Aluminum alloy hollow ingot semi-continuous casting crystallizer and application thereof

A hollow ingot and aluminum alloy technology, which is applied in the field of aluminum alloy casting, can solve the problems of hollow ingots that cannot be lubricated with oil, and achieve the effects of avoiding potential safety hazards, convenient liquid level control, and reducing inclusion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

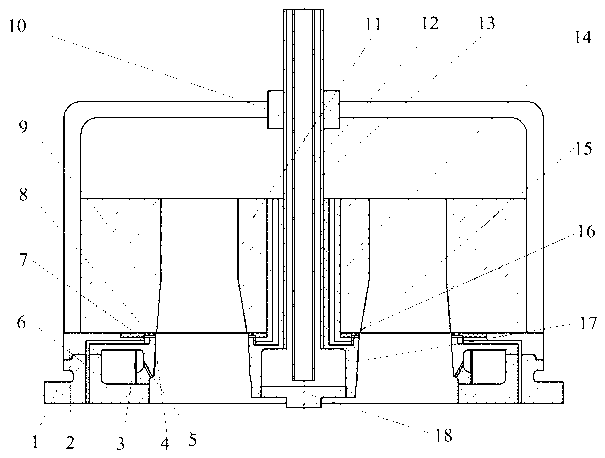

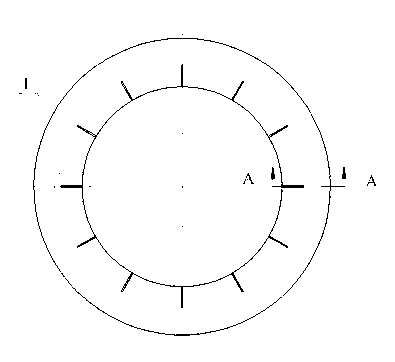

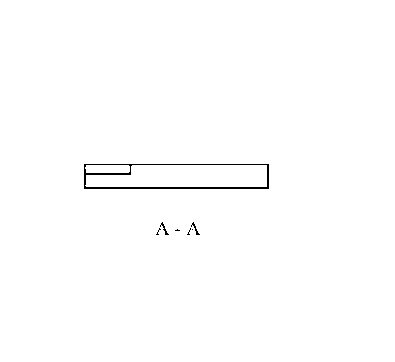

[0019] Such as figure 1 As shown, the aluminum alloy hollow ingot semi-continuous casting mold includes a water jacket 1, an outer mold body 2 and a core body 17, the water jacket 1 is connected with the outer mold body 2, and the cooling water cavity of the water jacket 1 is set There is a water divider ring 3, and the water spray hole 5 connected with the cooling water cavity faces the outer crystallizer cooling wall 4, and the outer mold body 2 is provided with an outer lubricating oil channel 6, and one end of the outer lubricating oil channel 6 passes through the oil supply pipe and The oil supply device is connected, the other end is open to the external oil storage tank 7, and the external oil injection ring 8 tightly pressed on the external oil storage tank 7 faces the outer crystallizer cooling wall 4, and an external thermal cap 9 is fixed on the external crystallizer body 2, and the external thermal cap 9 The side is provided with the same horizontal flow groove; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com