the driven wheel 33 is covered with an inner screen sleeve shaft 21 with a number of inner screen rods 22. The separation assembly 2 includes an inner screen end plate 23, an outer screen connecting end plate 24, an inner screen The net 25, the inner screen ring 26, the ring are set on the inner screen end plate...

Embodiment 2

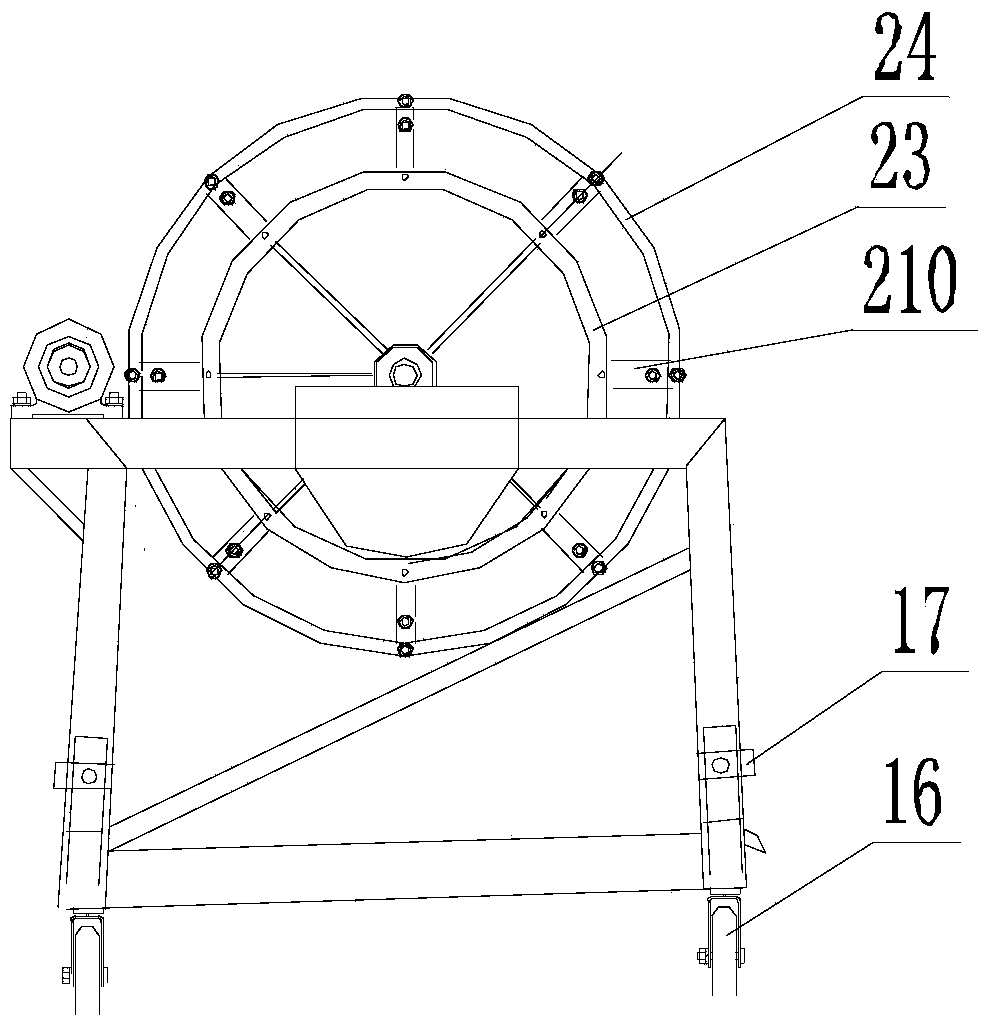

[0039] The present invention provides a combined double-layer rolling separator, the difference between the combined double-layer rolling separator and embodiment 1 is, as Figure 5 and Figure 6 As shown, the three parts of the monomer also include an inner screen spacer 211 with several reinforcing rods 212, the reinforcing rods 212 are fixed on the inner screen sleeve shaft 21, and the inner screen spacer 211 is connected to the inner screen frame rod 27. The three parts of the monomers are connected through the inner screen tie rods 213 mounted on the reinforcing rods 212 .

Embodiment 3

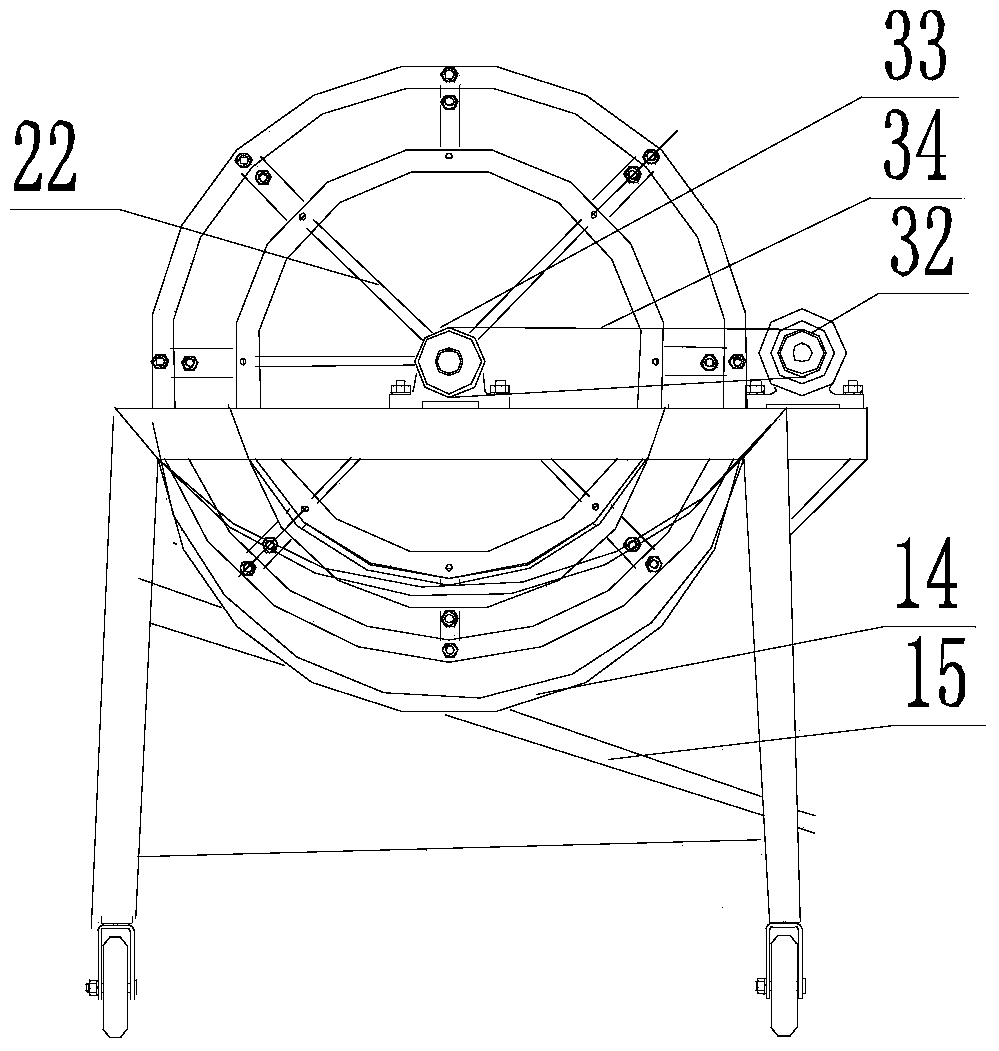

[0041] The present invention provides a combined double-layer rolling separator, which is different from Embodiment 2 in that, as Figure 7 As shown, the inner sieve end plate 23 and the outer sieve connecting end plate 24 are ring-shaped and located on the same plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com