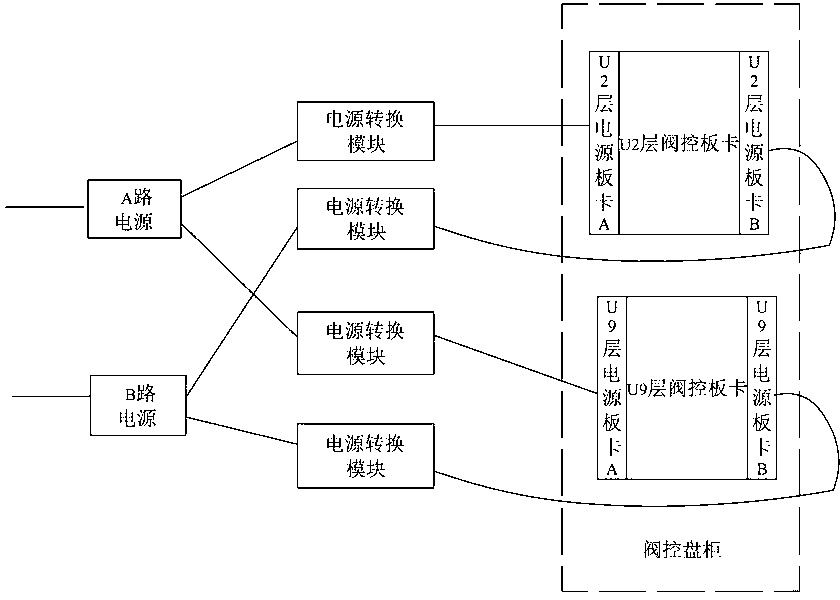

Converter valve control system inside direct current converter station

A DC converter station and control system technology, applied to electrical components, emergency power supply arrangements, circuit devices, etc., can solve problems such as abnormalities in the control system of converter valves, affecting maintenance efficiency, and disturbances in DC transmission systems, so as to ensure maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

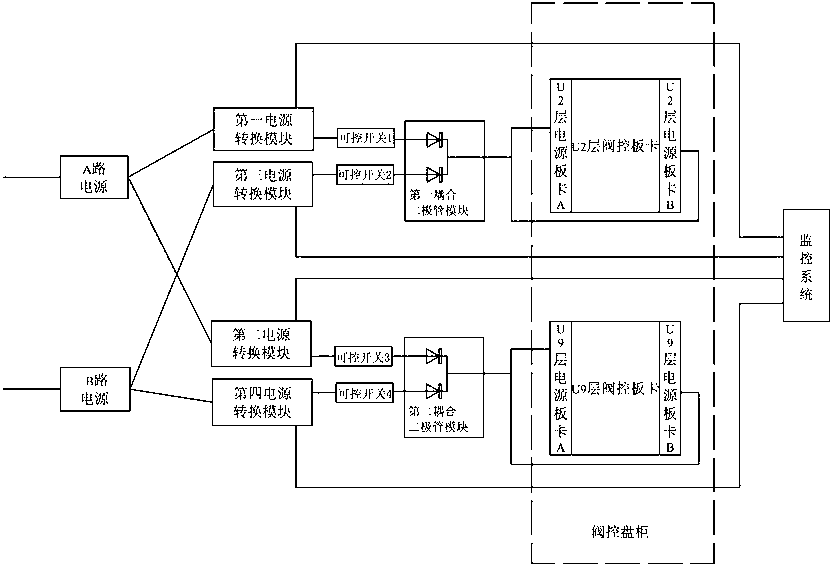

[0016] To facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] refer to figure 2 , a control system for a converter valve in a DC converter station, comprising: a power supply of A circuit, a first valve control board and a second valve control board of a B circuit power supply, first to fourth power conversion modules, first to fourth Controllable switch, first and second coupling diode modules.

[0018] In this embodiment, both the A-channel power supply and the B-channel power supply are 110V power supplies, the four power conversion modules are all 110 / 24V DC / DC power conversion modules of the same model and parameters, and the models of the coupling diode modules are all QUINT-DIODE / 40 , which is equivalent to two diodes, the input terminals of the two diodes are not connected, and the output terminals are connected in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com