A maintenance method for an all-electric melting furnace

An all-electric melting and kiln technology, applied to electric furnaces, furnaces, furnace materials, etc., can solve the problems of long repair period, increased energy consumption, and poor material quality, so as to avoid economic losses and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a maintenance method for the upper pool wall in an all-electric melting furnace, comprising the following steps:

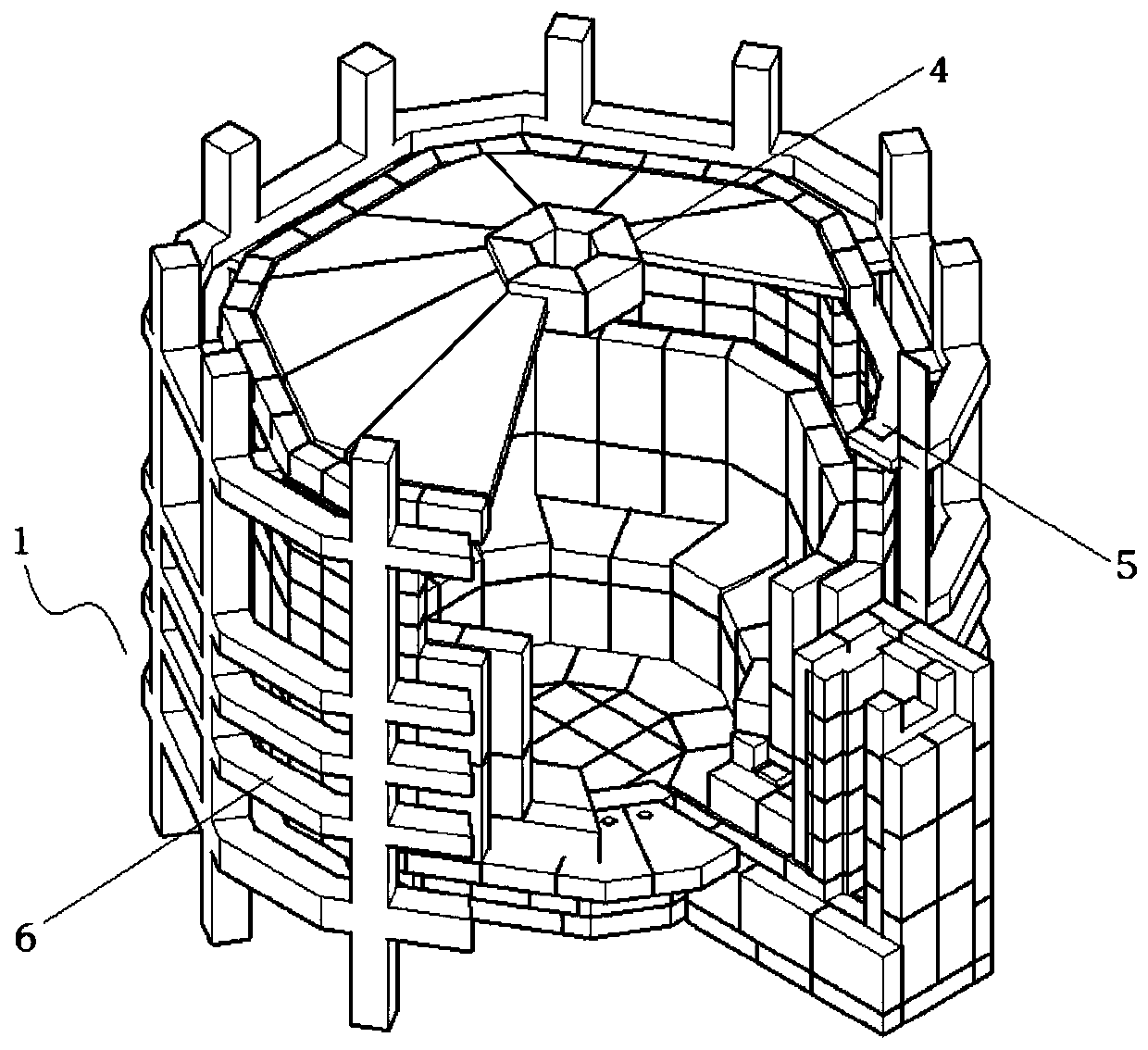

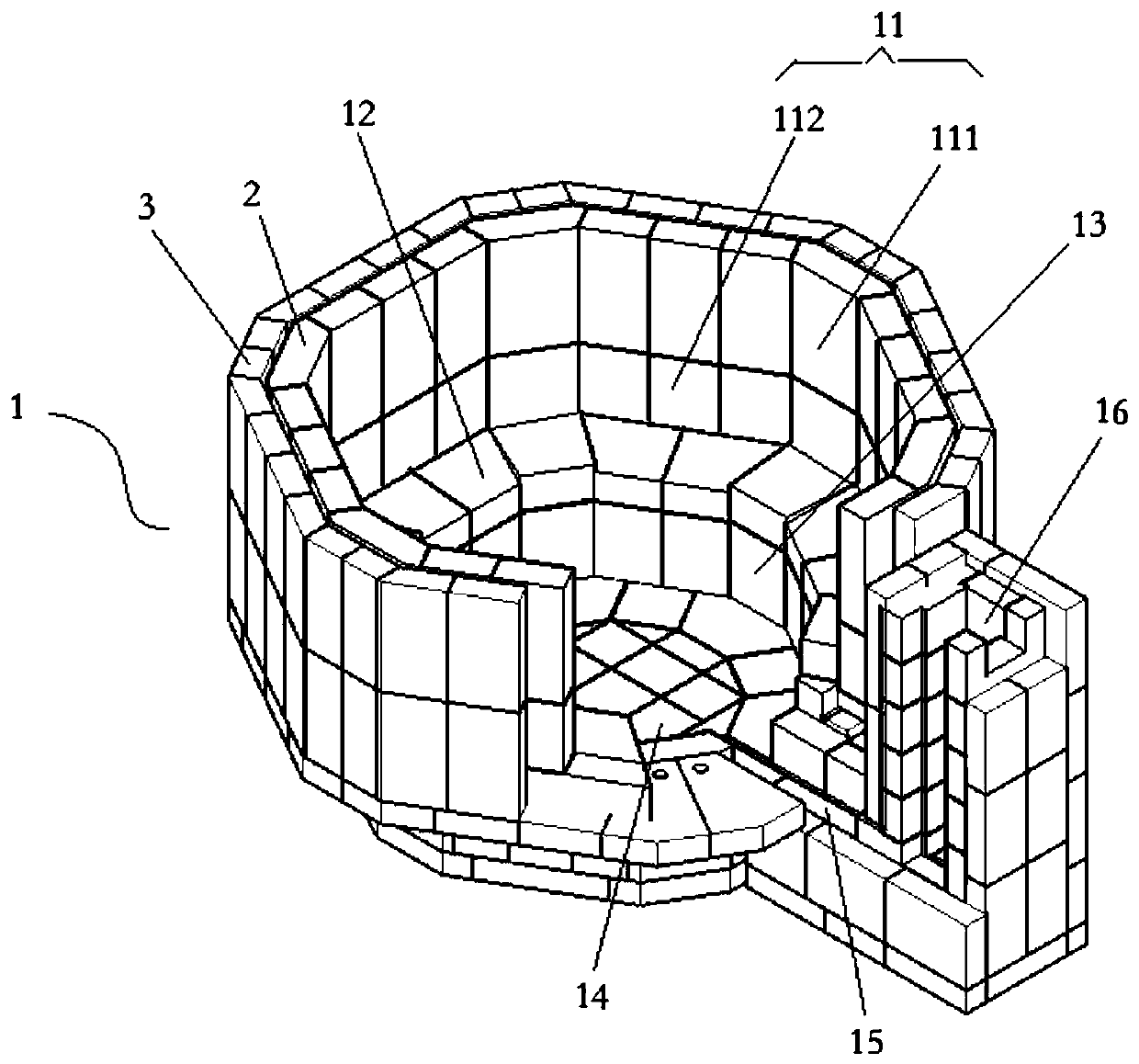

[0038] (1) if Figures 1 to 2 As shown, at first, support iron 5 is added on the column, and the dome 4 is separated from the furnace body 1, and the cost of making the dome 4 can be saved when the furnace body 1 is disassembled for maintenance, so that one-time investment can benefit multiple times, saving Time, manpower, material resources and financial resources, wherein the body of furnace comprises an upper pool wall 11, a lower pool wall 13 and a transition brick 12 arranged between the upper pool wall 11 and the lower pool wall 13, and the upper pool wall 11 is composed of the upper first upper pool wall 111 and the lower second upper pool wall 112, the end of the first upper pool wall 111 is located below the molten silicate liquid level in the full electric melting furnace, the first upper pool wall 111 and the second upper p...

Embodiment 2

[0043] The present invention provides a maintenance method for the transition brick 12 in an all-electric melting furnace, comprising the following steps:

[0044] (1) Firstly add supporting iron 5 on the column to separate the dome 4 from the furnace body 1, so that when the furnace body 1 is disassembled for maintenance, it is not necessary to invest in the cost of making the dome 4 again, so as to achieve multiple benefits from one investment and save time, human, material and financial resources;

[0045] (2) Shut down the main electrode load of the all-electric melting furnace, and adjust the starting electrode and the liquid flow hole to the state of heat preservation, heat preservation for 6 days, and when the temperature of the upper pool wall 11 drops to 95°C, start to treat the affected Replace the damaged upper pool wall brick 11 and transition brick 12, and reserve a gap of 5 cm between the new corundum brick 2 and the insulation brick 3 to fill the corundum powder...

Embodiment 3

[0049] The present invention provides a method for maintaining the lower pool wall 13 of an all-electric melting furnace, comprising the following steps:

[0050] (1) Firstly add supporting iron 5 on the column to separate the dome 4 from the furnace body 1, so that when the furnace body 1 is disassembled for maintenance, it is not necessary to invest in the cost of making the dome 4 again, so as to achieve multiple benefits from one investment and save time, human, material and financial resources;

[0051] (2) Shut down all the electrode loads of the large furnace of the all-electric melting furnace. After the glass liquid in the electric melting furnace is cooled, clean the glass liquid to a position 8cm away from the main electrode, and start to clean the damaged lower pool wall bricks. Replace it, and reserve a gap of 5cm between the new corundum brick 2 and the insulation brick 3 to fill the corundum powder for bonding;

[0052] (3) Observe and measure the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com