Multiloop combination-switch lever-type mechanical interlocking mechanism

A combination switch and interlocking mechanism technology, applied in the direction of air switch parts, etc., can solve the problems of complicated installation, loss of interlocking effect, and inability to open the large cover of the main cavity, and achieve the effect of ensuring safe operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

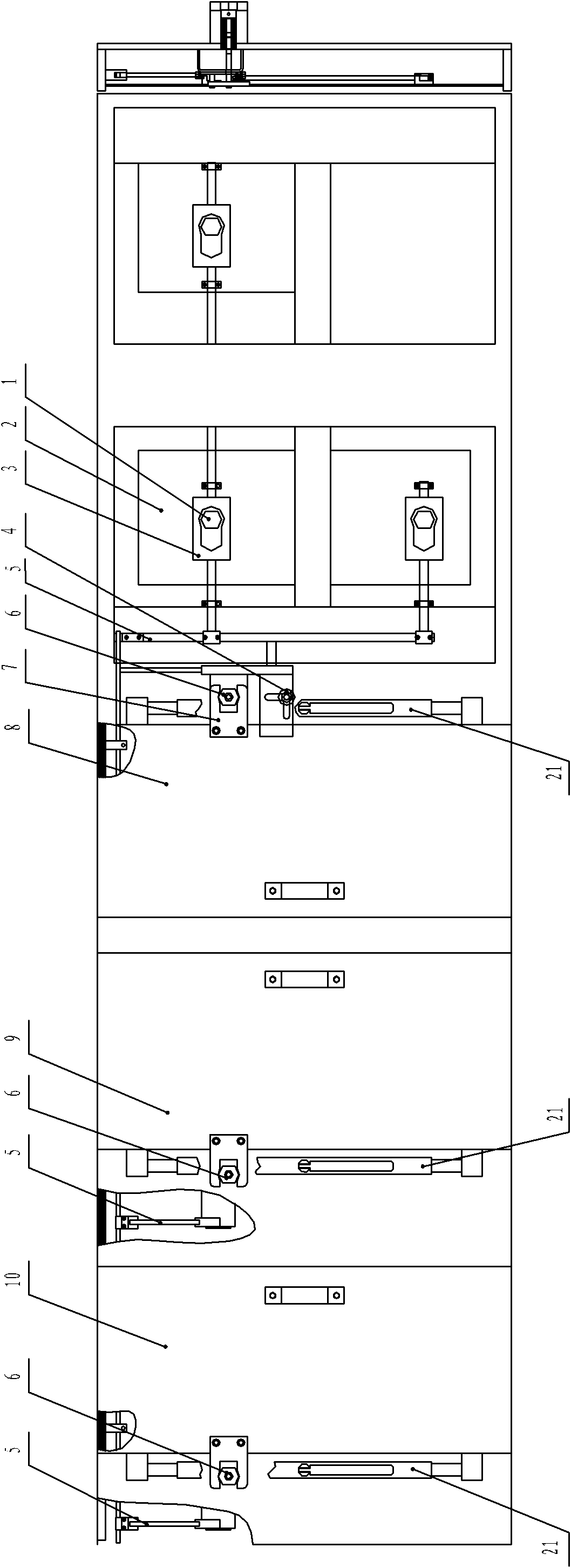

[0011] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

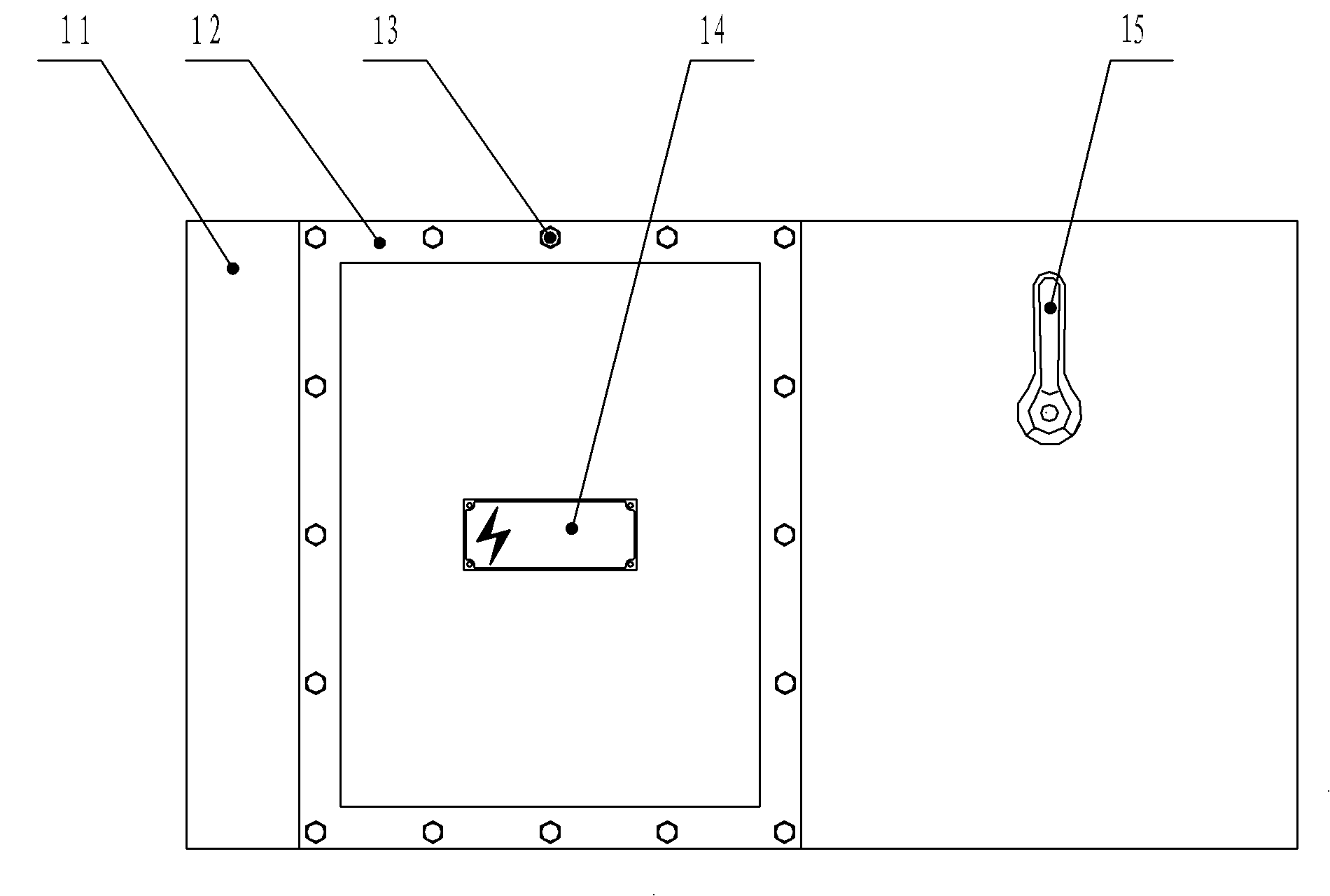

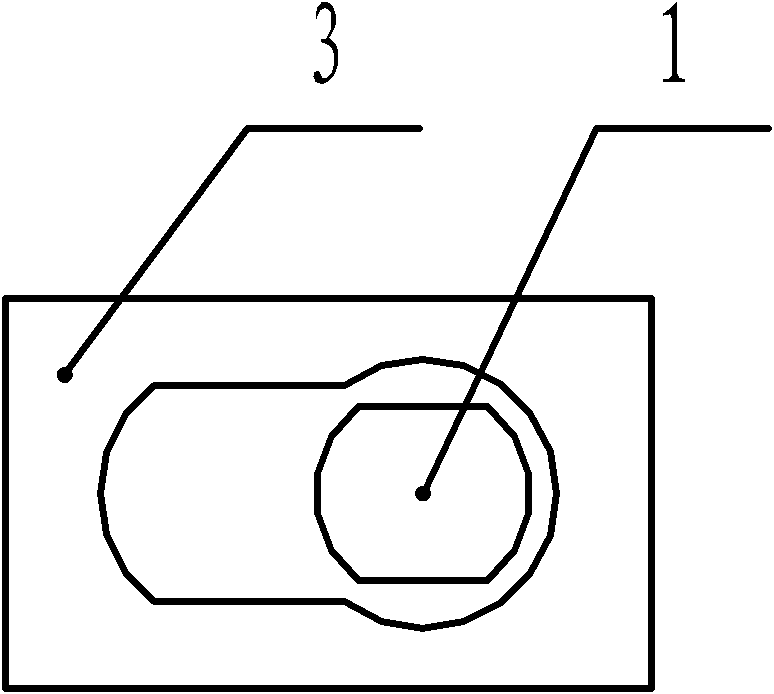

[0012] Such as figure 2 As shown, the multi-circuit combination switch lever mechanical interlock mechanism of the present invention includes a disconnector switch main shaft 1, a disconnector switch 2, an interlock slider 3, a first lever rotary mechanism 4, a connecting rod 5, and a second lever rotary mechanism 6 , the interlocking block 7, the first main cavity cover 8, the second main cavity cover 9, the third main cavity cover 10, the door opening mechanism 21, the isolating switch main shaft 1 is fixed on the isolating switch 2 and passes through the interlocking slide Block 3, the interlock slider 3 is slidably connected with the connecting rod 5, the second lever rotary mechanism 6 is slidably connected with the interlock block 7, the first lever rotary mechanism 4 is slidably connected with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com