Patents

Literature

54results about How to "Warranty Repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

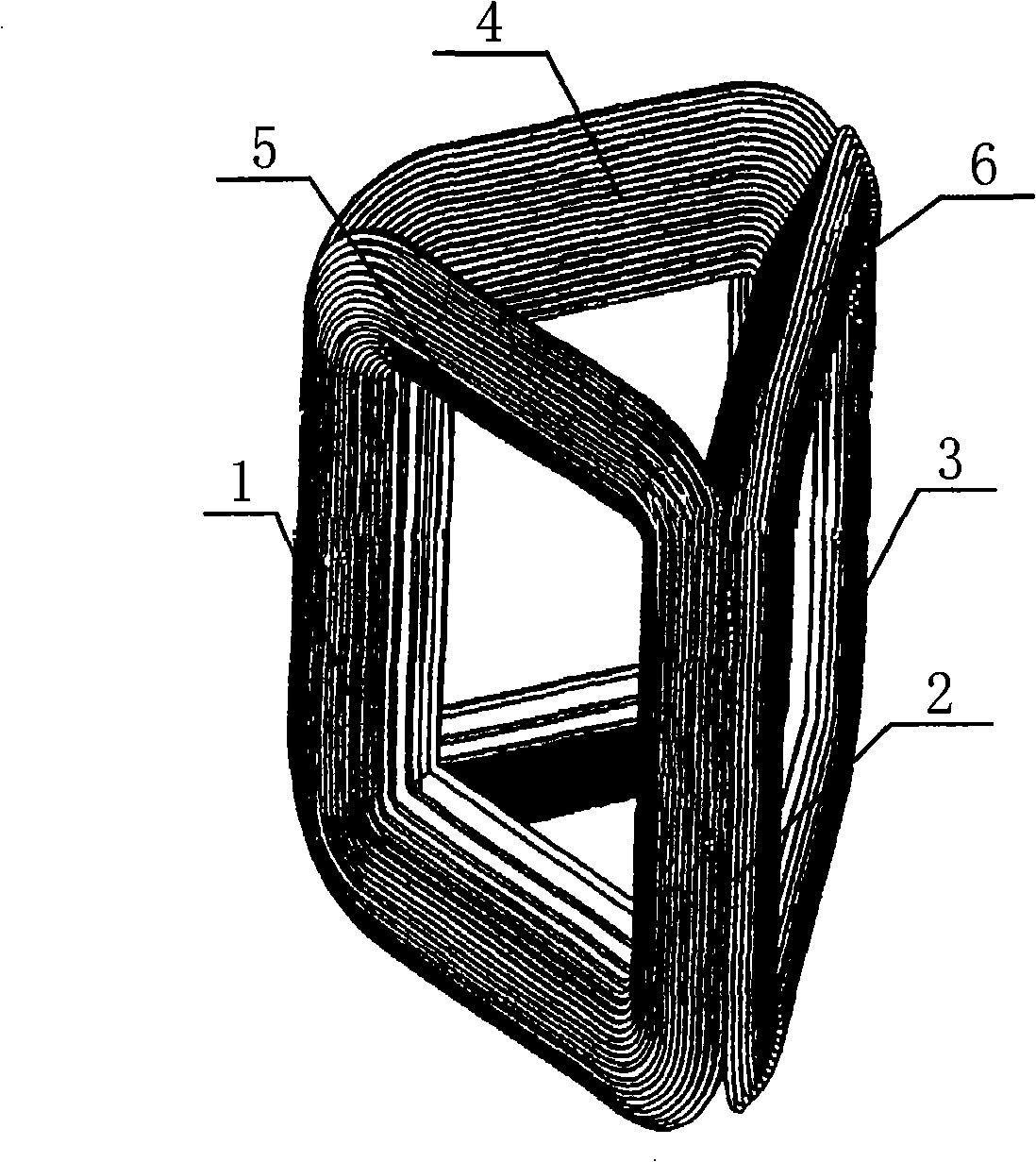

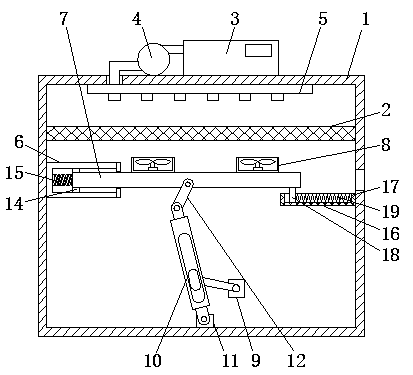

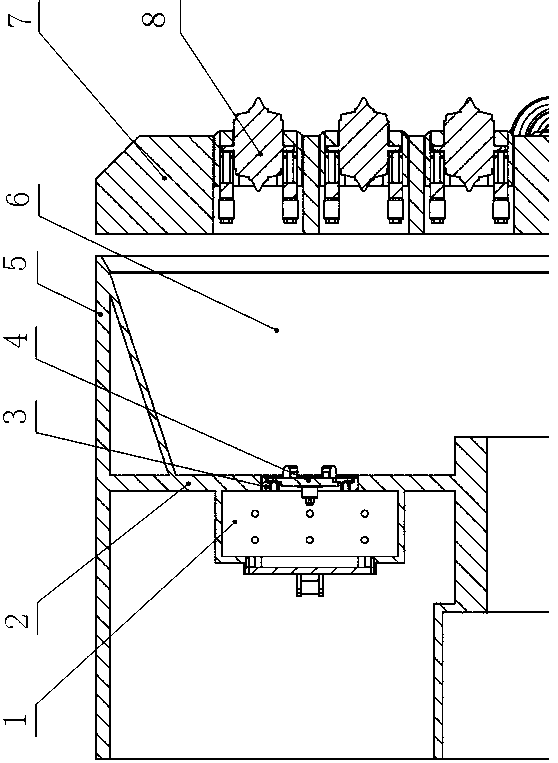

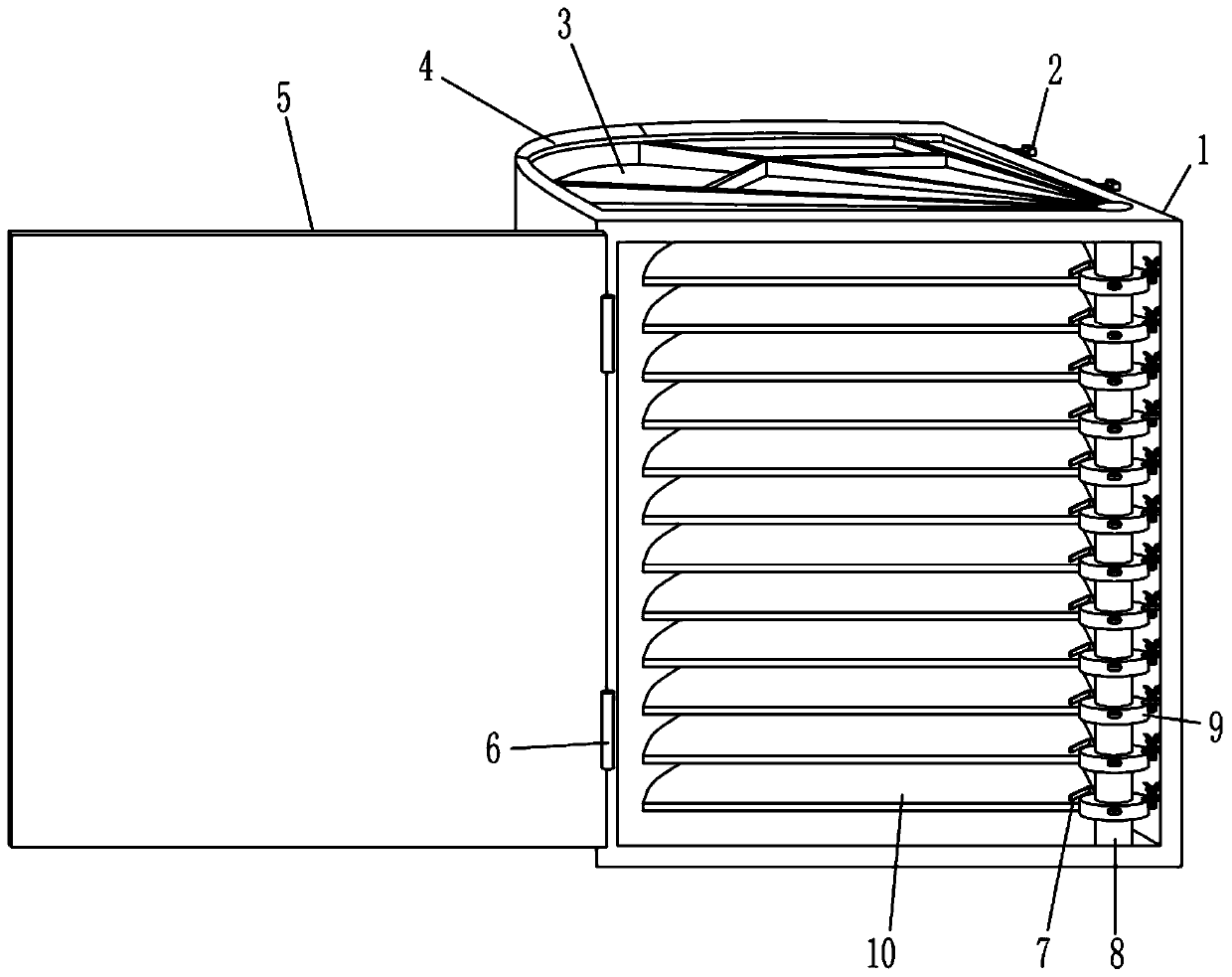

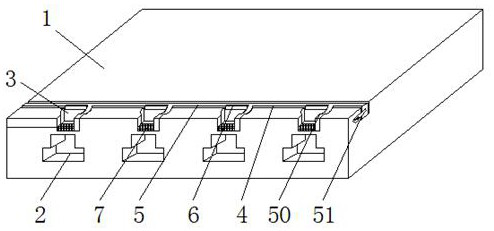

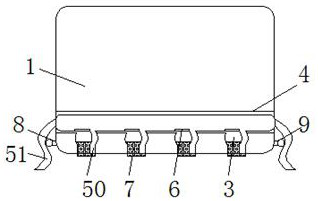

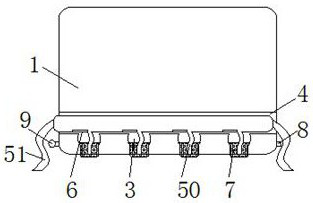

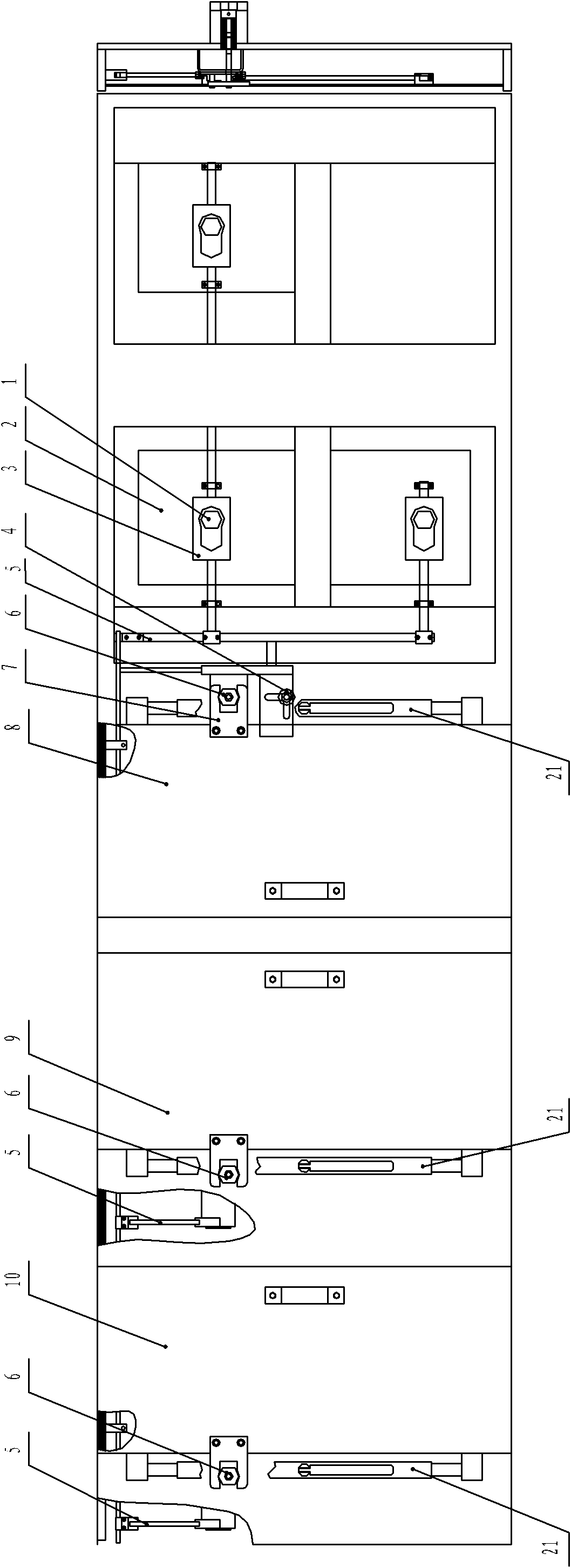

On-track maintenance supporting device for gear and rack lifting equipment

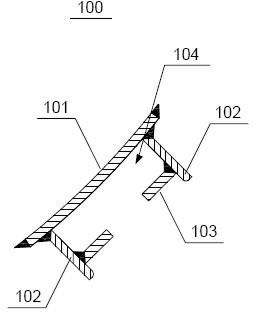

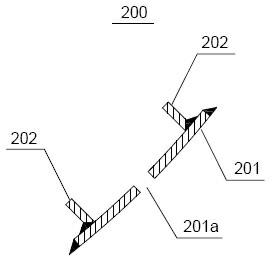

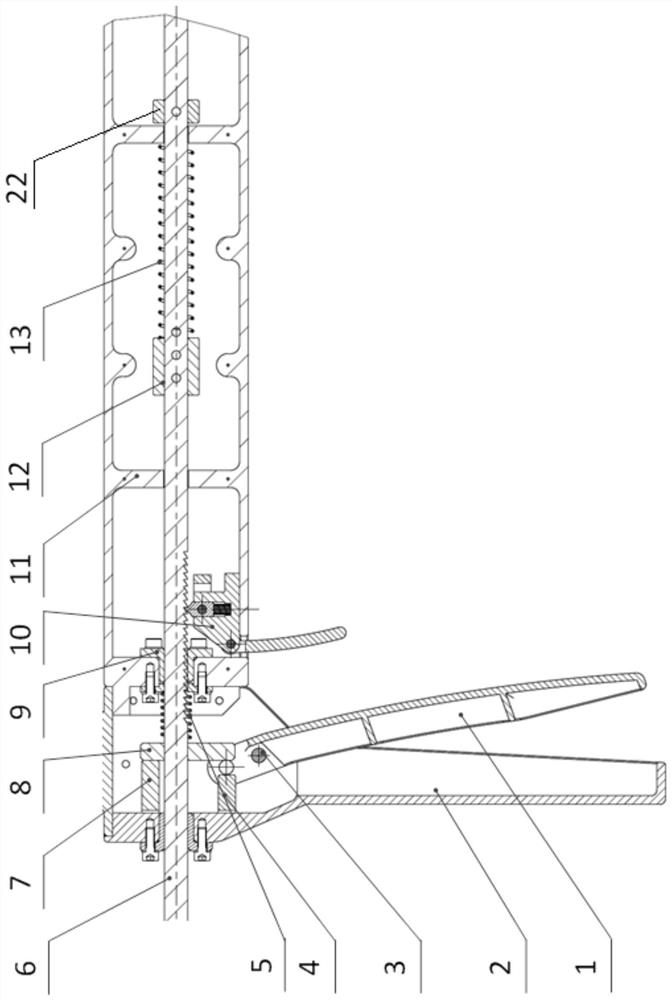

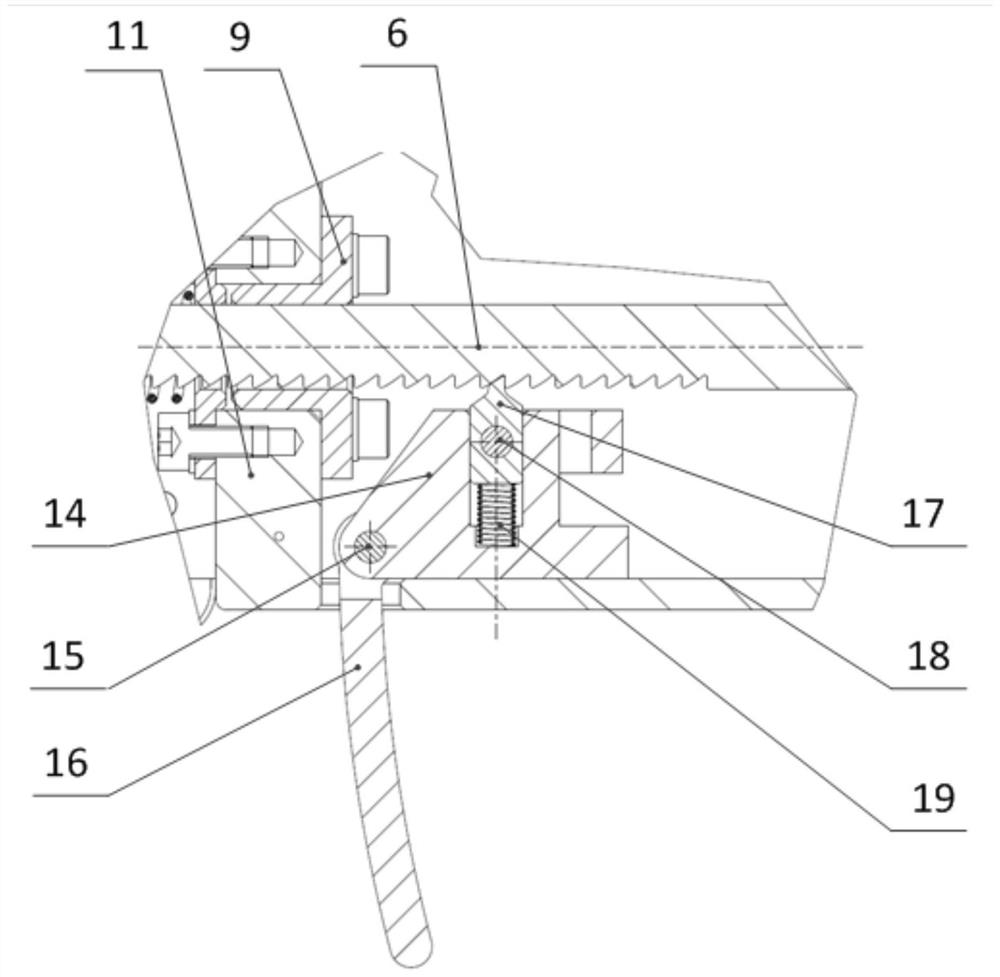

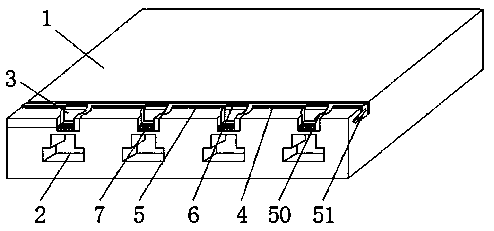

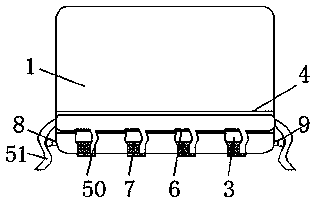

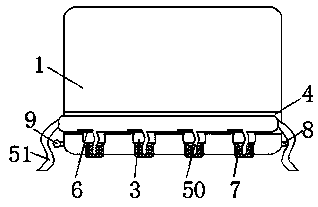

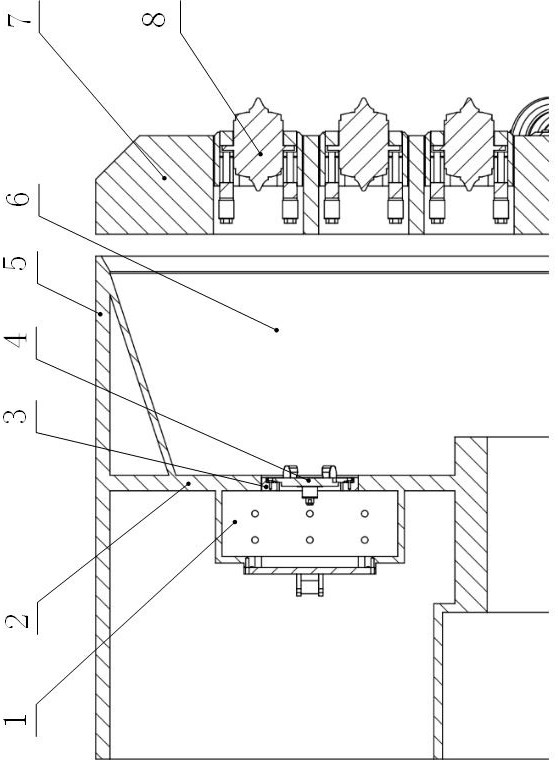

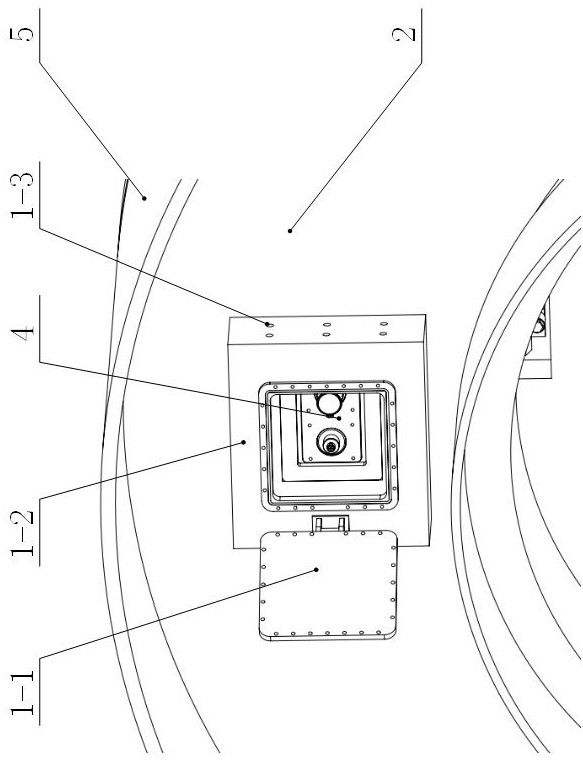

The invention discloses an on-track maintenance supporting device for gear and rack lifting equipment. The on-track maintenance supporting device is characterized by comprising at least one independent safety braking device and at least one maintenance worktable; the at least one independent safety braking device independently realizes reliable braking fixation for the lifting equipment without dependence on a driving system of the lifting equipment and comprises a horizontal electromagnetic drive independent safety braking device; when the at least one maintenance worktable is unfolded to be in a first working state, a worker can stand in a lifting equipment car for checking or maintaining equipment closer to the outer part of the lifting equipment car through a window; when the at least one maintenance worktable is unfolded to be in a second working state, the worker can stand on a working platform for checking or maintaining equipment further from the outer part of the lifting equipment car; and the on-track maintenance supporting device realizes the beneficial effects that the effective space is saved, the working efficiency and the working quality are improved, and the safety protection degree is improved.

Owner:TIANJIN JINHANG COMP TECH RES INST

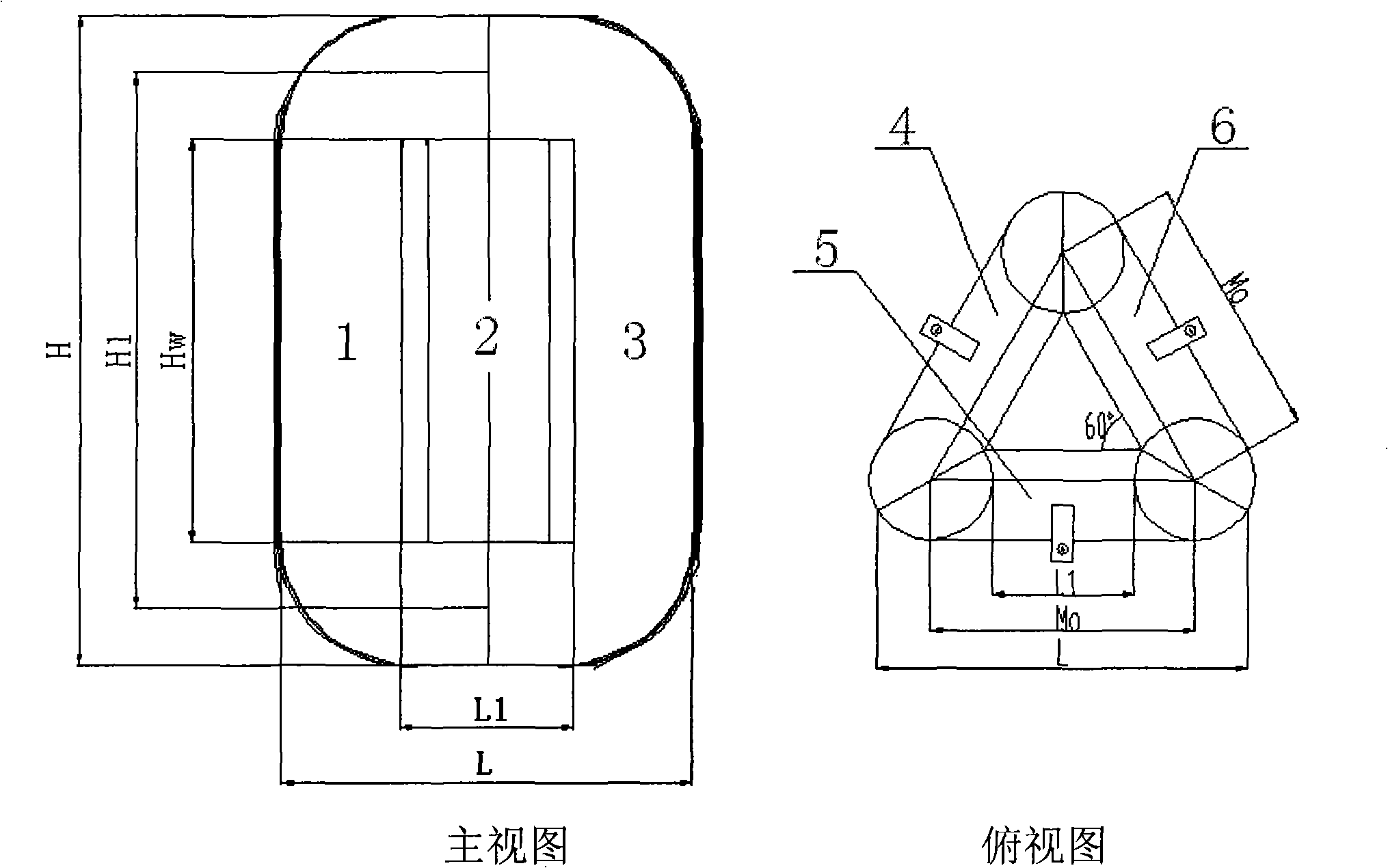

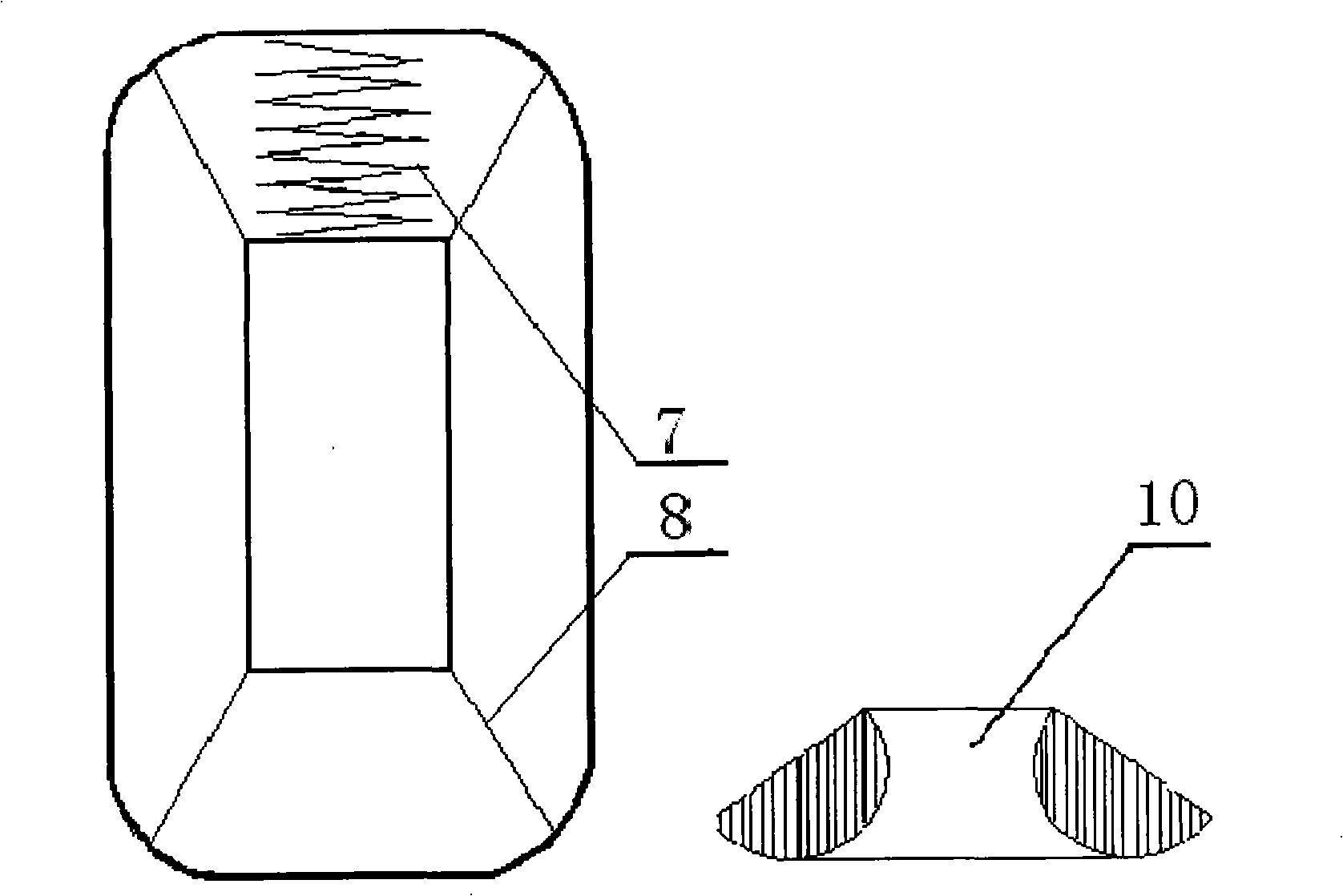

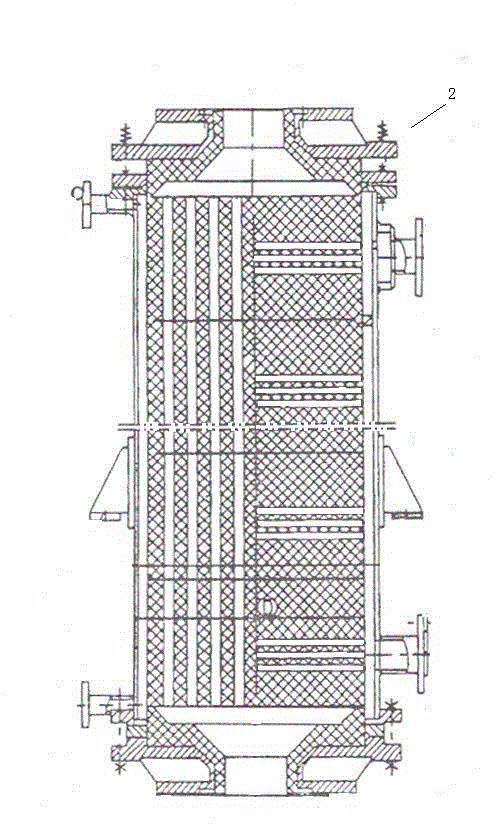

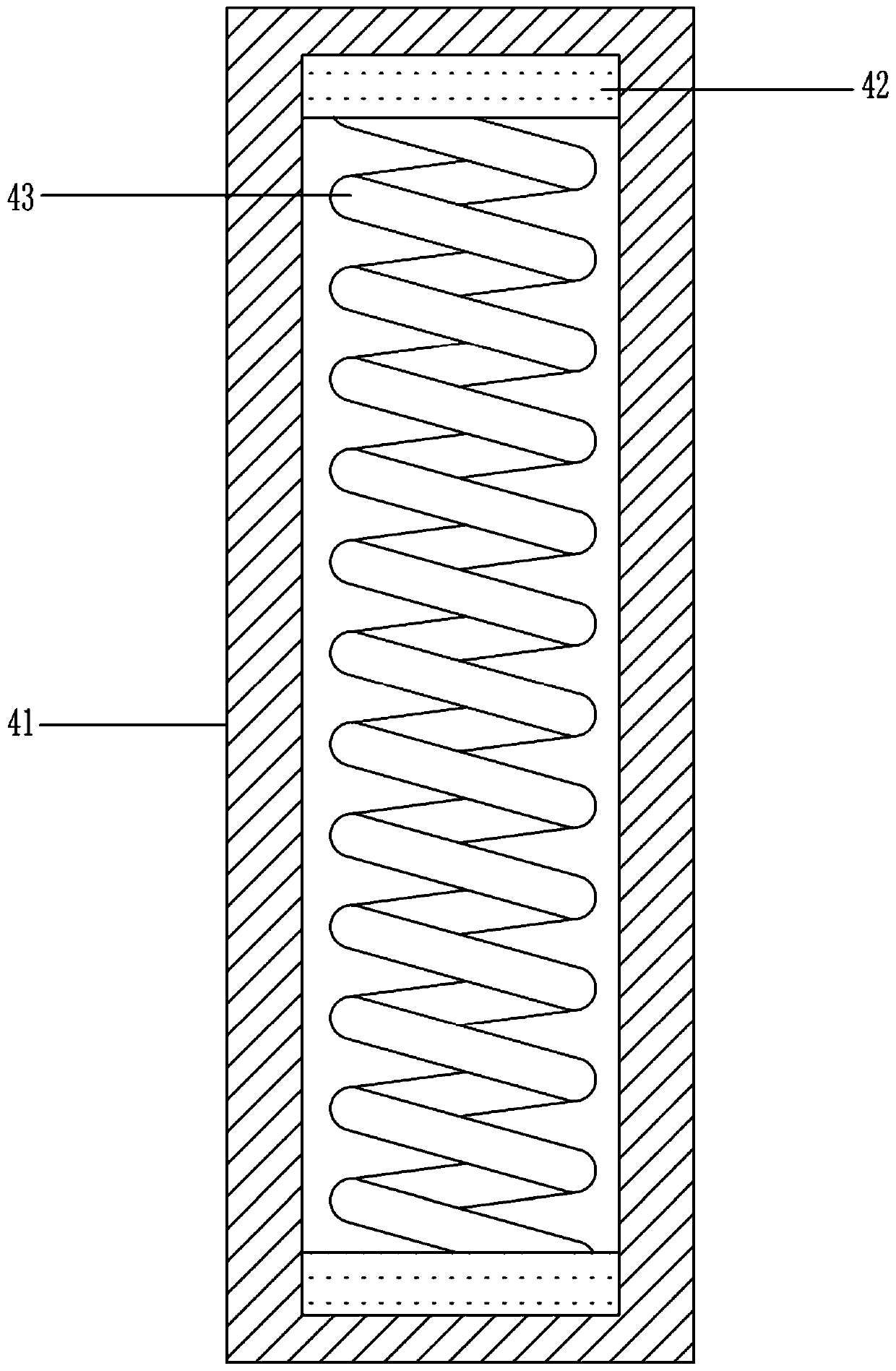

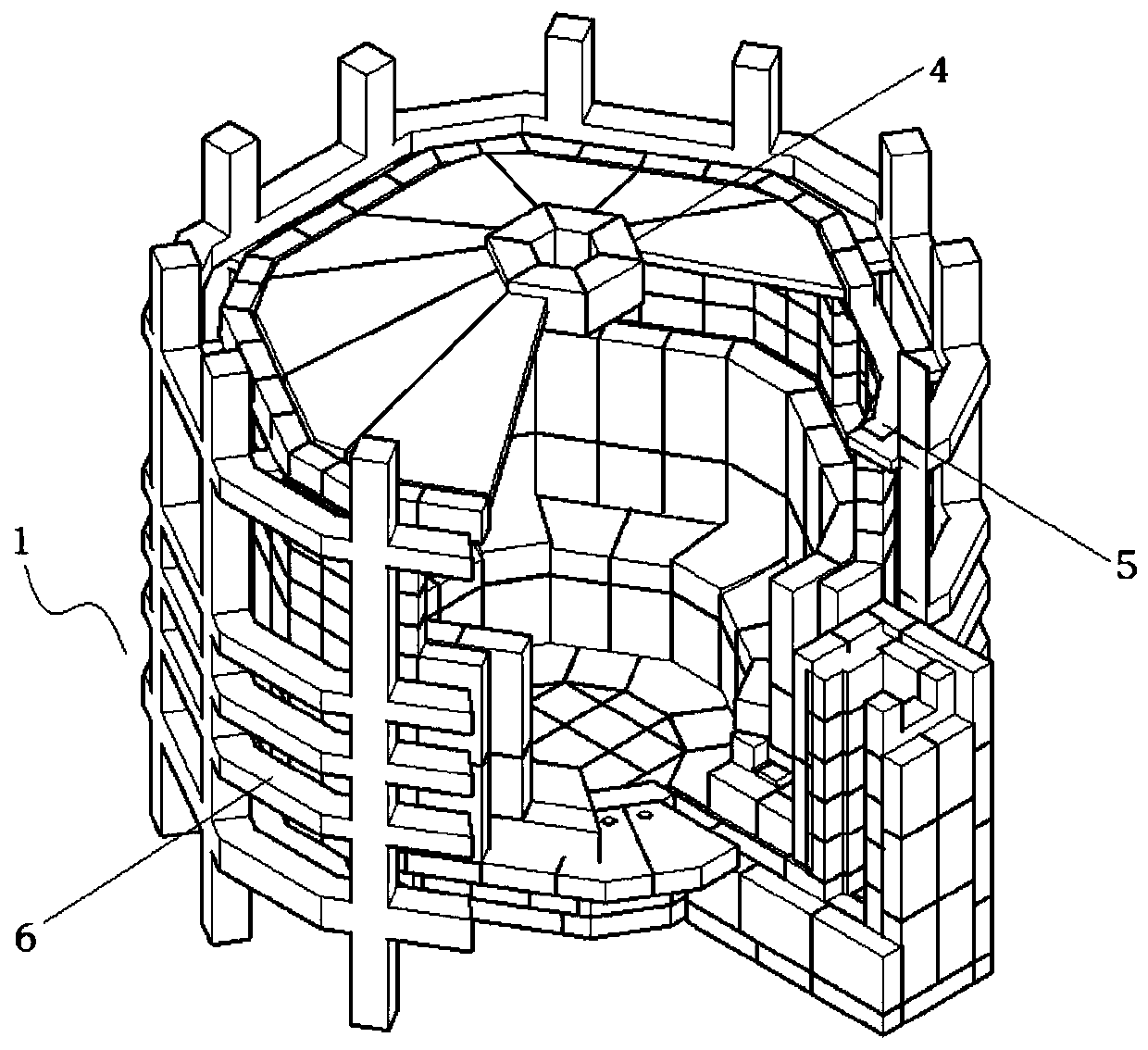

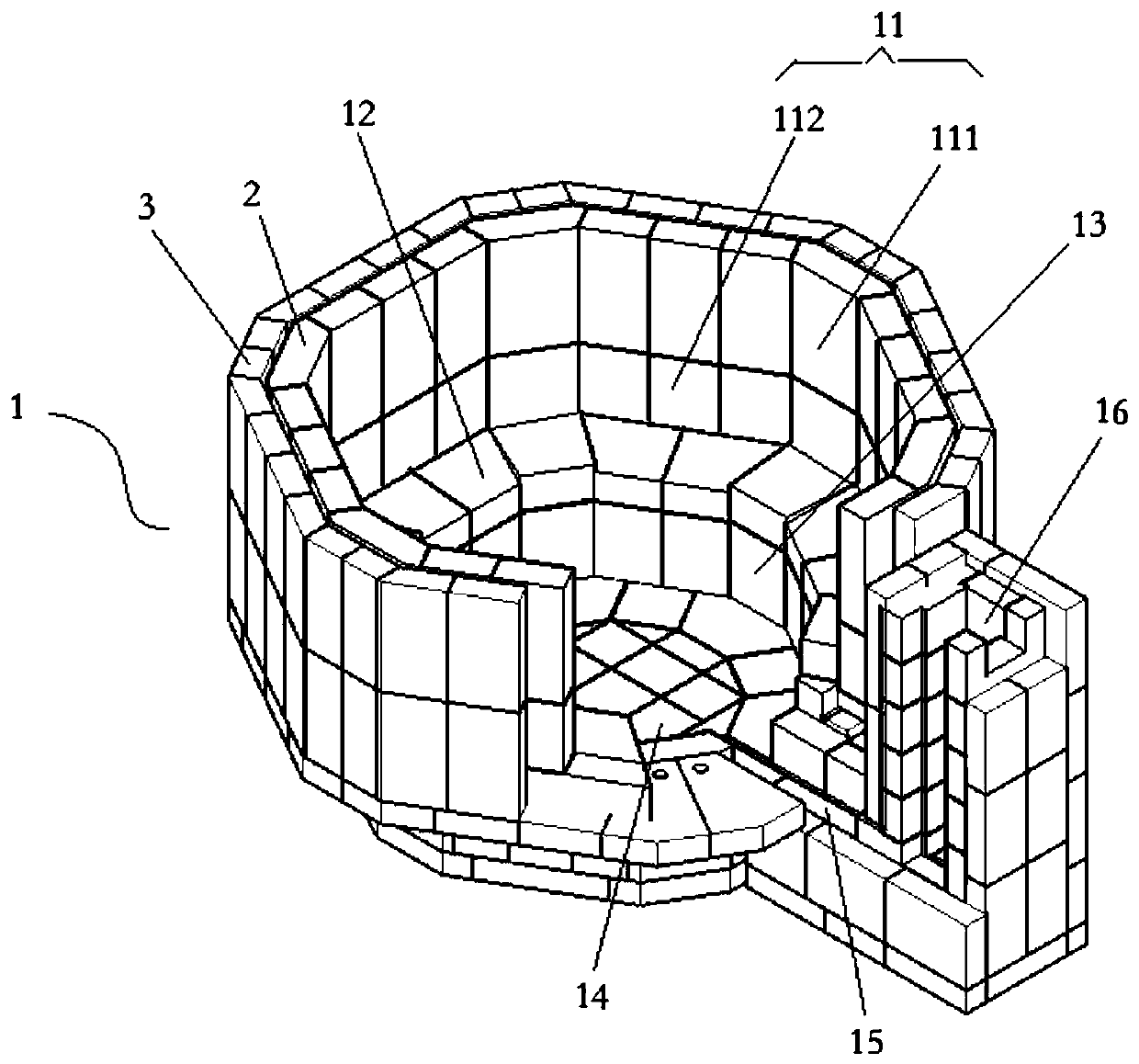

Oil-immersed type transformer for tridimensional triangle iron core

InactiveCN101276679AStrong resistance to sudden short circuitSave materialTransformers/inductances coolingTransformers/inductances magnetic coresLow voltageEngineering

The invention relates to a tridimensional trigonal iron core oil-immersed type power transformer, which comprises an iron core, high-voltage sleeves (11), low-voltage sleeves (14), a grounding line (16), an oil level indicator (15), an exhauster (12), a tapping switch (17), and heat radiating fins (13). The iron core of the transformer has a tridimensional trigonal structure formed by combining and assembling three independent single-phase open rolled iron cores with same shapes in an angle of 120 degrees, the section area of each single-phase iron core yoke is (the formula) times larger than that of the core column of each single-phase iron core, and the sections of three columns of the tridimensional trigonal open iron core after assembling can be ellipses or polygons (circumcircles). Because of the open characteristic of the iron core, the coil can be winded singly during production, and the coil can be mounted or replaced by opening the iron core at an open slot position during production and maintaining.

Owner:齐会南

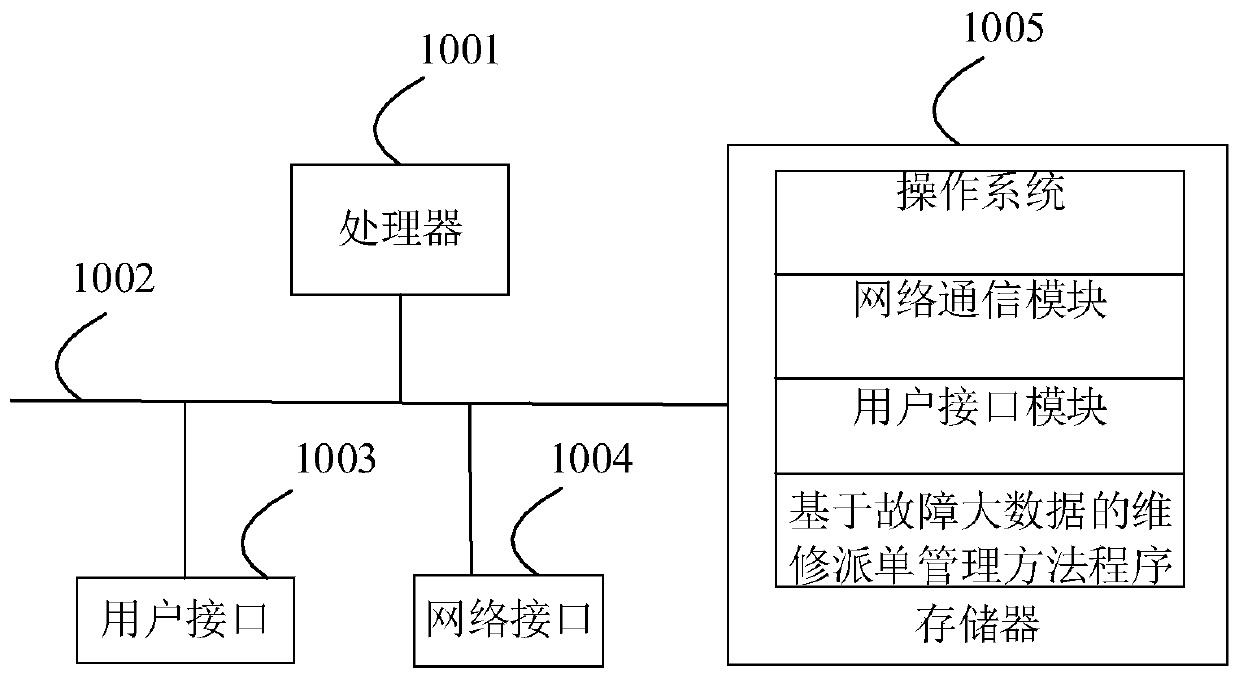

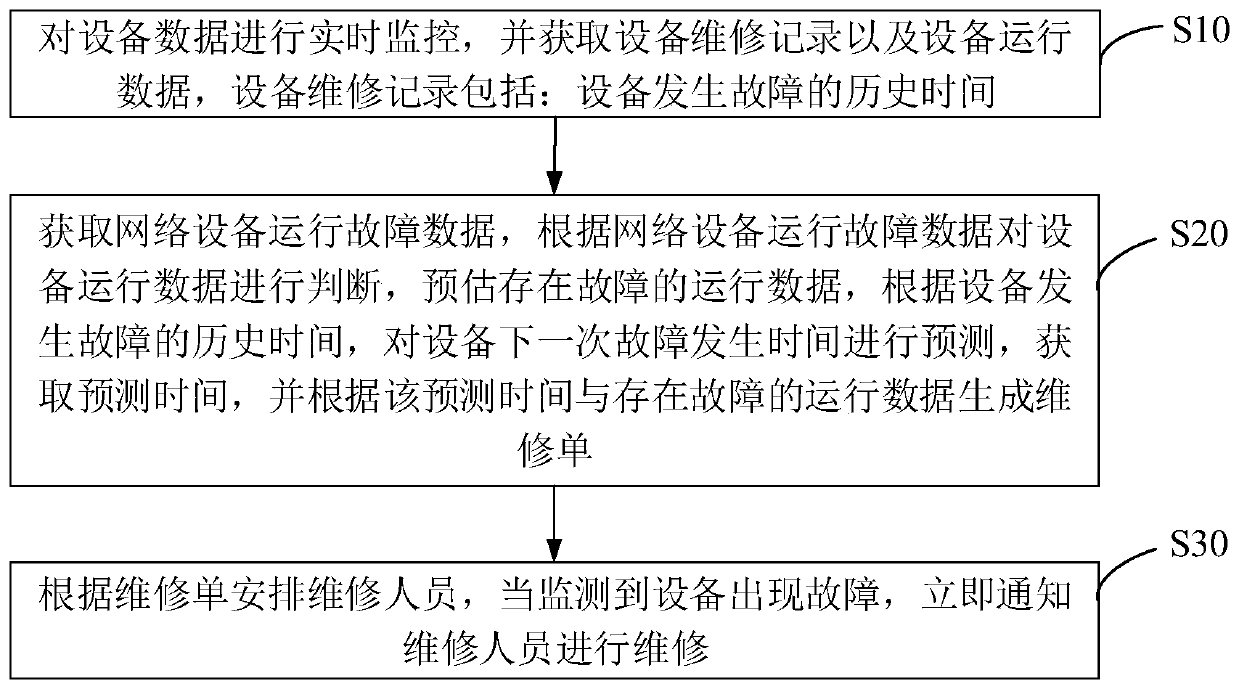

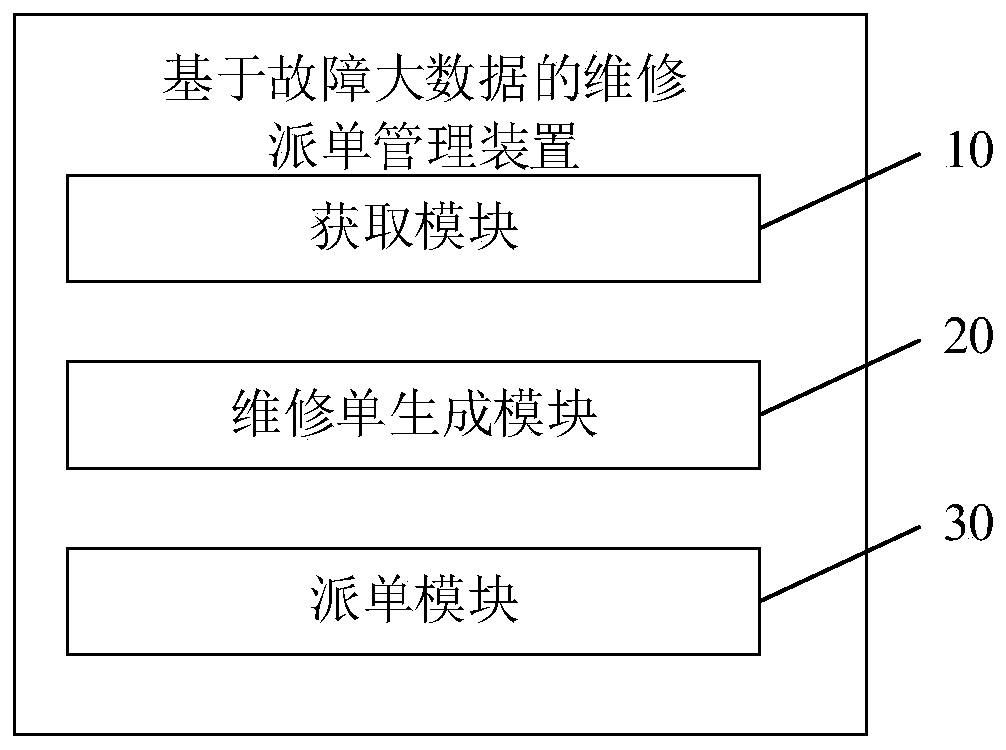

Maintenance order dispatching management method and device based on fault big data, equipment and medium

PendingCN110738352AImmediate and reasonable arrangementWarranty RepairForecastingMonitor equipmentComputer science

The invention provides a maintenance order dispatching management method and device based on fault big data, equipment and a medium. The method comprises the steps of monitoring equipment data in realtime, and acquiring equipment maintenance records and equipment operation data; obtaining network equipment operation fault data, judging the equipment operation data according to the network equipment operation fault data, estimating the operation data with faults, predicting the next fault occurrence time of the equipment according to the historical fault occurrence time of the equipment, obtaining the prediction time, and generating a maintenance list according to the prediction time and the operation data with faults; arranging maintenance personnel according to the maintenance list; andnotifying the maintenance personnel to maintain when monitoring that equipment is in failure. According to the invention, the fault big data is acquired from the network to predict the fault of the equipment, the time and mode that the equipment may fail are predicted in advance, and the maintenance personnel are arranged in advance for standby, so that the equipment can be maintained at the firsttime.

Owner:武汉儒松科技有限公司

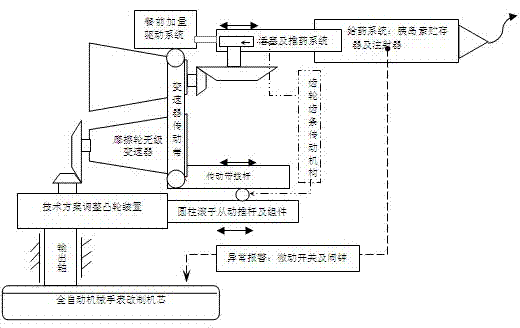

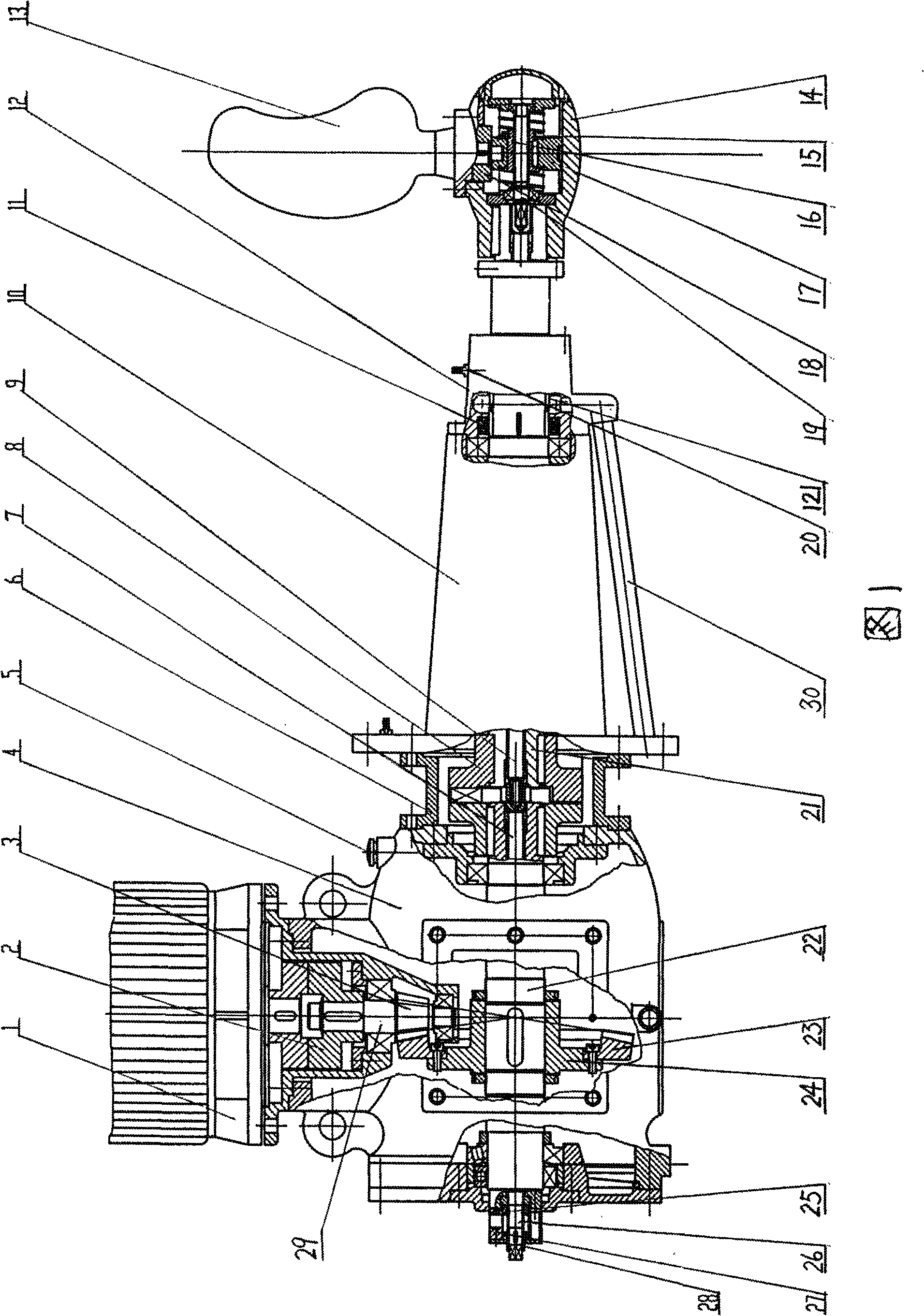

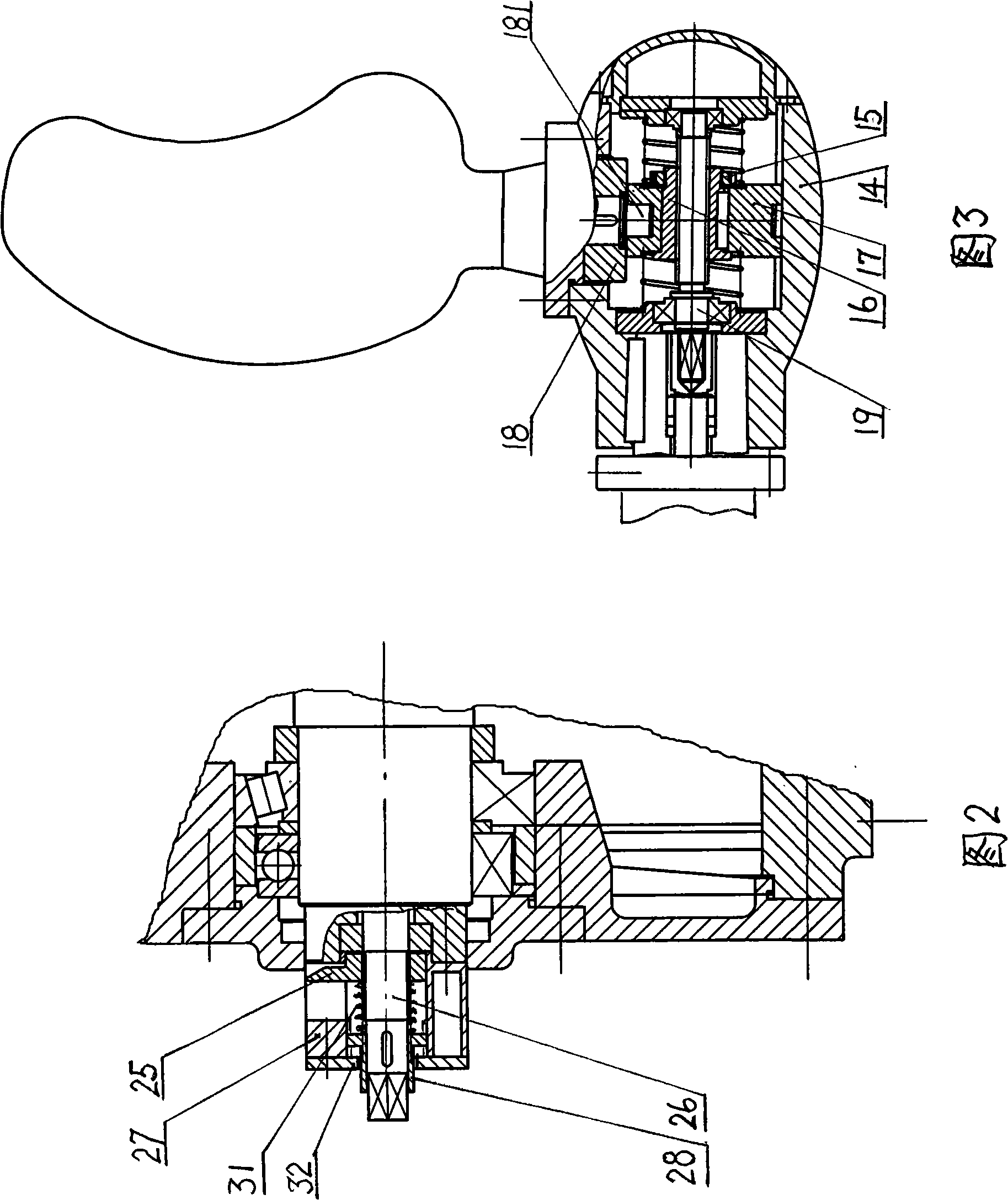

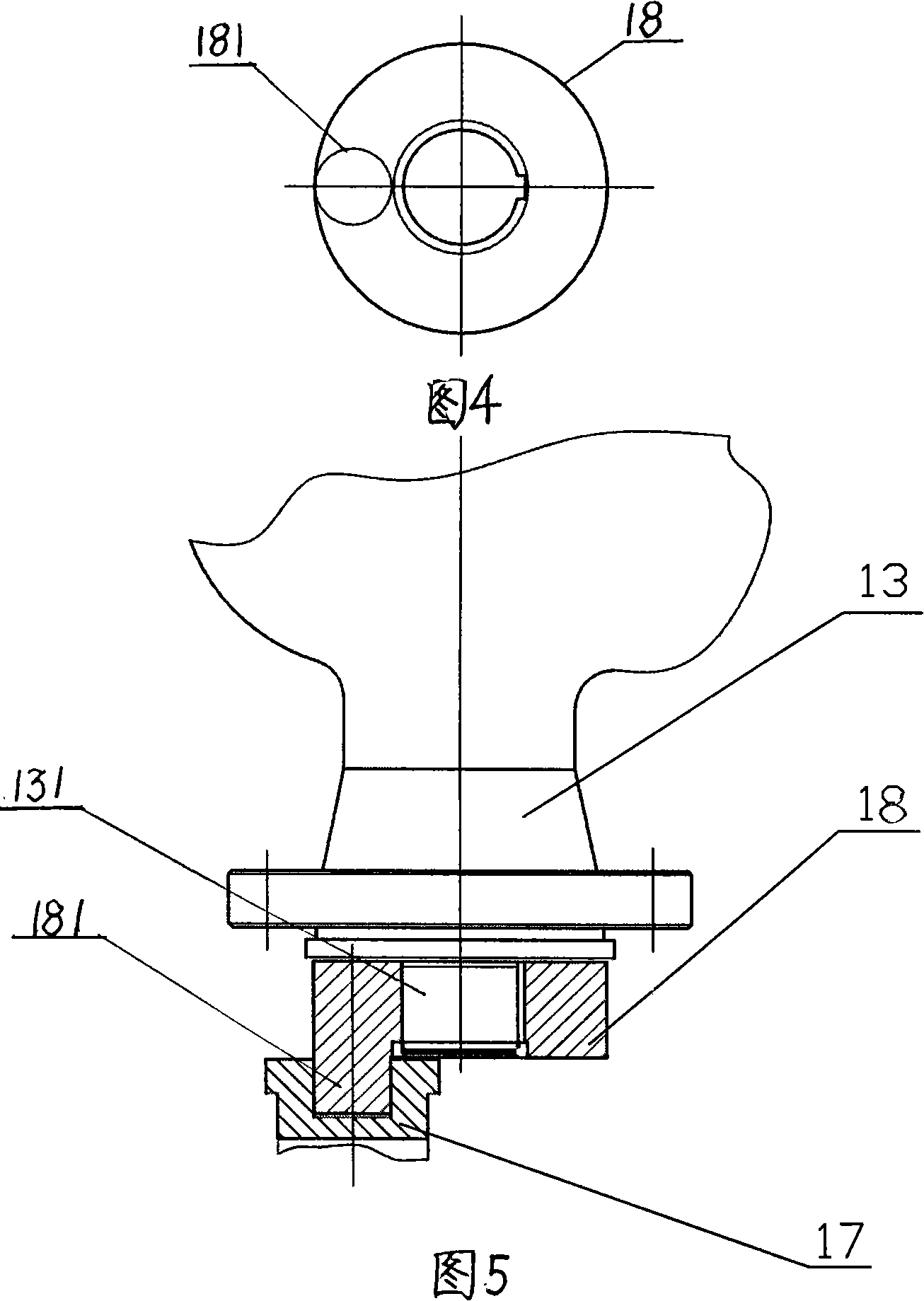

Fully-automatic mechanical insulin injection pump

InactiveCN102526840ASmooth transmissionNo pollution in the processAutomatic syringesLife qualityTreatment effect

The invention discloses a fully-automatic mechanical insulin injection pump, which comprises a reformed mechanism of a mechanical watch, a continuously variable transmission of a belt friction wheel, an adjusting cam device of technical scheme, a gear rack precise injection and transmission mechanism, a dosage injection mechanism before meal, a medicine feeding system and the like. On the one hand, the output shaft of the mechanism drives the adjusting cam device of the technical scheme to further drive the continuously variable transmission of the belt friction wheel and the gear rack precise injection and transmission mechanism and finally drives the medicine feeding system to perform micro-injection of basic amount. On the other hand, a driven push rod on the cam device pushes a transmission belt on the continuously variable transmission of the belt friction wheel to change the axial position of the friction wheel so as to adjust the transmission ratio of the continuously variable transmission of the belt friction wheel. The fully-automatic mechanical insulin injection pump driven by fully-automatic mechanical way is environmentally friendly, safe and reliable, and can reduce the use cost. Therefore, the invention can vigorously accelerate the treatment effect of diabetes patients, alleviate the economic and spiritual pressure, improve the life quality and obtain good economic and social benefits.

Owner:HUAIHAI INST OF TECH

Dedusting device used for textile manufacturing machine

InactiveCN107930289AImprove dust removal efficiencyGuaranteed stabilityDispersed particle filtrationTransportation and packagingTextile manufacturingEngineering

The invention discloses a dedusting device used for textile manufacturing machine. The dedusting device comprises a box body; a filter screen is fixedly arranged in the box body; a dust storage box isfixedly arranged on the top of the box body; a transfer pump is fixedly arranged on the top of the box body, and on the left side of the dust storage box; a dust outlet pipe of the transfer pump is communicated with the dust storage box; a dust inlet pipe of the transfer pump is designed to penetrate through the box body, stretch into the box body, and be communicated with a dust suction pipe; afixing support is fixedly arranged at the bottom of the filter screen, and on the left side of an internal cavity of the box body. According to the dedusting device, the filter screen is adopted, so that shielding of dust generated in production process of textile manufacturing machine is realized; the dust storage box, the transfer pump, the dust suction pipe, the fixing support, a moving plate,a blower fan, a motor, and an adjusting plate are adopted, so that dust on the surface of the filter screen is cleaned, dedusting efficiency is increased, and problems in the prior art that effectiveand rapid cleaning of dust on the filter screen is impossible to realize, cleaning effect is poor, and the physical and mental health of operators is influenced are solved.

Owner:苏州聚飞纺织科技有限公司

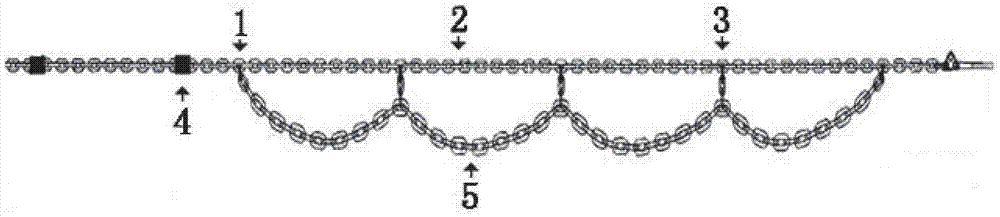

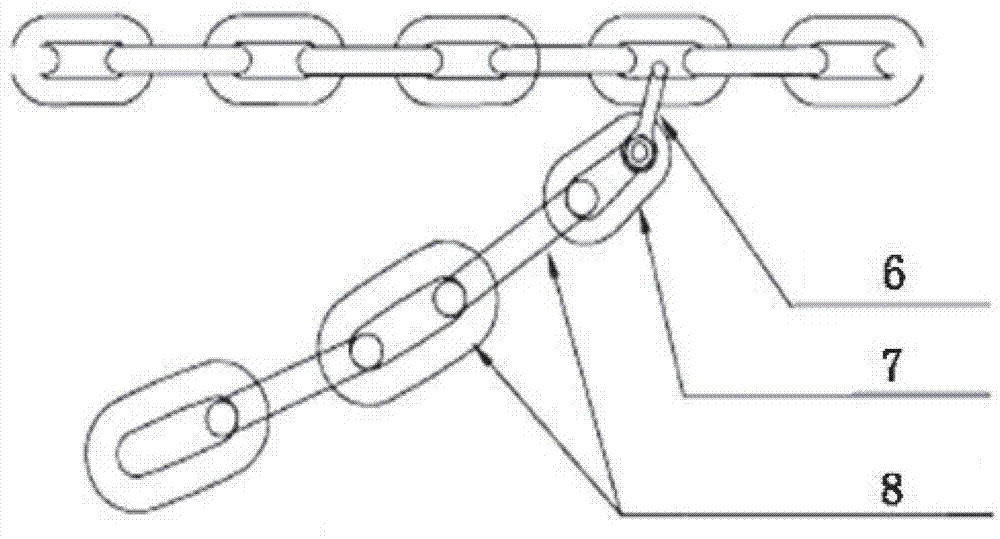

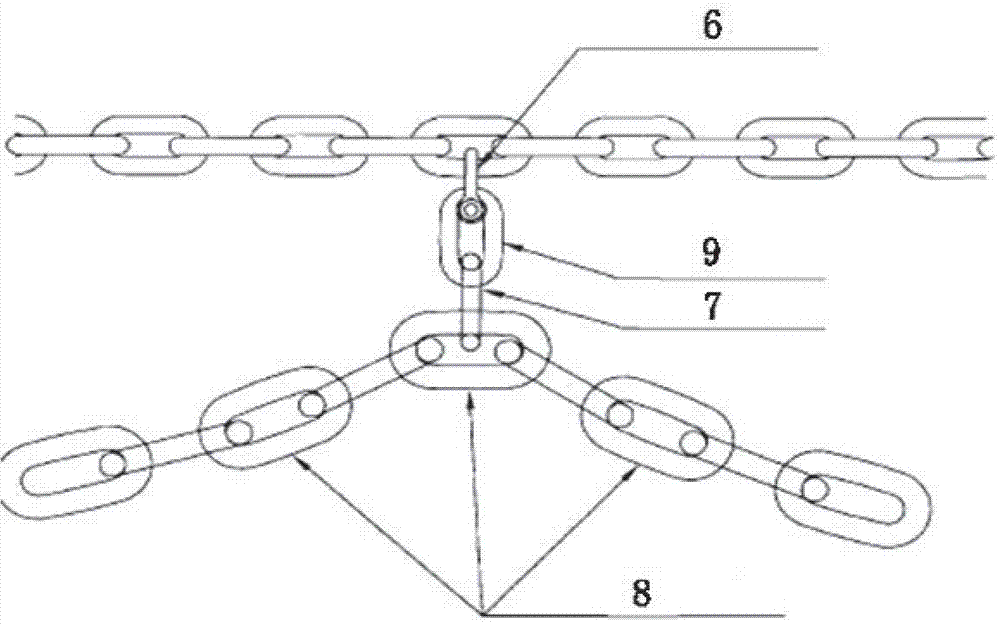

Maintenance method of counter weight of anchor chain of single point mooring system

InactiveCN102815369AReduce the difficulty of operationShorten working timeVessel partsWhole bodyAgricultural engineering

The invention discloses a maintenance method of a counter weight of an anchor chain of a single point mooring system. The maintenance method is characterized in that a counter weight chain is arranged at a position of a fallen counter weight block of the anchor chain; connection points of the counter weight chain and the anchor chain are uniformly distributed on the anchor chain of a falling section of the counter weight block; the connection points are divided into end connection points and middle connection points according to different connection manners; the counter weight chain at each end connection joint is connected with the anchor chain through a transition ring and a connection shackle; the counter weight chain at each middle connection joint is connected with an ordinary chain ring through the transition chain ring, and then is connected with the anchor chain through the connection shackle; and with the adoption of the connection, the connection points are tightly connected with the anchor chain to form a whole body. With the adoption of the maintenance method provided by the invention, the problem that the counter weight block of the anchor chain is easy to fall can be solved; the possibility of falling the shackle, caused by corrosion at the connection points, can be reduced; and meanwhile, the simple and easy installation is realized; the operation time is reduced; and the construction efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +3

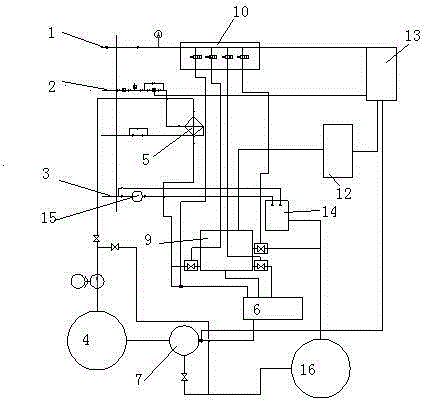

Steel product acid dipping test erosion integration device

InactiveCN103063501AEvenly heatedGuaranteed temperaturePreparing sample for investigationLiquid storage tankElectric control

The invention discloses a steel product macroscopic examination device. A steel product acid dipping test erosion integration device comprises a compressed air source, a vapor source, a tap water source, an acid liquor preheating circulating system, an acid dipping test circulating system, an acid fog neutralizing tower, a rinse tank and a waste liquid tank , wherein the acid liquor preheating circulating system comprises an acid liquor preheating tank and a graphite heat exchanger which are successively connected, and the graphite heat exchanger returns to the acid liquor preheating tank through an acid buffer pool and an acid returning middle tank; the acid dipping test circulating system shares each device of an acid liquor preheating system and a pickling tank is arranged between the graphite heat exchanger and the acid liquor buffer pool, and the compressed air source can control pneumatic valves at the acid liquor inlet and acid liquor outlet of the pickling tank through a pneumatic control box; the acid fog neutralizing tower is controlled by an electric control cabinet and is connected with the pickling tank, the tap water source is connected with the cold water inlet of the rinse tank and is simultaneously connected in parallel with a water heater and is connected with the hot water inlet of the rinse tank; and the outlets of the rinse tank and the pickling tank are respectively connected with a waste liquid storage tank. The steel product macroscopic examination device provided by the invention has the advantages that the heating speed is rapid and uniform, and the acid concentration is unaffected.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

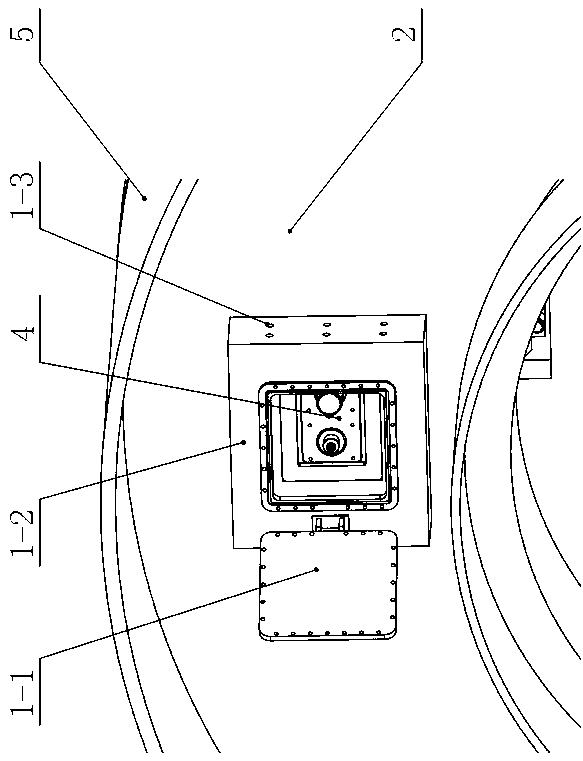

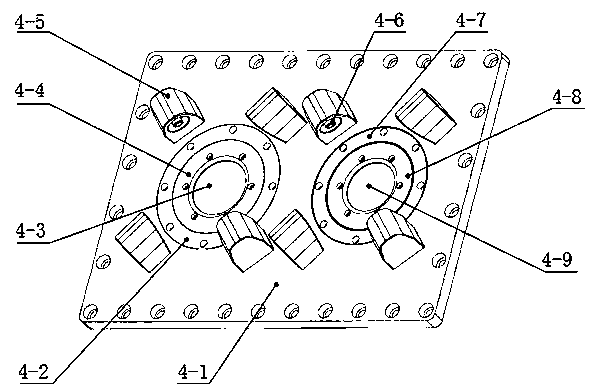

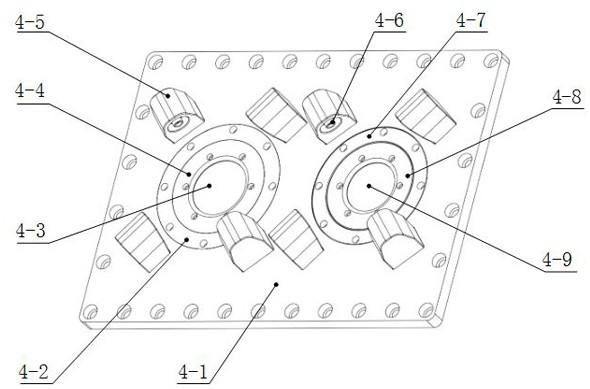

Earth pressure balance shield machine hob abrasion monitoring device and method based on image analysis

ActiveCN111043964AGuarantee the environmentGuaranteed replacementUsing optical meansThermodynamicsImaging analysis

The invention discloses an earth pressure balance shield machine hob abrasion monitoring device and method based on image analysis. The earth pressure balance shield machine hob abrasion monitoring device comprises a hob monitoring device, wherein the hob monitoring device is arranged in a pressure-bearing sealing device, and the hob monitoring device is opposite to a hob box assembly. The deviceis simple in structure, convenient to install and clear in visual field, has the characteristic of being good in protection effect and flushing effect, and provides a stable and reliable structural basis for image analysis and processing. Online measurement of tool abrasion can be achieved through the abrasion monitoring method. Meanwhile, the hob state is directly observed through the monitoringvideo, and the safety, convenience, economical efficiency and reliability of hob abrasion monitoring are improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

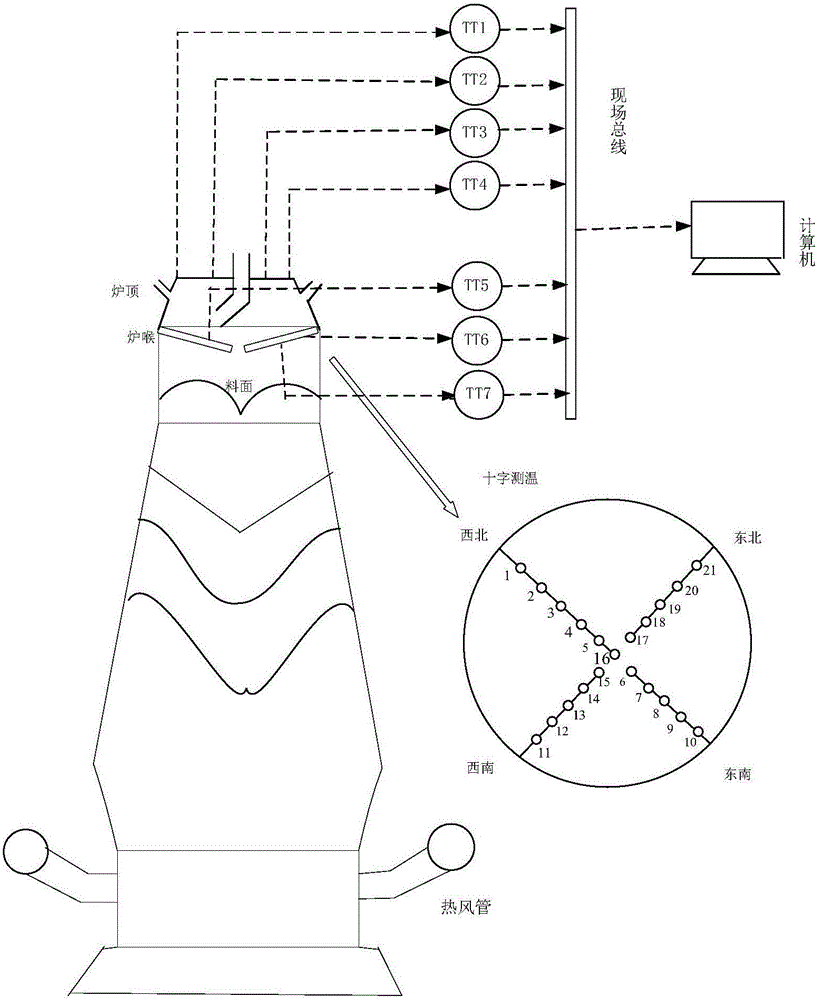

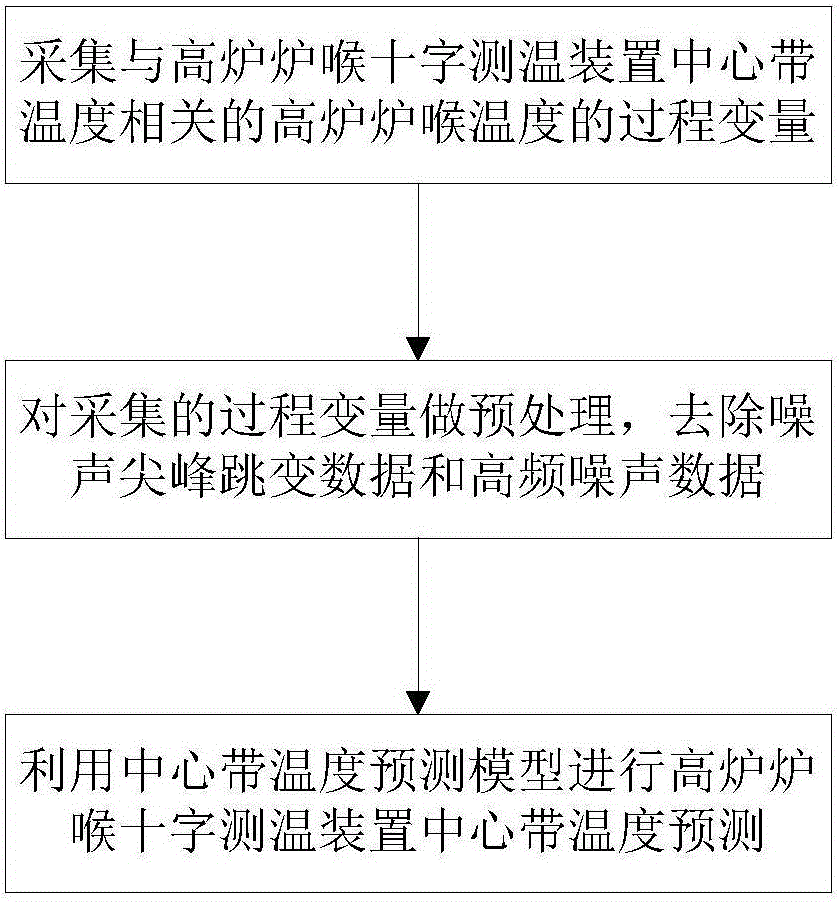

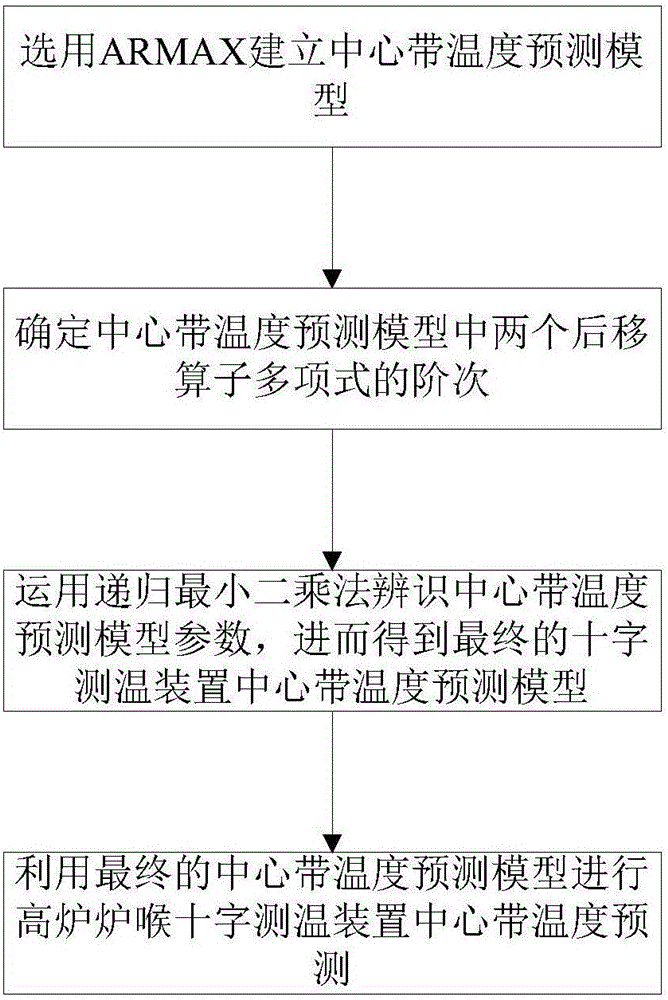

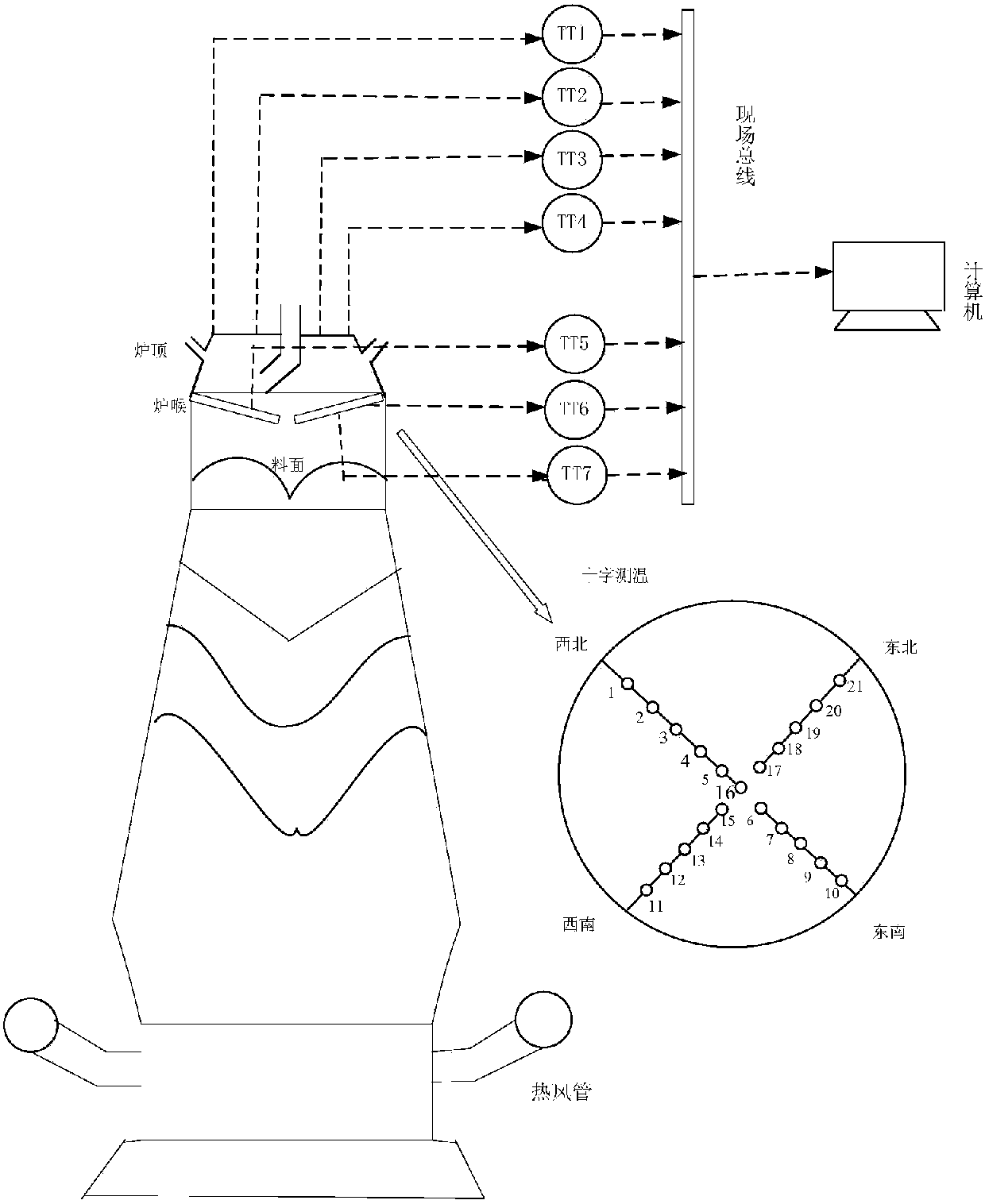

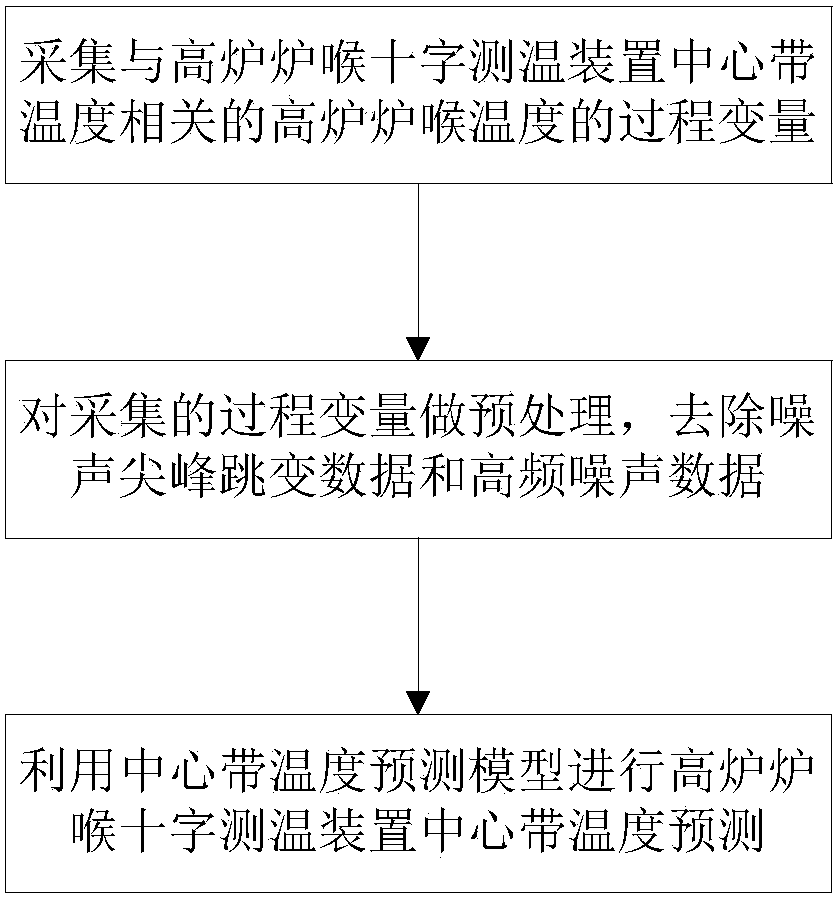

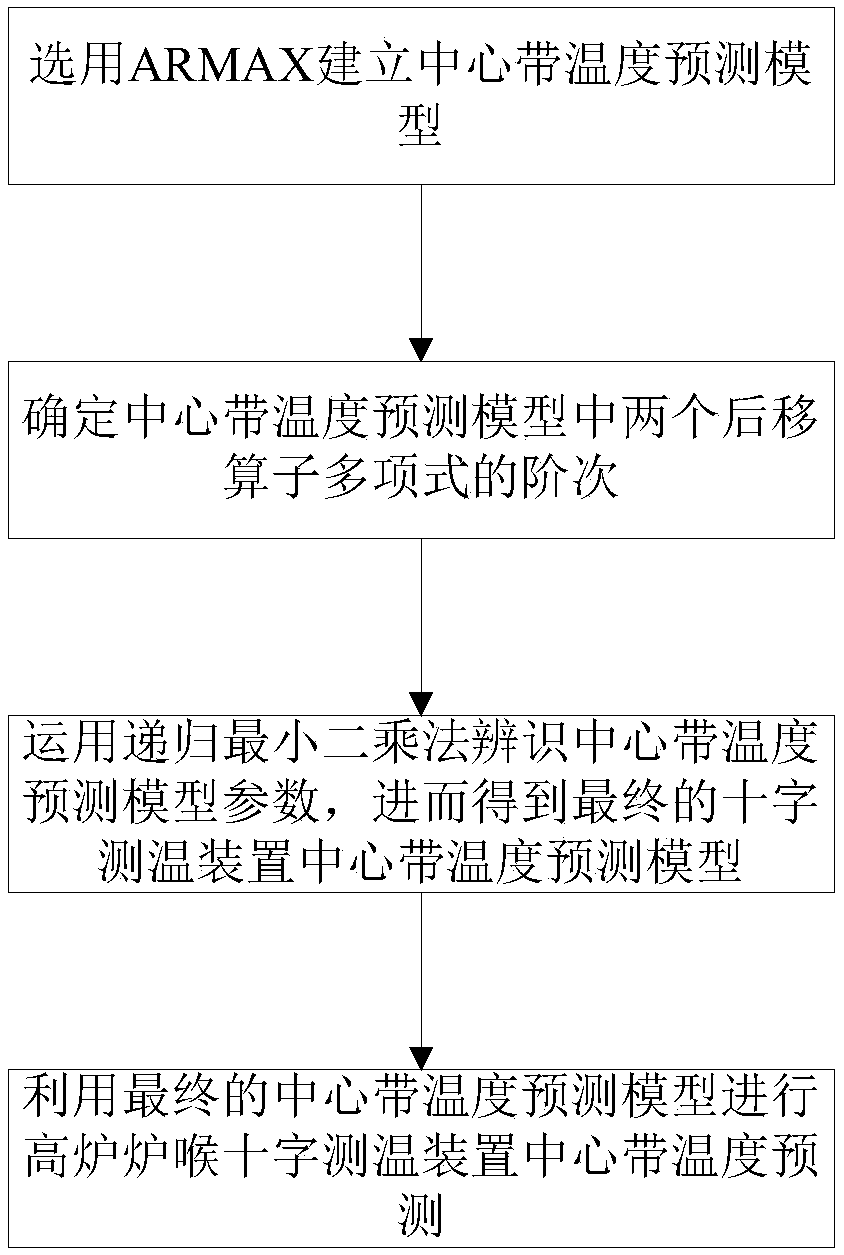

Method and system for predicting central zone temperature of cross temperature measurement device of blast furnace throat

ActiveCN106227699AAccurate judgmentWarranty RepairChecking devicesComplex mathematical operationsThroatComputer module

The invention provides a method and system for predicting a central zone temperature of a cross temperature measurement device of a blast furnace throat. The method comprises the steps that a course variable of a blast furnace throat temperature related to the central zone temperature of the cross temperature measurement device of the blast furnace throat is collected; the collected course variable is pre-processed, and noise peak jumping data and high-frequency noise data are removed; and a central zone temperature prediction model is used to predict the central zone temperature of the cross temperature measurement device of the blast furnace throat. The system comprises a collection module, a pre-processing module and a prediction module. According to the invention, input and output historical data selected by the prediction model of the central zone temperature is used to predict future central zone temperature output of the cross temperature measurement device; relations between the temperature output and control input can be expressed accurately; when a central temperature sensor of the cross temperature measurement device needs to be repaired or is damaged, a basis can be provided for a blast furnace operator to make accurate judgments and adjust systems of upper and lower parts of a blast furnace in time; and further, steady, efficiency and safe running of the blast furnace can be implemented.

Owner:NORTHEASTERN UNIV

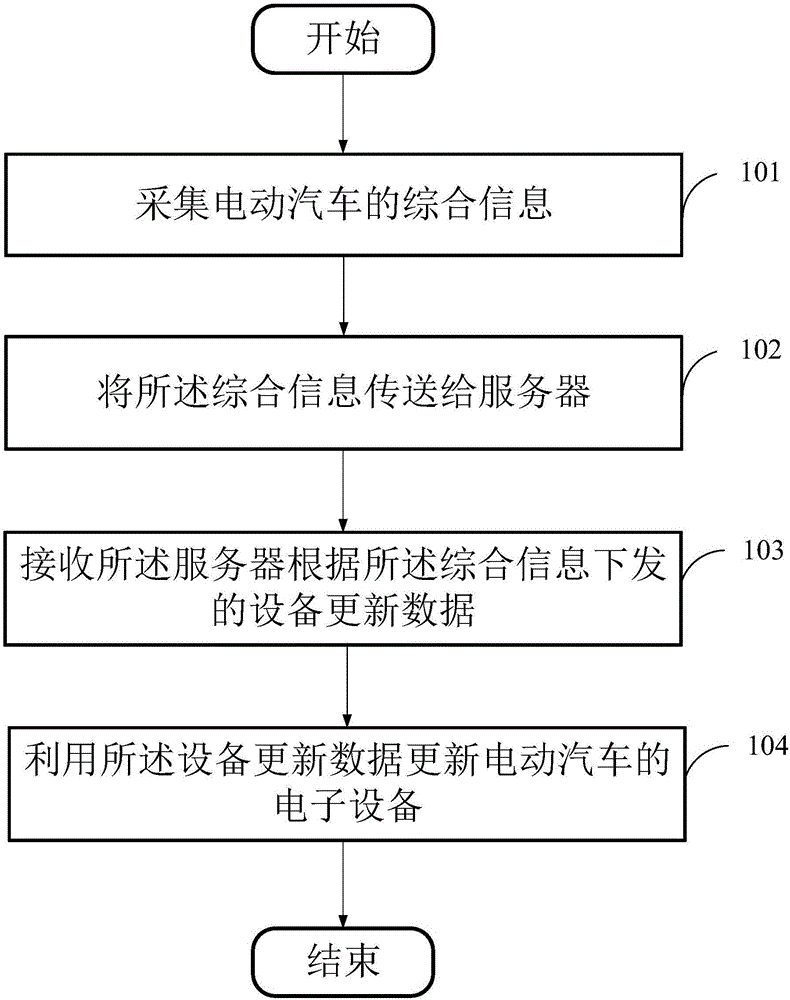

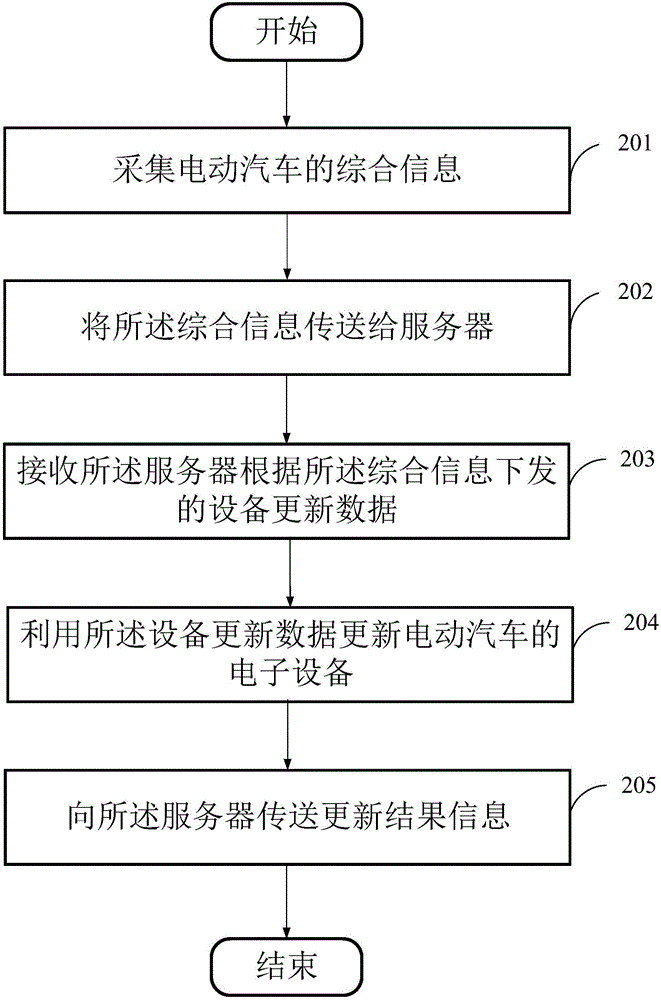

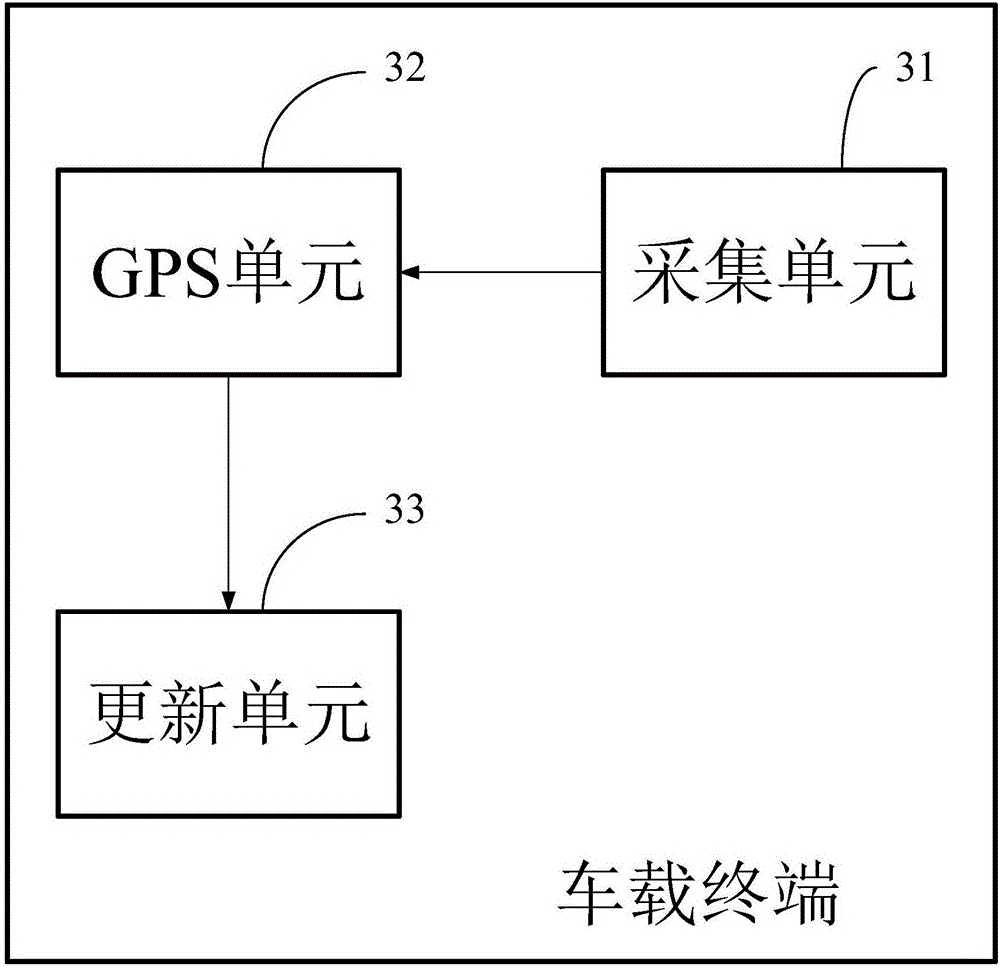

Electrocar intelligent management method and system, terminal and server

InactiveCN106779108ADetailed managementGuaranteed detection effectRegistering/indicating working of vehiclesIntelligent managementComputer terminal

The invention provides an electrocar intelligent management method and system, a terminal and a server. The method comprises the steps of collecting comprehensive information of the electrocar; transferring the comprehensive information to the server; receiving equipment updating data sent down by the server according to the comprehensive information; utilizing the equipment updating data to update electronic equipment of the electronic. According to the electrocar intelligent management method and system, the terminal and the server, the intelligent management of the electrocar is achieved, the management level of the electrocar is improved, and the user experience degree is increased.

Owner:山东元齐新动力科技有限公司

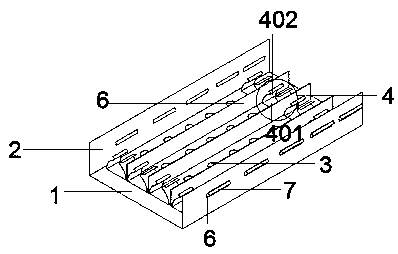

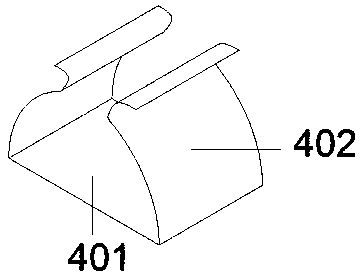

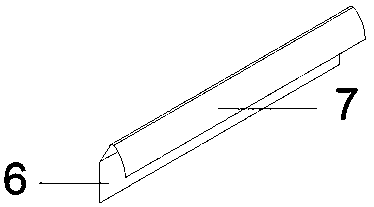

Cable bridge convenient for mounting and dismounting cable

The invention relates to a cable bridge convenient for mounting and dismounting a cable, comprising a first supporting plate and second supporting plates, wherein the second supporting plates are respectively fixedly connected with the two sides of the first supporting plate, first heat dissipation holes are formed in the upper surface of the first supporting plate in an array, second heat dissipation holes are formed, and a dustproof plate is arranged above the second heat dissipation holes, so that external dust can be avoided from entering into the cable bridge while heat dissipation is carried out, pollution can not be produced to the surface of the cable, the cable can not be corroded either, and service life of the cable is prolonged; a separating plate is arranged, so that the cableis clearer when the cable is arranged; meanwhile, when a fault is checked, a worker also can conveniently find and maintain a faulted cable.

Owner:扬州中恒电气有限公司

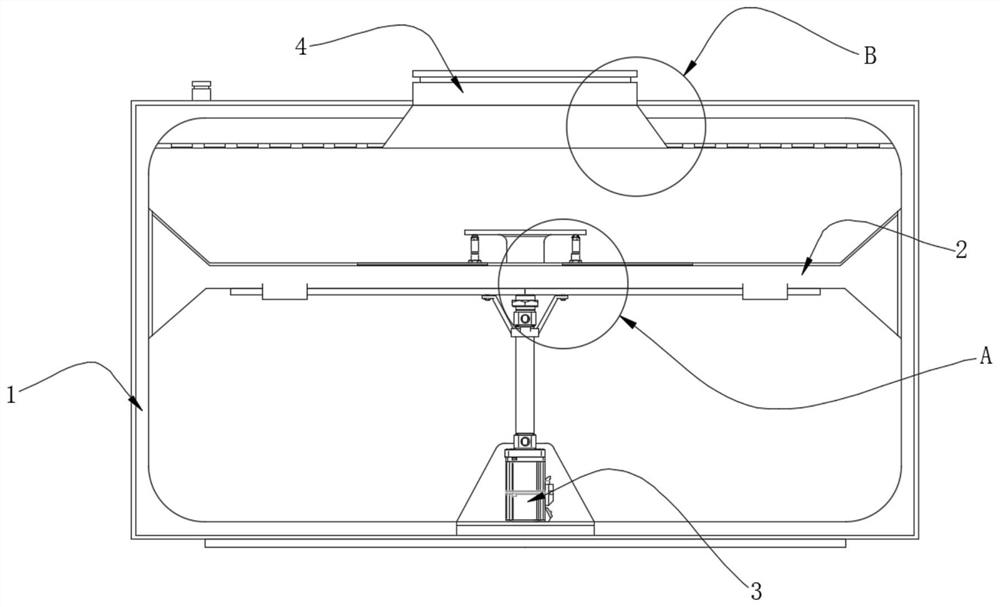

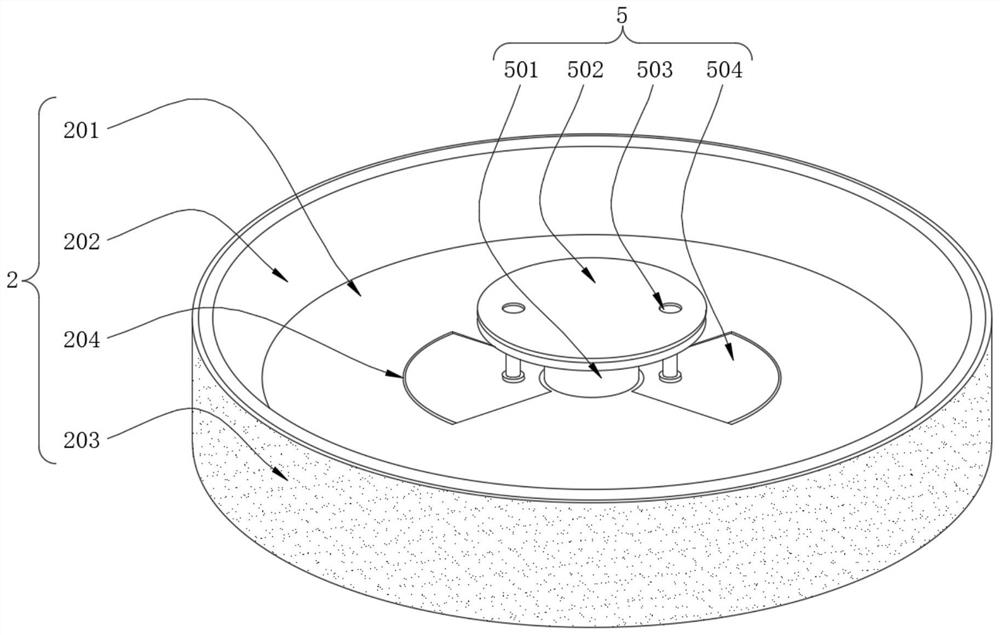

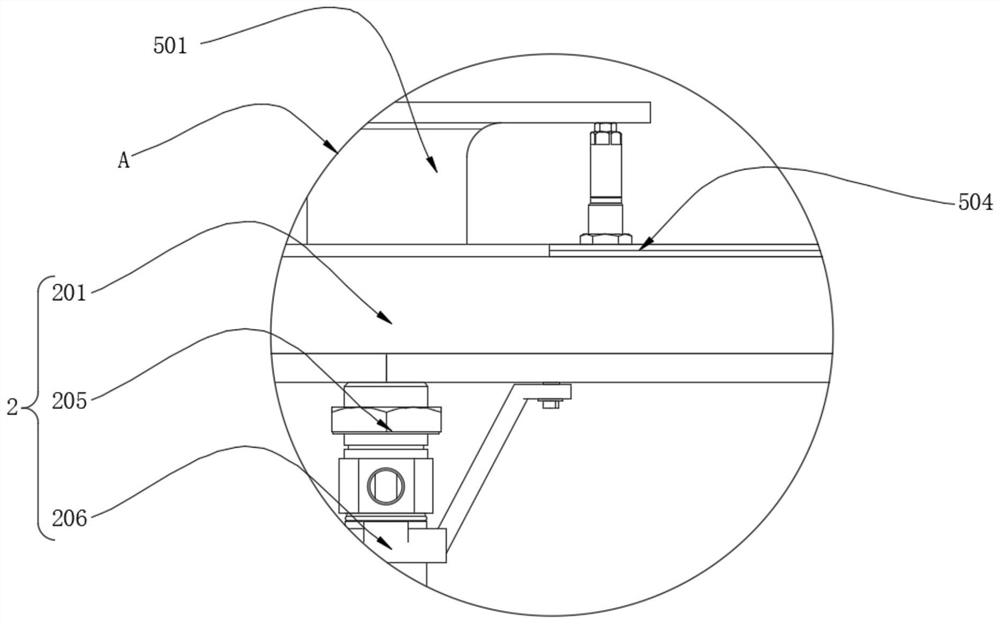

Connecting device used for connecting low-temperature storage tank and base

The invention provides a connecting device used for connecting a low-temperature storage tank and a base. The connecting device comprises a first fixing piece, a second fixing piece and a connecting piece, wherein the first fixing piece is used for being fixed to the low-temperature storage tank; the second fixing piece is used for being fixed to the base; and a first end of the connecting piece is used for being fixed to the first fixing piece, and a second end of the connecting piece is used for being fixed to the second fixing piece, so that the low-temperature storage tank is connected with the base. The connecting device can connect the low-temperature storage tank with the base, has enough strength for supporting the low-temperature storage tank so as to realize the reliable connection between the low-temperature storage tank and the base, and the transportation as a whole, the installation or maintenance between the low-temperature storage tank and the base, so that the running cost is lowered.

Owner:NANTONG CIMC TANK EQUIP CO LTD

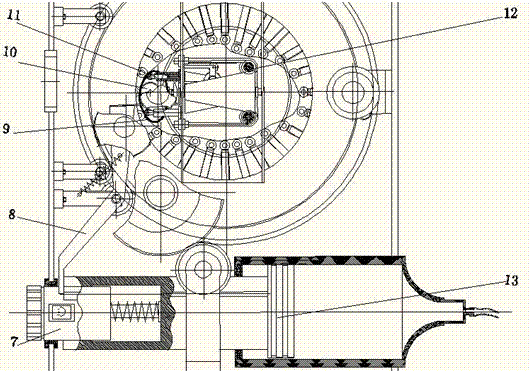

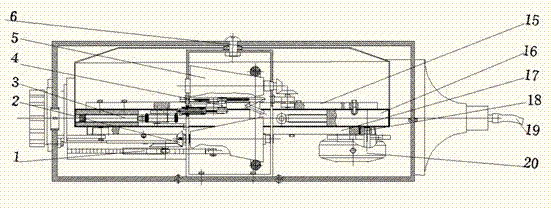

Reciprocating propelling mechanism

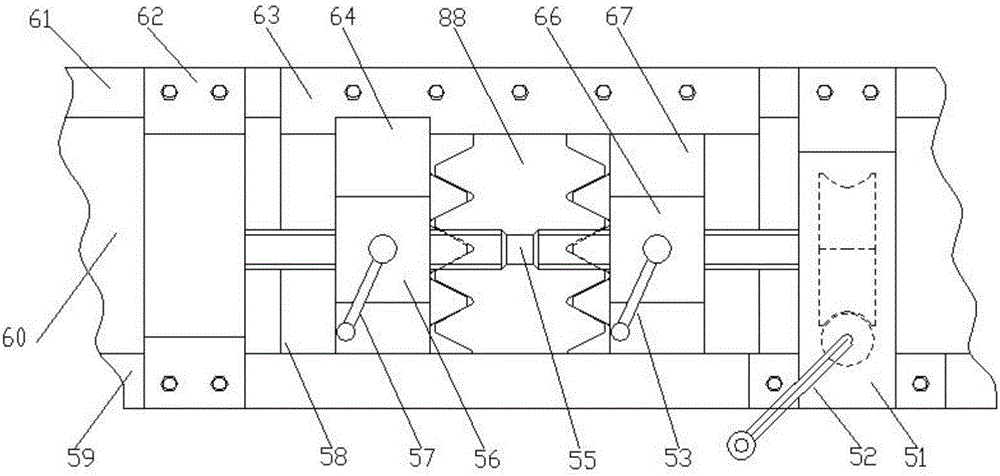

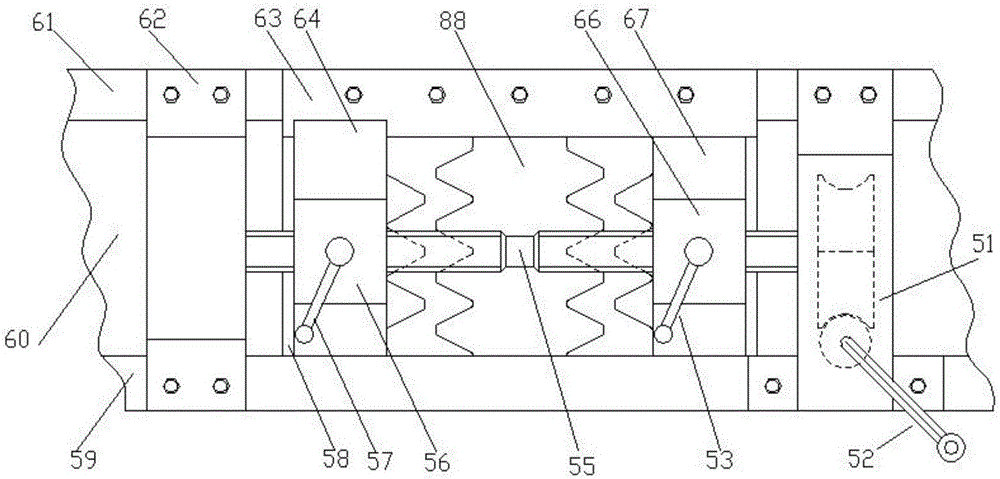

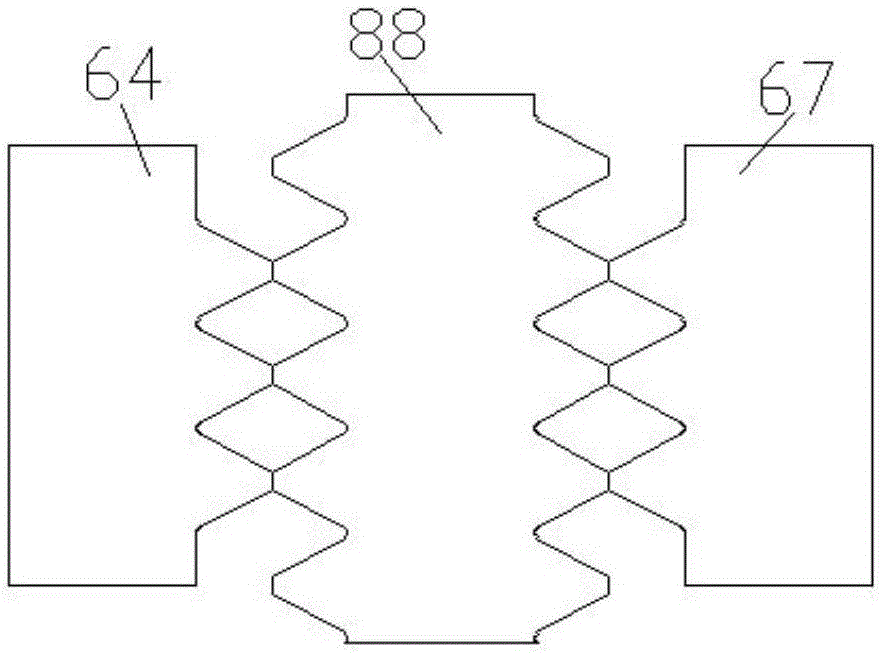

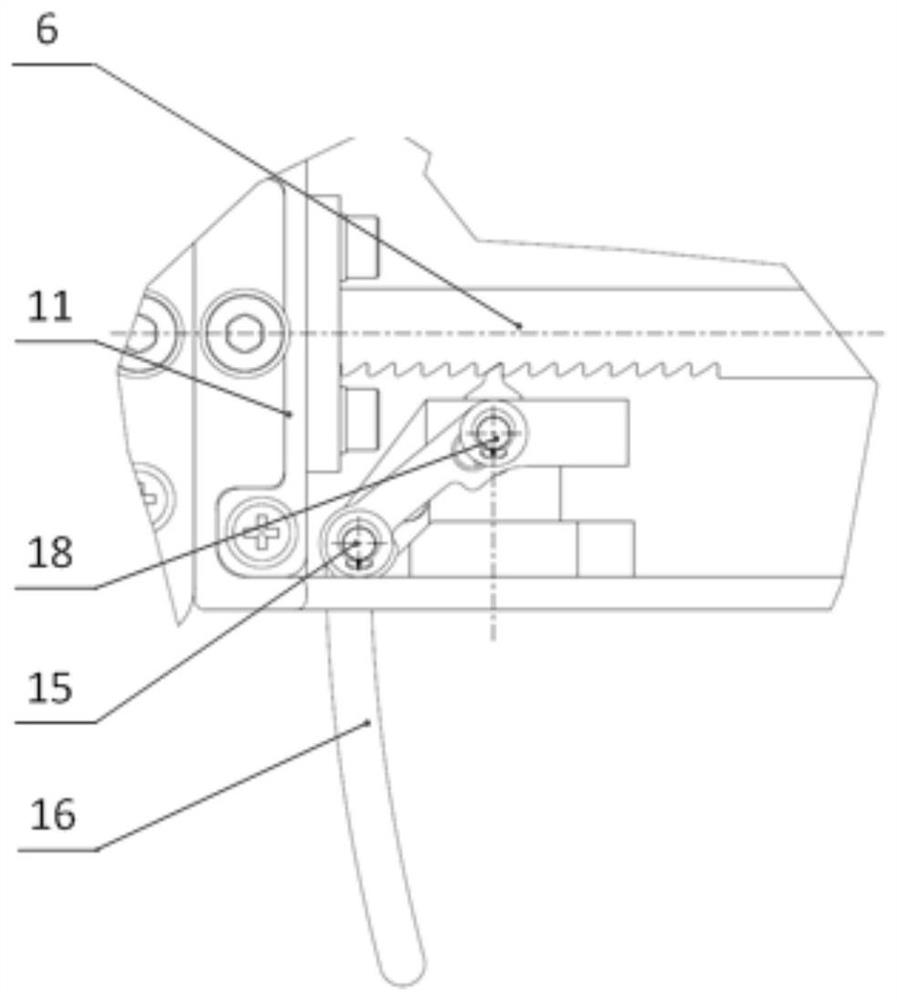

PendingCN113522678AMeet ergonomic requirementsImprove reliabilityLiquid surface applicatorsCoatingsReciprocating motionControl engineering

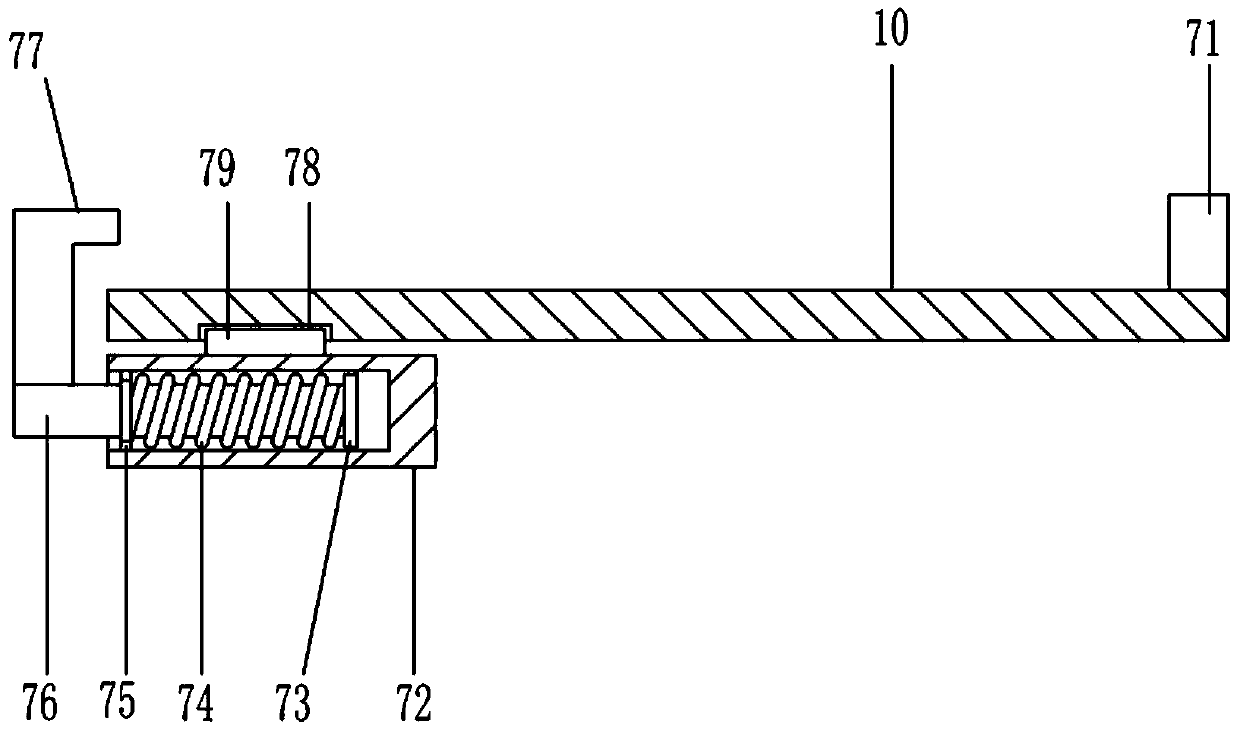

The invention provides a reciprocating propelling mechanism, and belongs to the field of driving equipment. The reciprocating propelling mechanism comprises a support, wherein a push rod moving back and forth relative to the axial direction of the support is arranged in the support; a locking assembly for positioning the advancing position of the push rod is arranged below the push rod; the locking assembly is fixedly arranged on the support; the locking assembly comprises a locking block; the locking block can move up and down and move upwards to correspond to a tooth groove in the push rod so as to limit the push rod; the locking block moves downwards so as to be separated from the tooth groove in the push rod; and the push rod is reset under the action of a push rod reset spring, so that the push rod can move back and forth in a reciprocating mode. According to the reciprocating propelling mechanism provided by the invention, the locking reliability in a working in-place state can be improved, and an unlocking mechanism is optimized, so that the reciprocating propelling mechanism better meets the requirements of man-machine ergonomics, and the return reset operation is more convenient.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Gravel screening equipment for building construction

InactiveCN114472158AAvoid snappingEnsure stabilitySievingScreeningArchitectural engineeringSupport plane

The gravel screening equipment for building construction comprises a screening box, a screening assembly, a cleaning assembly and a screened residue treatment mechanism, the cleaning assembly is arranged at the top of the upper end of the screening box, a motor set is arranged at the bottom end of the interior of the screening box, and the screening assembly is arranged at the top of the upper end of the motor set; and a screened residue treatment mechanism is arranged at the top of the upper end of the screening assembly, and the screening assembly comprises a main screening plate, a side screening plate, a plastic layer, a discharging groove, a hydraulic rod and an auxiliary supporting frame. According to the gravel screening equipment for building construction, the filter plate serves as a main body structure for gravel screening, gravel at the upper end of the filter plate is in a movable state under the two external force modes of lifting transmission and rotating operation, gravel screening operation can be conveniently completed by penetrating through the filter plate, the gravel is washed in the screening process, and the gravel screening efficiency is improved. Therefore, the cement can be mixed with cement in the subsequent building construction, so that the adhesiveness of the cement in the building process is improved.

Owner:谢东海

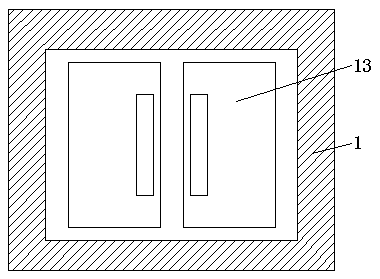

Switch for communication engineering

ActiveCN109451369AIngenious structural designEasy to operateSelection arrangementsTelecommunications engineeringArchitectural engineering

The invention discloses a switch for communication engineering. The switch comprises a switch body, wherein a plurality of clamping slots are set on a top edge of a side wall of the switch body closeto communication cable sockets; a horizontal groove is set on the top of the switch body; the groove is communicated with the plurality of clamping slots; limiting rods are fixed and clamped in the groove; a plurality of limiting blocks are fixedly connected with the side walls of the limiting slots; each limiting block is clamped in the corresponding clamping slot; flexible plastic tapes are fixedly connected with two ends of the limiting rods; a horizontal upright post is fixedly connected with symmetrical side walls of the switch body away from the communication cable sockets; and a clamping small ball is fixedly connected with one end of the upright posts. According to the switch, communication cables can be clamped, a plurality of communication cables can be clamped efficiently and rapidly, the mounting and maintenance of the communication cables are ensured, the condition that the cables and the switch body are in poor contact within a pulling process is reduced, and normal use of the switch body is ensured.

Owner:安徽长泰科技有限公司

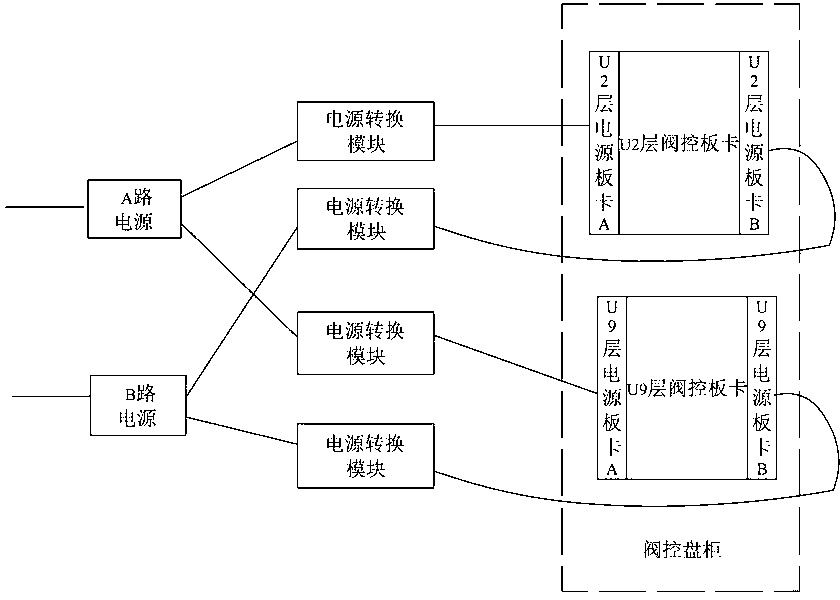

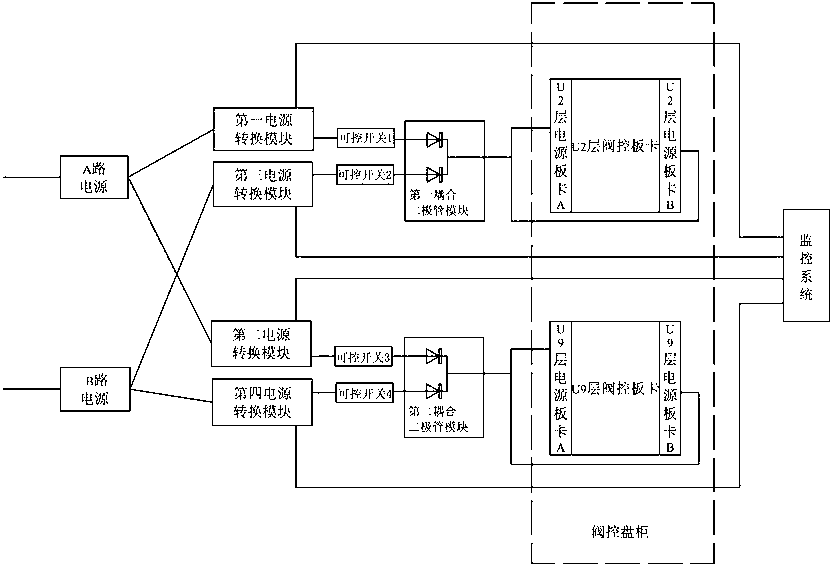

Converter valve control system inside direct current converter station

InactiveCN103166299AWarranty RepairSafe external power transmissionEmergency power supply arrangementsElectricityControl system

The invention relates to a converter valve control system inside a direct current converter station. An A route power source is connected with a first power source switching module and a second power source switching module, a B route power source is connected with a third power source switching module and a fourth power source switching module, the first power source switching module and the third power source switching module are respectively connected to an input end of a first coupling diode module through a first controllable switch and a second controllable switch, an output end of the first coupling diode module is connected to two power source board cards of a first valve control board card, and the second power source switching module and the forth power source switching module are respectively connected to two power source board cards of a second valve control board card. Each power source switching module is monitored by a monitoring system. When any rote of power source or any power source switching module has a fault, the converter valve control system can still transmit electricity to the outside safely and stably and the monitor system can emit warming to prompt the circuit or the power source switching module which has the fault so as to guarantee quickness and effectiveness of repair.

Owner:STATE GRID CORP OF CHINA +1

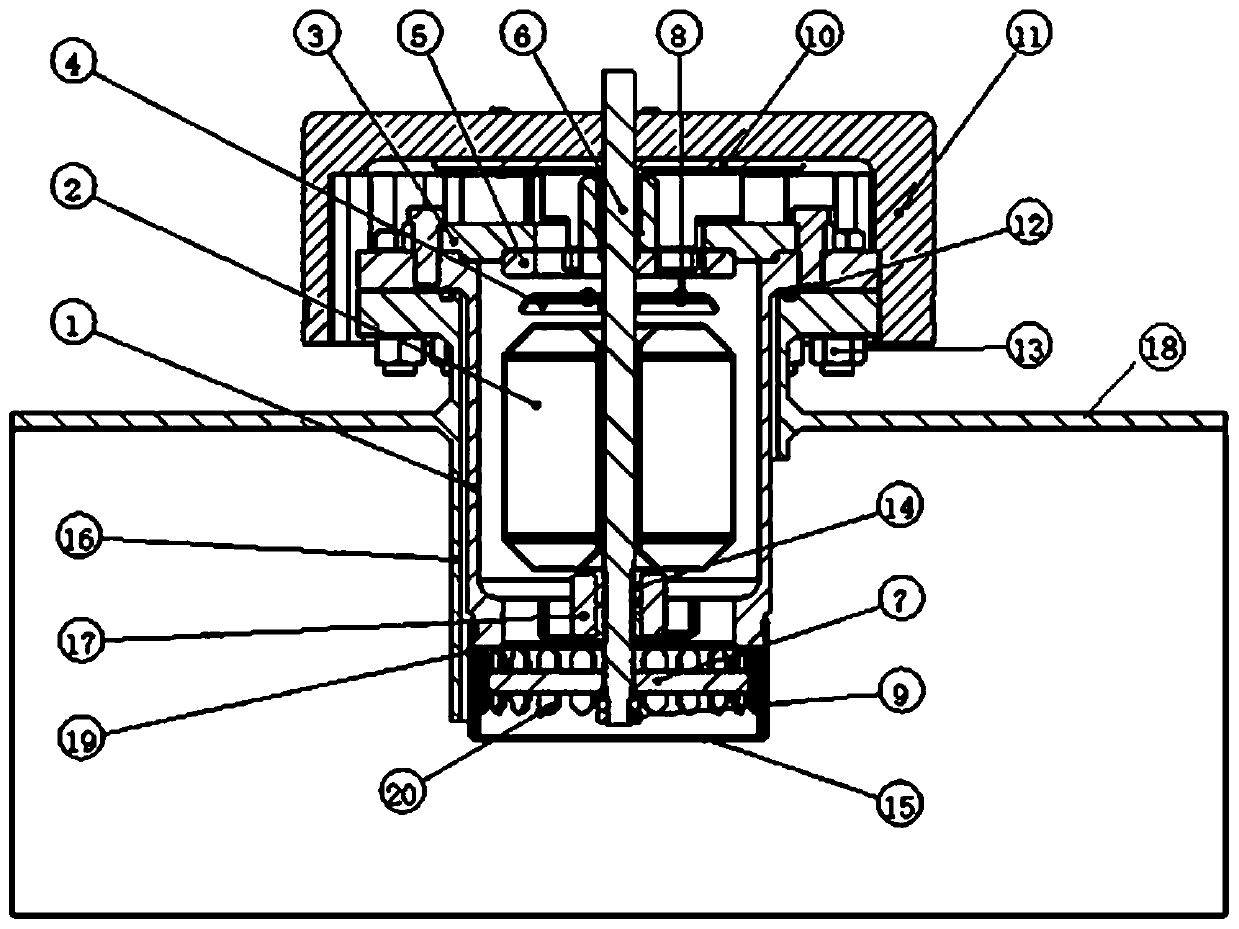

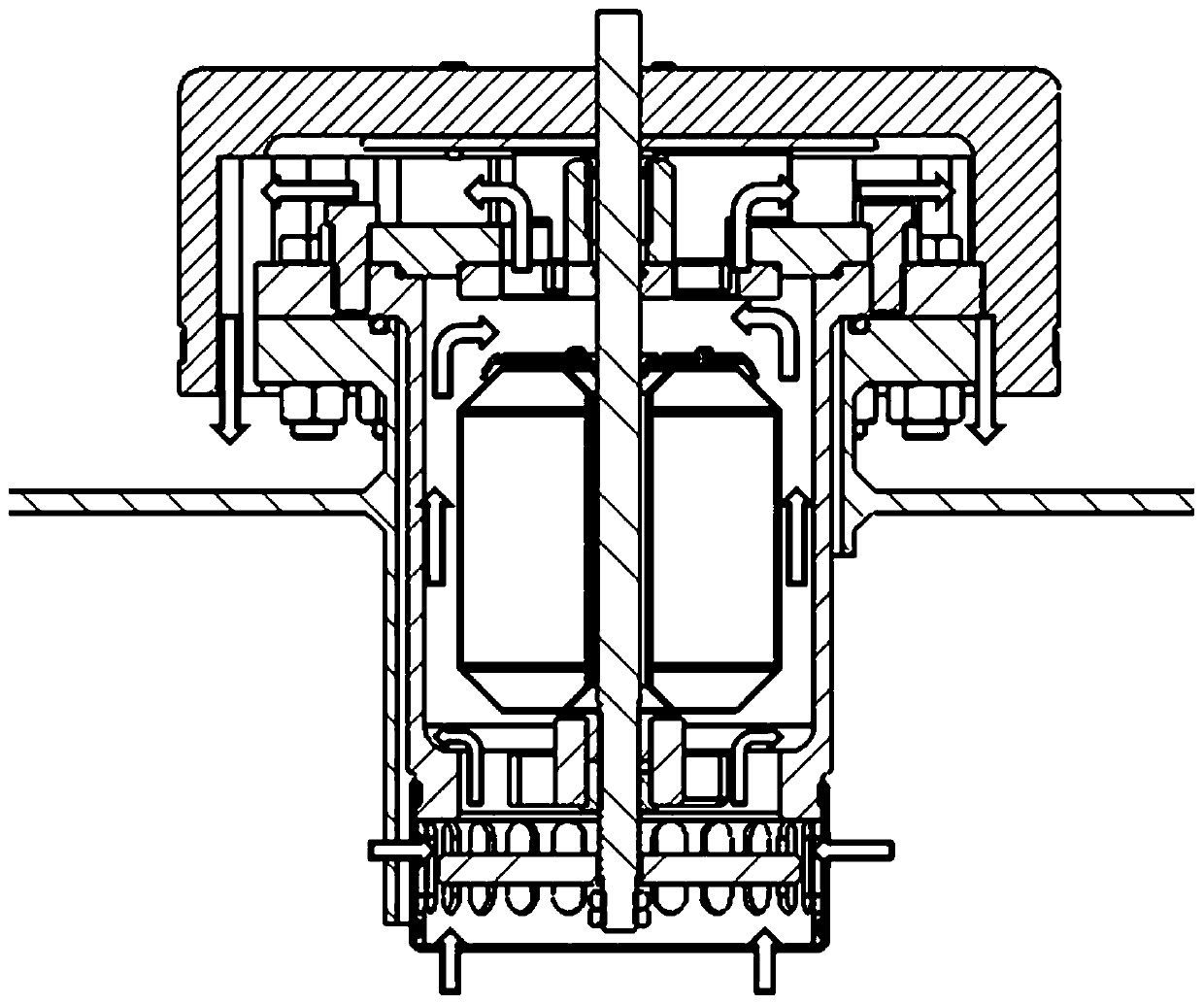

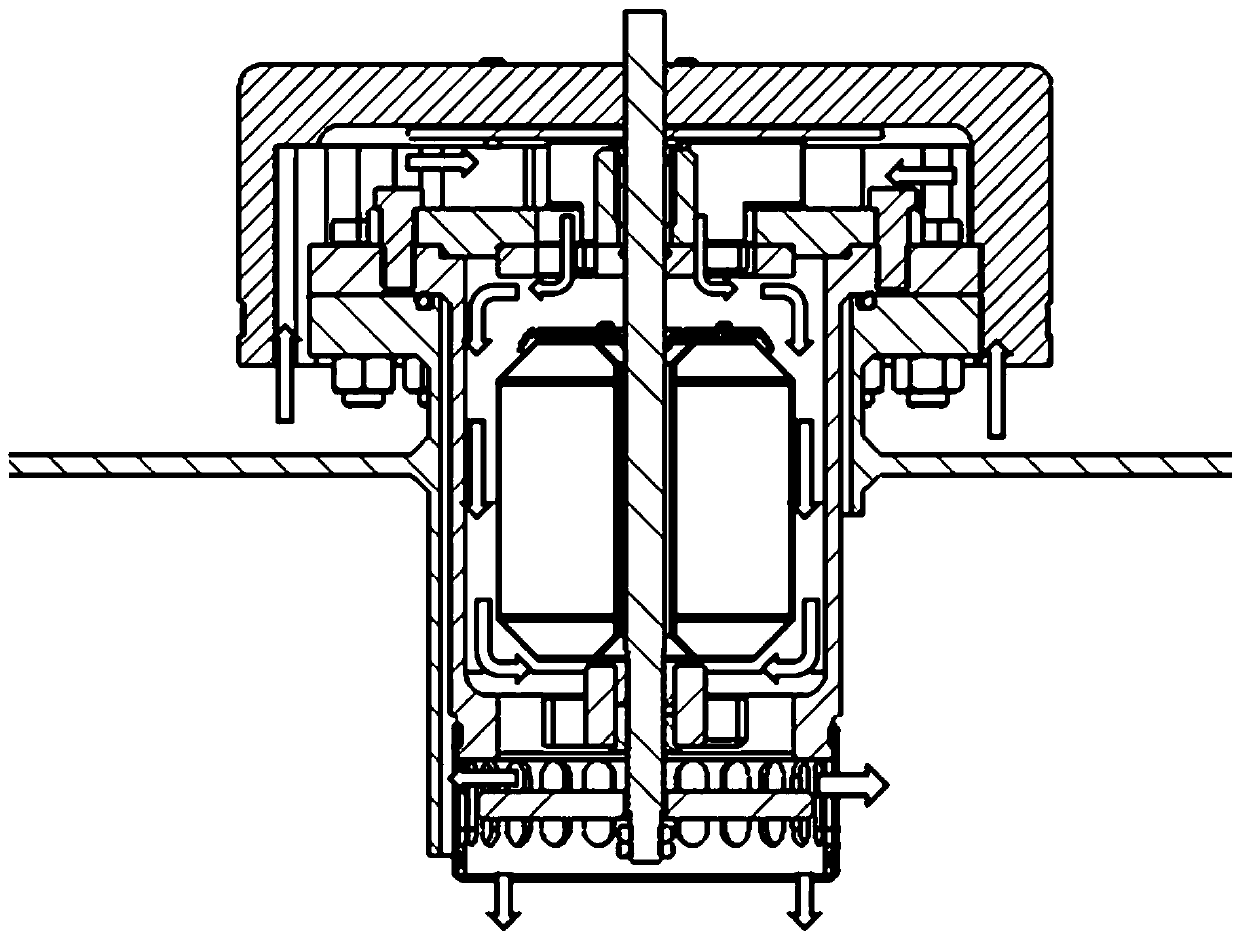

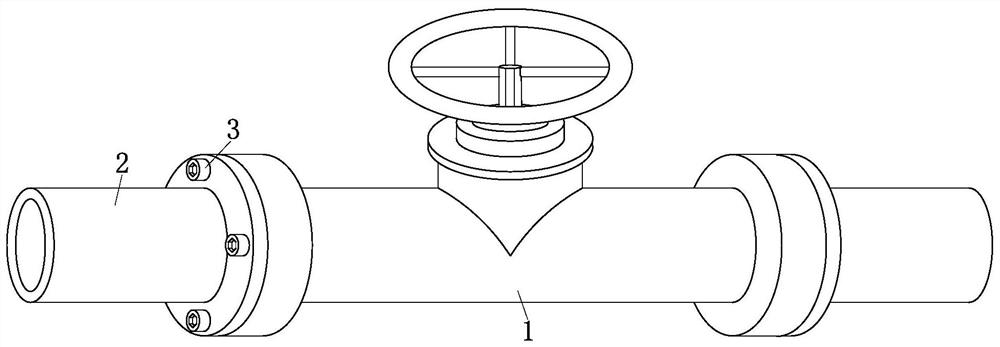

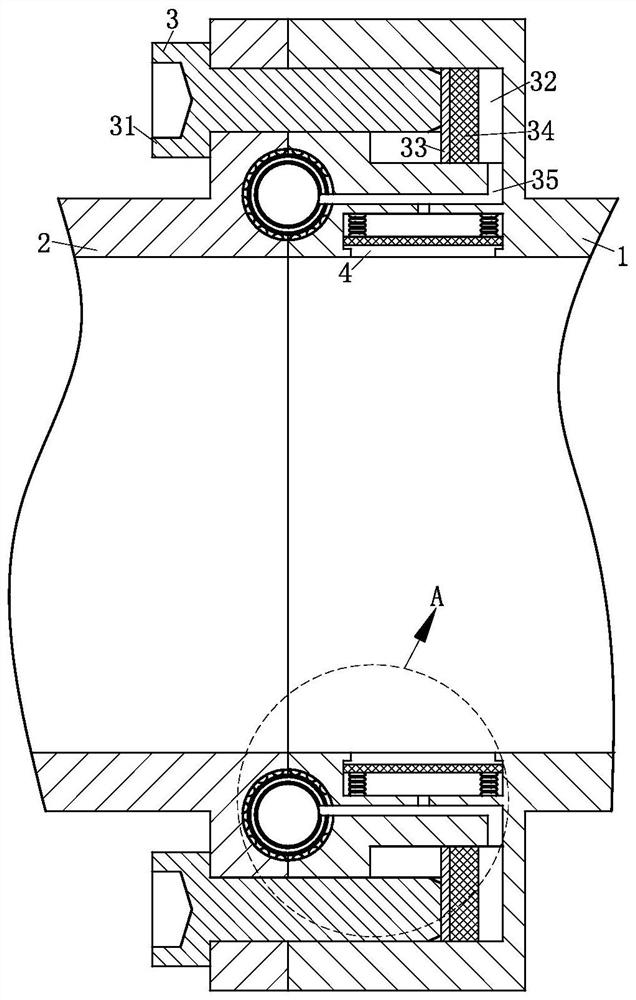

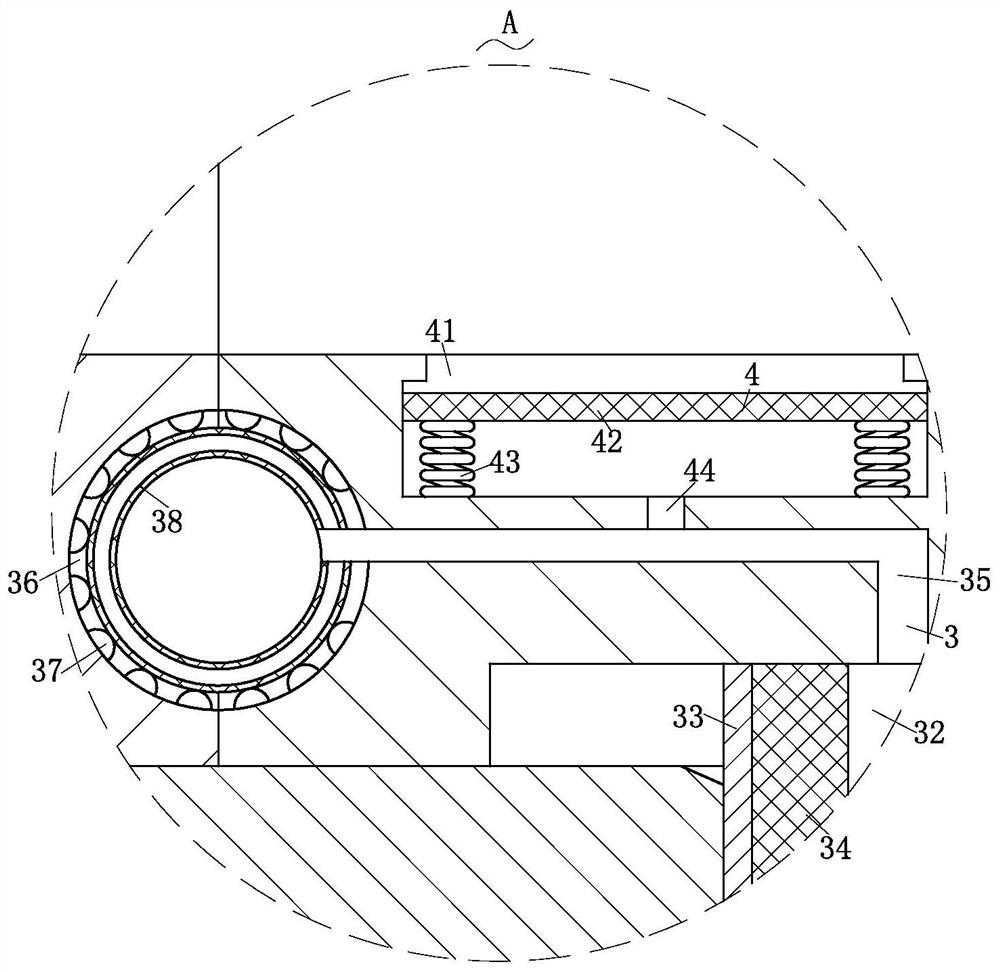

Anti-freezing exhaust valve

PendingCN110792813APromote repairPrevent freezingOperating means/releasing devices for valvesThermal insulationExhaust valveEngineering

The invention relates to an anti-freezing exhaust valve. The anti-freezing exhaust valve is fixedly arranged on a water conveying pipeline through a cylindrical housing and comprises a cylindrical valve body, a circular-ring-shaped valve cover and a valve shaft, wherein the cylindrical valve body is inserted into the housing and is fixedly connected with the housing; the circular-ring-shaped valvecover is fixed to the upper end face of the valve body and is provided with a central through hole; the valve shaft penetrates through the upper end face and the lower end face of the valve body; thetop end of the valve shaft is rotated; and a locking nut is fixed to the bottom end of the valve shaft. The anti-freezing exhaust valve further comprises an upper sealing exhaust mechanism arranged on the upper end face, a lower sealing exhaust mechanism arranged on the lower end face and a nut driving mechanism fixed to the inner wall of the lower part of the valve body. Compared with the priorart, the anti-freezing exhaust valve has the advantages of being isolated, convenient to maintain, comprehensive in function, capable of reducing heat loss, capable of preventing freezing and sundriesand the like.

Owner:SHANGHAI KARON VALVES MACHINERY

Device and method for hob wear monitoring of earth pressure balance shield machine based on image analysis

ActiveCN111043964BGuarantee the environmentGuaranteed replacementUsing optical meansImaging analysisStructural engineering

The invention discloses an earth pressure balance shield machine hob wear monitoring device and method based on image analysis. The hob cutter box assembly is opposite. The invention has the advantages of simple structure, convenient installation, clear field of vision, good protection effect and washing effect, and provides a stable and reliable structural basis for image analysis and processing. The on-line measurement of tool wear can be realized through the wear monitoring method, and at the same time through monitoring Video directly observes the hob status, which improves the safety, convenience, economy and reliability of hob wear monitoring.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Adjustable energy-conserving type multifunctional mixer

The invention provides an adjustable multifunctional stirrer, which belongs to a stirring device, and has an electromotor fixed on a transmission box, a main shaft of the transmission box is fixed with one end of a main shaft of a conical tube, and the other end of the main shaft of the conical tube is fixed with a blade seat on which a plurality of blades are arranged, an inner shaft and another inner shaft are respectively disposed in the main shaft of the transmission box and the main shaft of the conical tube, and the other end of the another inner shaft is fixed with an adjusting screw, an adjusting nut is arranged at the outside of the adjusting screw, the adjusting nut and an adjusting body are mounted together, the third shaft of each blade is arranged on a balance wheel, thus the stirrer has advantages of more stable transmission, low noise, high transmission efficiency, reduced energy consumption, stable supporting of the main shafts, high smoothness when in operation, extended service life, simple and convenient angle adjustment of blades, convenient maintenance, and ensuring the safety of personnel, and the stirrer can also be used for propelling slurries, and has a plurality of functions.

Owner:曹大渭

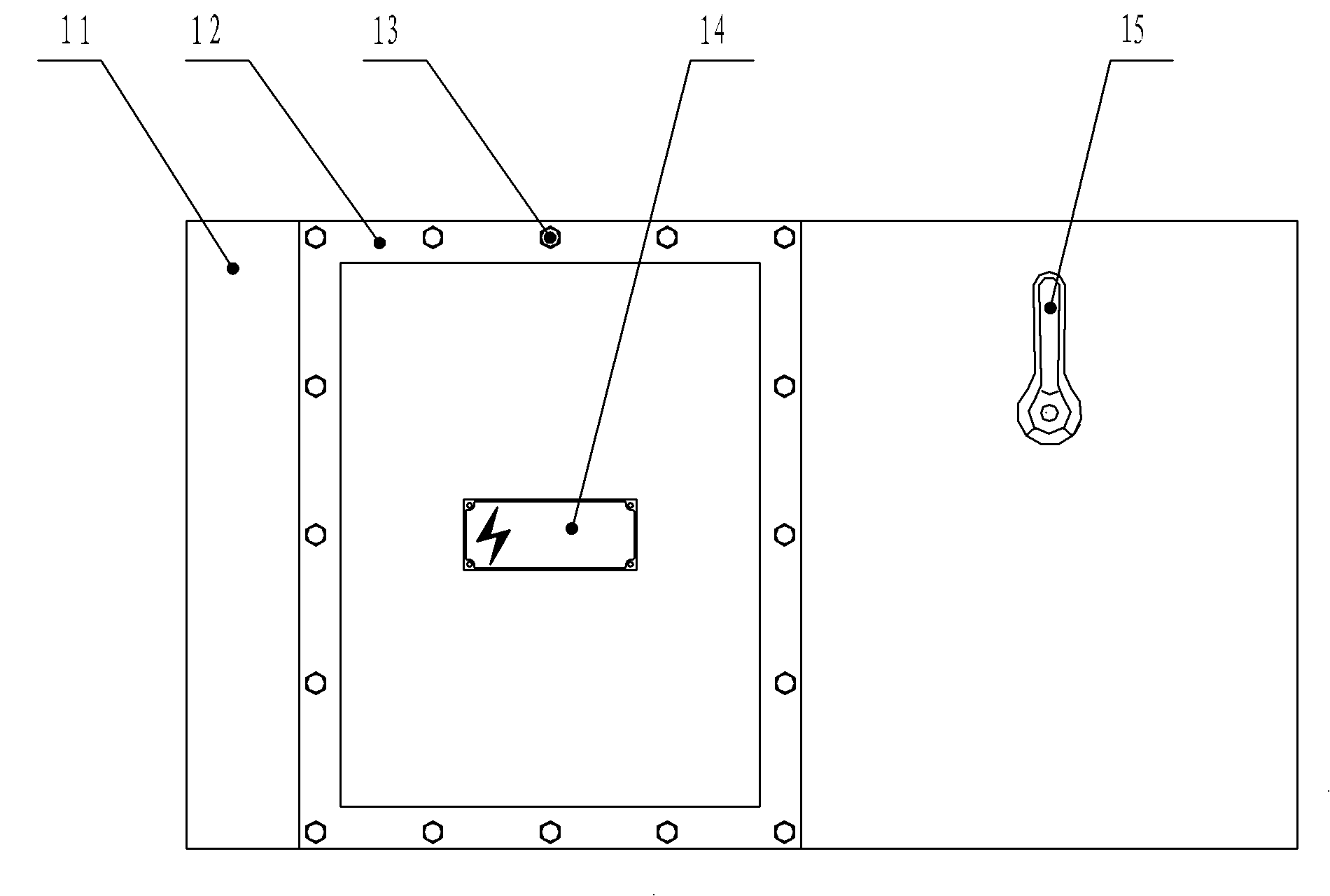

Convenient-to-store workbench for circuit board maintenance

ActiveCN111465206AReach normal storageAvoid erosionPrinted circuits repair/correctingLocking mechanismWorkbench

The invention relates to the field of circuit board equipment, particularly to a convenient-to-store workbench for circuit board maintenance. The technical problem to be solved by the invention is toprovide a convenient-to-store workbench for circuit board maintenance, wherein the convenient-to-store workbench can provide maintenance and storage integration and can prevent moisture erosion in humid weather. The convenient-to-store workbench comprises an arc-shaped work box, a welding gun hanging plate, a part placing groove, a damp-proof mechanism, a dustproof cover, a hinge frame, a clampingmechanism, a supporting column, a locking mechanism and an arc-shaped placing plate, wherein the part placing groove is formed in the outer top surface of the arc-shaped working box, the damp-proof mechanism is embedded in the arc-shaped working box and is positioned at the arc-shaped part, and the welding gun hanging plate is fixedly connected to the outer side wall of the arc-shaped work box and located beside the part placing groove. According to the invention, the convenient-to-store workbench provides maintenance and storage integration and can prevent moisture erosion in humid weather.

Owner:合肥森岑汽车用品有限公司

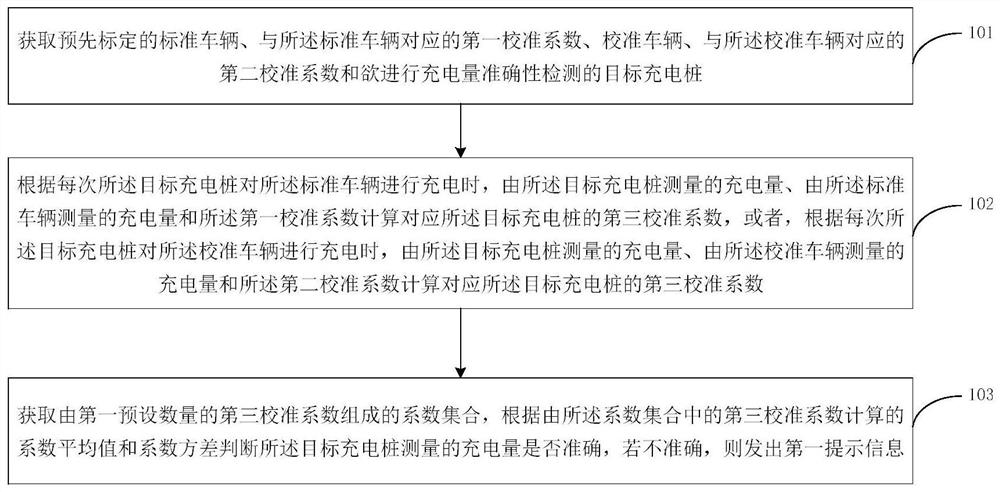

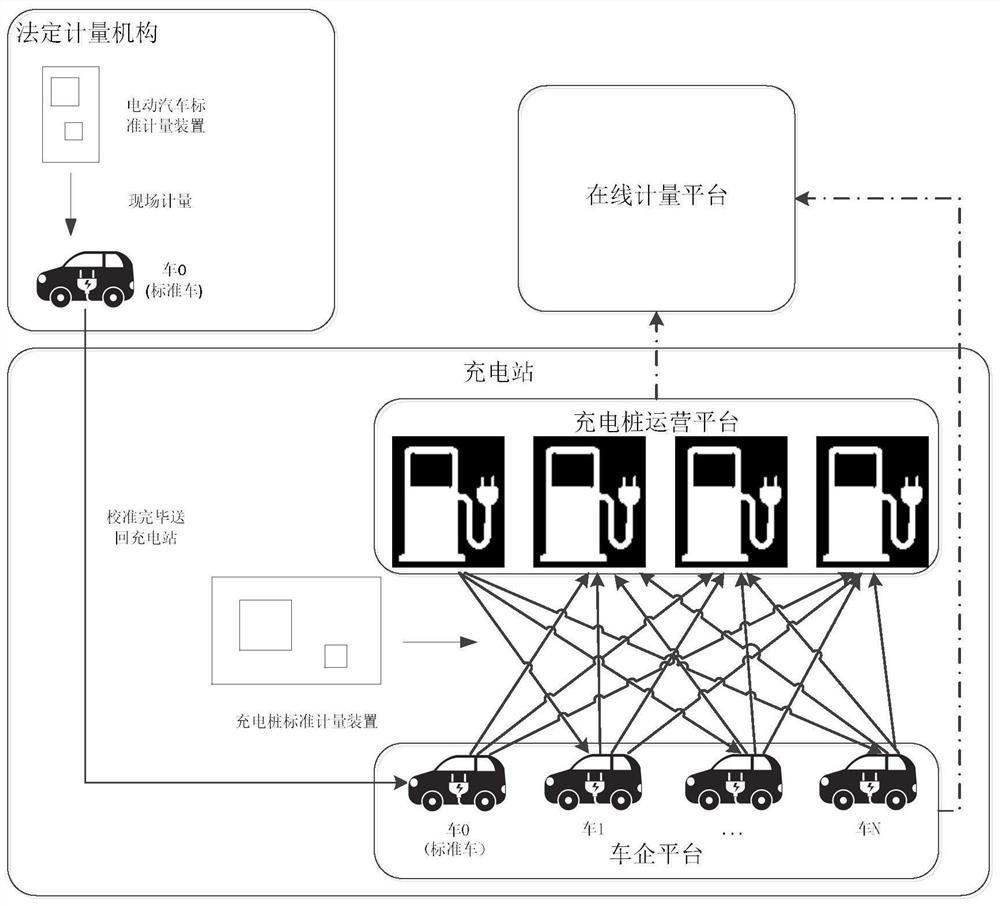

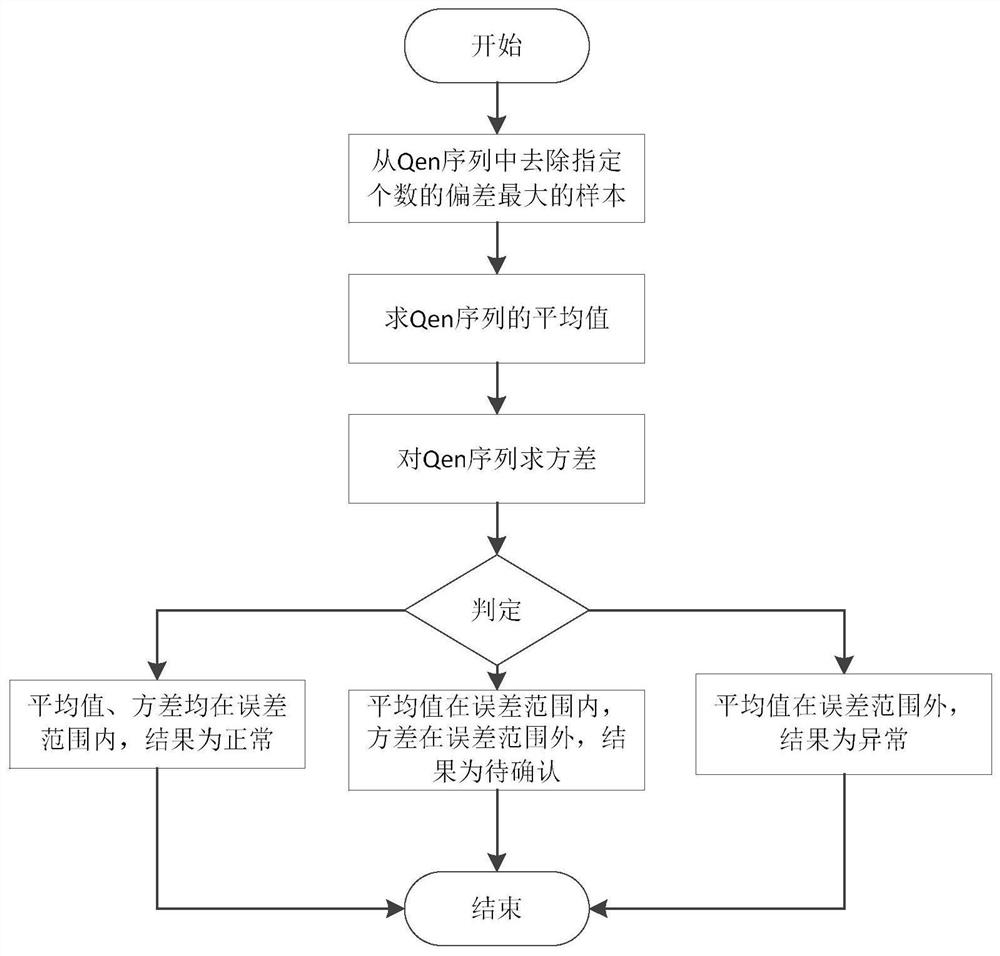

A method and device for online detection of the charging accuracy of charging piles

ActiveCN110682820BImprove accuracyWarranty RepairCharging stationsElectric vehicle charging technologyComputational physicsControl theory

The embodiment of the present invention discloses a method and a device for online detection of the accuracy of the charging amount of the charging pile. The method obtains the charging amount measured by the target charging pile online during the charging process of the target charging pile to the standard vehicle or the calibration vehicle. The third calibration coefficient of the target charging pile is calculated from the charging amount and the first calibration coefficient or the second calibration coefficient. Whether the charging amount measured by the target charging pile is accurate is judged by the coefficient average value and coefficient variance of the third calibration coefficient. The method uses the charging amount detected during the use of the charging pile to judge the accuracy of the charging capacity measurement, and the judgment result truly reflects the accuracy of the charging capacity measurement during the use process of the charging pile, and ensures that the maintenance of the charging pile can be improved. The accuracy of the charging capacity measurement during the use of the charging pile. On the other hand, this detection method of obtaining the charging amount of the charging pile online does not need to test the accuracy of the measurement of the charging pile one by one, and the detection efficiency is high.

Owner:POTEVIO INFORMATION TECH CO LTD

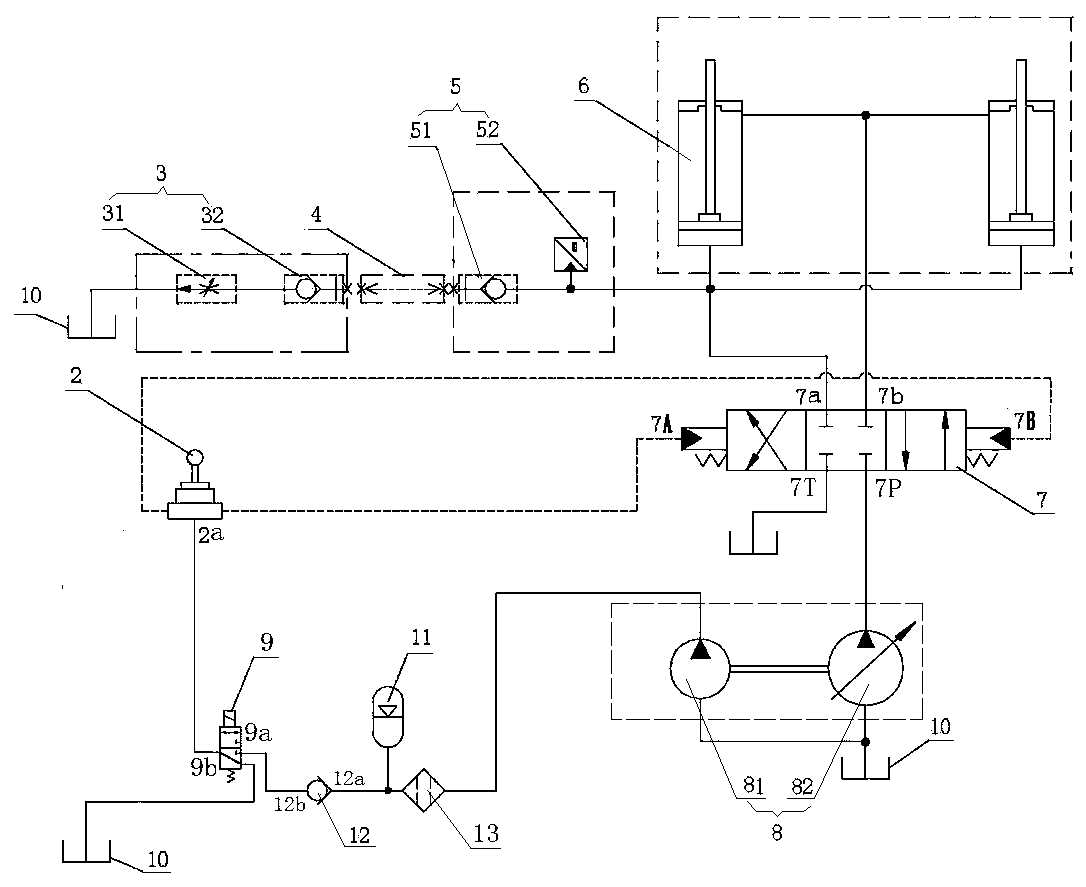

Emergency unloading device of hydraulic actuating element of engineering machine

ActiveCN110608207AGuaranteed daily maintenanceGuaranteed maintenanceFluid-pressure actuator safetyServomotor componentsElectricityFuel tank

The invention discloses an emergency unloading device of a hydraulic actuating element of an engineering machine and belongs to the technical field of engineering machines. The emergency unloading device comprises an unloading connector connected with the hydraulic actuating element of the engineering machine and an unloading speed controller connected with an oil tank. A detachable connection pipe is connected between the unloading connector and the unloading speed controller. The unloading speed controller comprises a speed control throttle valve and a first pressure measuring connector which are connected in series. The unloading connector comprises a second pressure measuring connector and a pressure sensor which are connected in series. The connection pipe is arranged between the first pressure measuring connector and the second pressure measuring connector. The emergency unloading device of the hydraulic actuating element of the engineering machine can solve the problem that since the whole machine cannot be electrified or a pilot unlocking electromagnetic valve is damaged or an energy accumulator is damaged, an existing hydraulic actuating element of the engineering machinecannot achieve unloading.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

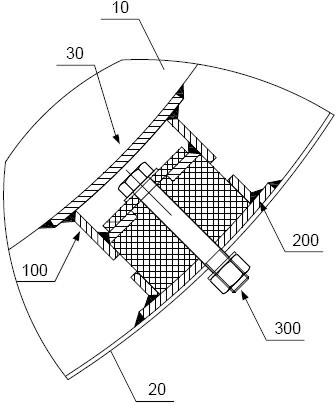

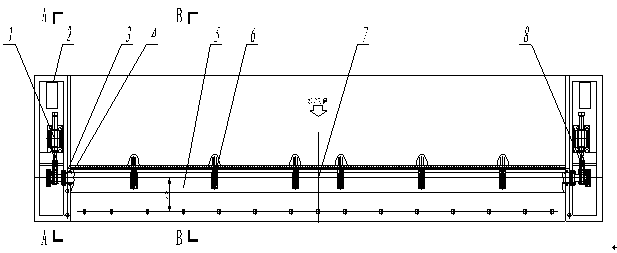

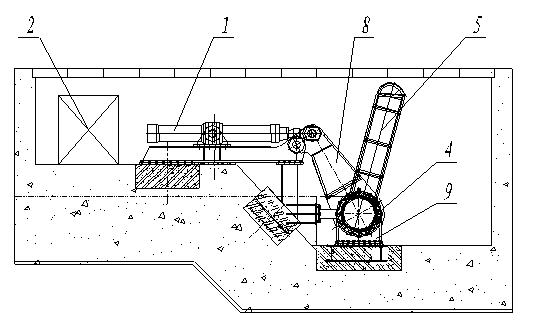

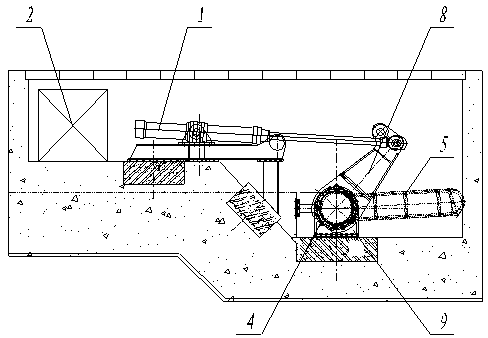

Bottom shaft driven flap gate

ActiveCN102704446BGood water sealing effectSimple structureBarrages/weirsWater brakeStructural engineering

The invention discloses a bottom shaft driven flap gate, and aims to provide the bottom shaft driven flap gate capable of improving a water sealing effect at a middle support and eliminating influence of bottom shaft expansion caused by linear expansion due to temperature variation and stress deformation on a pier penetrating water seal and a gate flap. The technical scheme provided by the invention is that the bottom shaft driven flap gate comprises a driving device, a driving arm and a bottom shaft connected with a gate flap, wherein the bottom shaft is arranged on the middle support of the bottom shaft; the bottom shaft is connected in sections through a connecting device; the middle support of the bottom shaft is in an open structure; and the bottom water seal is in continuous linear contact with the bottom shaft. The bottom shaft driven flap gate has the beneficial effects that the middle support is in the open structure; the bottom water seal can be in continuous linear contact with the bottom shaft, the water seal effect of a bottom water stop is greatly improved, the support can be maintained in the working state that water is stopped in front of the gate and no water exists behind the gate, the middle connecting device of the bottom shaft is a synchronous power transmission and gap telescopic connecting device, and the influence of length expansion of the bottom shaft and the gate flap caused by the temperature variation and the stress change on the pier penetrating sealing effect of the bottom shaft and the engineering operation safety is eliminated. The gate has the advantages of simple and compact structure, good water sealing effect, convenience in mounting and maintenance and capability of guaranteeing the engineering operation safety.

Owner:SHANDONG SURVEY & DESIGN INST OF WATER CONSERVANCY

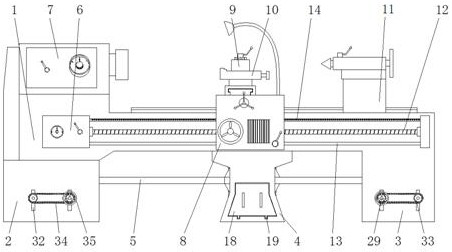

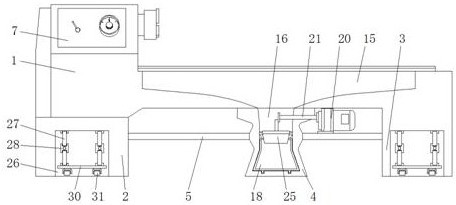

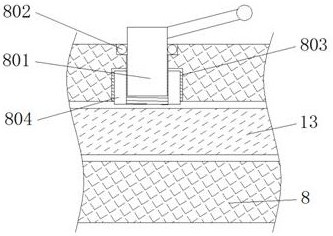

A safe and efficient lathe

ActiveCN110587368BEasy to moveEasy to guarantee movingMaintainance and safety accessoriesPressesStructural engineeringMechanical engineering

The invention discloses a safe and high-efficiency lathe, which comprises a bed, a first bed foot is fixedly installed at the lower left corner of the bed, a supporting column foot is arranged under the middle part of the bed, and the front left side of the bed is A feed box is provided on the side, a bed saddle is provided on the outside of the middle part of the bed, and a screw rod is connected to the right side of the feed box. There is a concentrating plate, the top end of the shaft is connected with a connecting plate, the bottom end of the connecting rod is connected with a pressure plate, the inside of the first foot of the bed is provided with an empty groove, and the bottom end of the support rod is connected with a connecting plate , a mounting plate is provided under the support rod, and an adjustment slot is provided on the outside of the top of the adjustment rod. The safe and high-efficiency lathe is convenient to ensure the collection and treatment of waste, to ensure the efficient operation of the lathe and the safety of work, and to facilitate the movement of the lathe to ensure the progress of repairs and other work.

Owner:湖南信本精密机械有限公司

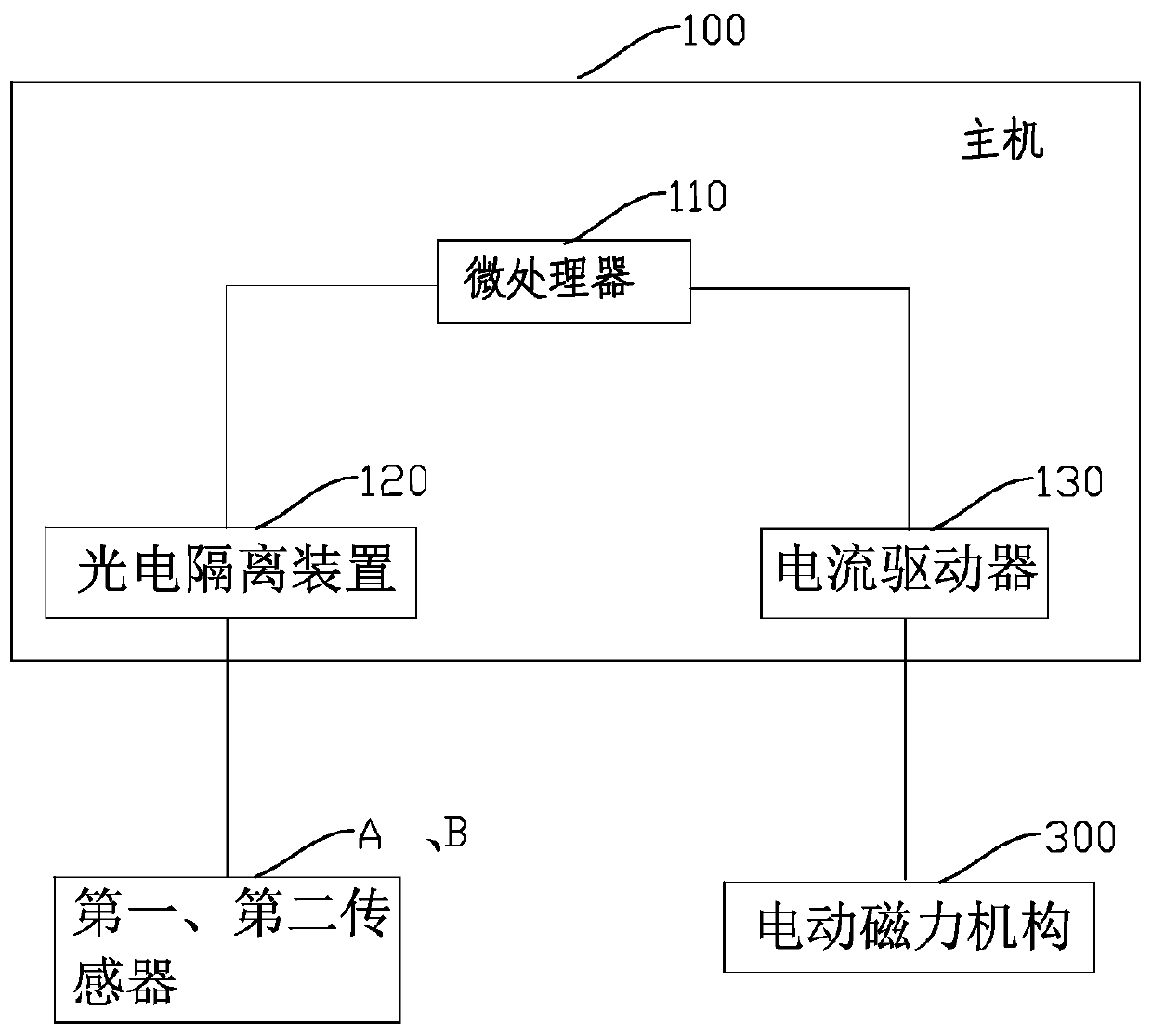

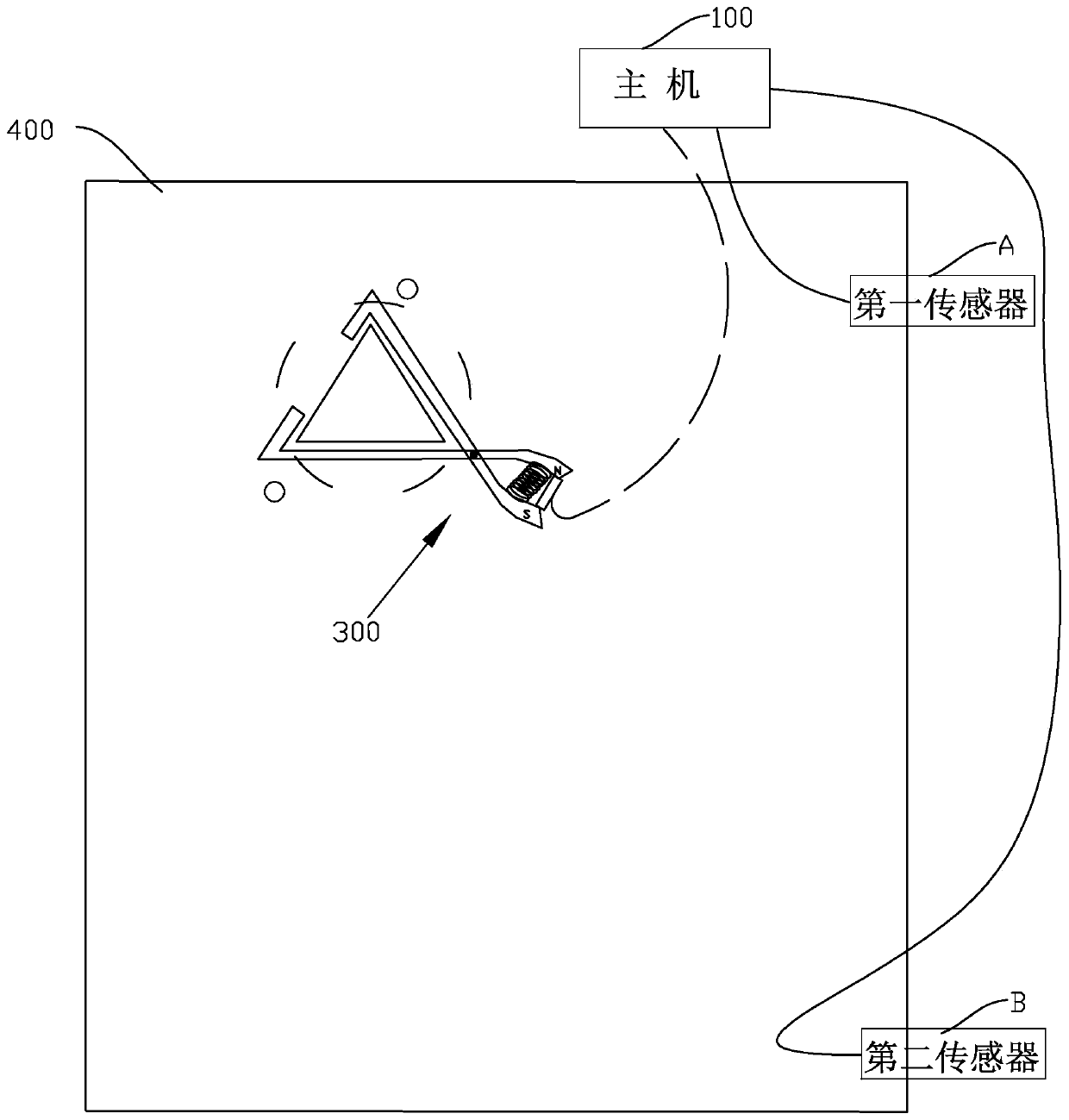

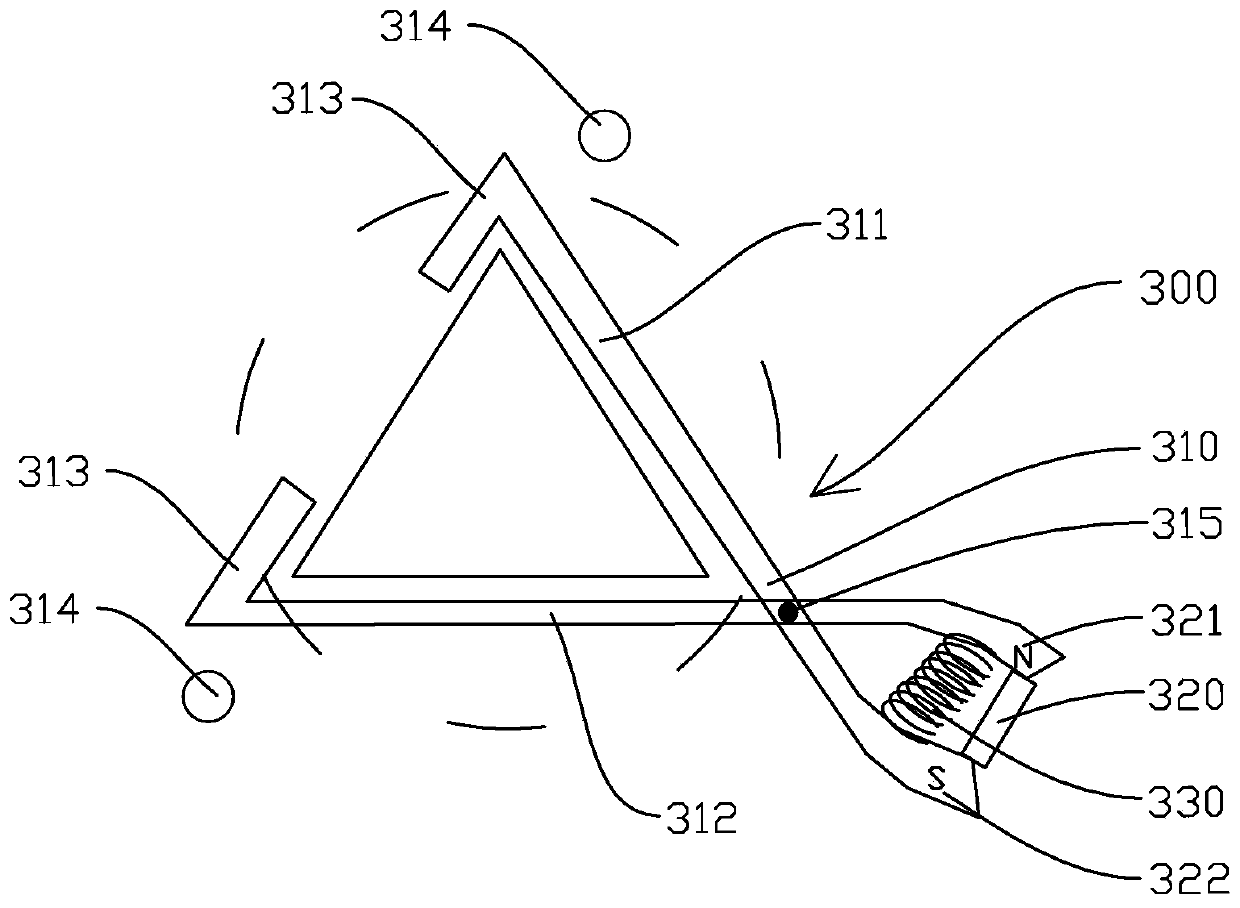

Elevator landing door lock protective device and elevator landing door

PendingCN111285231APlay a protective effectEnsure safetyBuilding liftsControl signalMechanical engineering

The invention discloses an elevator landing door lock protective device and an elevator landing door. The elevator landing door lock protective device comprises a mainframe, a first sensor, a second sensor, and an electric magnetic mechanism, wherein the first sensor and the second sensor are separately mounted at upper and lower ends of the elevator landing door for detecting the position of an elevator car, and transmitting a detected signal to the mainframe; the electric magnetic mechanism is arranged on a landing door lock, and is used for receiving a control signal transmitted by the mainframe and realizing opening or closing of the landing door lock according to the control signal; while the elevator is in a normal operation state, the device can achieve the protective effect on thelanding door lock, so that the landing door lock can be ensured to be opened while the elevator car is on a set position; and the landing door lock cannot be opened while the elevator is on an unset position. Safety of rescue, maintenance or staff in the car is ensured.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST

A switch for communication engineering

ActiveCN109451369BIngenious structural designEasy to useSelection arrangementsStructural engineeringMechanical engineering

The invention discloses a switch for communication engineering, which comprises a switch body. The switch body is provided with a plurality of card slots on the top edge of the side wall near the communication cable socket. The top of the switch body is provided with a horizontal groove, and the grooves communicate with multiple The card slot, the limit rod is fixedly clamped in the groove, and a plurality of limit blocks are fixedly connected on the side wall of the limit rod, wherein each limit block is clamped in the corresponding card slot, and the limit rod Both ends are fixedly connected with tough plastic belts, and the switch body is fixedly connected with a horizontal column on a symmetrical side wall away from the communication cable socket, and one end of the column is fixedly connected with a clamping ball. The present invention can realize the clamping of the communication cables, and can efficiently and quickly clamp multiple communication cables, so as to ensure the installation and maintenance of the communication cables, and also reduce the possibility of poor contact between the cables and the switch body during the pulling process. In this case, the normal use of the switch body is guaranteed.

Owner:安徽长泰科技有限公司

A method and system for predicting the center zone temperature of a blast furnace throat cross temperature measuring device

ActiveCN106227699BGuaranteed to run smoothlyAccurate judgmentChecking devicesComplex mathematical operationsThroatPre treatment

The invention provides a method and system for predicting the center zone temperature of a blast furnace throat cross temperature measuring device. The method includes: collecting process variables of the blast furnace throat temperature related to the center zone temperature of the blast furnace throat cross temperature measuring device; and analyzing the collection process. Variables are preprocessed to remove noise peak jump data and high-frequency noise data; the central zone temperature prediction model is used to predict the central zone temperature of the blast furnace throat cross temperature measurement device. The system includes: acquisition module, preprocessing module, and prediction module. The present invention predicts the future temperature output of the central zone of the cross temperature measuring device through the historical data of the selected input and output of the central zone temperature prediction model, can accurately express the relationship between the temperature output and the control input, and can ensure that the cross temperature measurement Repair or damage of the temperature sensor in the center of the device will provide a basis for blast furnace operators to accurately judge and timely adjust the upper and lower systems of the blast furnace, thereby achieving stable, efficient, safe and smooth operation of the blast furnace.

Owner:NORTHEASTERN UNIV LIAONING

A pipeline valve Internet of things monitoring system

ActiveCN110307391BAchieve sealingAct as a preliminary sealSleeve/socket jointsStands/trestlesImpellerWater leakage

Owner:马治强

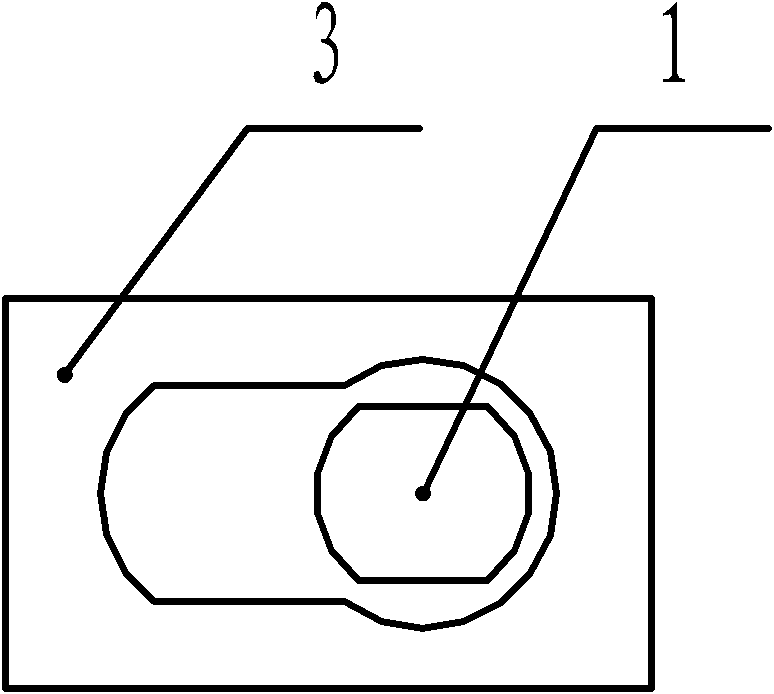

A maintenance method for an all-electric melting furnace

ActiveCN109631588BAvoid economic lossWarranty RepairLinings repairGlass furnace apparatusBrickHigh pressure

The invention discloses a maintaining method for an all-electric melting kiln. The maintaining method for the all-electric melting kiln comprises a hot maintaining method and a cold maintaining method. The hot maintaining method comprises the steps that (1), a main electrode load of the all-electric melting kiln is stopped, a starting electrode and a liquid flowing hole are adjusted to be in a heat preservation state, and when the temperature of the upper bath wall is lowered to 95-105 DEG C, a damaged bath wall brick or transition brick is locally repaired; (2), the length of a molybdenum electrode in the all-electric melting kiln is observed and measured, and the molybdenum electrode is replaced or continues to be kept according to the damage degree of the molybdenum electrode so as to be in the optimal working state; and (3), the main electrode load is adjusted to a high-voltage gear till the temperature in a bath rises to 850-900 DEG C, and a main melting electrode is added for further energized heating till the daily production working condition requirements are met. According to the maintaining method for the all-electric melting kiln, it can be guaranteed that the all-electric melting kiln can recover such as new without needing to be completely pushed down when the life of the all-electric melting kiln is end, corrosion of molten glass on corundum bricks is relatively and greatly reduced, the service life of the kiln is prolonged, the production cost is effectively reduced, safety and environmental friendliness are achieved, and energy conservation and consumption reduction are achieved.

Owner:王贵江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com