Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

A fiber finishing, textile fiber technology, used in fiber processing, fiber separation, textiles and papermaking, etc., can solve the structural and spatial constraints of the degree of retraction, the irregular deposition of carding strips, the impossibility of obtaining high operating speeds, etc. problems, to achieve the effect of reduced machine vibration, increased productivity, and high operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

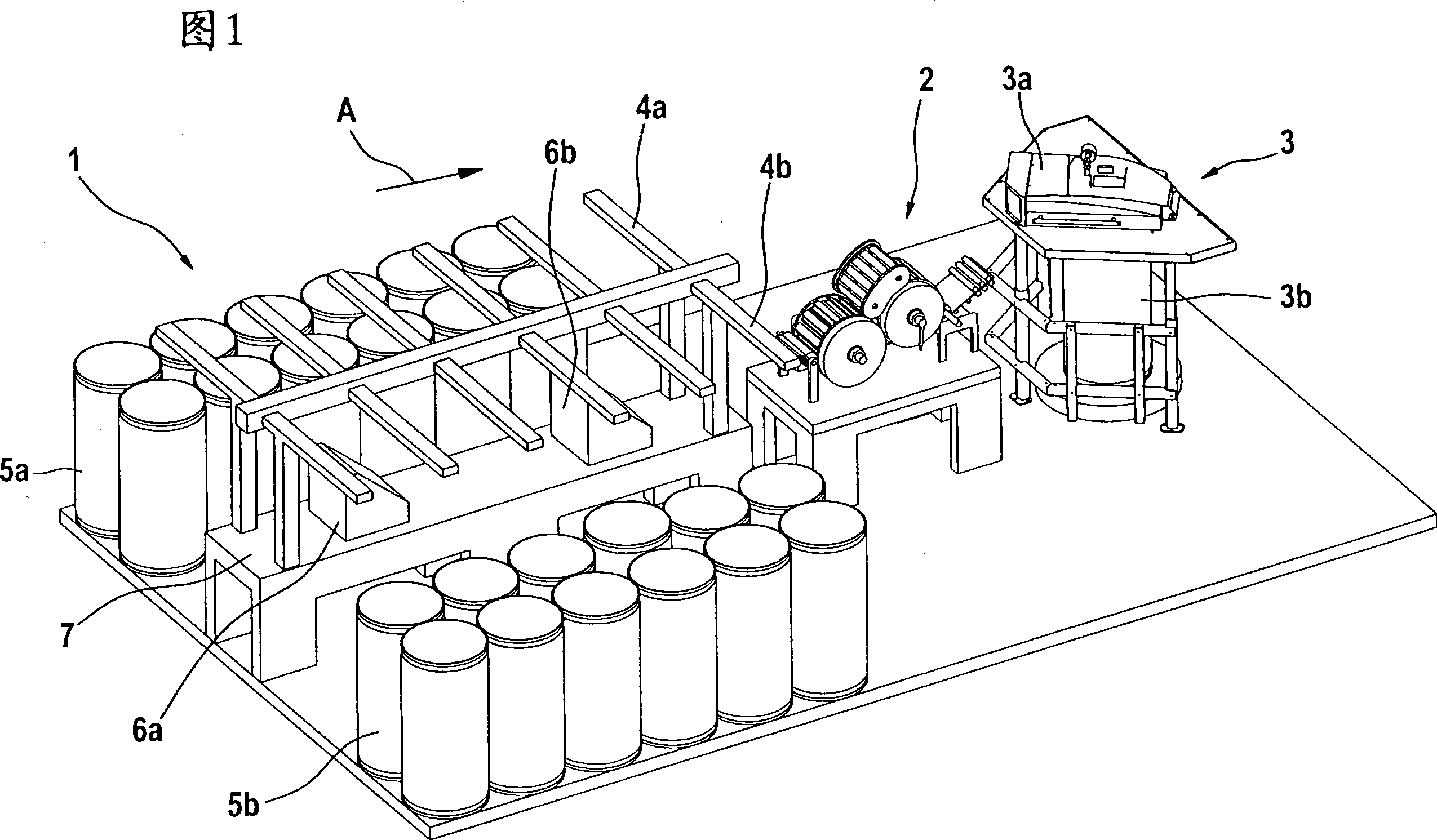

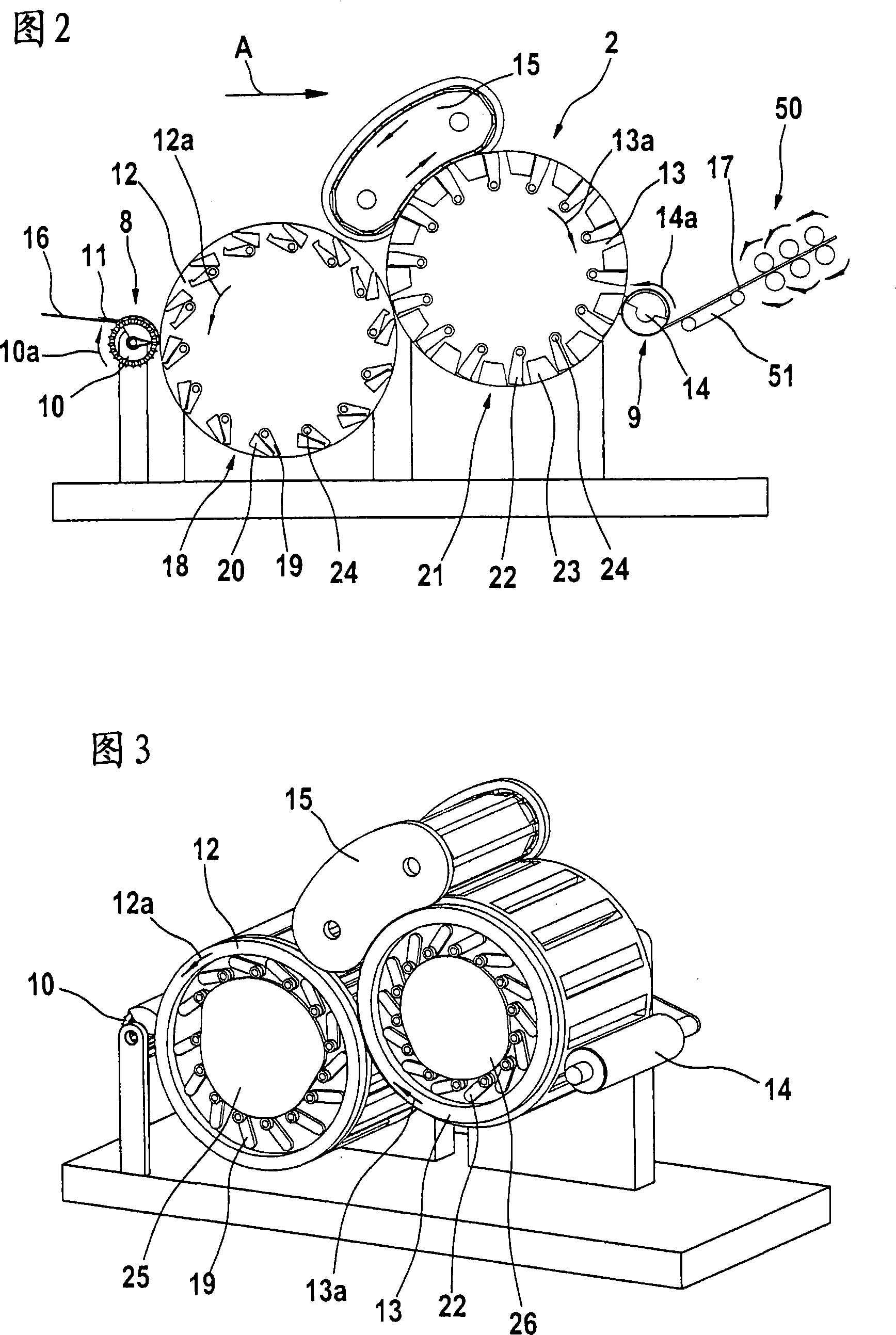

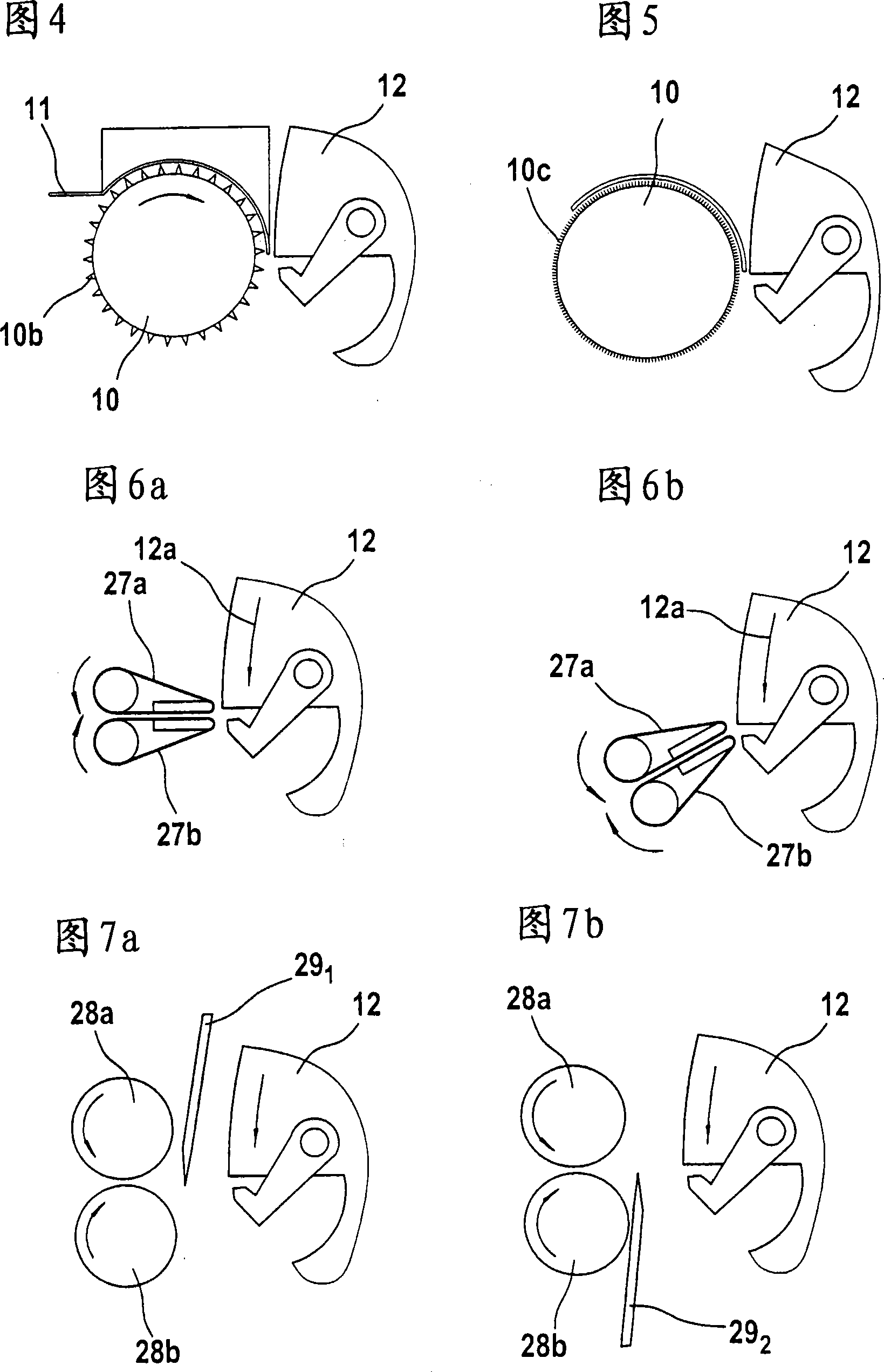

[0031]According to FIG. 1 , the card preparation machine 1 has a spinning chamber machine that is supplied with sliver and transports the reel and two supply tables 4 a, 4 b (can creels) arranged parallel to each other, below which each supply table 4 a, 4 b is arranged fiber-containing Two rows of cans 5a, 5b for bars (not shown). The fiber slivers drawn off from the cans 5 a, 5 b enter two drafting systems 6 a, 6 b arranged next to each other of the card preparation machine 1 after being redirected. From the drafting system 6a, the already formed sliver webs are guided on the wire table 7 and stacked on top of each other at the outlet of the drafting system 6b with the sliver web being produced therein. Via the drafting systems 6a, 6b, in each case a plurality of fiber strands are combined to form a roll and these fiber strands are drawn together. Multiple drafting rolls (two rolls in the example shown) are formed by placing one on top of the other to form a double roll. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com