A high-efficiency cyclone oil-water separation device

An oil-water separation device and water technology, which are used in centrifugal separation of water/sewage treatment, mining fluids, mining wastewater treatment, etc. performance, cost reduction, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

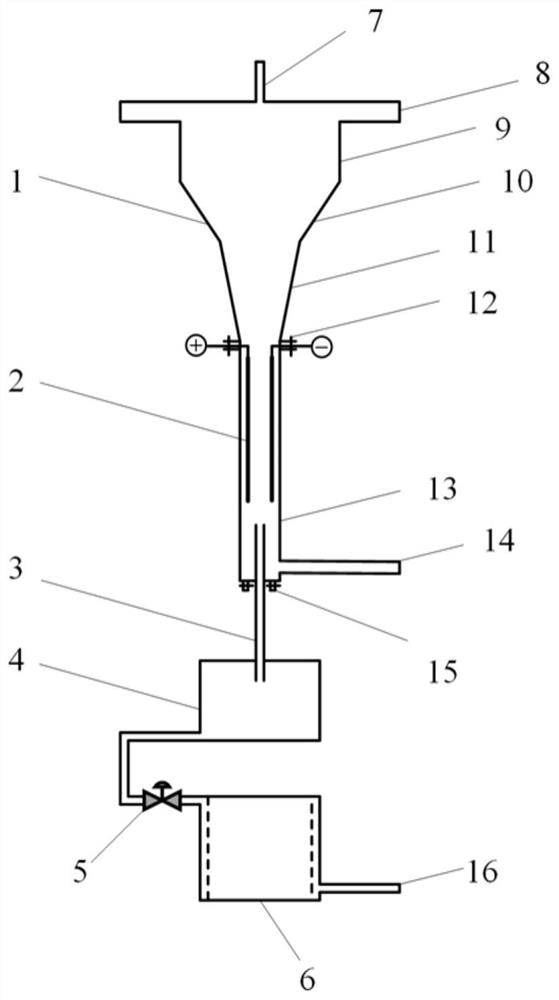

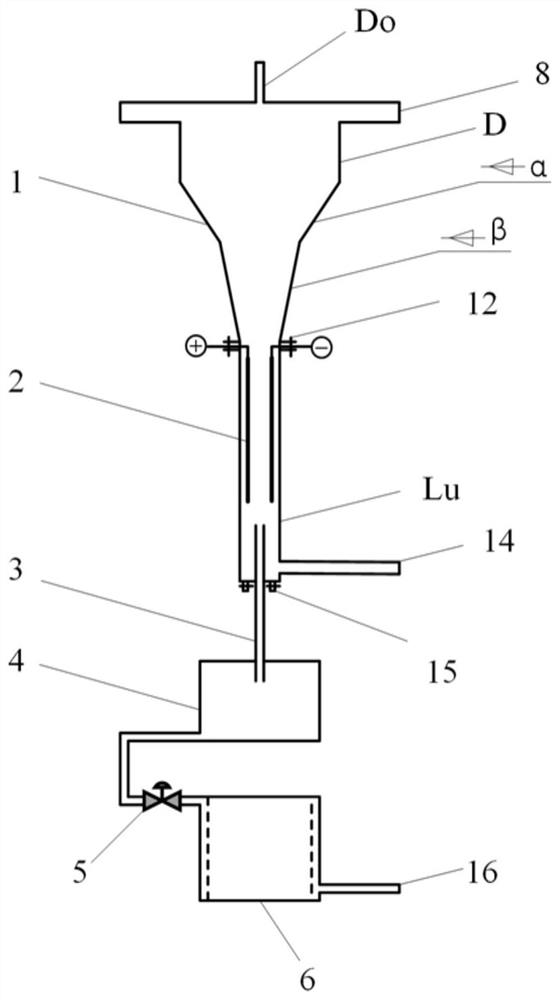

[0033] Using metals such as iron or aluminum as the anode, under the action of direct current, the anode is eroded to produce ions such as Al and Fe. After a series of hydrolysis, polymerization and oxidation of ferrous iron, the colloidal impurities and suspended impurities in the water Condensation and precipitation are discharged through the sewage outlet 15; in addition, the oxygen and hydrogen bubbles generated by the electrolysis of water collide with and adhere to the oil droplets that rotate with the fluid in the cyclone during the floating process, forming oil droplets and air bubbles The polymer is discharged from the overflow port 7; the treated water is discharged through the No. 1 water outlet 14.

[0034] The guide tube 3 is connected to the bottom of the tail pipe section 12, and the outside is connected to the water collection chamber 4. The depth of the guide tube 3 inserted is 1 / 4 of the length of the tail pipe section 12. High aqueous drainage for further pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com