Adjustable energy-conserving type multifunctional mixer

An energy-saving and multi-functional technology, which can be used in textile and paper making, fiber raw material processing, etc., and can solve the problems of gas poisoning, high risk, and overall bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

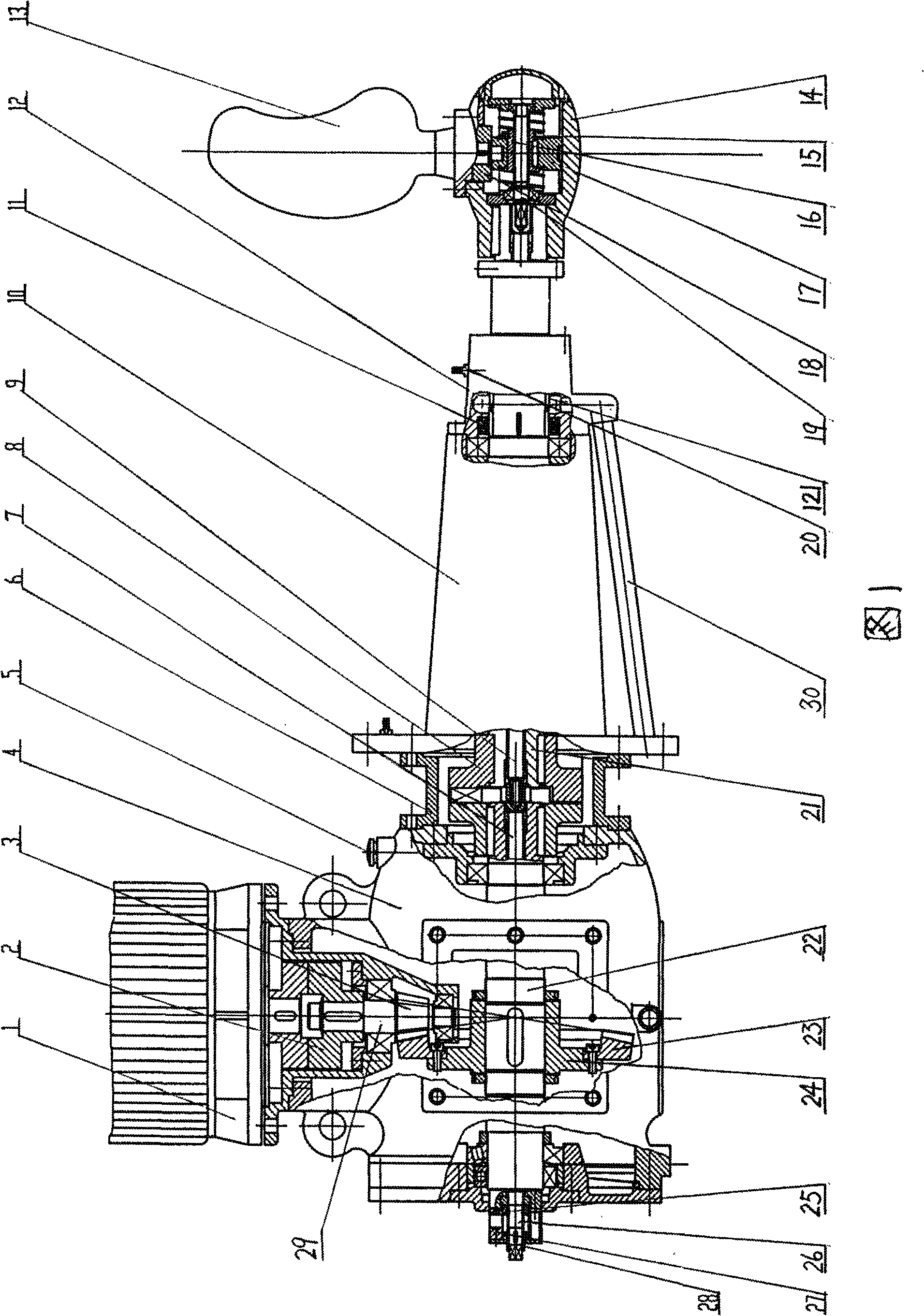

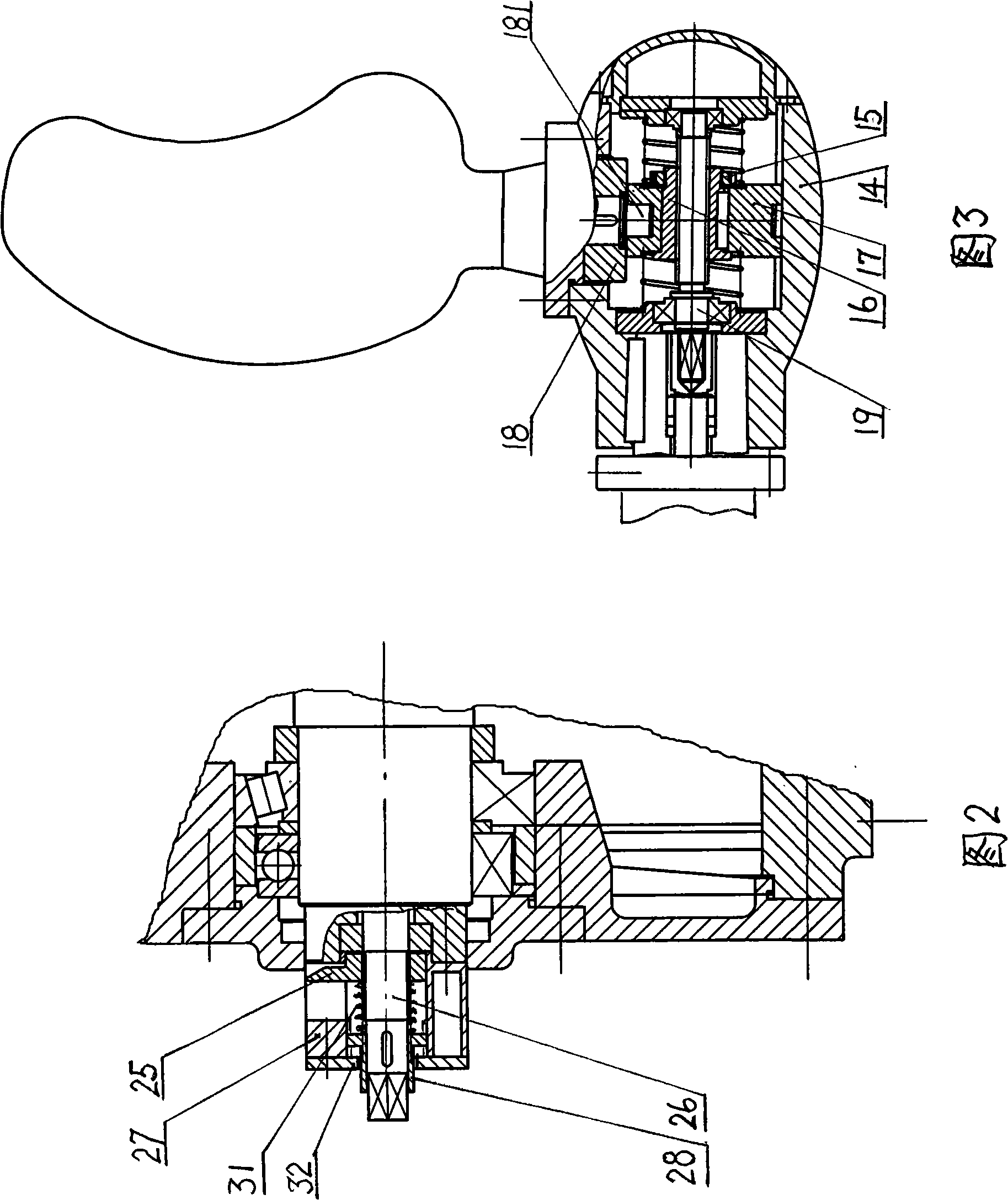

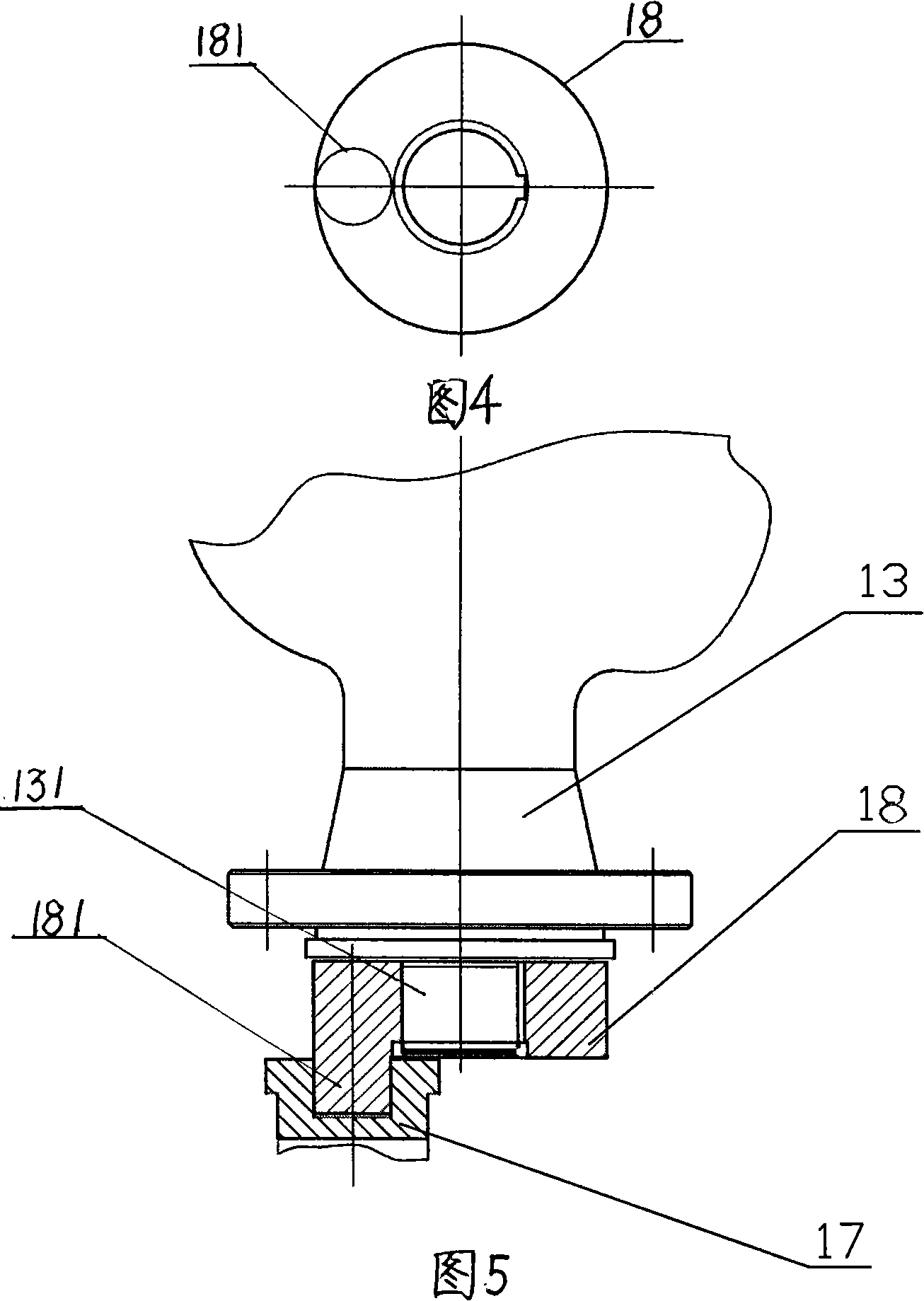

[0011] The specific structure and working principle of the present invention are illustrated below in conjunction with the embodiments given in the accompanying drawings.

[0012] As shown in the accompanying drawings, the adjustable energy-saving multifunctional agitator of the present invention has a motor 1 fixed on the transmission box 4, and the shaft of the motor passes through the shaft coupling 2 and the shaft 29 on which the bevel gear 3 is installed in the transmission box. Fixed together, the bevel gear 3 meshes with the gear ring 23 installed on the main shaft 22 of the transmission box, the shaft 29 is perpendicular to the main shaft of the transmission box, and the main shaft of the transmission box is fixed with one end of the main shaft 21 of the tapered tube through another coupling 8 , the other end of the tapered pipe main shaft is fixed with a blade seat 14, and a plurality of blades 13 are installed on the blade seat. The tapered pipe 10 outside the tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com