Anti-freezing exhaust valve

An exhaust valve, suction and exhaust technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of unfavorable facility insulation, increase the height of exhaust facilities, etc., and achieve easy maintenance, comprehensive functions, and reduce heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

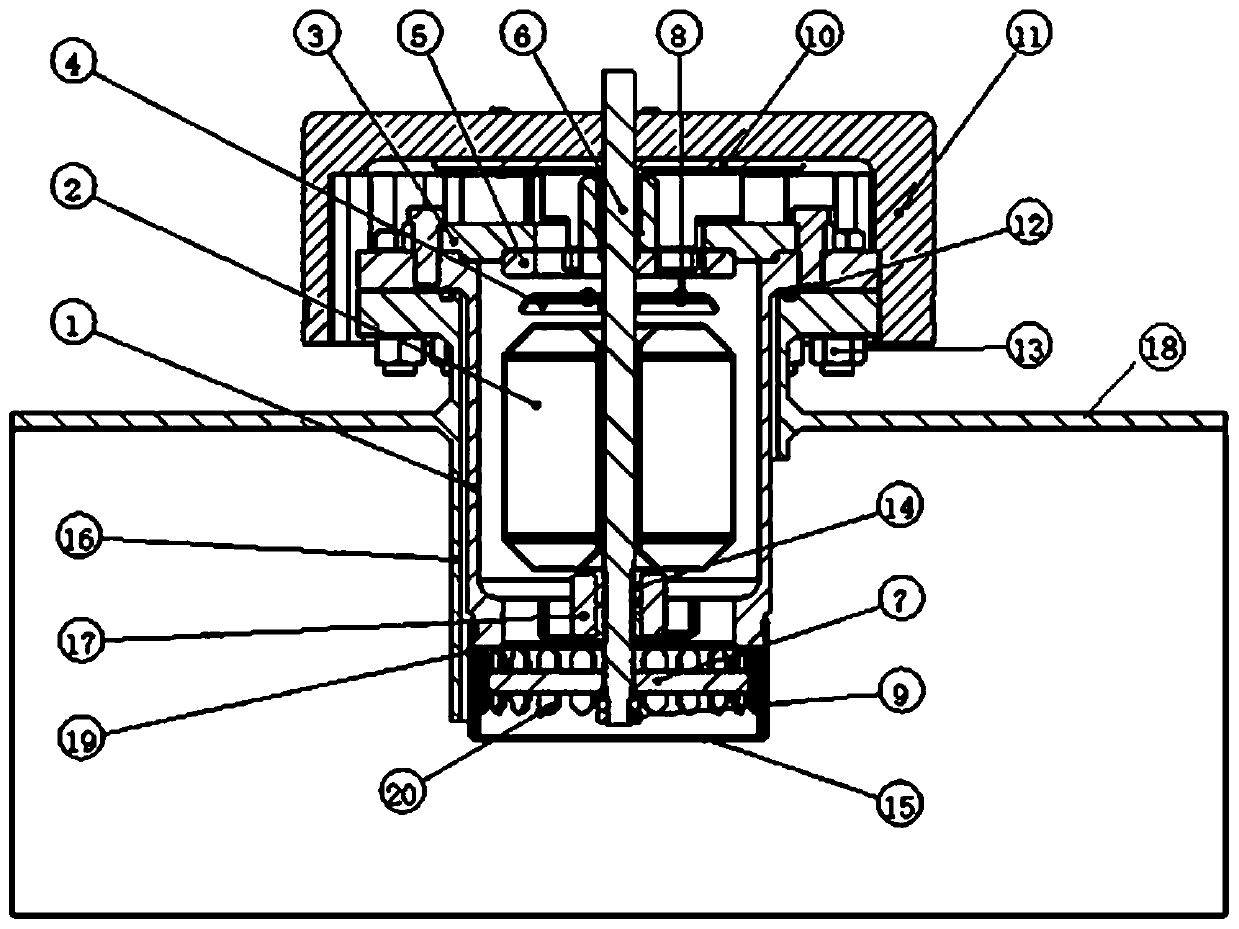

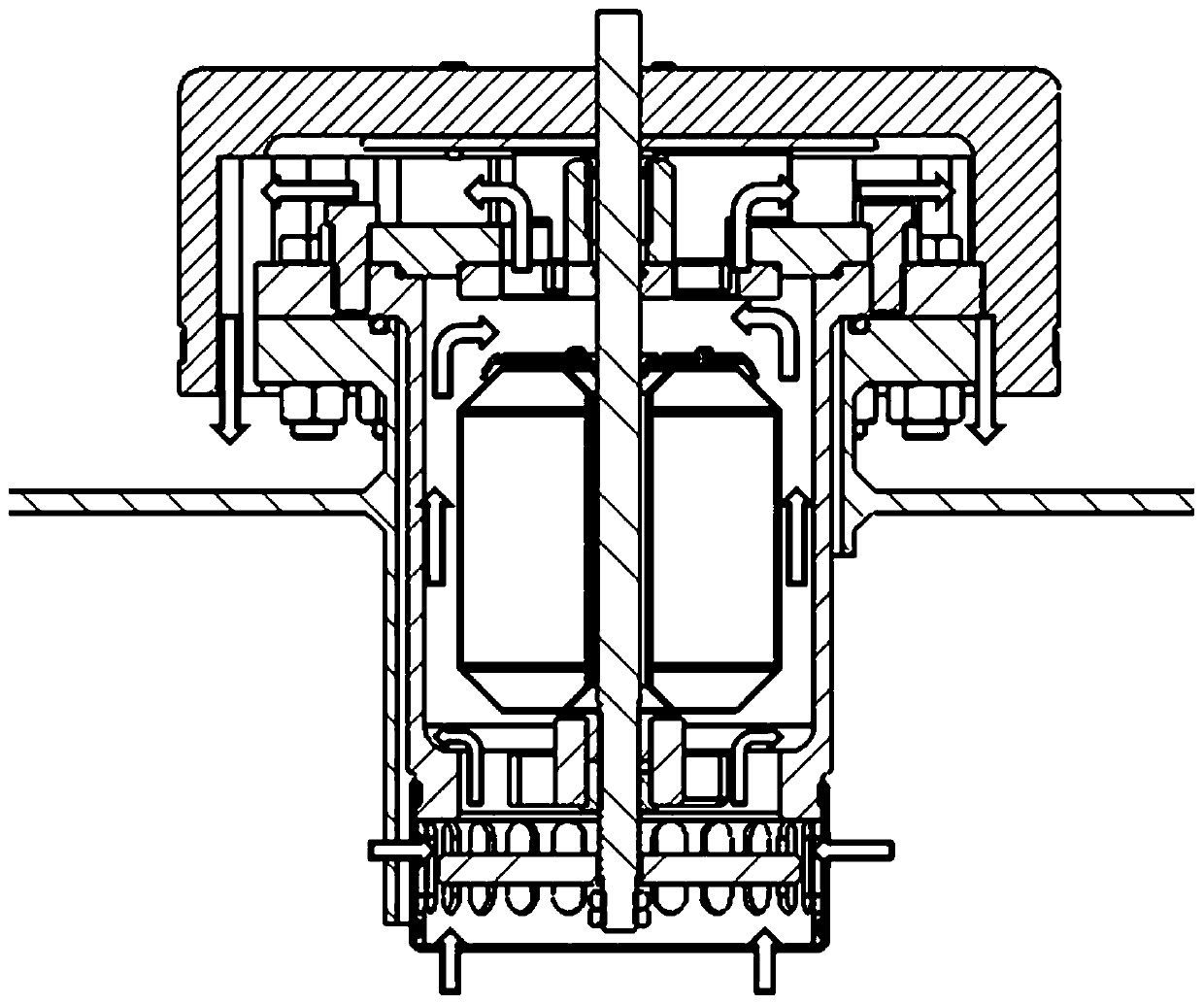

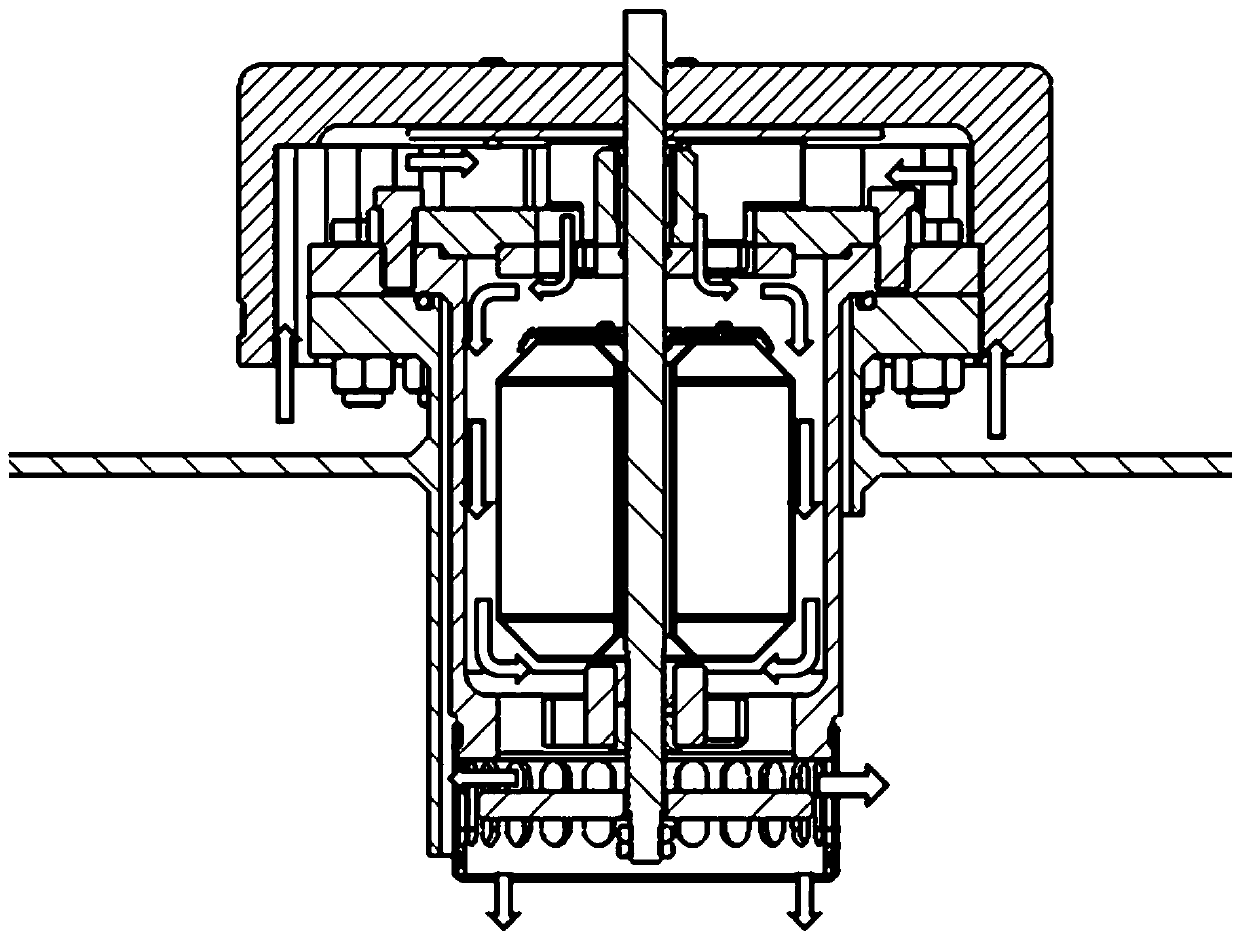

[0032] Such as figure 1 As shown, the present invention provides an antifreeze exhaust valve, which mainly consists of the following components:

[0033] Valve body 1, float 2, valve cover 3, suction and exhaust valve 4, valve seat sealing ring 5, valve shaft 6, isolation / buffer plate 7, small hole seat 8, lock nut 9, air cover plate 10, heat preservation cover 11 , sealing ring 12, fastener 13, drive nut assembly 14, filter screen 15 and housing 16.

[0034] The buoy 2 is a fully enclosed annular cylinder structure with both ends closed. The annular inner hole of the cylinder body allows the valve shaft 6 to pass through. When the buoy 2 is submerged in water, its buoyancy is greater than gravity, and the difference between buoyancy and gravity is greater than that of the suction and exhaust valves. The weight of 4 pushes the suction and exhaust valve 4 to move upward, and realizes sealing with the valve seat sealing ring 5.

[0035] The suction and exhaust valve 4 is a rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com