Steel product acid dipping test erosion integration device

An integrated device and acid leaching technology, which is used in the field of corrosion devices for steel or billet acid leaching tests, can solve problems such as reducing acid concentration, electrical interface corrosion, and indurability, ensuring environmental quality, stable equipment operation, and heating speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

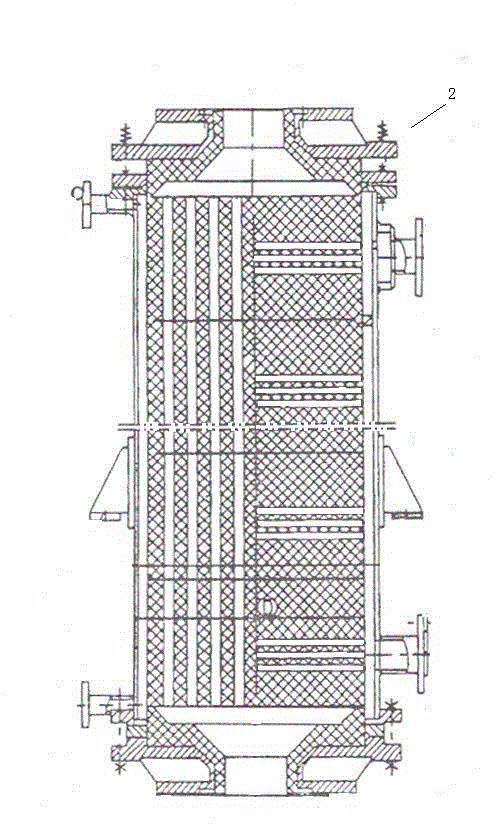

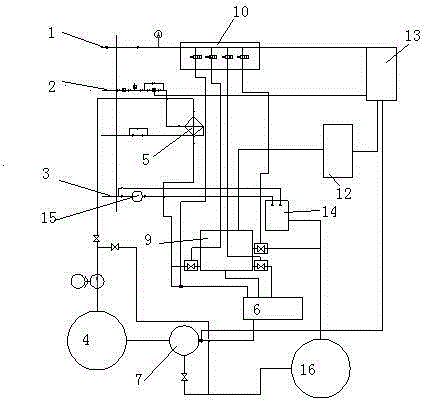

[0022] Such as figure 1 Shown: an integrated device for steel acid leaching test corrosion, which includes compressed air source 1, steam source 2, and tap water source 3, the integrated device includes:

[0023] Acid liquid preheating circulation system and acid leaching test circulation system, the acid liquid preheating circulation system includes acid liquid preheating tank 4 and graphite heat exchanger 5 connected in sequence, graphite heat exchanger 5 passes through acid buffer tank 6 and back to The acid intermediate tank 7 returns to the acid liquid preheating tank 4;

[0024] In addition to the shared devices of the acid preheating system, the acid leaching test circulation system also sets a pickling tank 9 between the graphite heat exchanger 5 and the acid buffer pool 6; the compressed air source 1 Control the acid liquid inlet and the pneumatic valve at the outlet of the pickling tank 9 through a pneumatic control box 10; the pickling tank has an exhaust fan;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com