Method for producing titanium and titanium alloy wires through hot continuous rolling

A titanium alloy, hot continuous rolling technology, applied in the field of metal plastic processing, achieves the effect of advanced control level, high production efficiency, and improved product structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

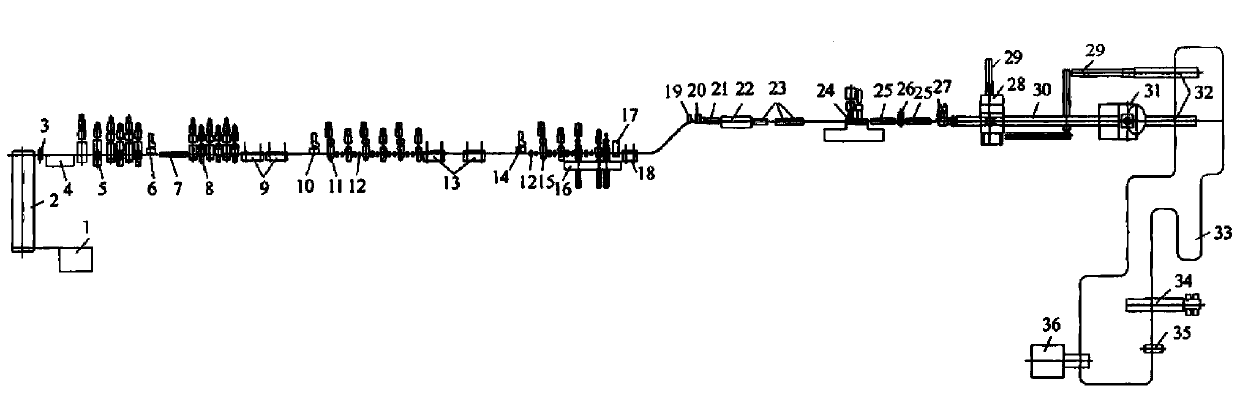

Method used

Image

Examples

Embodiment 1

[0100] The production of Φ6.0mm titanium alloy wire rod using the above hot continuous rolling production line includes the following steps:

[0101] a. Heating: Hold the forged billet of titanium alloy with a size of 150×150×12000mm at a heating temperature of 1000℃ for 3h;

[0102] b. Rough rolling: rough rolling the heated forged billet at a rolling speed of 0.7m / s, rolling 4 passes, with a pass elongation coefficient of 1.2; the final rolling temperature of the rolled piece is controlled to 850℃;

[0103] c. Intermediate rolling: After the rough-rolled piece is cut to 50-100mm, the intermediate rolling is carried out, the rolling speed is 1.2m / s, the rolling pass is 6 passes, the pass elongation coefficient is 1.3; the final rolling temperature control of the rolling piece 830℃;

[0104] d. Finishing rolling: the rolled piece after the intermediate rolling is cut to 50-100mm before rolling, the rolling speed is 4.2m / s, rolling 6 passes, the pass elongation coefficient is 1.2; the ...

Embodiment 2~ Embodiment 3

[0109] According to the steps of Example 1, the process parameters were changed to obtain a Φ8.0mm pure titanium wire and a Φ10.0mm titanium alloy wire. Table 4 lists the specific production process parameters of Φ6.0mm titanium alloy wire, Φ8.0mm pure titanium wire, and Φ10.0mm titanium alloy wire. The products produced in Example 1 to Example 3 all comply with the diameter, cross-sectional thickness and size tolerances of titanium and titanium alloy rods and wires specified in the GB / T2965-2007 standard.

[0110] Table 4 Specific process parameters of different specifications of wires

[0111]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com