Maintenance method of counter weight of anchor chain of single point mooring system

A single-point mooring and anchor chain technology, which is applied to ship parts, ships, transportation and packaging, etc., can solve the problems of anchor chain counterweights falling off easily, so as to shorten the operation time, reduce the difficulty of operation, and reduce the loss of shackles the effect of the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

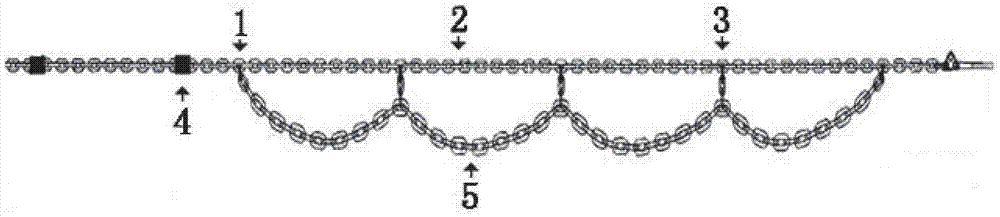

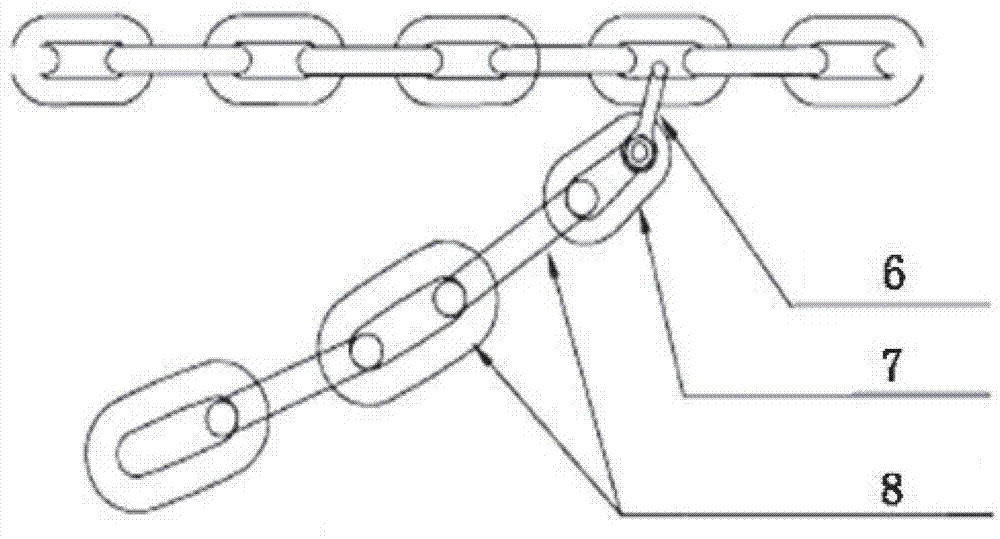

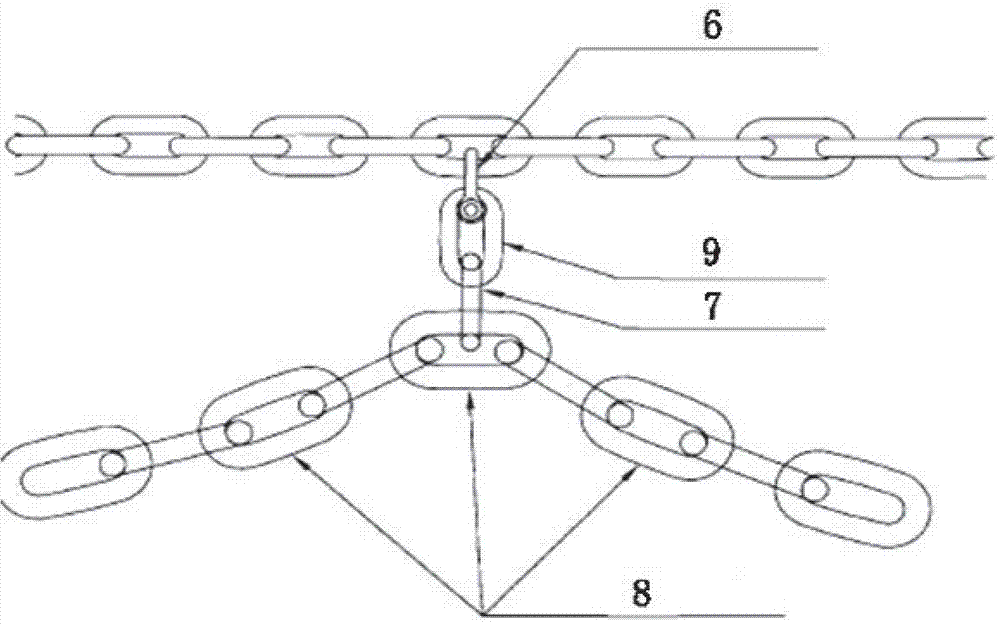

[0024] Such as figure 1 — image 3 As shown, the present invention obtains the shedding law of the counterweight 4 of the single-point system according to statistics, that is, the single-point buoy of the offshore floating production, storage and unloading tanker drives the mooring legs to move under the joint action of wind, waves and currents, and rotates in the near inward. At the tower type single point mooring system, the side anchor chain installed on the mooring leg has a large range of movement, while the side anchor chain installed on the mooring leg moves far away from the inner turret type single point mooring system The range is small, so that the counterweight 4 on the mooring chain near the inner turret type single point mooring system is prone to continuous shedding after repeated collisions with the seabed. Using this rule to set and install the counterweight chain 5, in order to Solve the problem of the counterweight of the anchor chain; the setting of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com