Determination method for content of arsenic, tin and zinc in steel

A method of determination, technology of zinc content, applied in the direction of measuring device, preparation of test samples, material analysis by electromagnetic means, etc., can solve the problems that the three elements cannot be measured at the same time, the environment and human body are harmful, and there are many chemical reagents, etc. Achieve the effect of simple and quick analysis method, fast analysis speed and less reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

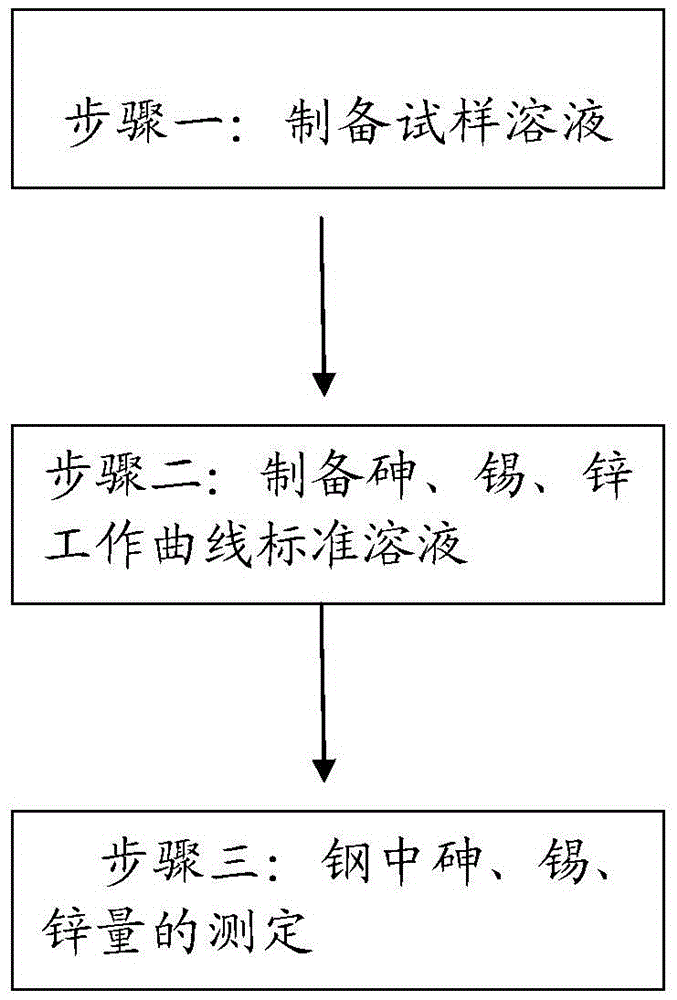

[0020] The method steps of this specific embodiment are as figure 1 as shown,

[0021] A kind of assay method of arsenic, tin, zinc content in steel, method comprises the following steps:

[0022] Step 1: Prepare sample solution

[0023] Weigh 0.1000g of sample into a polytetrafluoroethylene beaker, add 10mL of 1+1 nitric acid, 2mL of hydrofluoric acid, heat to dissolve at low temperature, remove and cool slightly, transfer to a 100mL plastic volumetric flask, and dilute to the mark with pure water; 1+1 nitric acid is made by mixing nitric acid and pure water at a volume ratio of 1:1.

[0024] Step 2: Prepare arsenic, tin, zinc working curve standard solution

[0025] Weigh six 0.1g high-purity iron samples into six polytetrafluoroethylene beakers, add 10mL of 1+1 nitric acid and 2mL of hydrofluoric acid, heat to dissolve at low temperature, remove and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com