Method for producing titanium and titanium alloy wire rods by hot continuous rolling

A titanium alloy, hot continuous rolling technology, applied in the field of metal plastic processing, to achieve the effects of low cost, automatic compensation of end face changes, and advanced control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

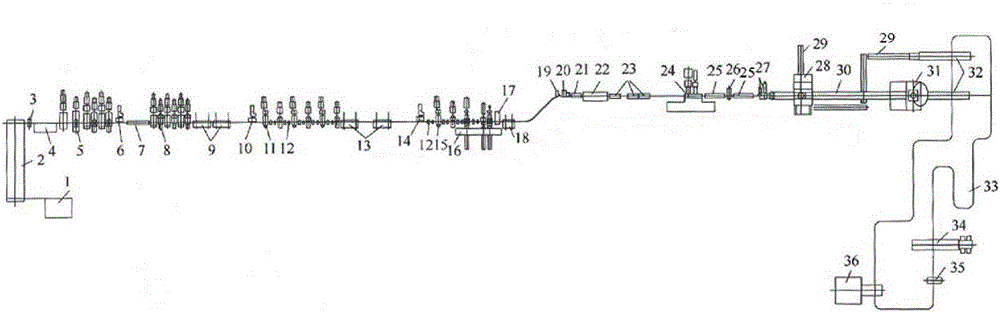

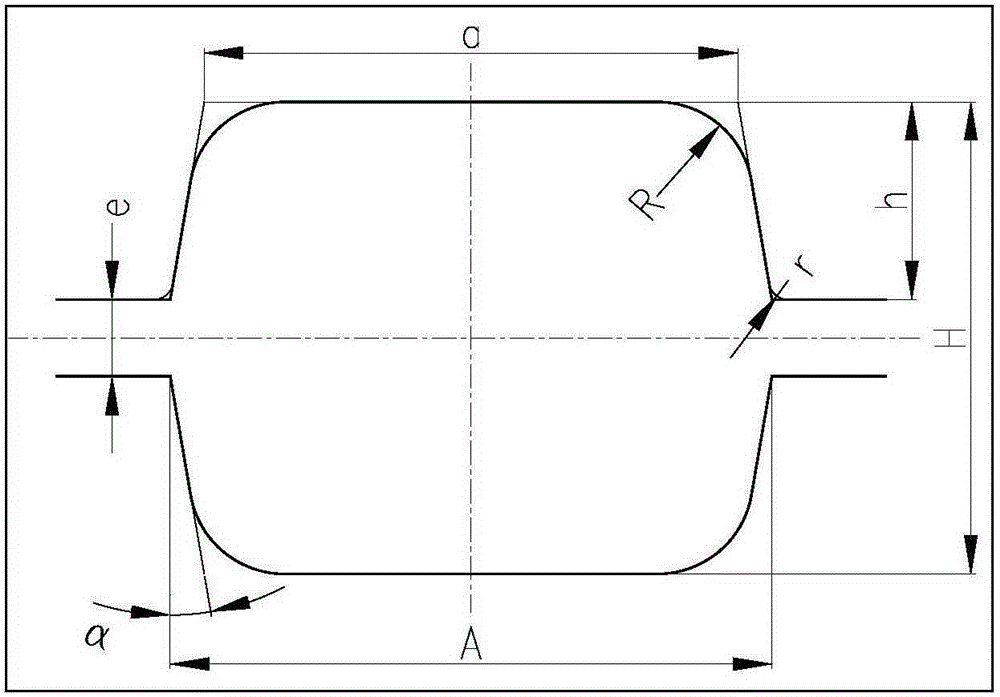

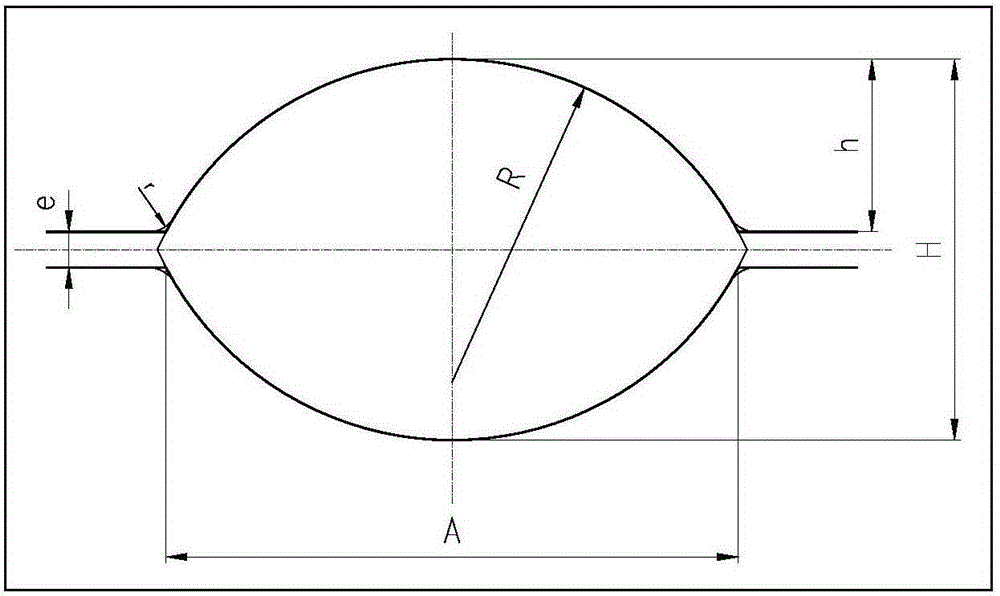

Method used

Image

Examples

Embodiment 1

[0100] The production of Φ6.0mm titanium alloy wire rod using the above-mentioned hot continuous rolling production line includes the following steps:

[0101] a. Heating: keep a forged billet of titanium alloy with a size of 150×150×12000mm at a heating temperature of 1000°C for 3 hours;

[0102] b. Rough rolling: rough rolling the heated forged billet, the rolling speed is 0.7m / s, rolling 4 passes, the pass elongation coefficient is 1.2; the final rolling temperature of the rolled piece is controlled at 850°C;

[0103] c. Intermediate rolling: after rough rolling, cut the head of the rolled piece by 50-100mm and then carry out intermediate rolling. The rolling speed is 1.2m / s, rolling 6 passes, and the pass elongation coefficient is 1.3; the final rolling temperature of the rolled piece is controlled is 830°C;

[0104] d. Finish rolling: after the intermediate rolling, the rolled piece is cut to 50-100mm and then rolled, the rolling speed is 4.2m / s, rolling 6 passes, the el...

Embodiment 2~ Embodiment 3

[0109] According to the steps of Example 1, the process parameters were changed to obtain Φ8.0mm pure titanium wire rod and Φ10.0mm titanium alloy wire rod. Table 4 lists the specific production process parameters of Φ6.0mm titanium alloy wire, Φ8.0mm pure titanium wire, and Φ10.0mm titanium alloy wire. The products produced in Examples 1 to 3 all conform to the diameter, cross-sectional thickness, and dimensional tolerances of titanium and titanium alloy rods and wires specified in the GB / T2965-2007 standard.

[0110] Table 4 Specific process parameters of wire rods with different specifications

[0111]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com