Forging method of super-large-specification high-temperature alloy cake blank

A superalloy and super-sized technology, which is applied in the forging field of super-sized superalloy cake blanks, can solve the problem of blank forging technology, and achieve the effects of reducing the amount of head and tail cutting, improving the total forging yield, and reducing the amount of peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

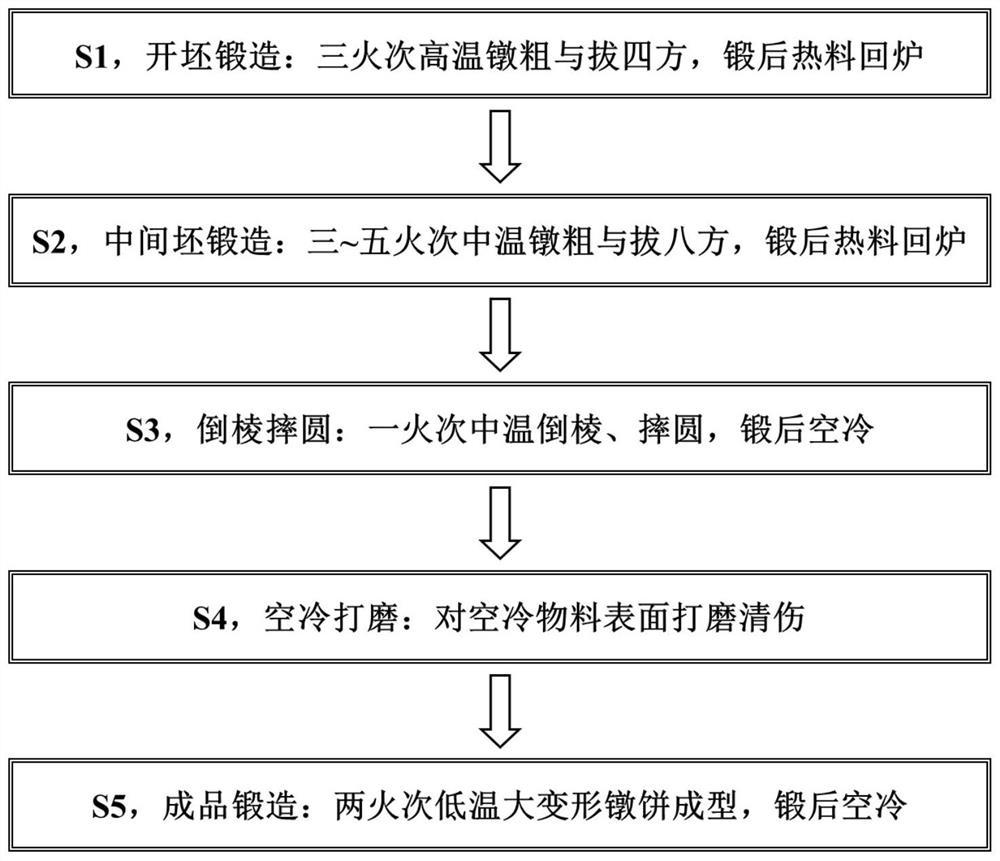

[0030] like figure 1 As shown in the figure, a forging method for super-sized superalloy cake blanks specifically includes the following contents:

[0031] Step S1, billet forging: the weight of the superalloy ingot used for forging is 6-8t, and the specification is Φ640mm. A fast forging machine is used to forge the ingot at high temperature for three times. The rough deformation is 15% to 25%, and the elongation deformation is 10% to 20%. After each fire, the billet needs to be slightly chamfered. After each fire, an intermediate billet with a square section is obtained. Return the material to the furnace for the next forging;

[0032] Step S2, forging of the intermediate blank: use a fast forging machine to forge the intermediate blank of the square section for three to five times at a medium temperature, the heating temperature of each fire is 1050 ° C to 1100 ° C, and the holding time after reaching the temperature is 3 to 5 hours. The fire forging method is upsetting ...

Embodiment 2

[0037] A method for forging super-sized superalloy cake blanks, comprising the following contents:

[0038]Step S1, billet forging: the weight of the superalloy ingot used for forging is 6.2t, and the specification is Φ640mm. A fast forging machine is used to forge the ingot at high temperature for the first fire. The heating temperature of the first fire is 1140 ° C, and after reaching the temperature, it is held for 4 hours. The forging method is upsetting and square drawing, and the upsetting deformation amount is 18 %, the deformation amount of square drawing is 12%, and the billet is slightly chamfered after drawing the square to prevent the risk of corner cracking of the billet due to the large size of the billet and the rapid temperature drop at the sharp edge. After forging in the first fire, an intermediate billet with a square cross-section is obtained. After forging, the hot material is returned to the furnace for the next forging; the heating temperature of the sec...

Embodiment 3

[0046] A method for forging super-sized superalloy cake blanks, comprising the following contents:

[0047] Step S1, billet forging: the weight of the superalloy ingot used for forging is 7t, and the specification is Φ640mm. A fast forging machine is used to forge the ingot at high temperature for the first fire. The heating temperature of the first fire is 1160°C, and after reaching the temperature, the ingot is kept for 4 hours and then released for forging. The forging method is upsetting and square drawing, and the upsetting deformation amount is 22 %, the square drawing deformation amount is 15%, and the blank is slightly chamfered after drawing the square to prevent the risk of corner cracking of the blank due to the large size of the blank and the rapid temperature drop at the sharp edge. After the first fire forging, an intermediate billet with a square cross-section is obtained. After forging, the hot material is returned to the furnace for the next fire forging; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com